Patents

Literature

36results about How to "Purification process reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

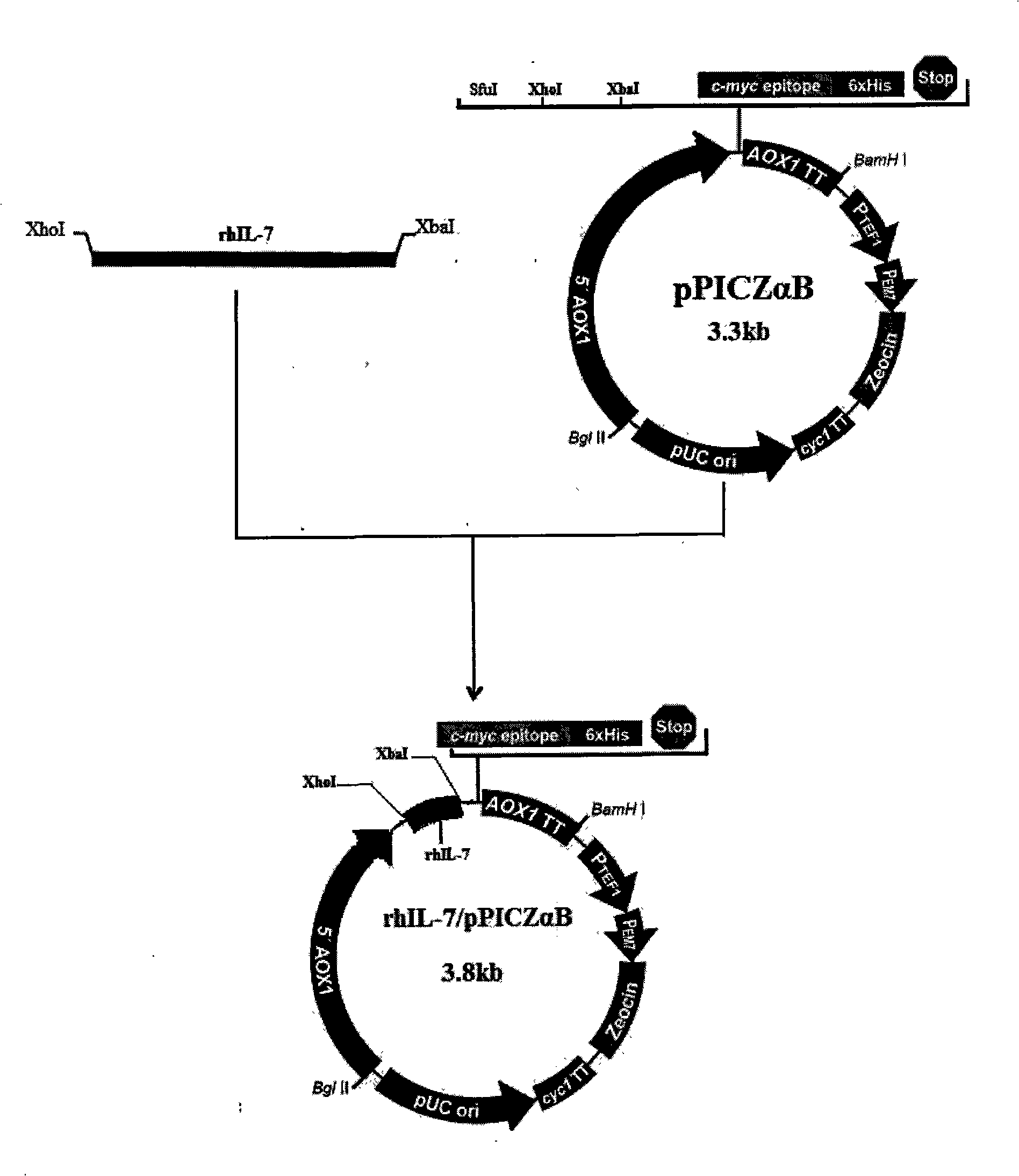

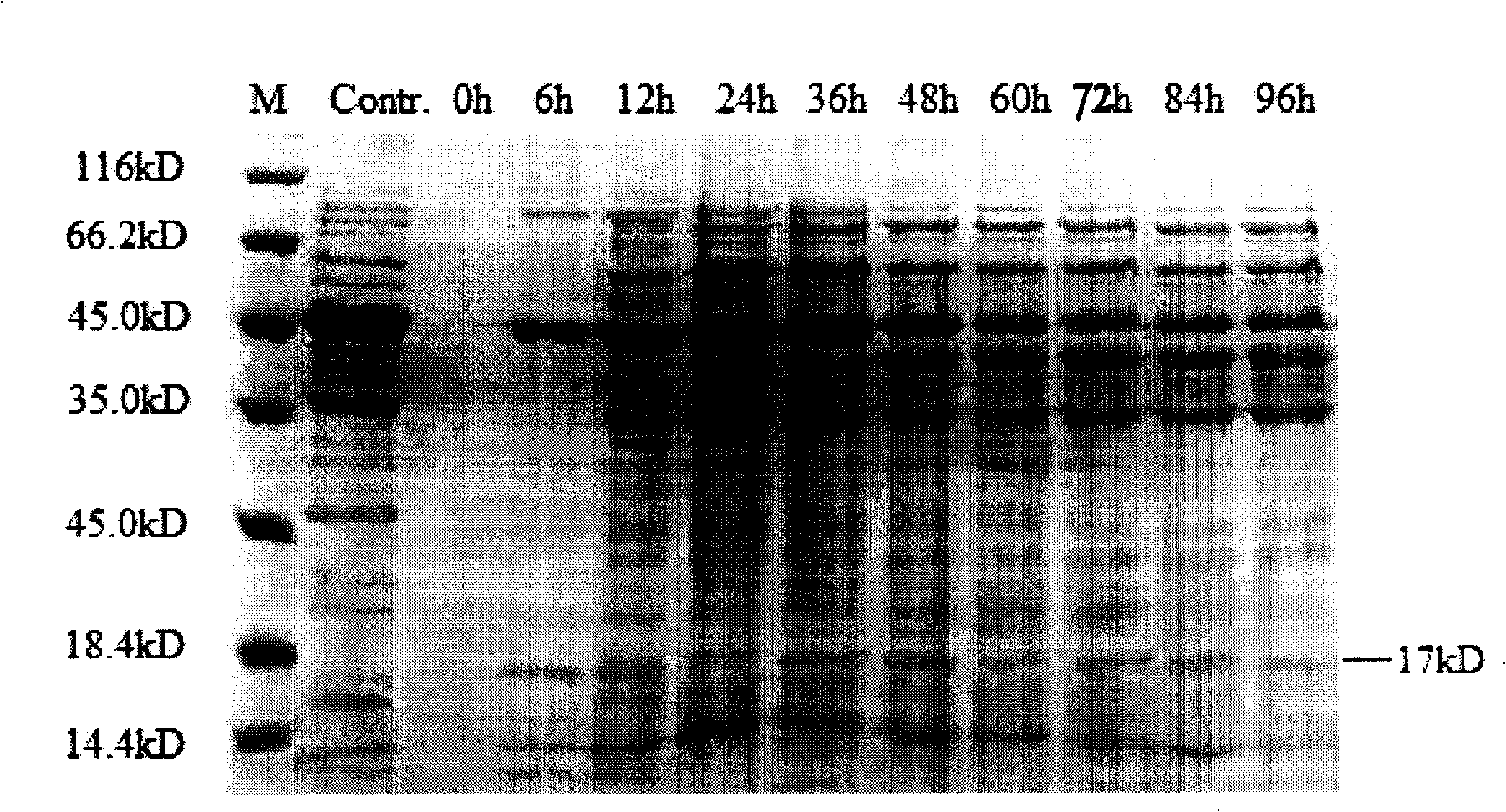

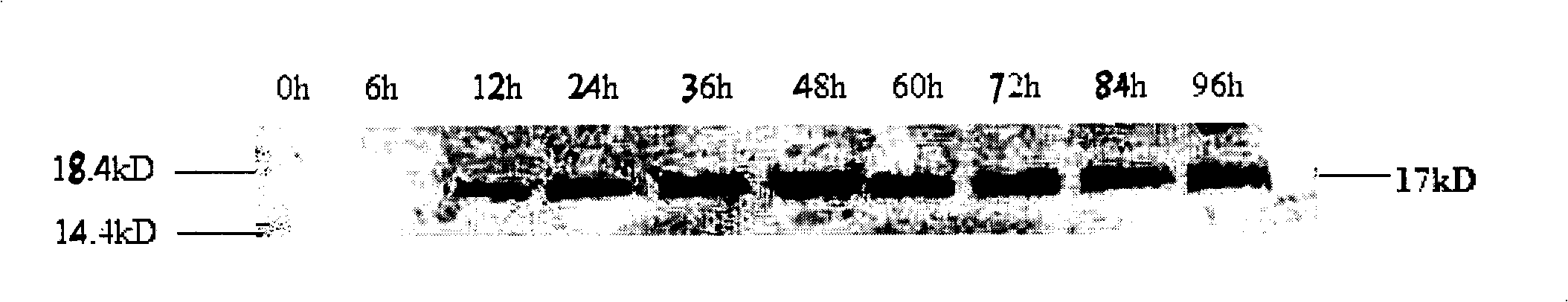

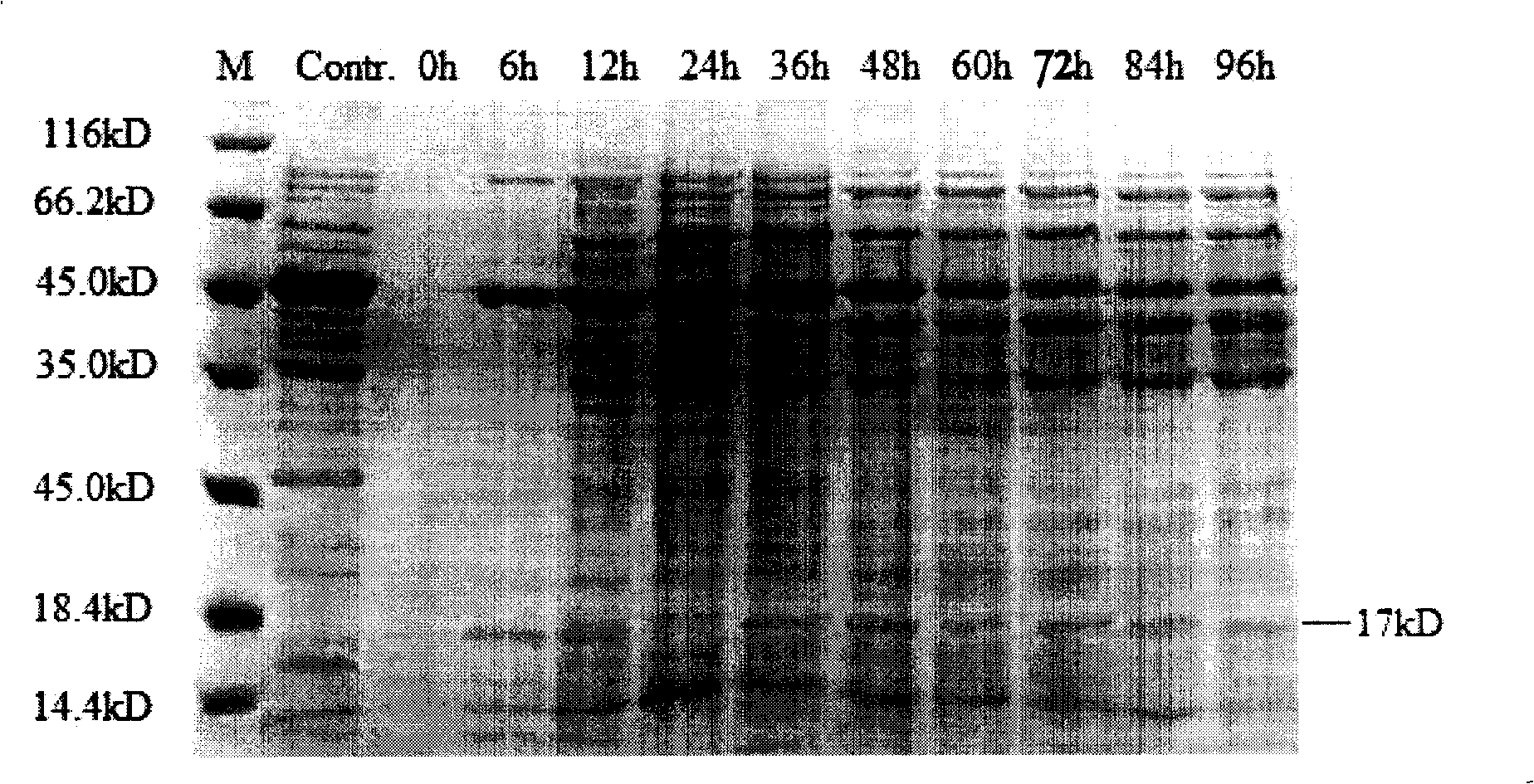

Expressing method of human interleukin 7 in eucaryon host

InactiveCN101302517AAvoid degradationReduce loadFermentationVector-based foreign material introductionPichiaInterleukin I

