Coke oven gas and synthesis gas production process of low-carbon alcohol and by-product natural gas

A technology of coke oven gas and low-carbon alcohol, which is applied in the production of bulk chemicals, preparation of organic compounds, gas fuels, etc., can solve the problems of insufficient utilization of components, waste of energy, environmental pollution, etc. The effect of reducing production costs, improving enterprise economic benefits and social and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

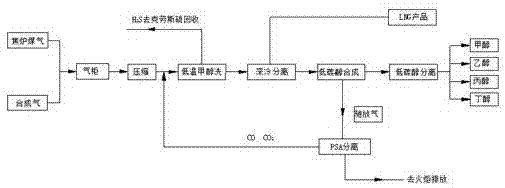

Image

Examples

Embodiment 1

[0032] Coke oven gas (mainly composed of H 2 : 58%, CO+CO 2 :16%, CH 4 : 21%, N 2 : 5%) and synthesis gas (mainly composed of CO: 47%, H 2 : 26%, CO 2 : 15%, CH 4: 12%, H 2 S: 0.21%) is passed into the gas cabinet and fully mixed to form a hydrogen-carbon molar ratio that satisfies the synthesis of low-carbon alcohols. 2 / CO=3.5 raw material gas,

[0033] The crude raw material gas is compressed to 3.2MPa and enters the low-temperature methanol washing and purification device to remove impurities such as hydrogen sulfide and carbon dioxide. 2 S off to less than 0.1ppm, CO 2 Less than 20ppm, the hydrogen sulfide H removed 2 S to Claus sulfur recovery, CO removal 2 Discharge at high altitude.

[0034] The raw material gas washed and purified by low-temperature methanol enters into cryogenic separation, using the mixed refrigerant of American Chemtex and Berkeley Weizi Company, at a temperature of -157°C and a pressure of 3.5Mpa, the methane in the crude gas is separat...

Embodiment 2

[0039] Coke oven gas (composed as H 2 : 52%, CO+CO 2 :18%, CH 4 : 23%, N 2 : 7%) and synthesis gas (composed of CO: 49%, H 2 : 23%, CO 2 : 16%, CH 4 : 12%, H 2 S: 0.22%) is passed into the gas cabinet and fully mixed to form a hydrogen-carbon molar ratio that satisfies the synthesis of low-carbon alcohols. 2 / CO=4.4 crude feed gas.

[0040] The crude raw material gas is compressed to 4.6MPa and enters the low-temperature methanol washing and purification device to remove impurities such as hydrogen sulfide and carbon dioxide. 2 S off to less than 0.1ppm, CO 2 Less than 20ppm, the hydrogen sulfide H removed 2 S to Claus sulfur recovery, CO removal 2 Discharge at high altitude.

[0041] The raw gas washed and purified by low-temperature methanol enters the cryogenic separation, and the methane in the crude gas is separated and liquefied at a temperature of -166°C and a pressure of 4.5Mpa by using a mixed refrigerant from American Chemtex and Berkeley Weitz Natural ga...

Embodiment 3

[0046] Coke oven gas (composed as H 2 : 56%, CO+CO 2 :15%, CH 4 : 25%, N 2 : 4%) and synthesis gas (composed of CO: 53%, H 2 : 20%, CO 2 : 16, CH 4 : 11%, H 2 S: 0.20%) is passed into the gas cabinet and fully mixed to form a hydrogen-carbon molar ratio that satisfies the synthesis of low-carbon alcohols. 2 / CO = 3.8 raw material gas.

[0047] The crude raw material gas is compressed to 5.1MPa and enters the low-temperature methanol washing and purification device to remove impurities such as hydrogen sulfide and carbon dioxide. 2 S off to less than 0.1ppm, CO 2 Less than 20ppm, the hydrogen sulfide H removed 2 S to Claus sulfur recovery, CO removal 2 Discharge at high altitude.

[0048] The raw material gas washed and purified by low-temperature methanol enters into cryogenic separation, using the mixed refrigerant from American Chemtex and Boclay Weizi Company, at a temperature of -161°C and a pressure of 5.1Mpa, the methane in the crude gas is separated and lique...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com