Adsorption method

A technology of adsorber and adsorption process, which is applied in the field of adsorption and can solve problems such as increased demand for external energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

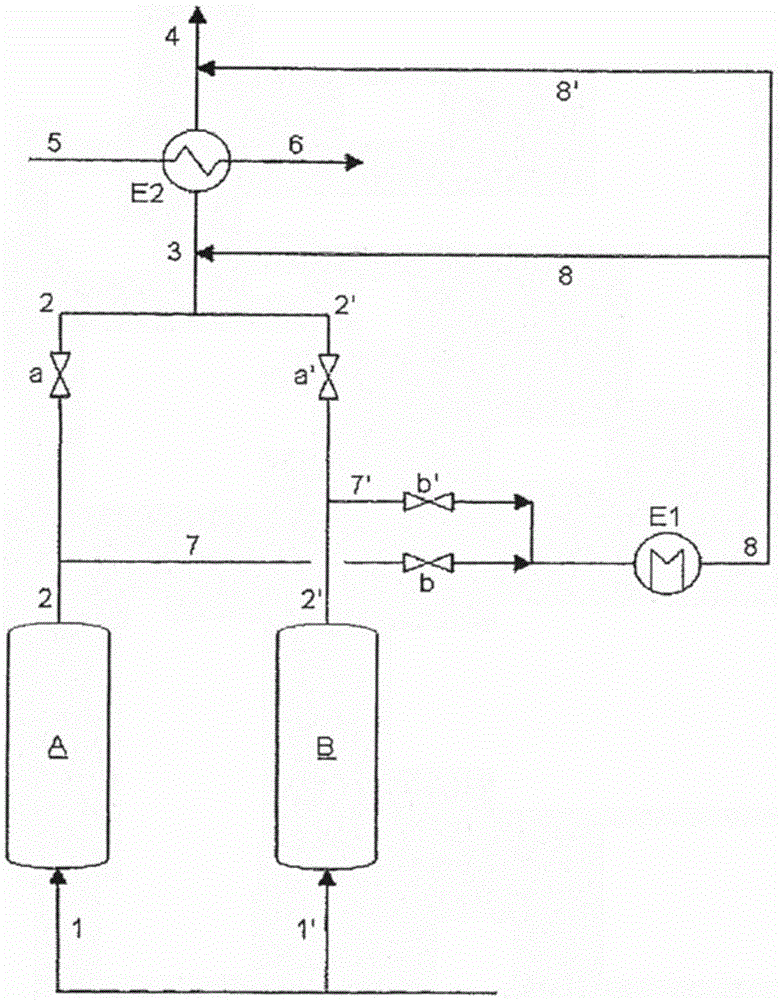

[0012] The adsorption process shown in the drawing takes place in two adsorbers A and B arranged parallel to one another. The process flow is explained below when the regeneration in adsorber B has ended (adsorber A is still in the adsorption phase).

[0013] The main flow of the gas mixture to be separated is supplied via line 1 to adsorber A in the adsorption stage. These are, for example, carbon dioxide-rich gas mixtures, wherein the adsorption process is designed or the adsorption medium is selected in such a way that the adsorption medium is able to bind the carbon dioxide. The largely carbon dioxide-depleted stream is withdrawn from the adsorber A via line 2 in which a regulating valve a is preferably arranged.

[0014] The secondary flow of the gas mixture to be separated is supplied to the adsorber B via line 1 ′ for cooling purposes. After the secondary flow has passed through the adsorber B, it is taken out through a line 2', in which line 2' is preferably also pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com