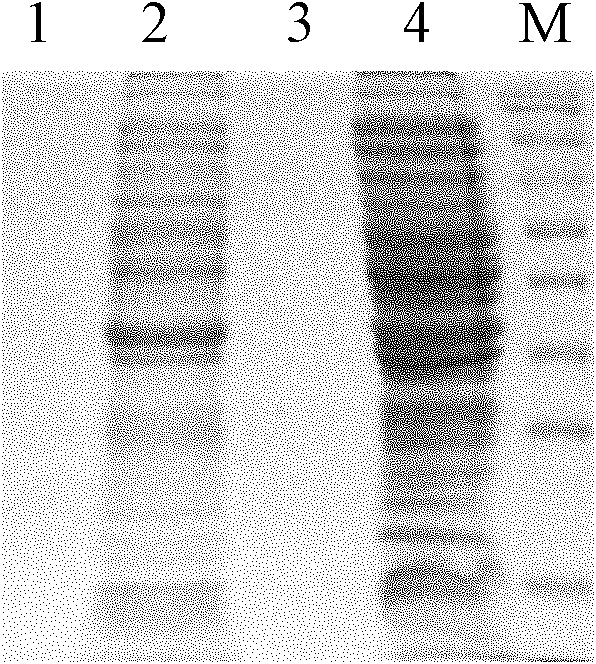

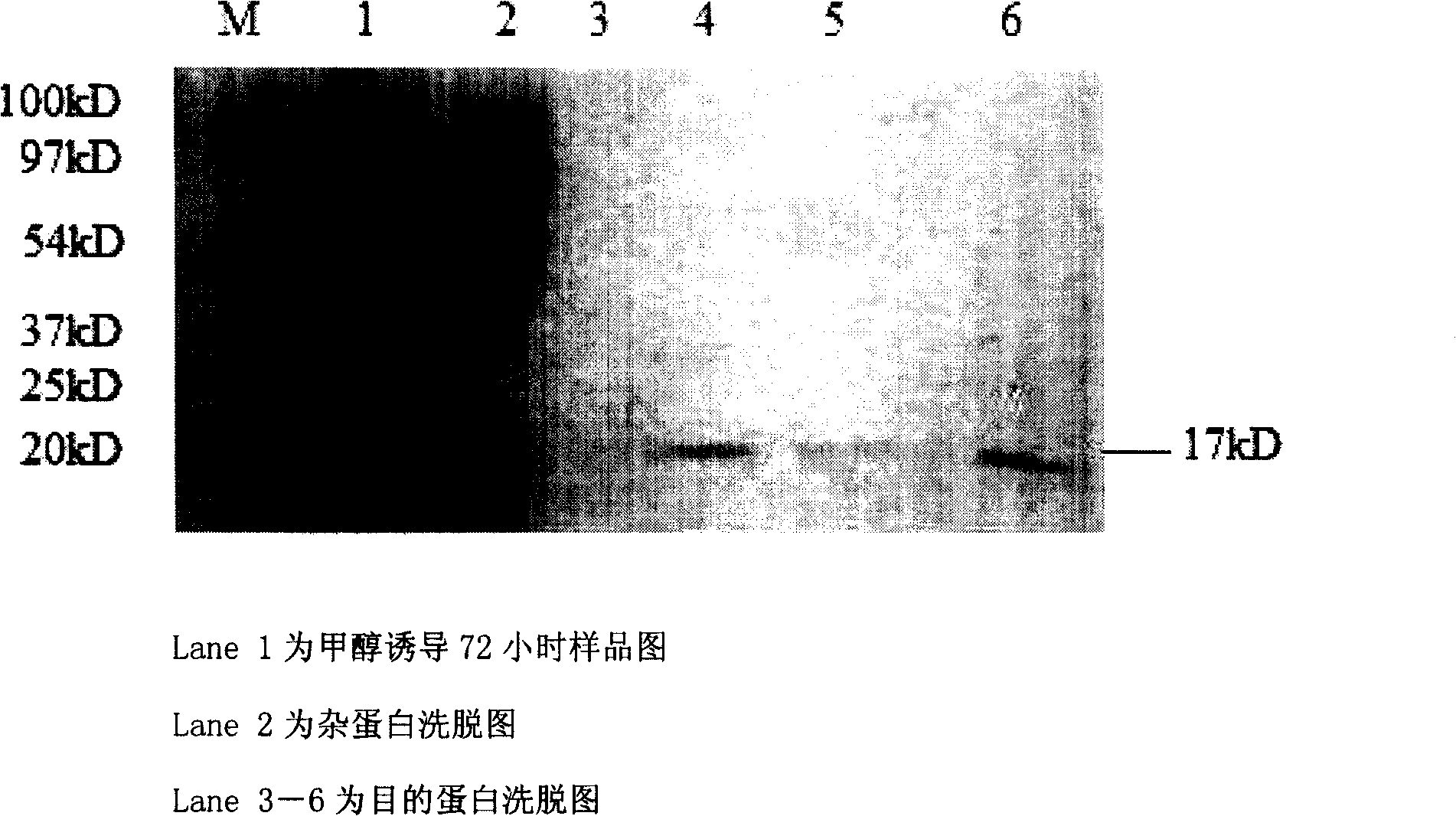

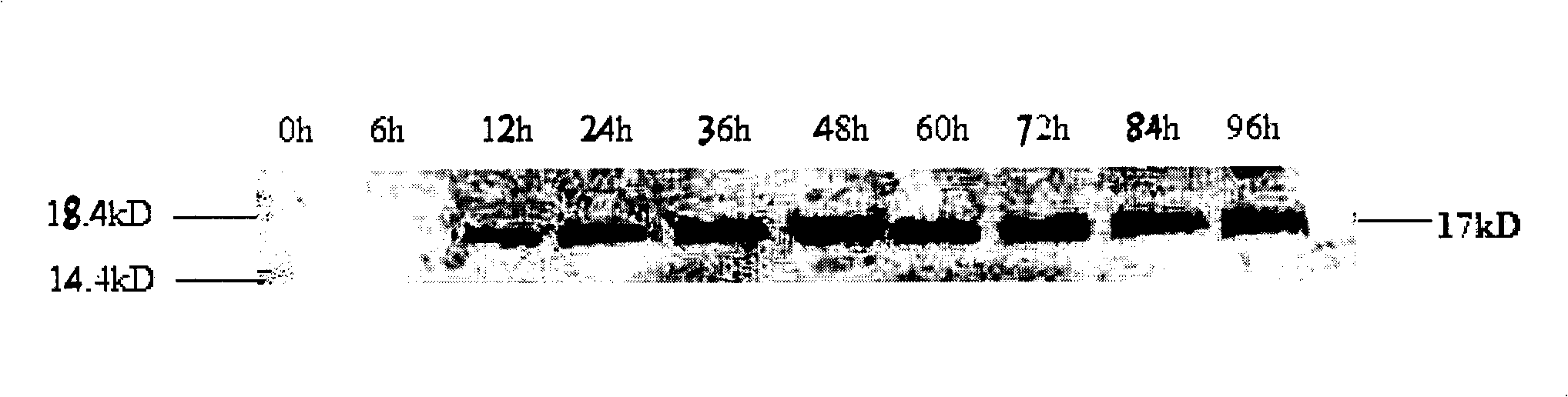

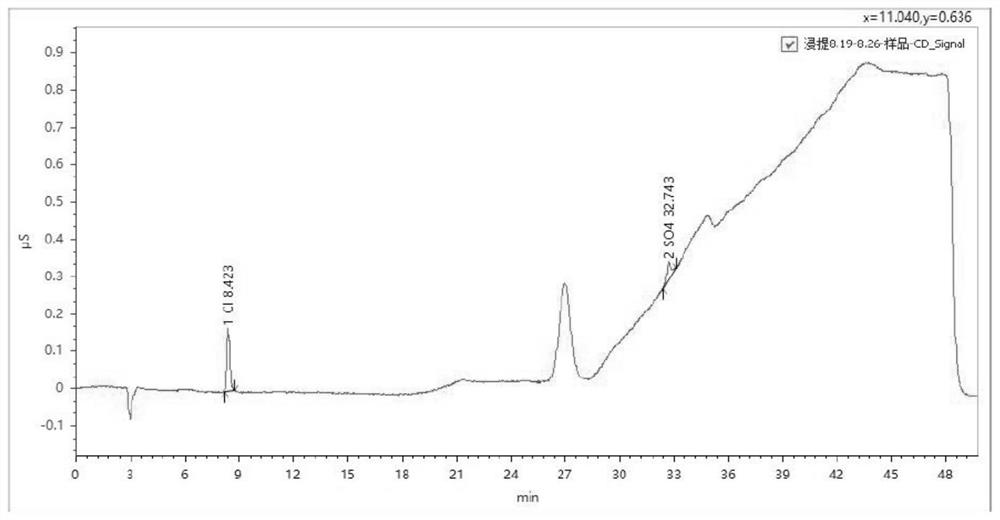

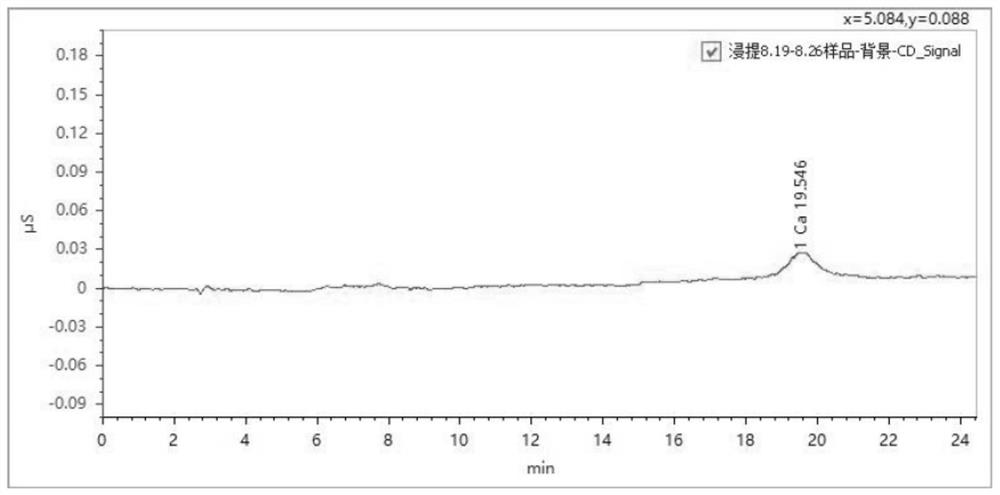

The invention discloses a method for expressing human interleukin 7 in eucaryotic host. When the eucaryotic host is pichia X-33, the method comprises the following steps of: (1) cloning an IL-7 gene of human; (2) building an eucaryotic expression vector; (3) transforming recombinant vector to the eucaryotic yeast host; and (4) expressing a rIL-7 protein in the yeast host. A prior method for expressing IL-7 by using prokaryotic host escherichia coli is changed, and a method for expressing IL-7 through eucaryotic host pichia is searched out, thereby ensuring an IL-7 biologic activity and obtaining a large amount of stable protein.

Owner:GUANGZHOU INST OF BIOMEDICINE & HEALTH CHINESE ACAD OF SCI +1

Organopolysiloxane resin and preparation method thereof

InactiveCN107459651AThe preparation process is environmentally friendlyNo generationOrganic solventSilanes

The invention relates to an organopolysiloxane resin and a preparation method thereof. The general formula of the organopolysiloxane resin is (R13SiO0.5)m(R22SiO)n(R3SiO1.5)p(SiO2)q. The preparation method comprises the following steps: placing an end-capping reagent, deionized water, a cosolvent and acid into a reaction vessel and stirring; dropwise adding silane into the reaction vessel, raising the temperature of the reaction system to 60-80 DEG C and reacting for 2-4h; regulating pH value of the reaction solution to 7, stirring, raising the temperature to 80-120 DEG C and distilling till no fraction exists; dissolving the resin into an organic solvent, adding solid alkali, raising temperature to 70-140 DEG C and reacting for 2-4h; centrifuging the reaction solution and removing solid salt; and performing vacuum drying on the reaction solution, thereby acquiring the organopolysiloxane resin. The method has the advantages of high product yield, simple process, no pollution in a production process, less three-waste, energy-saving effect and environmental protection.

Owner:GUANGZHOU TINCI SILICONE TECHNOLOGY CO LTD

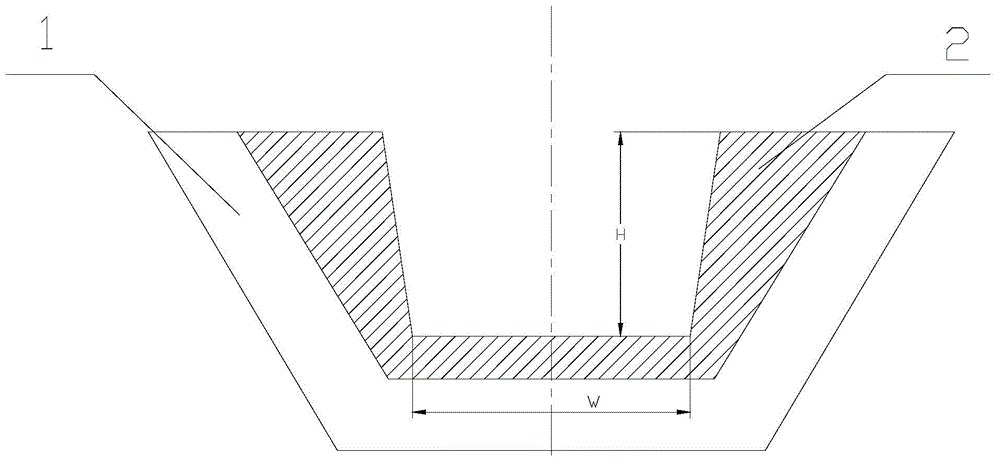

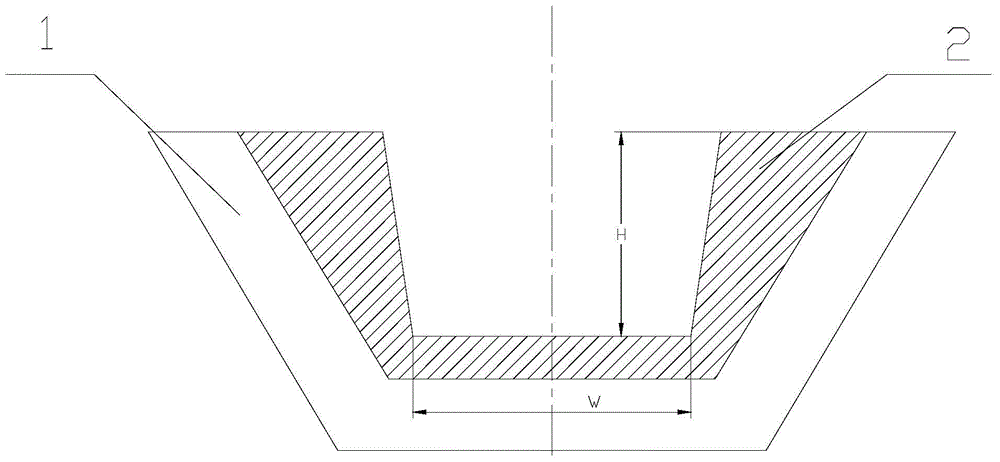

Method and device for removing metal impurities in polycrystalline silicon by electron beam overheat smelting

InactiveCN104556050AReduce the number of timesReduced purification processSilicon compoundsDirectional solidificationPolycrystalline silicon

The invention discloses a method and device for removing metal impurities in polycrystalline silicon by electron beam overheat smelting, and belongs to the field of metallurgy. The device comprises a water-cooled copper smelting crucible, wherein an inclined sidewall design is adopted for the water-cooled copper smelting crucible; the inner sidewall of the water-cooled copper smelting crucible forms an included angle of 105 to 120 degrees with the bottom of the water-cooled copper smelting crucible; a graphite bushing is arranged in the water-cooled copper smelting crucible; the outer surface of the graphite bushing is attached to the inner surface of the water-cooled copper smelting crucible to form a close fit design; the bottom of the graphite bushing and the bottom of the water-cooled copper smelting crucible are horizontal, the inner surface sidewall of the graphite bushing forms an included angle of 95 to 100 degrees with the bottom of the graphite bushing. According to the device, the metal impurities are removed by overheat smelting, so that the number of times of subsequent directional solidification and ingot casting can be reduced, a purification process can be eliminated, and the production cost can be reduced; by electron beam overheat smelting for polycrystalline silicon purification, post directional solidification can be reduced by one time or more, and the metal impurities in the polycrystalline silicon can be reduced by 30 percent or more.

