Microwave plasma exhaust gas purification method

A technology for microwave plasma and waste gas purification, which is applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of microwave plasma generator fouling and pretreatment, and achieve simplified waste gas purification methods, improved purification efficiency, and improved Effect of Purification Treatment Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

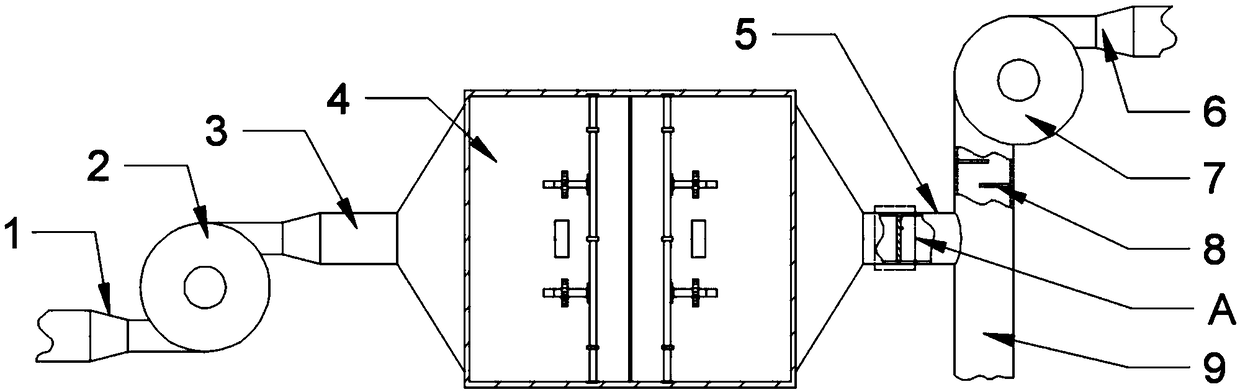

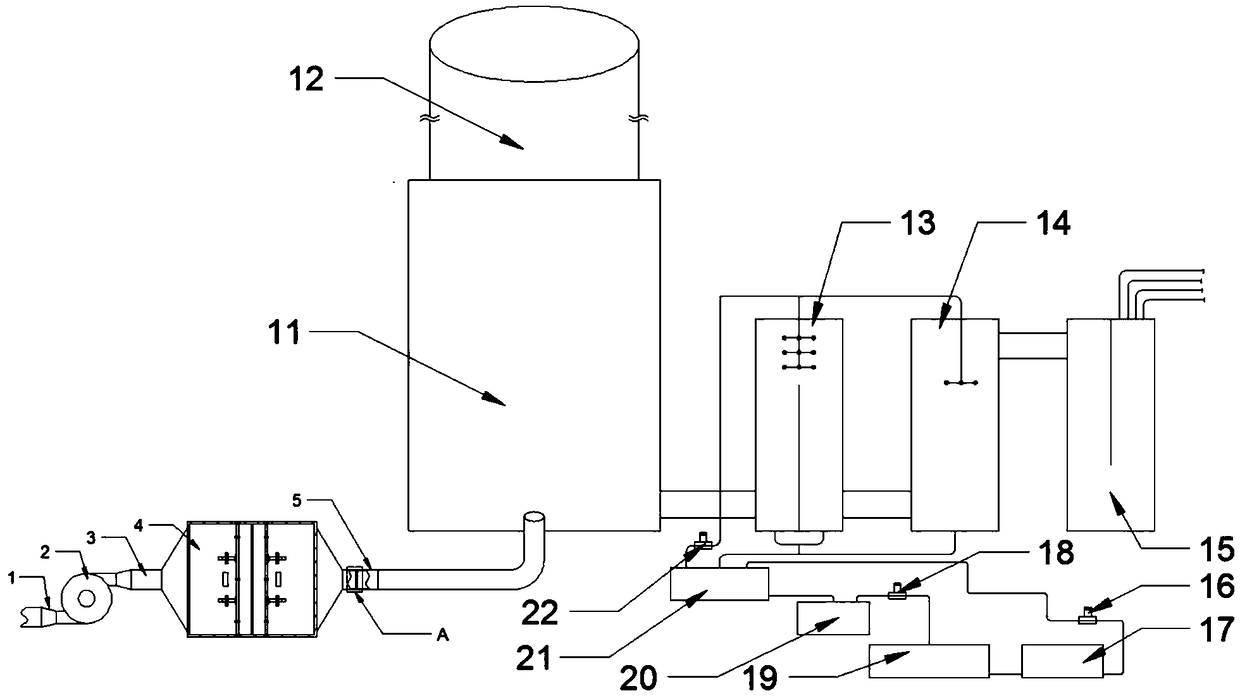

[0042] A method for purifying microwave plasma waste gas, which adopts microwave plasma generation as a plasma gas source for generating high-energy active substances, and a reaction chamber is connected to the gas outlet of the microwave plasma generator, and air is introduced into the microwave plasma generator until it is discharged. After a continuous and stable plasma flow appears at the gas port, the waste gas to be purified is introduced into the reaction chamber, the plasma flow and the waste gas are mixed in the reaction chamber, and the high-energy active substances contained in the plasma flow oxidize the organic matter contained in the waste gas Discharge after decomposition.

