Normal temperature semi-dry method circulating fluidized bed flue gas desulphurization system and method

A circulating fluidized bed and desulfurization system technology, applied in the field of flue gas purification, can solve the problems of complex system flow and structure, high investment and high operating costs, low removal efficiency, etc. Residence time, effect of increasing surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

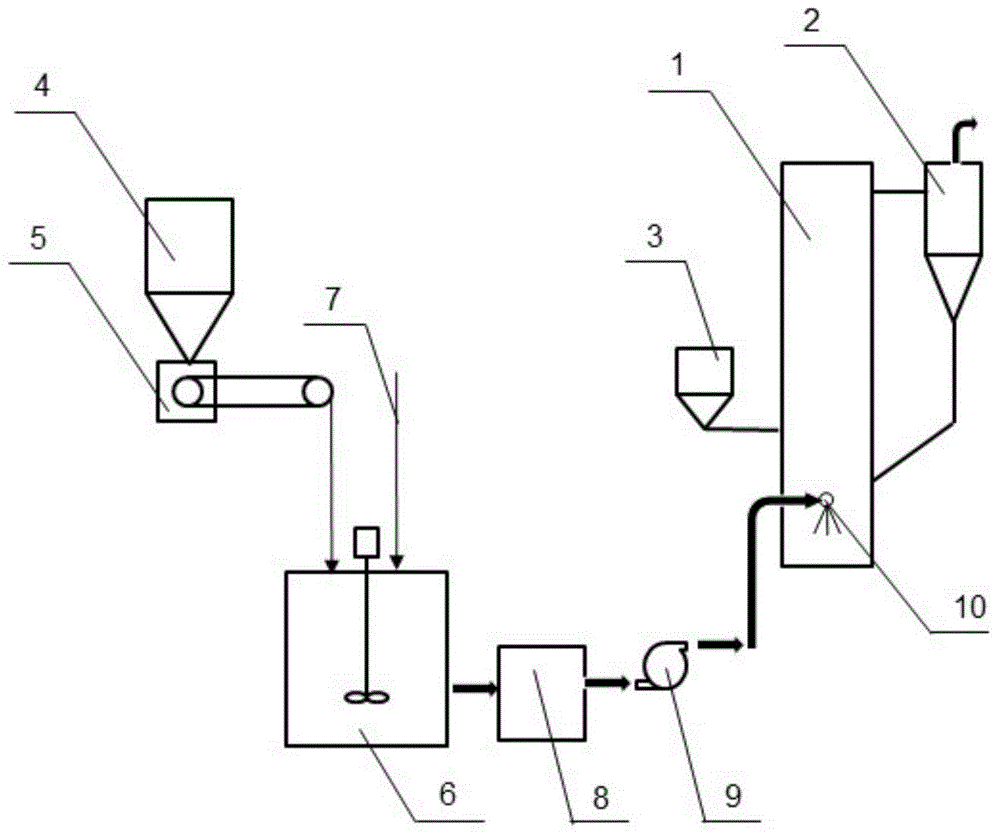

[0019] The principle, structure and working process of the present invention will be further described below in conjunction with the accompanying drawings.

[0020] figure 1 It is a structural schematic diagram of an embodiment of a normal-temperature semi-dry circulating fluidized bed flue gas desulfurization system provided by the present invention. The system includes a circulating fluidized bed reactor and a desulfurizing agent slurry preparation and delivery system; the circulating fluidized bed reactor includes a riser 1, a cyclone separator 2, a circulating material adding device 3 and a nozzle 10; the desulfurizing agent The slurry preparation and conveying system includes a quicklime bin 4, a metering control device 5, a slurry tank 6, a water supply pipe 7, a slurry filter 8 and a slurry pump 9; The slurry filter 8, the slurry pump 9 are connected to the nozzle 10, the nozzle 10 is arranged in the dense phase area of the riser 1, and the material outlet of the cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com