Owner:DALIAN UNIV OF TECH

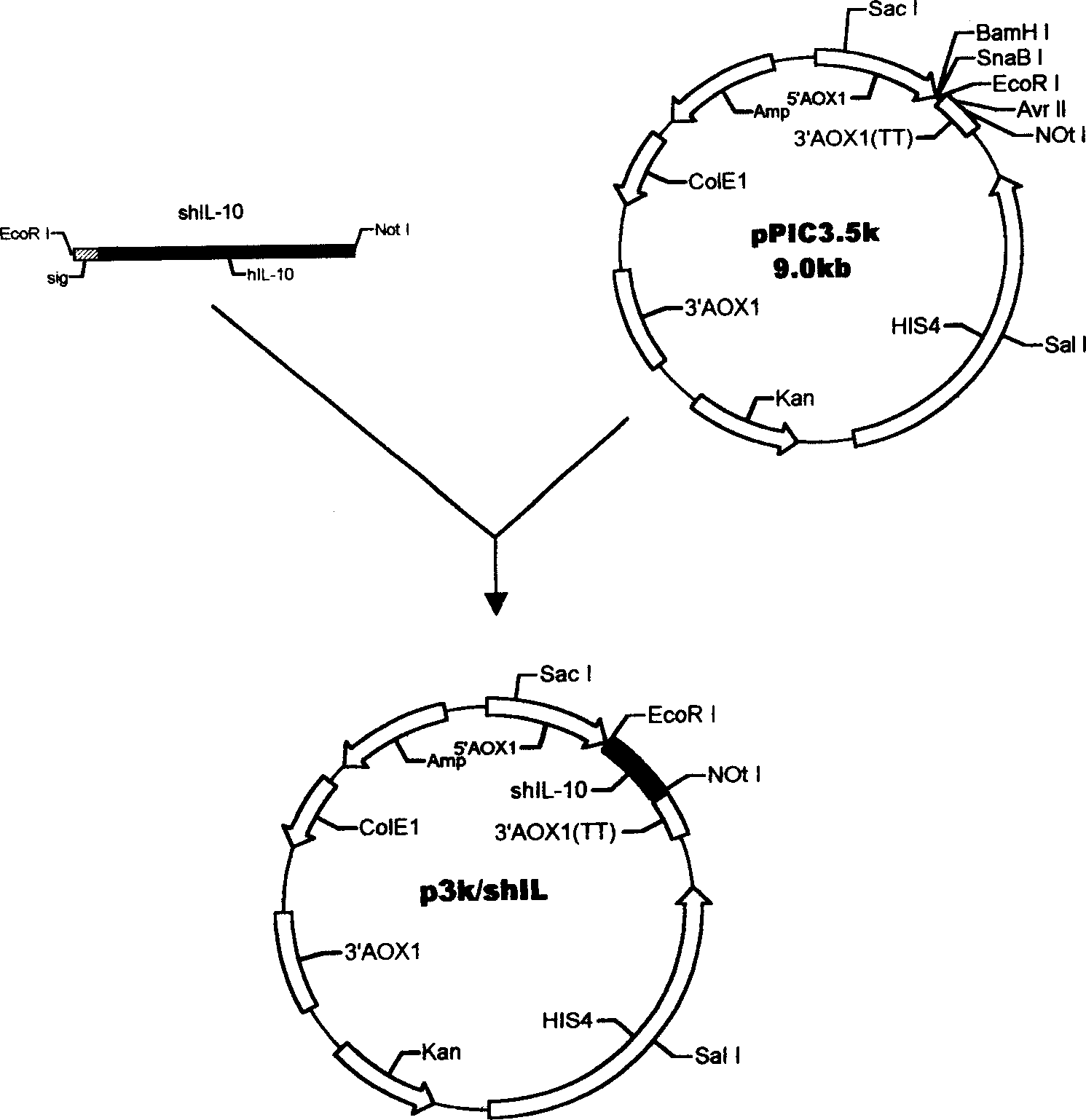

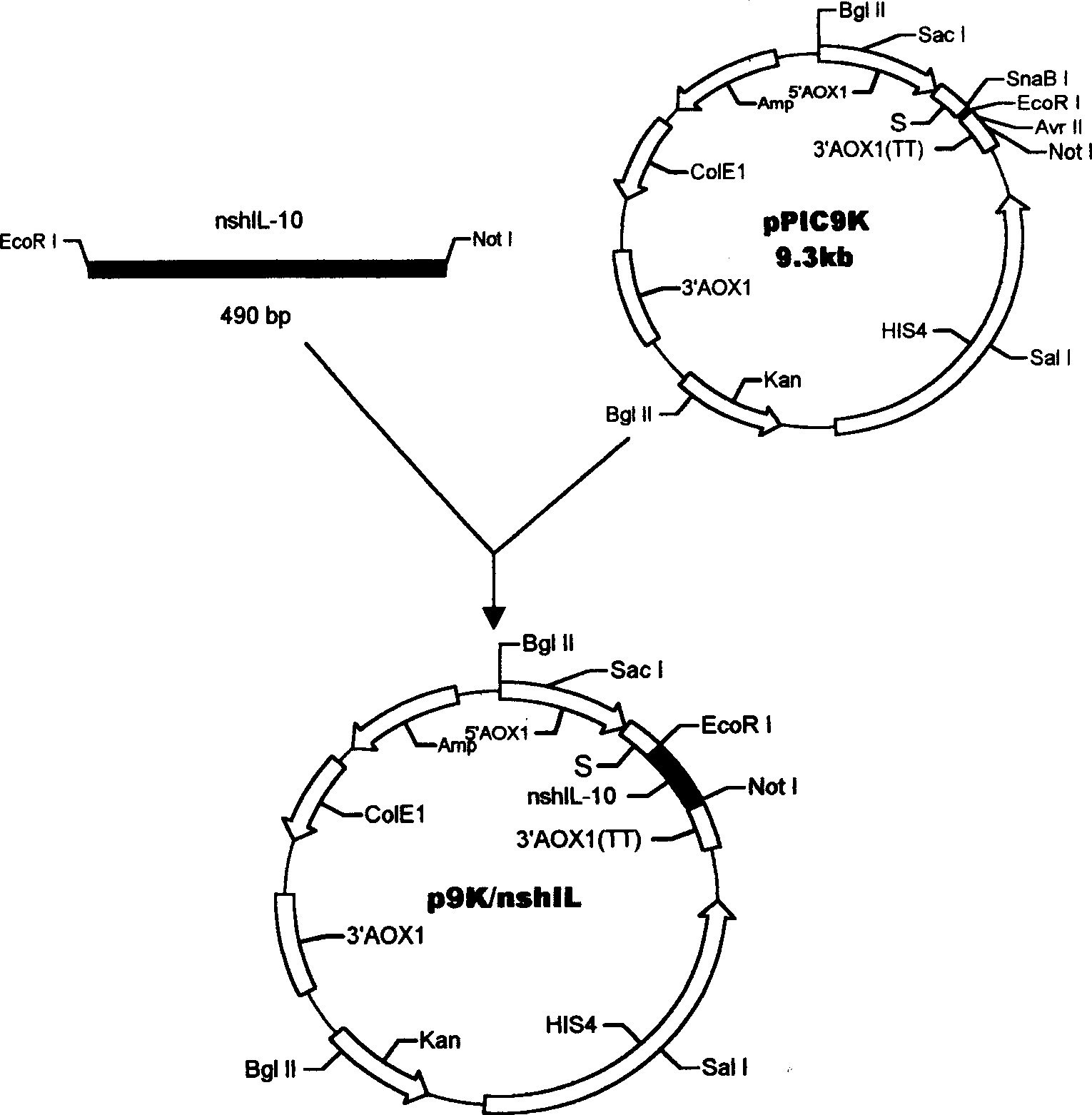

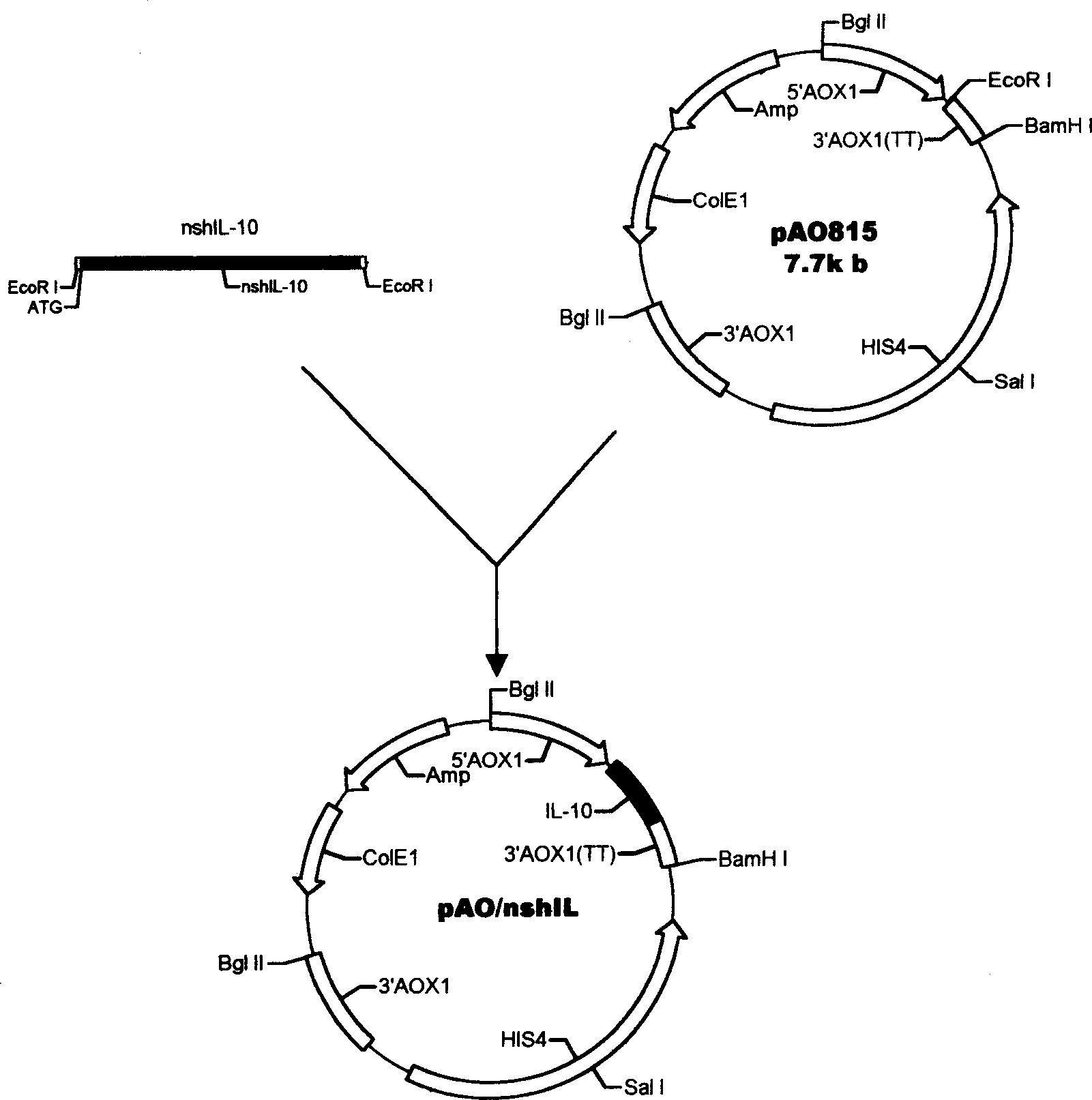

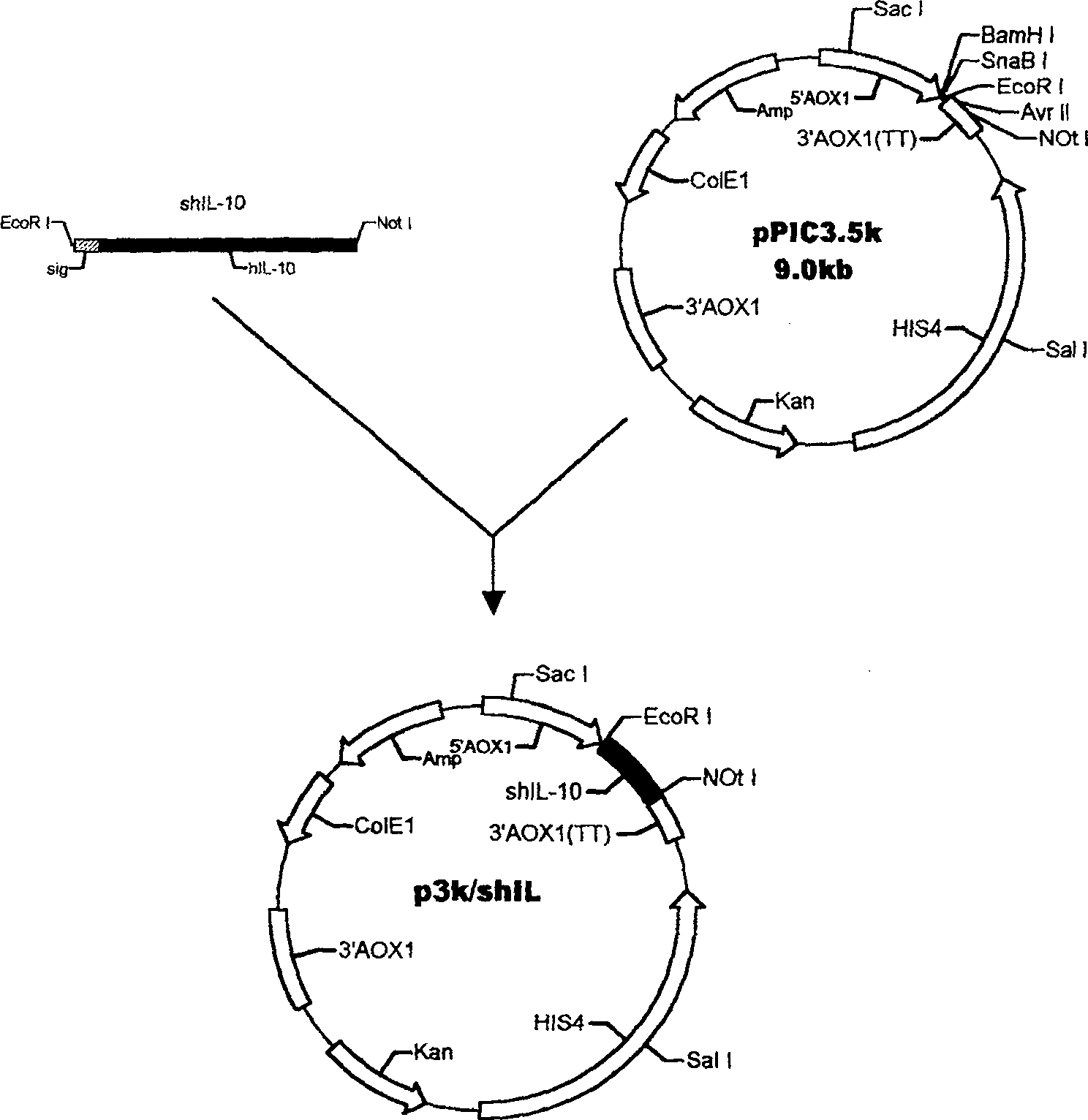

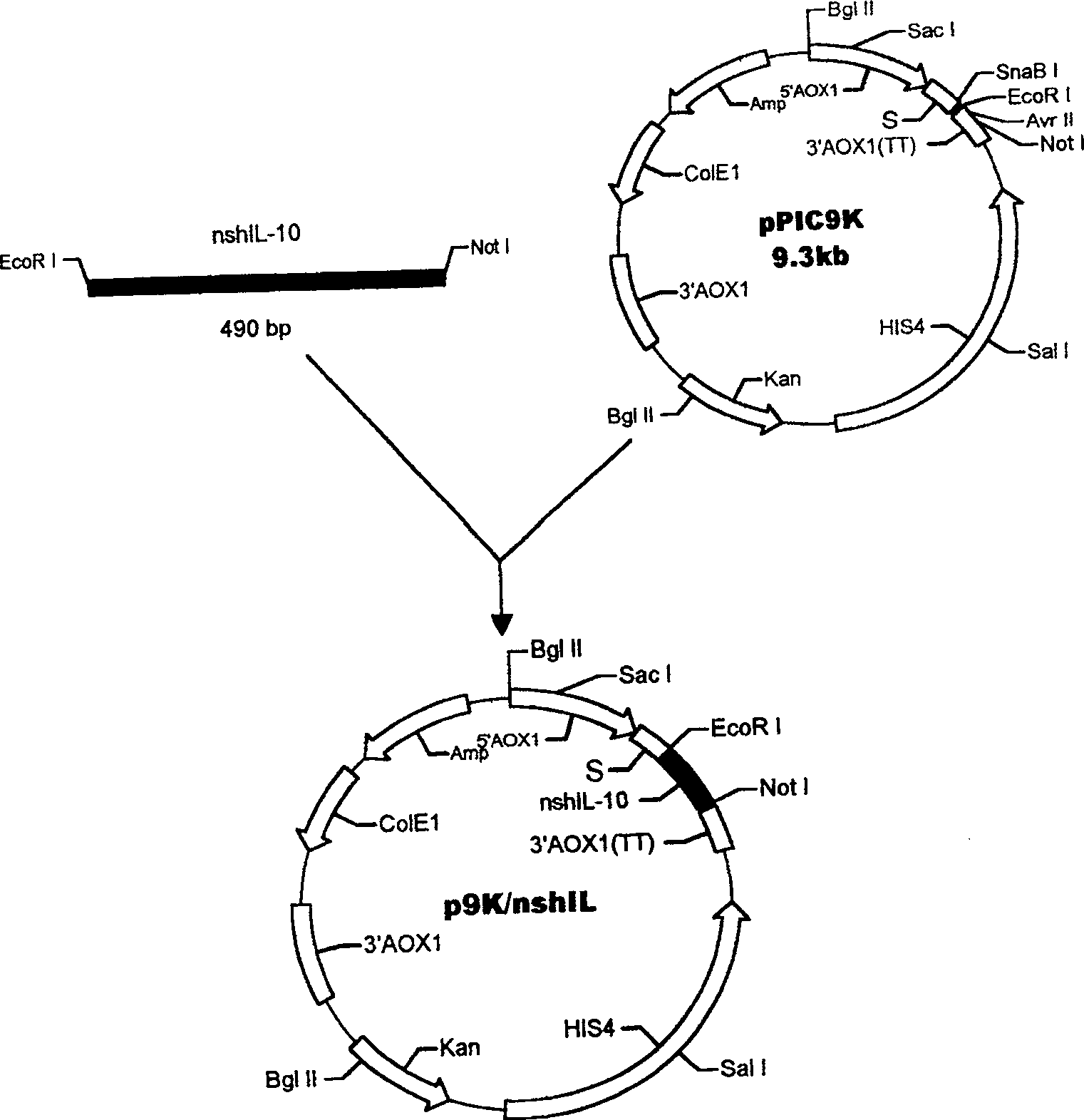

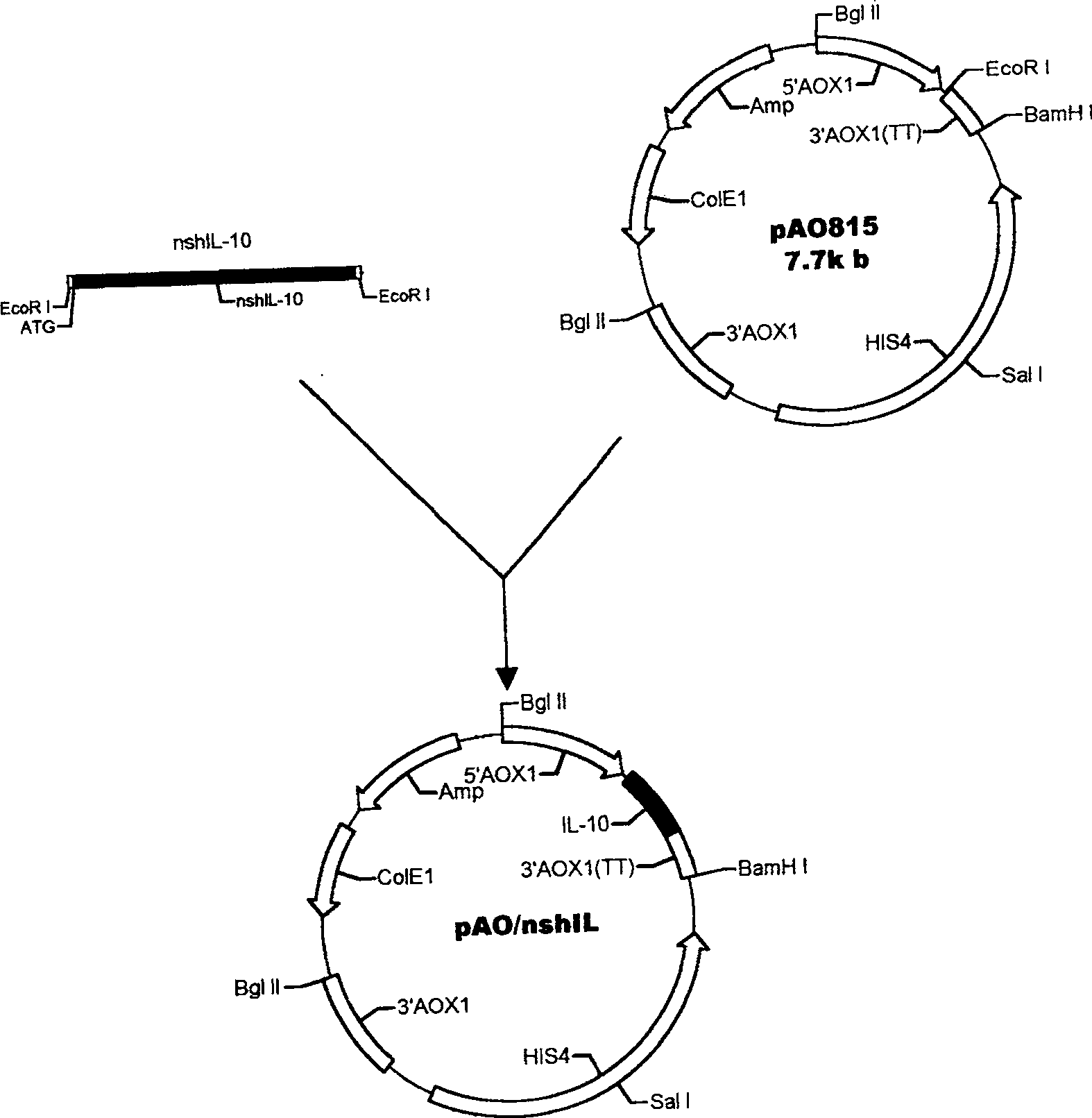

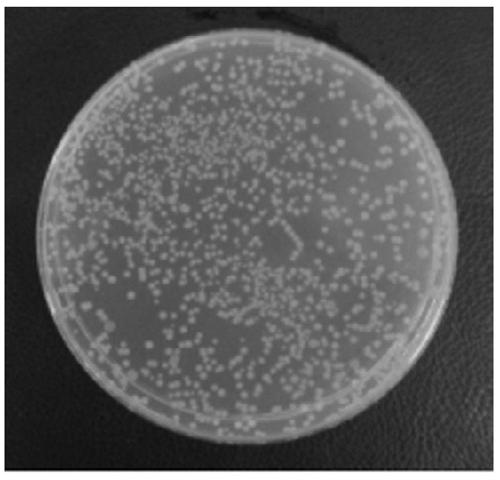

Method for yeast cell to express human interleukin 10

InactiveCN1506463AAvoid degradationSimple structureFermentationVector-based foreign material introductionBiotechnologyYeast chromosome

The method for yeast cell to express human interleukin 10 (hIL-10) has the technological scheme including artificially synthesizing all-gene sequence of hIL-10 including signal-carrying hIL-10 sequence, named shIL-10, and no-signal hIL-10 sequence, named nshIL-10; adding to the ends with EcorR I enzyme incising sequence and Not I enzyme incising sequence or with EcorR I enzyme incising sequences; double incising with EcorR I and Not I the integral expression vector pPIC3.5K and Ppic9K of destination gene shIL-10, nshIL-10 and Pichia yeast; constituting recombinant plasmid pPIC3.5K / shIL-10 and Ppic9K / nshIL-10; converting Pichia yeast cell via electrical perforation and plasmodic granule process; integrating recombinant plasmid and destination gene to yeast chromosome; and applying methanol to induce Pichia yeast for intracellular soluble expression and extracellular secretion type expression. The present invention is superior to expression in colibacillus.