[0043] Wherein, the reaction chamber is a pipeline structure;

[0044] The concentration of the high-energy active substance in the plasma gas flow is 85ppm;

[0045] The flow rate of the exhaust gas to be purified into the reaction chamber is 100000m 3 / h;

[0046] The flow rate of the p...

Embodiment 2

[0049] A method for purifying microwave plasma waste gas, which adopts microwave plasma generation as a plasma gas source for generating high-energy active substances, and a reaction chamber is connected to the gas outlet of the microwave plasma generator, and air is introduced into the microwave plasma generator until it is discharged. After a continuous and stable plasma flow appears at the gas port, the waste gas to be purified is introduced into the reaction chamber, the plasma flow and the waste gas are mixed in the reaction chamber, and the high-energy active substances contained in the plasma flow oxidize the organic matter contained in the waste gas Discharge after decomposition.

[0050] Wherein, the reaction chamber is a pipeline structure;

[0051] The concentration of the high-energy active substance in the plasma gas flow is 90ppm;

[0052] The flow rate of the exhaust gas to be purified into the reaction chamber is 175000m 3 / h;

[0053] The flow rate of the p...

Embodiment 3

[0056] A method for purifying microwave plasma waste gas, which adopts microwave plasma generation as a plasma gas source for generating high-energy active substances, and a reaction chamber is connected to the gas outlet of the microwave plasma generator, and air is introduced into the microwave plasma generator until it is discharged. After a continuous and stable plasma flow appears at the gas port, the waste gas to be purified is introduced into the reaction chamber, the plasma flow and the waste gas are mixed in the reaction chamber, and the high-energy active substances contained in the plasma flow oxidize the organic matter contained in the waste gas Discharge after decomposition.

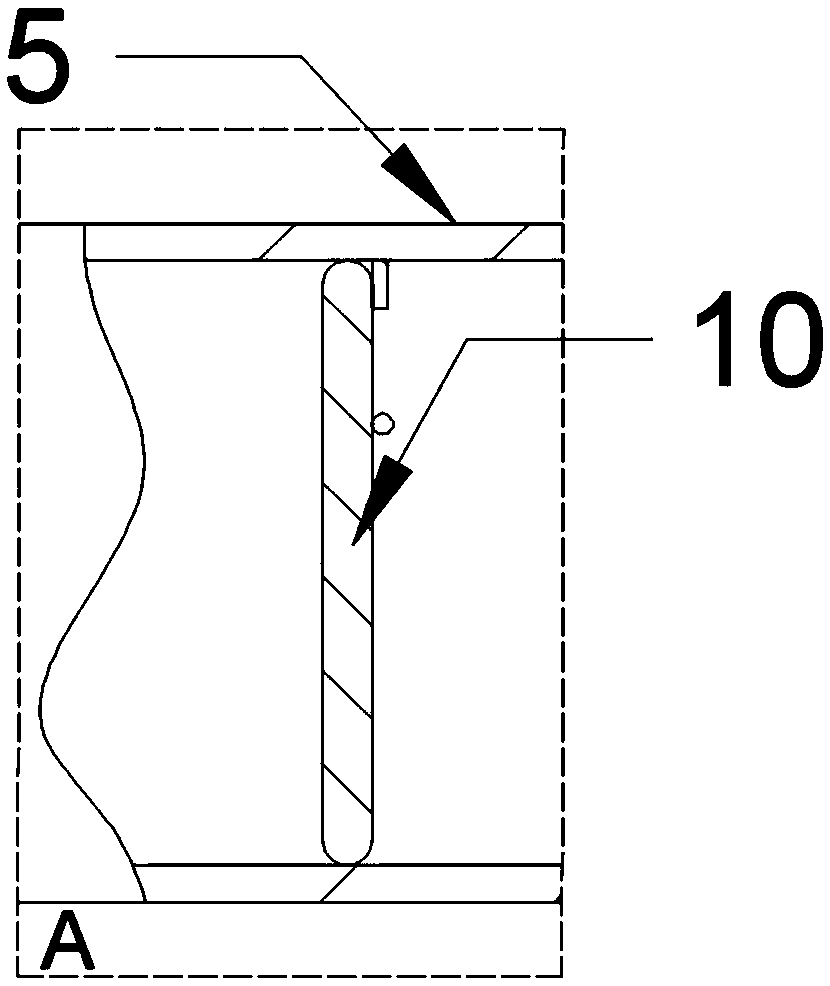

[0057] Wherein, the reaction chamber is a tank structure, specifically a large empty tank, the bottom of which communicates with the gas outlet, the side wall communicates with the waste gas inlet pipe, and the top communicates with the exhaust pipe for exhaust.

[0058] The concentration of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com