Owner:ARMY MEDICAL UNIV

Method for producing photo initiator FMT

InactiveCN101712696AImprove quantum efficiencyImprove thermal stabilityMetallocenesWastewaterTetrahydrofuran

The invention relates to a method for producing a photo initiator FMT which is prepared by the following process steps of: reacting 2,5-dimethoxy tetrahydrofuran with 2,4-difluoroaniline in a low-temperature reaction kettle to generate 2,4- difluorophenylpyrrole; and directly adding titanocene dichloride and solvent in the low-temperature reaction kettle to dechlorinate under the catalysis of organic strong alkali. The method adopts a 'one-pot method' (i.e. the reaction is finished in one reaction kettle); since the process for purifying crude 2,4-difluorophenylpyrrole is saved, the method has easy reaction, high yield, stable product quality and easy purification. The invention simplifies the production process, saves the equipment investment, reduces the production cost, improves the yield of products (up to 85-90 percent), greatly reduces the discharge amount of wastewater and waste liquid, and is beneficial to environmental protection.

Owner:荆门市昱奎化工有限责任公司

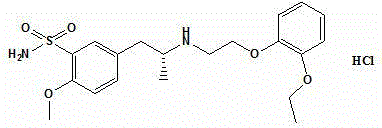

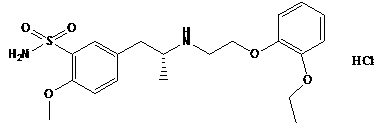

Preparation method of tamsulosin hydrochloride with high optical purity

ActiveCN104926699AGuaranteed optical purityPurification process reductionOrganic chemistryOrganic compound preparationOrganosolvEthyl group

The invention discloses a preparation method of tamsulosin hydrochloride with high optical purity, and belongs to a medicine technology and a chemical field. A recrystallization method is adopted, crude products of (R)-5-(2-(2-(2-ethoxyphenoxy) ethyl amino) propyl)-2-methoxyl phenyl sulfonamide hydrochloride are refined, so that pure products of the (R)-5-(2-(2-(2-ethoxyphenoxy) ethyl amino) propyl)-2-methoxyl group sulfonamide hydrochloride of which the e.e. value is larger than 99.8% is obtained; a crystallizing solvent adopted by the recrystallization method is a mixed solvent consisting of an organic solvent and water, the organic solvent is selected from one of methanol, ethyl alcohol, acetone, acetonitrile and isopropyl alcohol, and the recrystallization temperature is under 15 DEG C. The preparation method disclosed by the invention is simple to operate, short in period, low in cost and good in repeatability, and can solve the inevitable problem of rework for treatment in the industrial production.

Owner:CHENGDU LIKAI CHIRAL TECH

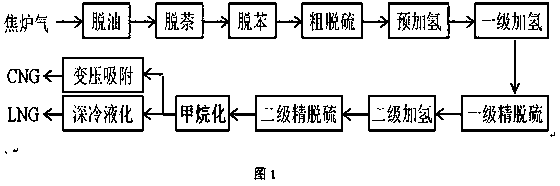

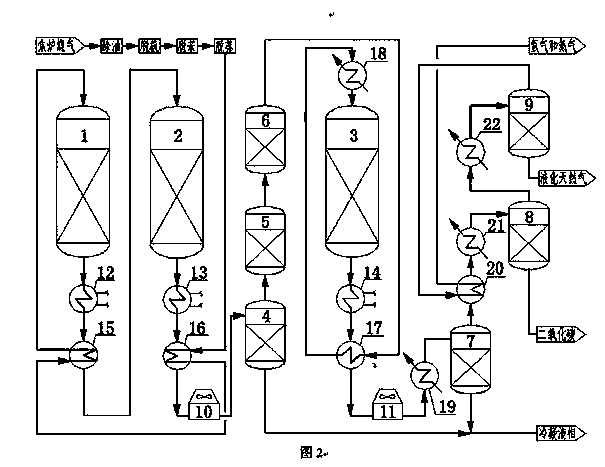

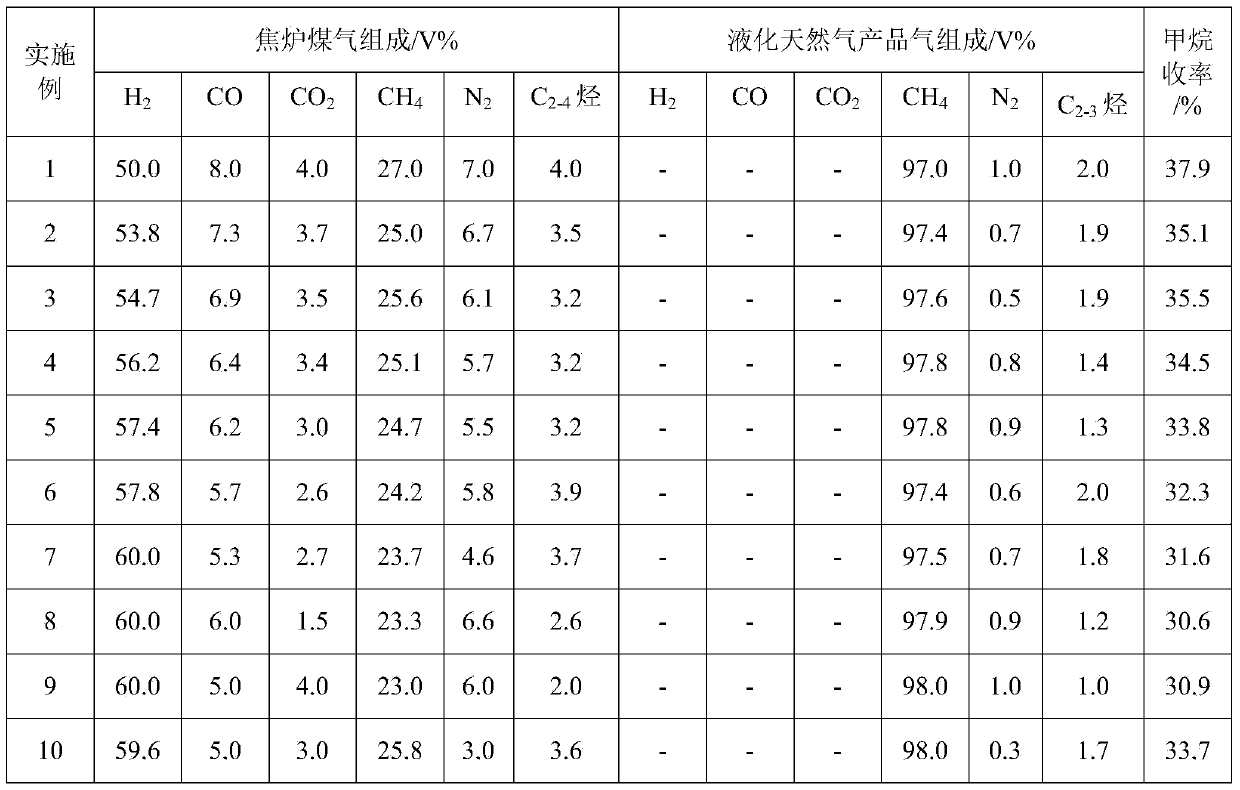

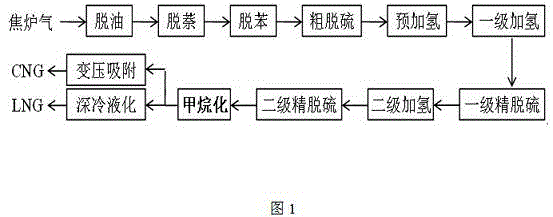

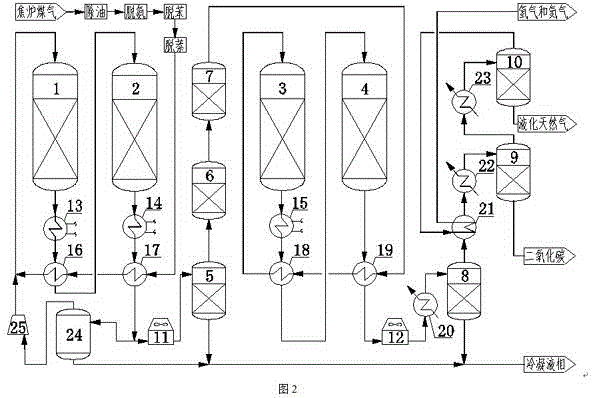

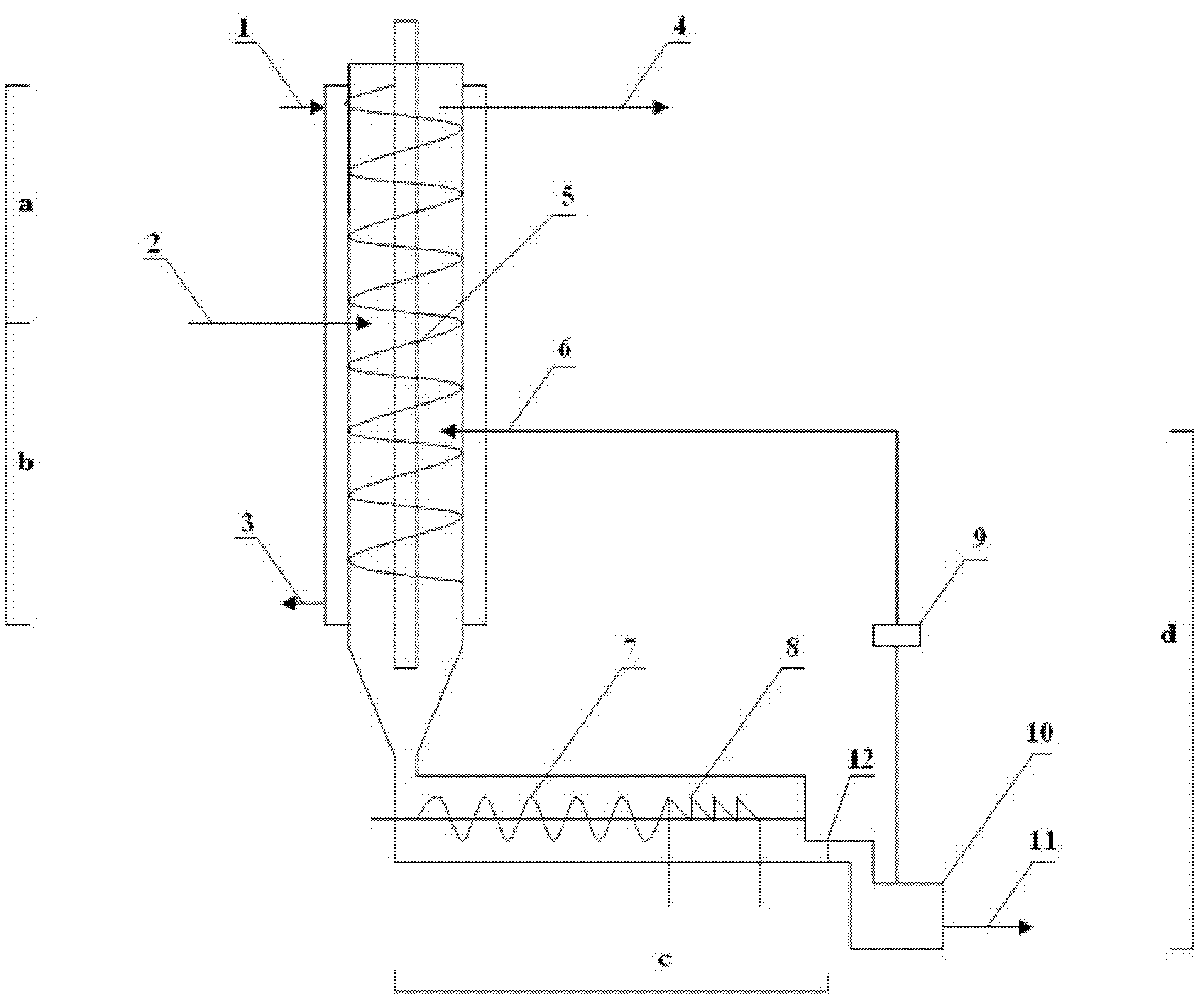

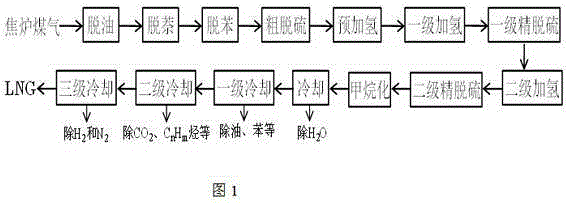

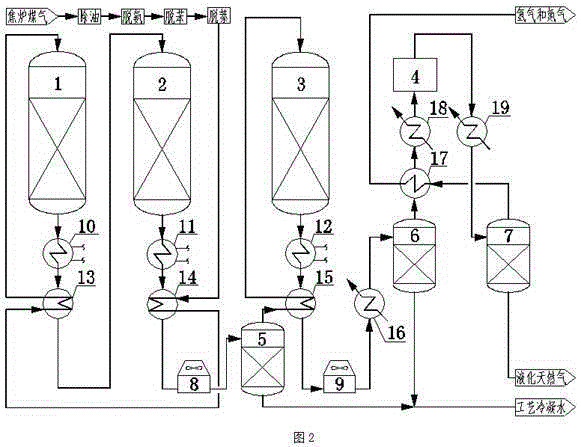

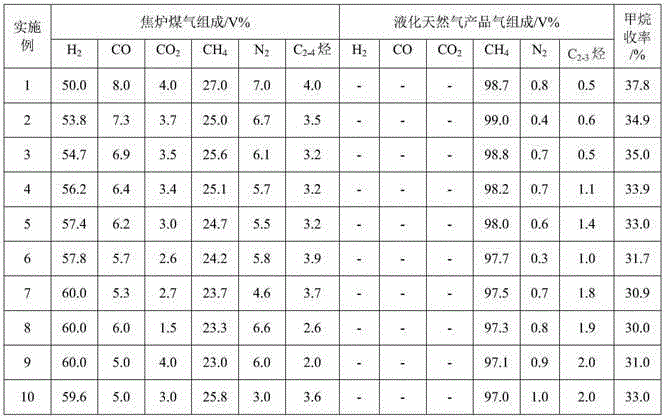

Technique for synthesizing natural gas from coke oven gas by sulfur-resistant methanation

InactiveCN104194851AOvercoming cumbersome desulfurization operationsPurification process reductionGaseous fuelsIron oxideActivated carbon

The invention relates to a technique for synthesizing natural gas from coke oven gas by sulfur-resistant methanation, which comprises the following steps: carrying out oil removal, naphthalene removal, benzene removal and removal of other impurities on the coke oven gas, directly carrying out two-stage methanation reaction on a supported molybdenum-base sulfur-resistant methanation catalyst, carrying out ferric oxide crude desulfurization and activated carbon fine desulfurization, carrying out cleaning reaction by Ni-base methanation reaction, and finally, carrying out cryogenic liquefaction to separate out impurities N2, H2, H2O and a small amount of CO2, thereby obtaining the liquefied natural gas product with the methane content of up to 99%. The technique has the advantages of simple technical process, less equipment investment, and comprehensive energy consumption and high quality of the natural gas product.

Owner:SEDIN ENG +1

Multifunctional composite gas purification film material

ActiveCN108295674APurification process reductionSmall sizeSemi-permeable membranesMembranesFiberMixed materials

The invention relates to a multifunctional composite gas purification film material, which comprises a film layer and a substrate, wherein the film layer is a polytetrafluoroethylene biaxial stretch film; the substrate is formed by mixing carrier fiber and low-temperature denitration catalysis fibers; the carrier fiber accounts for 40 to 70 weight percent and is a mixed material of organic fiber and inorganic fiber; the inorganic fiber accounts for 10 to 30 weight percent; the low-temperature denitration catalysis fiber has a bead particle structure; the bead particle diameter is 0.1 to 3 mum;the catalysis active ingredients comprises 20 to 50 weight percent of TiO2, 5 to 15 weight percent of Mn, 3 to 10 weight percent of Cr, 10 to 20 weight percent of V, 1 to 10 weight percent of Sn, 0.5to 2 weight percent of Ce and 0.5 to 2 weight percent of Cu. The dust removal and the denitration are performed at 120 to 160 DEG C; the dust removal and the denitration are coupled; the tail gas purification process is shortened; the dimension of the tail gas purification equipment is reduced; the heat recovery and utilization efficiency in the tail gas is improved.

Owner:南京科赫科技有限公司

Method for expressing and purifying neutral protease (NPR)

InactiveCN102168078AHigh expressionPurification process reductionBacteriaHydrolasesResearch resultPromoter activity

The invention relates to a method for expressing and purifying neutral protease (NPR). Research results find that good expression effect can be obtained by modifying pET series carriers and expressing a full-length gene of neutral protease. Thus, the invention provides a method for expressing the neutral protease, which comprises the following steps of: (1) constructing a recombinant expression plasmid through the full-length gene of the neutral protease and the pET carriers with eliminated T7 promoter activity, and (2) transforming escherichia coli through the recombinant expression plasmid constructed through the step (1) so as to express the neutral protease. According to the method provided by the invention, pure NPR protein can be conveniently and simply obtained, and the purification process of the NPR is simplified.

Owner:BEIJING STRONG BIOTECH

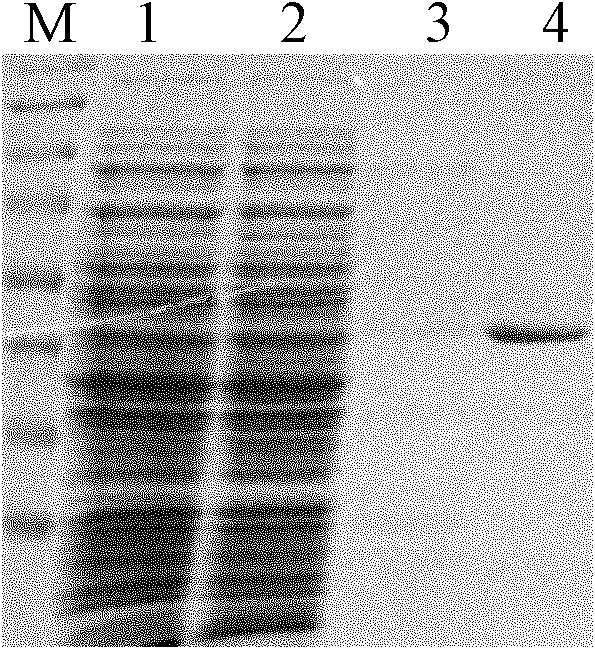

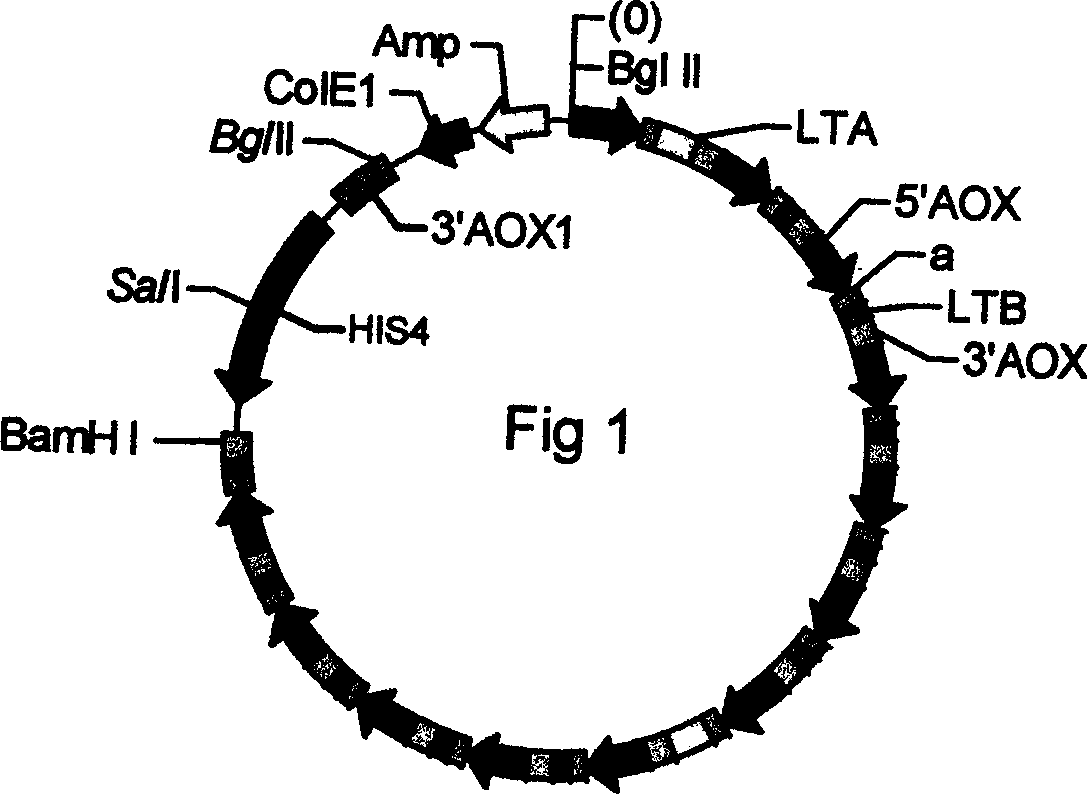

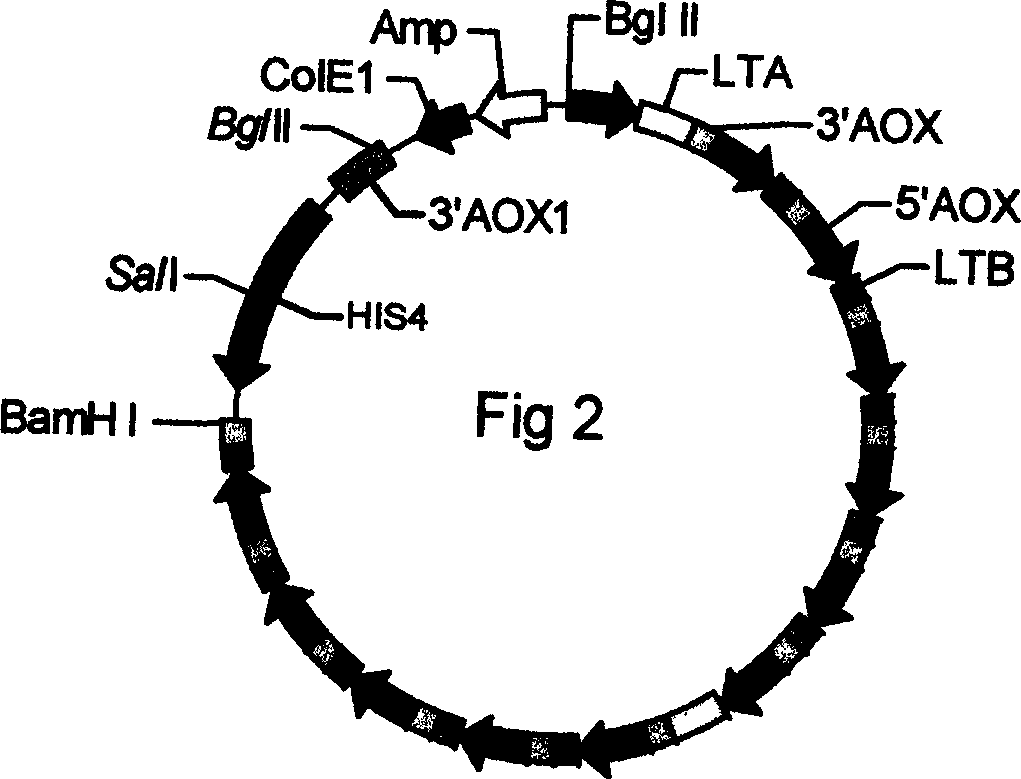

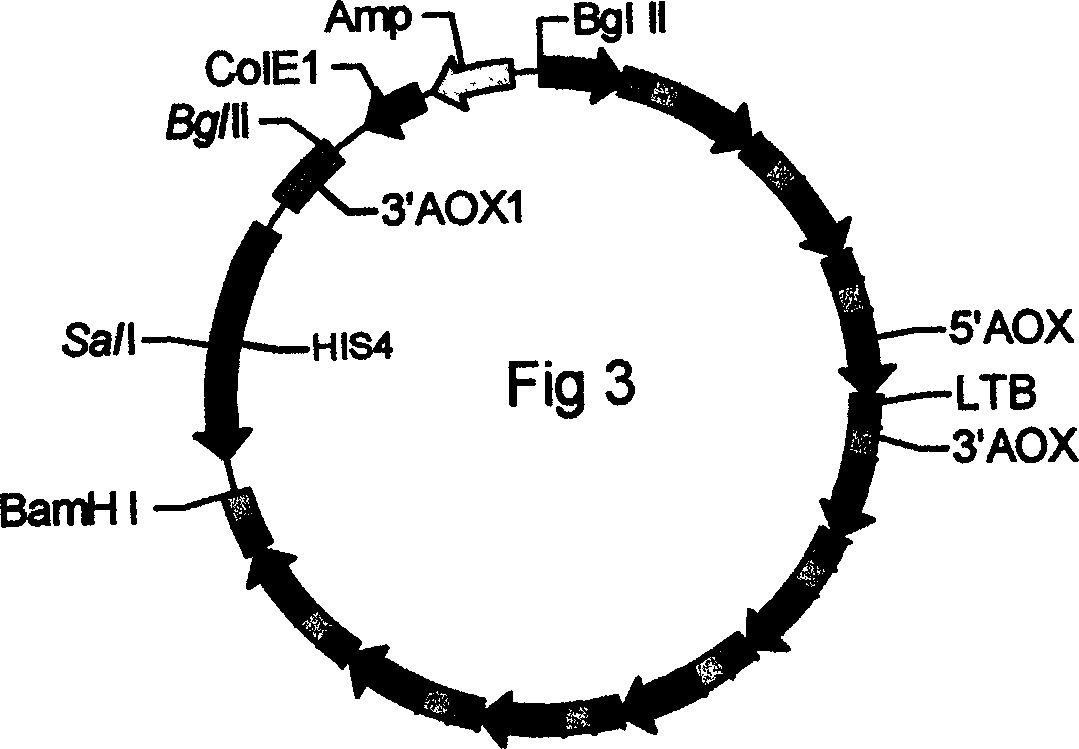

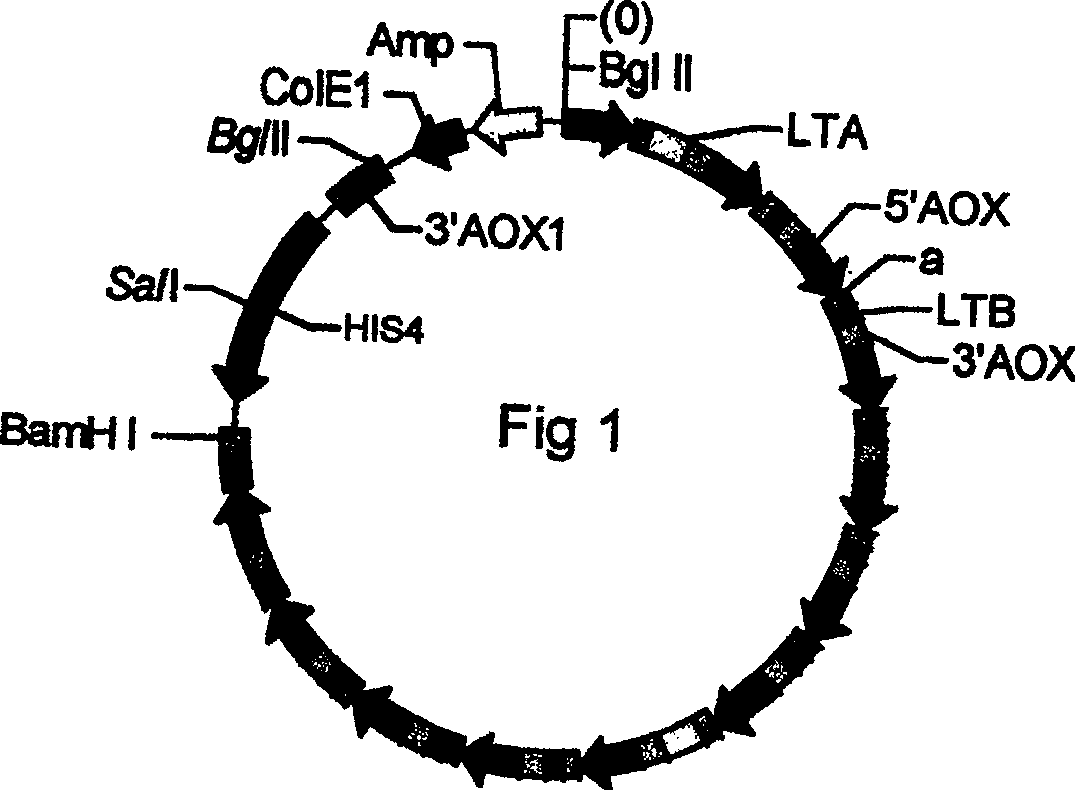

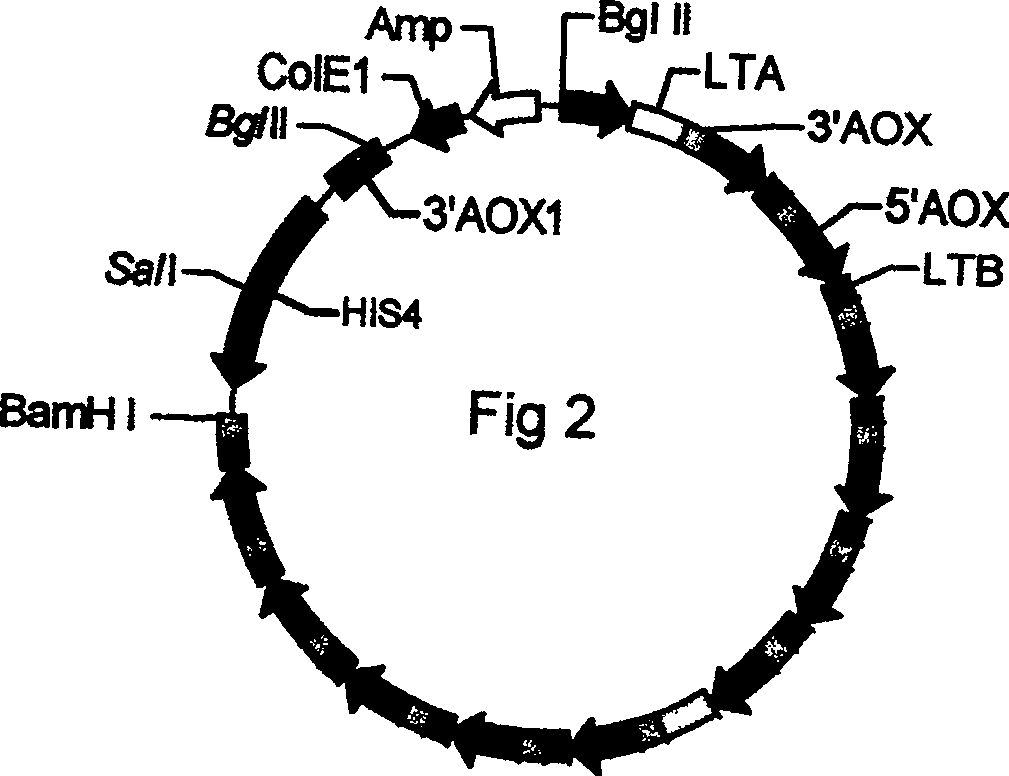

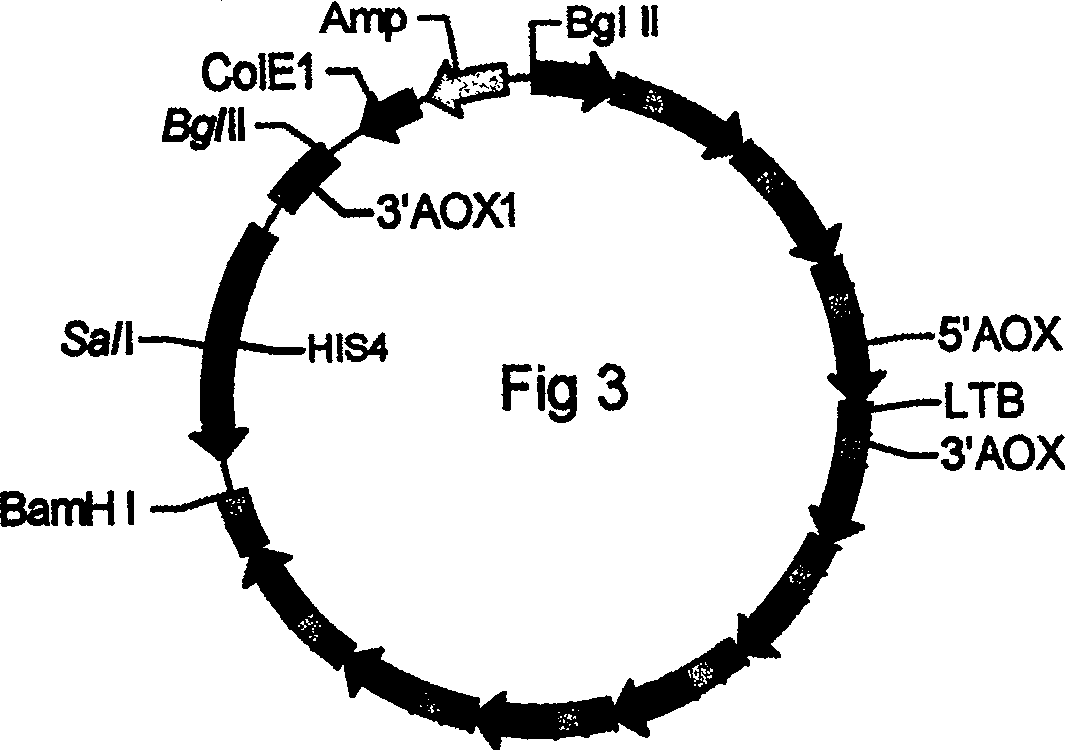

Process for preparing heat-labile enterotoxin of E, coli

InactiveCN1821398ADoes not affect translatioDoes not affect synthesis speedFungiMicroorganism based processesBiotechnologyEscherichia coli

The present invention discloses the preparation process of heat labile enterotoxin of E. coli, and the preparation process has intracellular expression or secretory expression of LT or LTB in yeast cell. Exogenously expressing LT and its mutant or subunit in eukaryotic yeast cell has greatly raised expression level. The present invention constitutes multicopy LT or LTB subunit expression kit, has increased gene dosage of LT or LTB in yeast, LT or LTB gene recombination following alcohol dehydrogenase promoter as the powerful promoter of Pichia yeast expression vector, methanol induced high expression of exogenous protein in yeast cell and thus raised expression level of LT and its mutant or LTB in yeast cell, simple post purification and safe clinical application. The present invention has low production cost and high target protein yield, and is significant in the scale production and clinical application of mucous membrane adjuvant.

Owner:KUNMING UNIV OF SCI & TECH

Microwave plasma exhaust gas purification method

InactiveCN108926975AAvoid defacementExtended service lifeGas treatmentDispersed particle separationPurification methodsHigh energy

The invention relates to a microwave plasma exhaust gas purification method. According to the microwave plasma exhaust gas purification method, a microwave plasma generator is used as a plasma gas source for generating high-energy active substances; a reaction chamber communicates with the gas outlet of the microwave plasma generator; air is introduced into the microwave plasma generator, and after a continuous and stable plasma gas flow occurs at the gas outlet, exhaust gas to be purified is introduced into the reaction chamber; and the plasma gas flow and the exhaust gas are mixed in the reaction chamber, the high-energy active substances contained in the plasma gas flow realize oxygenolysis of organic matters included in the exhaust gas, and then the exhaust gas is discharged. Through the split design of the exhaust gas and the plasma gas flow, volatile organic oxides and impurities such as dust in the exhaust gas are effectively prevented from contaminating the functional components of the microwave plasma generator; and thus, the service life of the microwave plasma generator is prolonged, and the purification effect of the microwave plasma generator is ensured. At the same time, since the exhaust gas does not enter and pass through the microwave plasma generator, plasma purification can be directly performed without pre-treatment.

Owner:眉山金豆智能科技有限公司

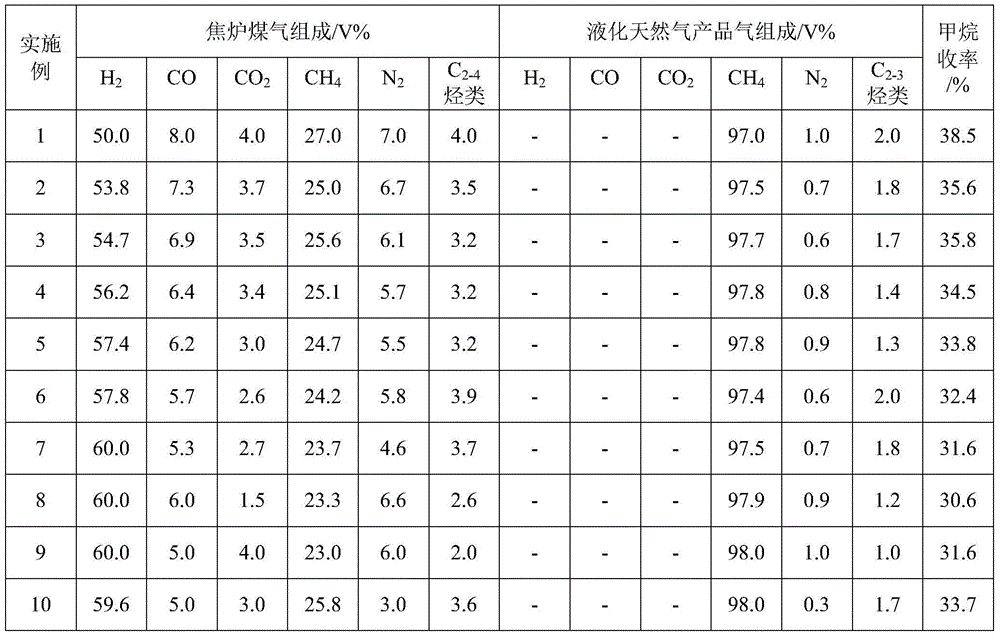

Process for preparing substitute liquefied natural gas (LNG) with coke-oven gas

InactiveCN104164264AWith characteristicsHave made significant progressGaseous fuelsMethanationImpurity

The invention provides a process for preparing substitute liquefied natural gas (LNG) with coke-oven gas. The process is characterized by subjecting the coke-oven gas to direct two-stage methanation reactions on a supported molybdenum-based sulphur-tolerant methanation catalyst after removing the impurities such as oil, naphthalene, benzene and the like from the coke-oven gas, then carrying out clean reaction through two-stage Ni-based methanation reactions after ferric oxide coarse desulfurization and activated carbon fine desulfurization, and finally separating the impurities such as N2, H2, H2O and little CO2 through subzero liquefaction, thus obtaining the LNG product with methane content higher than 97%. The process has the advantages of simple process flow, small equipment investment, low comprehensive energy consumption and excellent natural gas products.

Owner:SEDIN ENG +1

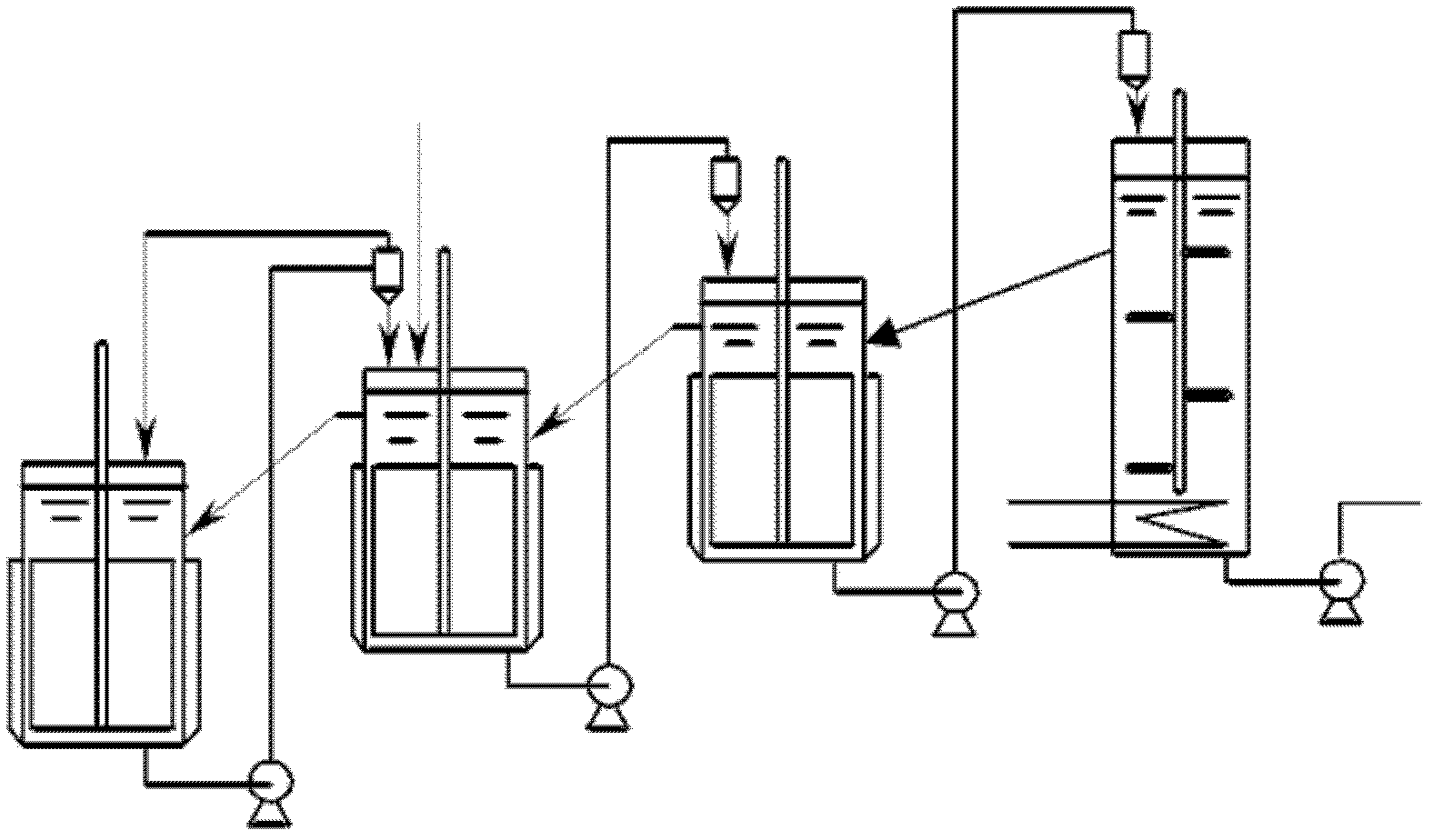

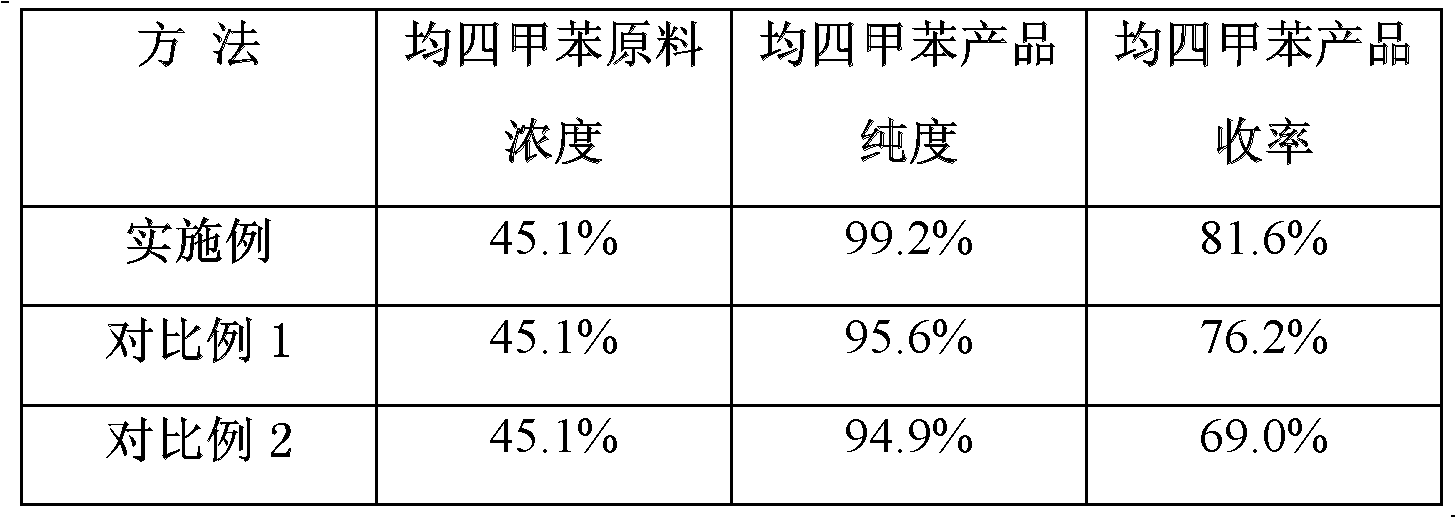

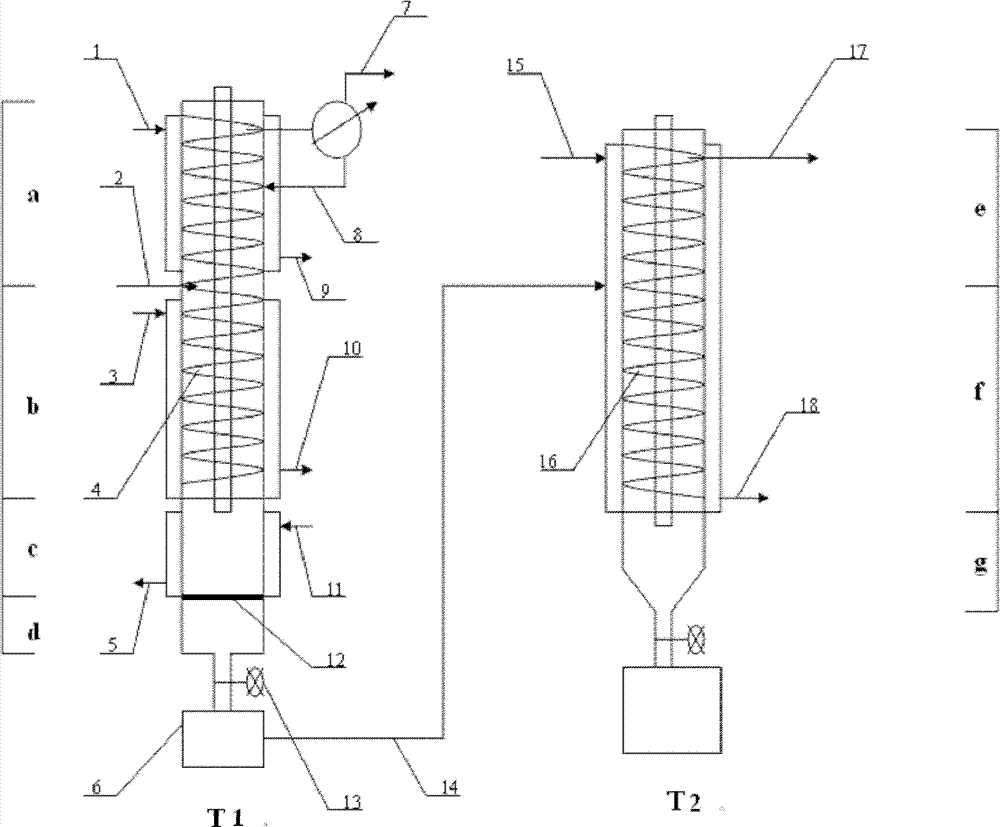

Apparatus and method for continuously separating and purifying durene

ActiveCN103083935BHigh purityPurification process reductionSolution crystallizationCrystallisation purification/separationEngineeringToluene

The present invention discloses an apparatus and a method for continuously separating and purifying durene. The apparatus comprises: a vertical tower body and a horizontal tower body, wherein rotation scrapers are respectively arranged inside the vertical tower body and the horizontal tower body, the outer side of the vertical tower body is provided with a constant temperature material inlet, the vertical tower body is sequentially provided with a residue liquid recovery section and a crystal purification section from top to bottom, the horizontal tower body comprises a crystal collection section and a melting crystal reflux section, the melting crystal reflux section comprise a constant temperature melting crystal collection tank, a reflux pump and a heater, and the melting crystal reflux section is connected with the crystal purification section through a reflux port. The method comprises that: a durene raw material continuously enters the apparatus, and is sequentially subjected to countercurrent washing, re-crystallization and purification separation to obtain the pure durene. With the apparatus and the method, continuous material feeding, continuous high purity durene crystal extraction and continuous residue liquid recovery can be achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

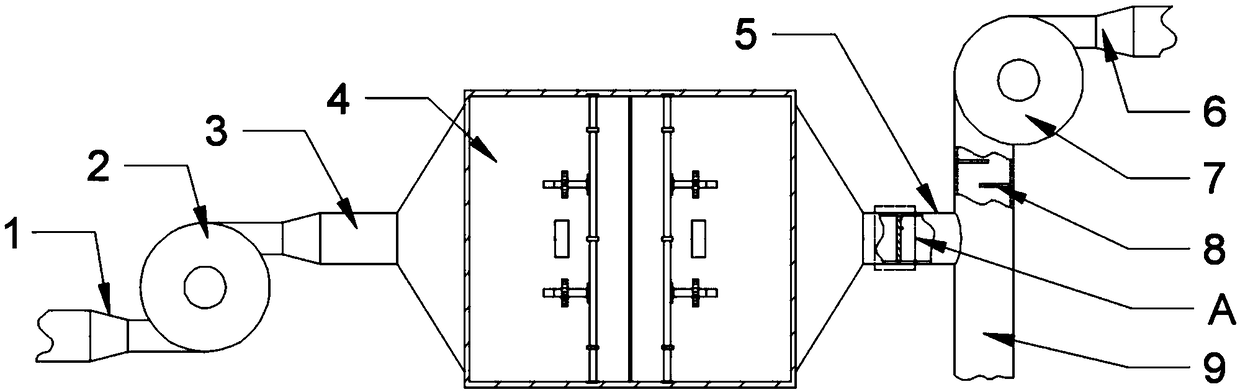

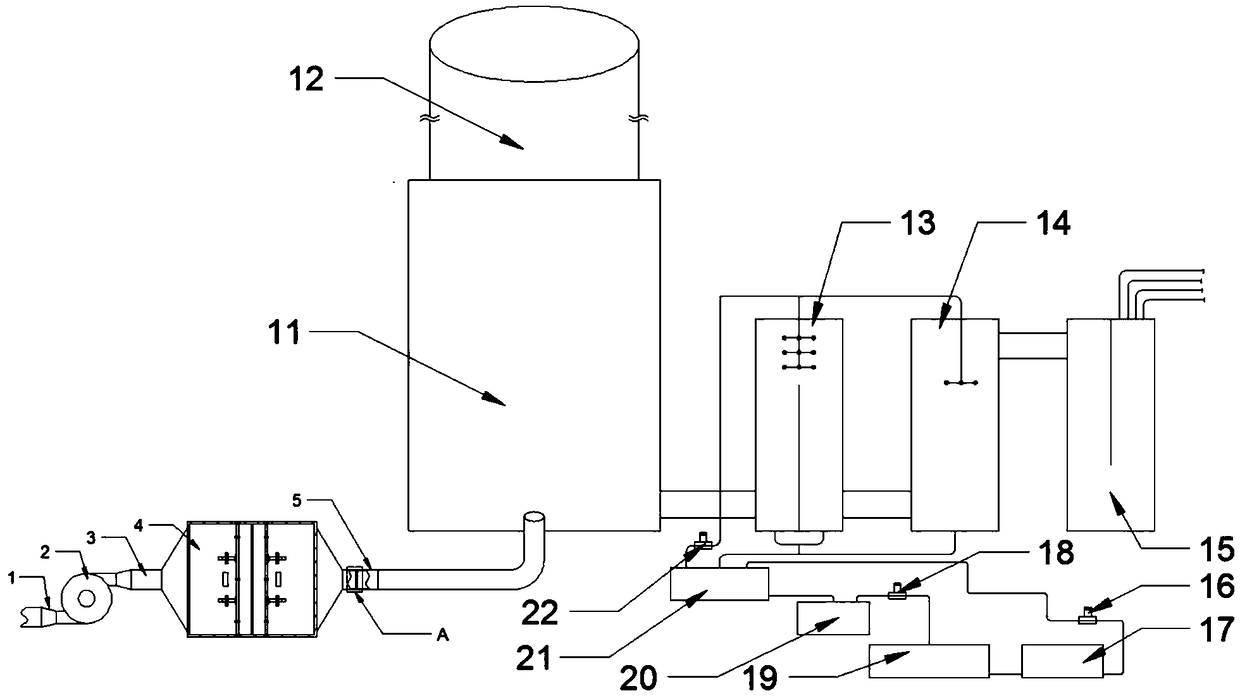

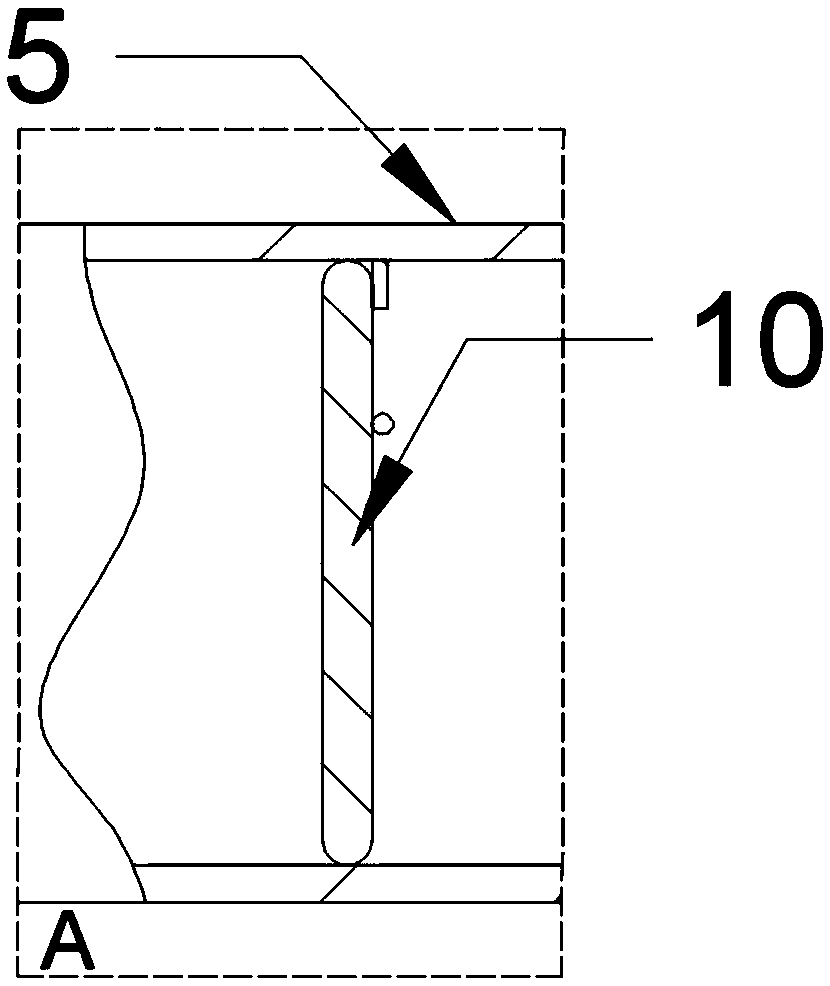

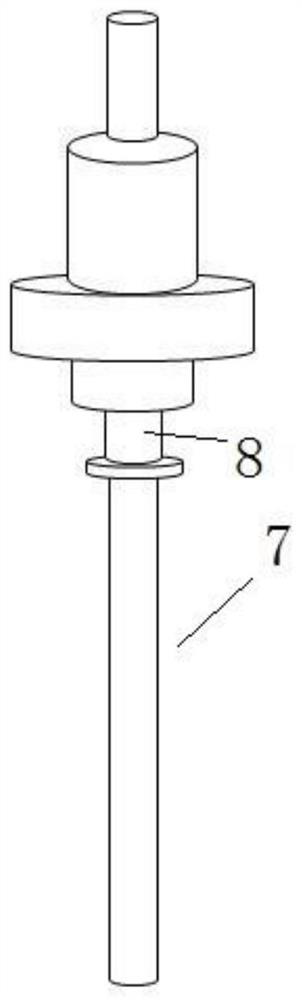

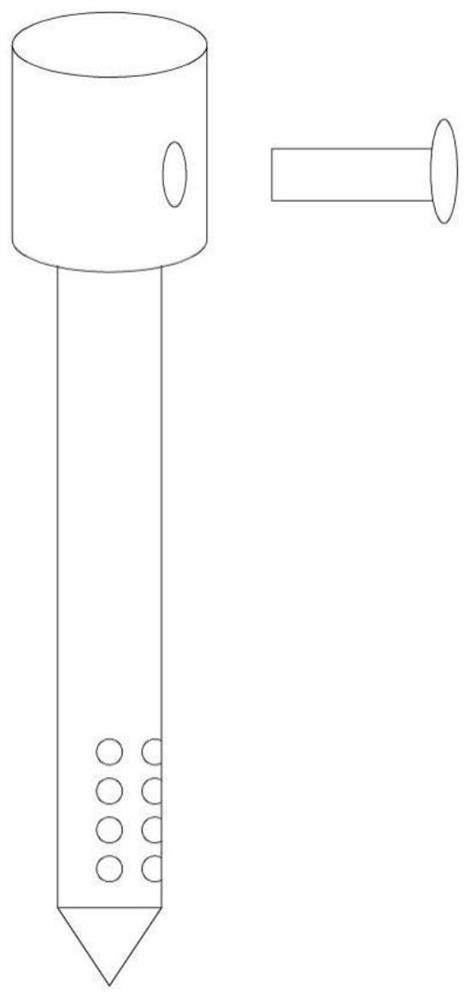

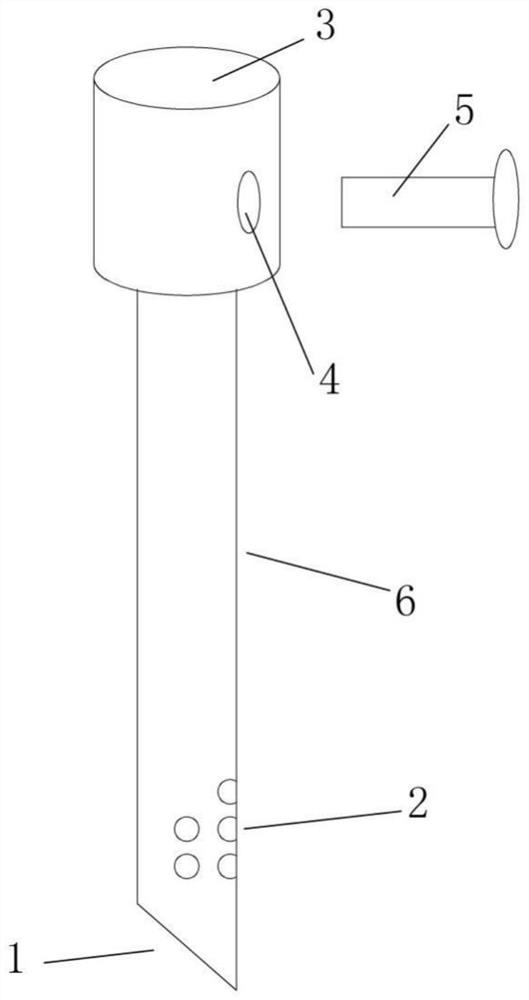

Antigen harvesting device for infectious bronchitis

PendingCN111763611AReduce cloggingQuick drawBiological material testing proceduresSpecific use bioreactors/fermentersYolkAntigen

The invention relates to the technical field of antigen harvesting, and especially relates to an antigen harvesting device for infectious bronchitis. The harvesting device includes a harvesting head;the harvesting head includes a liquid suction rod (7) and a coat; the coat is formed by a liquid suction rod inserting head (3) and a liquid suction rod coat (6) in successive arrangement from top tobottom through connection; the lower end of the liquid suction rod coat (6) is a beveled sharp head (1), and the included angle between the inclined plane of the beveled sharp head (1) and a horizontal plane is 30-45 degrees; and the sidewall, on the same side with the tip of the beveled sharp head (1), of the liquid suction rod coat (6) is provided with multiple liquid suction holes (2). The beveled sharp head of the device is only in contact with the eggshell edge of chicken embryo during harvesting, and the incline plane can effectively avoid the yolk when going down; and the harvesting head has more liquid suction holes at the top part and less liquid suction holes at the bottom part, so that liquid suction rod can be further shortened, therefore, blocking can be effectively avoided, allantoic fluid can be quickly sucked, and thorough suction can be achieved.

Owner:兆丰华生物科技(南京)有限公司

A kind of preparation method of tamsulosin hydrochloride with high optical purity

ActiveCN104926699BGuaranteed optical purityPurification process reductionOrganic chemistryOrganic compound preparationAlcoholOrganic solvent

Owner:CHENGDU LIKAI CHIRAL TECH

Hydrogen sulfide vanadium removal technology

The invention provides a hydrogen sulfide vanadium removal technology which comprises the following steps: injecting coarse TiCl4 into a reaction kettle A; directly introducing hydrogen sulfide gas and nitrogen into the reaction kettle A, wherein the mass ratio of the hydrogen sulfide gas to the coarse titanium tetrachloride is (1-2):1,000; controlling the temperature in a reaction kettle B to 120-130 DEG C, and performing an aging reaction for 1-2 hours; and feeding pure titanium tetrachloride to the tower bottom and discharging into a finished product tower kettle to obtain a finished product of TiCl4, wherein the finished product of TiCl4 is colorless and transparent in a liquid form without obvious scaling phenomenon, and the vanadium content in the finished product of TiCl4 is less than or equal to 0.0024%. In the invention, hydrogen sulfide reacts with VOCl3 and impurities in the coarse TiCl4 to generate VOCl2 which is discharged in a form of slurry; and the technological method is simplified, the process is shortened, and the equipment and raw material cost is lowered.

Owner:仙桃市中星电子材料有限公司

Process for preparing heat-labile enterotoxin of E, coli

InactiveCN100500842CImprove expression levelIncreased gene dosageFungiMicroorganism based processesBiotechnologyEscherichia coli

The present invention discloses the preparation process of heat labile enterotoxin of E. coli, and the preparation process has intracellular expression or secretory expression of LT or LTB in yeast cell. Exogenously expressing LT and its mutant or subunit in eukaryotic yeast cell has greatly raised expression level. The present invention constitutes multicopy LT or LTB subunit expression kit, has increased gene dosage of LT or LTB in yeast, LT or LTB gene recombination following alcohol dehydrogenase promoter as the powerful promoter of Pichia yeast expression vector, methanol induced high expression of exogenous protein in yeast cell and thus raised expression level of LT and its mutant or LTB in yeast cell, simple post purification and safe clinical application. The present invention has low production cost and high target protein yield, and is significant in the scale production and clinical application of mucous membrane adjuvant.

Owner:KUNMING UNIV OF SCI & TECH

Process for processing ethylene oxide streams containing nox or organic nitrogen compounds

InactiveCN101568505ASimple purification processPurification process is simplified and less expensiveOrganic compound preparationPreparation by hydrolysisEthylene oxideNitrogen

Crude aqueous alkylene oxide streams are converted to the corresponding alkylene glycol. The crude alkylene oxide stream contains NOx or organic nitrogen compounds. The hydrolysis reaction is conducted in the presence of water-soluble reducing agents, of which an alkali metal bisulfite is a preferred type.

Owner:DOW TECH INVESTMENTS

A multifunctional composite gas purification membrane material with denitrification and dust removal functions

ActiveCN108295674BPurification process reductionSmall sizeMembranesSemi-permeable membranesPhysical chemistryFilm material

A multifunctional composite gas purification membrane material, including a membrane layer and a substrate. The membrane layer is a biaxially stretched polytetrafluoroethylene membrane. The substrate is made of a mixture of carrier fiber and low-temperature denitration catalytic fiber. The carrier fiber accounts for 40‑ 70wt%, the carrier fiber is a mixed material of organic fiber and inorganic fiber, in which the inorganic fiber content accounts for 10-30wt%, the low-temperature denitration catalytic fiber has a bead structure, the bead diameter is 0.1-3μm, and the catalytic active component is TiO 2 Content 20‑50wt%, Mn content 5‑15wt%, Cr content 3‑10wt%, V content 10‑20wt%, Sn content 1‑10wt%, Ce content 0.5‑2wt%, Cu content 0.5‑2wt%. Both dust removal and denitrification operate at 120-160°C. Coupling dust removal and denitrification shortens the exhaust gas purification process, reduces the size of the exhaust gas purification equipment, and improves the heat recovery and utilization efficiency in the exhaust gas.

Owner:南京科赫科技有限公司

A method and device for removing metal impurities in polysilicon by electron beam overheating melting

InactiveCN104556050BPurification process reductionReduce manufacturing costSilicon compoundsCrucibleIngot casting

The invention discloses a method and device for removing metal impurities in polycrystalline silicon by electron beam overheat smelting, and belongs to the field of metallurgy. The device comprises a water-cooled copper smelting crucible, wherein an inclined sidewall design is adopted for the water-cooled copper smelting crucible; the inner sidewall of the water-cooled copper smelting crucible forms an included angle of 105 to 120 degrees with the bottom of the water-cooled copper smelting crucible; a graphite bushing is arranged in the water-cooled copper smelting crucible; the outer surface of the graphite bushing is attached to the inner surface of the water-cooled copper smelting crucible to form a close fit design; the bottom of the graphite bushing and the bottom of the water-cooled copper smelting crucible are horizontal, the inner surface sidewall of the graphite bushing forms an included angle of 95 to 100 degrees with the bottom of the graphite bushing. According to the device, the metal impurities are removed by overheat smelting, so that the number of times of subsequent directional solidification and ingot casting can be reduced, a purification process can be eliminated, and the production cost can be reduced; by electron beam overheat smelting for polycrystalline silicon purification, post directional solidification can be reduced by one time or more, and the metal impurities in the polycrystalline silicon can be reduced by 30 percent or more.

Owner:DALIAN UNIV OF TECH

Expressing method of human interleukin 7 in eucaryon host

InactiveCN101302517BAvoid degradationReduce loadFermentationVector-based foreign material introductionYeastBiotechnology

The invention discloses a method for expressing human interleukin 7 in eucaryotic host. When the eucaryotic host is pichia X-33, the method comprises the following steps of: (1) cloning an IL-7 gene of human; (2) building an eucaryotic expression vector; (3) transforming recombinant vector to the eucaryotic yeast host; and (4) expressing a rIL-7 protein in the yeast host. A prior method for expressing IL-7 by using prokaryotic host escherichia coli is changed, and a method for expressing IL-7 through eucaryotic host pichia is searched out, thereby ensuring an IL-7 biologic activity and obtaining a large amount of stable protein.

Owner:GUANGZHOU INST OF BIOMEDICINE & HEALTH CHINESE ACAD OF SCI +1

Preparation method of polyphenylene sulfide resin with low ion precipitation

ActiveCN114854016AMaintain microscopic stabilityLow costChemical recyclingEnd-groupPhysical chemistry

The invention discloses a preparation method of polyphenylene sulfide resin with low ion precipitation, relates to the field of preparation of polyphenylene sulfide resin with low anion and cation precipitation, solves the problems that the existing purification process only solves the problem of low-chlorine resin and other ions cannot be removed, and comprises the steps of sodium sulfide dehydration, paradichlorobenzene dissolution and first-stage prepolymerization. Carrying out second-stage polymerization, filtering, washing and drying, third-stage polymerization and fourth-stage polymerization, cooling to below 50 DEG C after constant temperature is finished, and separating to obtain low-ion precipitation polyphenylene sulfide resin; after the polyphenylene sulfide resin subjected to primary polymerization is washed, the activity of the water-containing resin is increased, and unstable positive ions and negative ions on end groups on the surface layer of the polyphenylene sulfide resin are removed; removing moisture, adding N-methyl pyrrolidone and a catalyst again to open the chain of the polyphenylene sulfide again, removing unstable end groups in the resin and trace anions and cations wrapped in the middle of the resin, separating out the polyphenylene sulfide, and polymerizing again through the catalyst to obtain the polyphenylene sulfide resin with high purity and low ion separation.

Owner:四川中科兴业高新材料有限公司

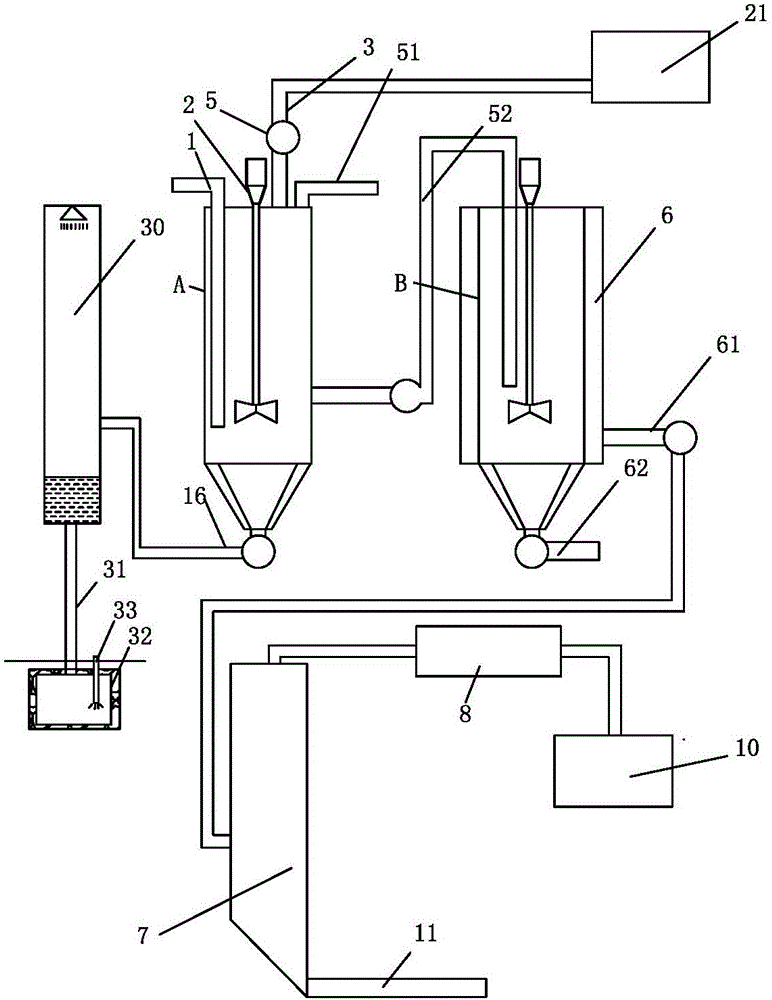

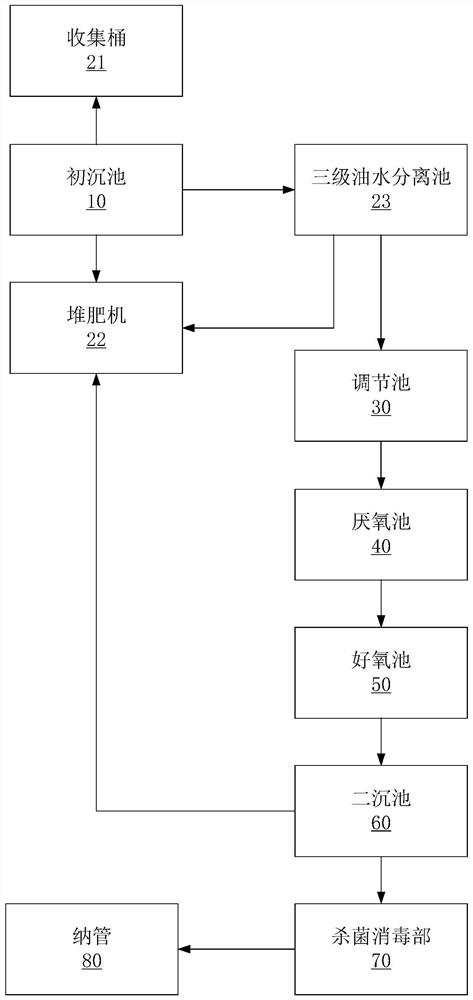

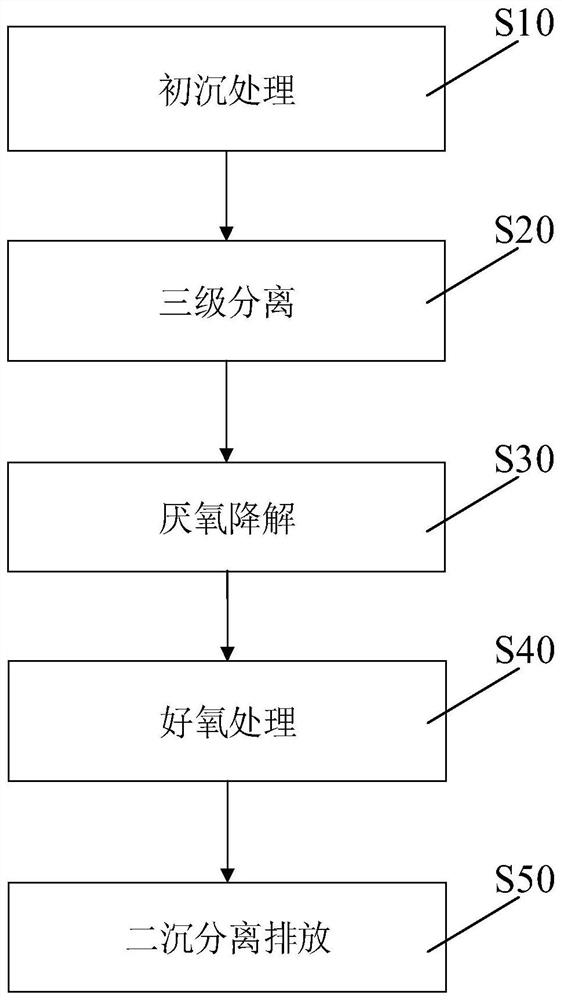

Wastewater purification device for kitchen waste treatment and method thereof

PendingCN112028383AImprove purification effectPurification process reductionTreatment using aerobic processesWater/sewage treatment by irradiationWastewaterSewage

The invention discloses a waste water purification device for kitchen waste treatment and a method thereof. The device comprises a primary sedimentation tank, a collecting barrel, a three-stage oil-water separation tank, an adjusting tank, an anaerobic tank, an aerobic tank, a secondary sedimentation tank and a sterilization and disinfection part, wherein the primary sedimentation tank is connected with the collecting barrel and the three-stage oil-water separation tank, and the primary sedimentation tank outputs floating oil to the collecting barrel; oil and water are output to the third-stage oil-water separation tank; the third-stage oil-water separation tank outputs separated oil to the collecting barrel and outputs separated sewage to the regulating tank; wherein the regulating tank,the anaerobic tank, the aerobic tank, the secondary sedimentation tank and the sterilization and disinfection part are connected in sequence to degrade, remove organic matters and sterilize and disinfect sewage. According to the method, the complete life cycle of oil, water and slag is comprehensively considered, each part is subjected to harmless and resource utilization, secondary pollution is avoided, and environmental protection benefits are achieved.

Owner:蔚复来(浙江)科技股份有限公司

Method for preparing 2,4-dihydroxy-6-methoxy-3-methylacetophenone with high purity

ActiveCN102702157ALow impurity contentImprove extraction efficiencyOrganic chemistrySilica columnPhysical chemistry

The invention discloses a method for preparing 2,4-dihydroxy-6-methoxy-3-methylacetophenone with high purity. The method comprises the following steps: Euphorbia fischeriana is grinded and subjected to reflux extraction by using ethanol, then extract is filtrated to obtain a filtrate; the filtrate is condensed for recycling ethanol to obtain a thick paste; silica gel is added into the paste with a ratio of 5-10:1 of the silica gel to the paste to obtain a mixture, then the mixture is blended homogeneously, dried, subjected to column chromatography by using the silica gel as a carrier and eluted with an eluent, and the eluent is collected; the eluent is condensed to recycle solvents to obtain crude crystal of 2,4-dihydroxy-6-methoxy-3-methylacetophenone; the crude crystal is dissolved into ethanol, then silica gel is added and mixed to obtain another mixture, then the mixture is dried and subjected to column chromatography by using silica gel for 2-3 times to obtain pure 2,4-dihydroxy-6-methoxy-3-methylacetophenone. Extraction and purification costs of the method provided by the invention can be reduced by about 20%, at the same time, energy consumption can be significantly reduced and extraction efficiency can be increased to over 30%. The prepared 2,4-dihydroxy-6-methoxy-3-methylacetophenone has a purity of more than 99% and is especially suitable to be used as a standard substance for measuring contents of Stellera chamaejasme medical materials and related preparations like JIEHELING tablets.

Owner:广东恒健制药有限公司

A method for preparing liquefied natural gas by sulfur-resistant methanation of coke oven gas

Owner:SEDIN ENG +1

Fast united purification method of thyroglobulin and red kidney bean vegetable hemagglutinin

InactiveCN101555277BLow costIncrease productionPeptide preparation methodsPlant peptidesHemagglutininBiotechnology

The invention provides a method for separating and purifying red kidney bean vegetable hemagglutinin and thyroglobulin. The method mixes crude extract of red kidney bean vegetable hemagglutinin in redkidney bean with crude extract of thyroglobulin; the mixture is then extracted by coprecipitation method, purified and separated to respectively obtain hemagglutinin monomer and thyroglobulin. The method directly extracts vegetable agglutinin from red kidney bean and is applicable to obtaining of vegetable hemagglutinin without extraction of vegetable hemagglutinin after extracting of vegetable agglutinin, thereby simplifying purification process. Material used in the method is low in cost and wide in sources, and the raw materials are easy to obtain. The method has low production cost, simple operation and high yield which are applicable to industrial mass production. The vegetable hemagglutinin extracted by the method has not only high activity and high yield, but also low cost and short cycle. The method obtains hemagglutinin monomer together with thyroglobulin that the method has high product economic value, excellent generalizability, and relatively high economical and utility value.

Owner:CHENGDU MEDICAL COLLEGE

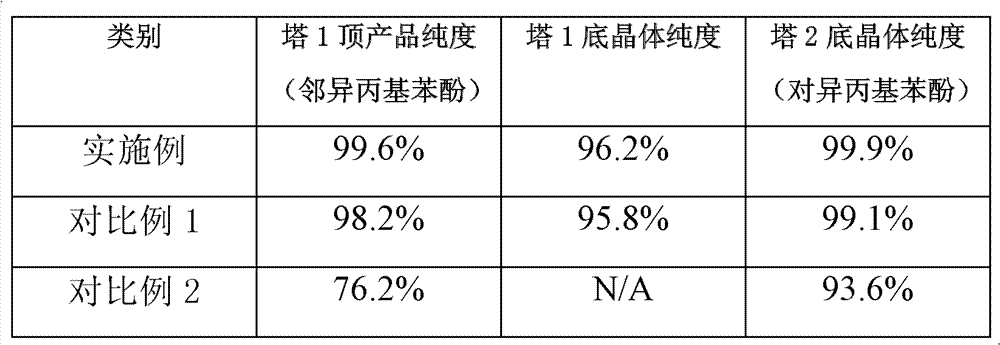

A kind of device and method for continuous separation of isopropyl phenol

ActiveCN103086846BPurification process reductionReduce energy consumptionOrganic chemistryOrganic compound preparationBody axisEngineering

The invention discloses an apparatus and a method for continuously separating o-isopropylphenol and p-isopropylphenol. The apparatus comprises: a tower 1 and a tower 2, wherein the tower 1 and the tower 2 are connected in series, rotation scrapers are respectively arranged on tower body axis centers inside the tower 1 and the tower 2, the lower portion inside the tower 1 is provided with a grid, the outer sides of the tower 1 and the tower 2 are provided with constant temperature material inlets, a liquid purification section, a crystal purification section, a melting purification section and a crystal deposition section are sequentially arranged inside the tower 1 from top to bottom, a residue liquid recovery section, a crystal re-purification section and a crystal re-deposition section are sequentially arranged inside the tower 2 from top to bottom, and an outlet on the bottom of the tower 1 is connected with the constant temperature material inlet on the middle part of the tower 2. The method comprises that: a material requiring separation is subjected to continuous re-crystallization in the tower 1 and the tower 2 to separate o-isopropylphenol and p-isopropylphenol. With the apparatus and the method, continuous material feeding and material discharging can be achieved, and high purity o-isopropylphenol and p-isopropylphenol products can be produced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing 2,4-dihydroxy-6-methoxy-3-methylacetophenone with high purity

ActiveCN102702157BLow impurity contentImprove extraction efficiencyOrganic chemistryMedicinal herbsSilica column

The invention discloses a method for preparing high-purity wolfbane B, which comprises the following steps: pulverizing Euphorbia chamaejasma, extracting with ethanol reflux, filtering the extract to obtain a filtrate; concentrating the filtrate, recovering ethanol to obtain a thick paste; Add 5 to 10 times the amount of silica gel to the thick paste, mix well, dry, perform column chromatography with silica gel as the carrier, elute with the eluent and collect the eluent; concentrate the eluent, recover the solvent, and obtain Coarse crystals of chamaejamabolin; dissolve the crude crystals with ethanol, add silica gel to mix, dry, and perform silica gel column chromatography for 2 to 3 times to obtain pure chamaejamacin. The extraction and purification cost of the method of the invention can be reduced by about 20%, and at the same time, the energy consumption can be greatly reduced, and the extraction efficiency of chamaejasme B can be increased to more than 30%. The prepared chamaejamasin B has a purity of more than 99%, and is especially suitable as a standard substance for content determination of chamaemachamata medicinal material and related preparation Jiejieling tablets.

Owner:广东恒健制药有限公司

Method for yeast cell to express human interleukin 10

InactiveCN100494386CAvoid degradationSimple structureFermentationVector-based foreign material introductionBiotechnologyYeast chromosome

Owner:ARMY MEDICAL UNIV

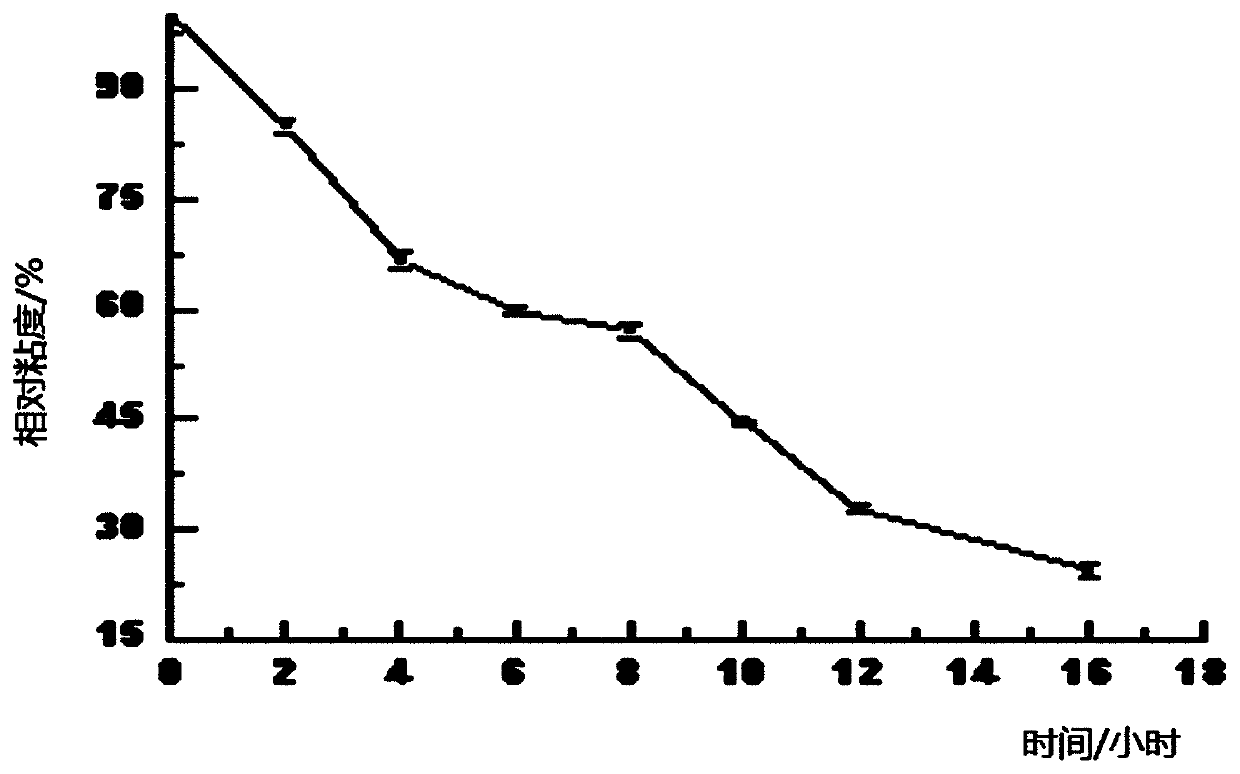

A method for infrared degradation of marine sulfated polysaccharides

ActiveCN106432544BHigh antibacterial activityPurification process reductionEscherichia coliSulfated polysaccharides

The invention discloses an infrared degradation method for ocean sulphated polysaccharide. The method comprises the following steps that ocean sulphated polysaccharide dry powder is laid on a clean stainless steel tray, the thickness ranges from 0.1 cm to 0.2 cm, the ocean sulphated polysaccharide dry powder is placed in a drying box containing a 2,200w infrared lamp to be heated for 2 h to 16 h, the height of the infrared lamp away from the ocean sulphated polysaccharide powder ranges from 10 cm to 30 cm, and low-molecular weight ocean sulphated polysaccharide dry powder is obtained. The infrared degradation method has the advantages that no chemical or biological reagent is introduced, the method is environmentally friendly, and subsequent purifying processes are reduced; the ocean sulphated polysaccharide is degraded in the state of dry powder, limit of polysaccharide solubleness is avoided, production efficiency is high, and dissolving, drying and other unit operation are reduced; operation is easy and convenient, equipment is simple, and the production cost is low; good biological activity is achieved, low-molecular weight fucoidan obtained after infrared degradation is carried out for 16 h shows good bacteriostatic activity, and the bacteriostasis rate of the low-molecular weight fucoidan with the concentration of 1.0 wt% on escherichia coli reaches 100%.

Owner:JIMEI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com