Preparation method of polyphenylene sulfide resin with low ion precipitation

A technology of polyphenylene sulfide resin and ions, which is applied in the field of polymer material synthesis, can solve the problems such as inability to remove ions, achieve the effects of reducing the discharge of three wastes, reducing the pickling process, and maintaining microscopic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

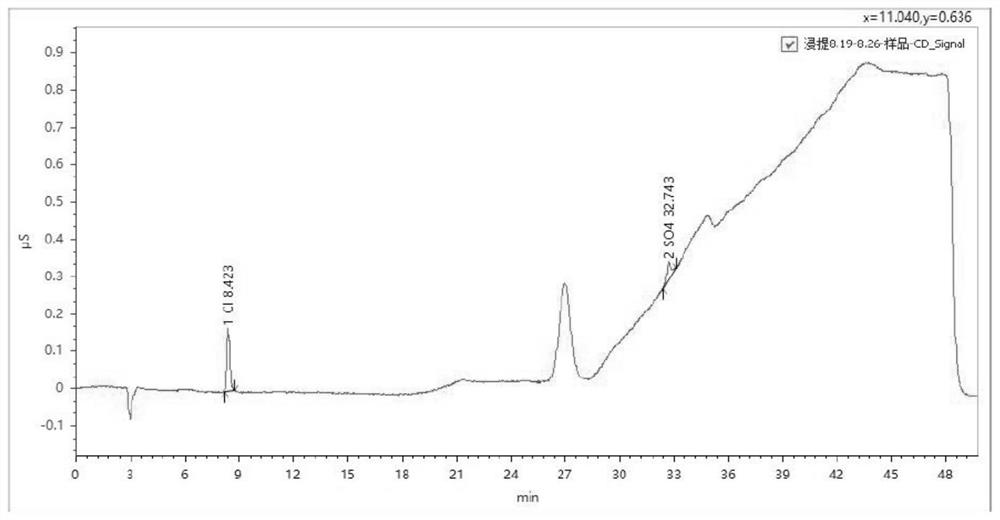

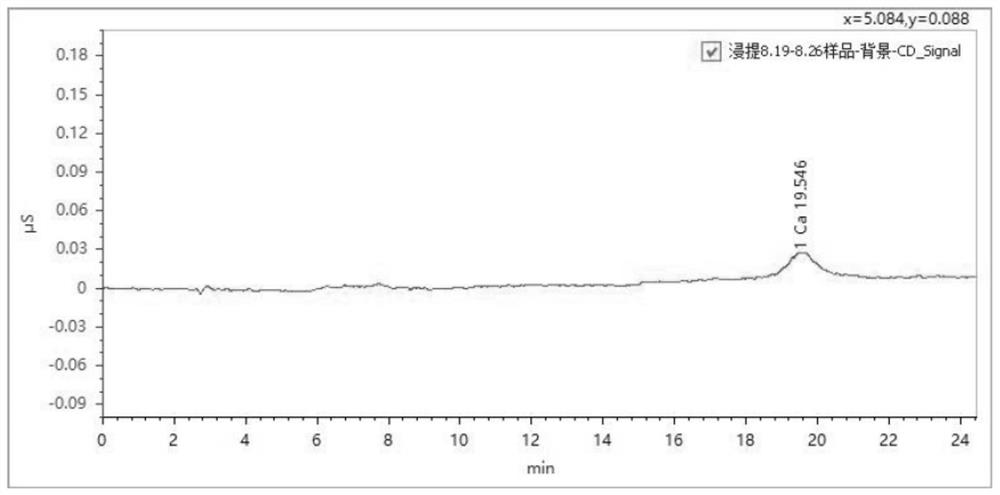

Image

Examples

Embodiment 1

[0038] A preparation method of low-ion precipitation polyphenylene sulfide resin, using sodium sulfide pentahydrate, sodium hydroxide, p-dichlorobenzene and lithium acetate composite catalyst as raw materials, in N-methylpyrrolidone solvent, polycondensation into low-ion precipitation The polyphenylene sulfide resin, the specific technological process comprises the following steps:

[0039] (1) dehydration of sodium sulfide: 17.5kgN-methylpyrrolidone is added in the reactor, then add sodium sulfide pentahydrate 7.6kg, sodium hydroxide 0.2kg, composite catalyst 0.64kg (the composite catalyst is barium hydroxide and lithium acetate, hydrogen The mol ratio of barium oxide and lithium acetate is 1:1), drop into the dehydration kettle successively, then feed into nitrogen protection, open stirring, and the stirring speed is controlled at 80rpm, and the temperature of the system kettle is from normal temperature with a heating rate of 1.5 ℃ / min. After warming up to 202℃ for 10min, s...

Embodiment 2

[0045] A preparation method of low-ion precipitation polyphenylene sulfide resin, using sodium sulfide, sodium hydroxide, p-dichlorobenzene and lithium acetate composite catalyst as raw materials, in N-methylpyrrolidone solvent, polycondensation into low-ion precipitation poly Phenyl sulfide resin, the concrete technological process comprises the following steps:

[0046] (1) dehydration of sodium sulfide: 17.5kgN-methylpyrrolidone is added in the reactor, then add sodium sulfide pentahydrate 7.6kg, sodium hydroxide 0.2kg, composite catalyst 0.64kg (the composite catalyst is barium hydroxide and lithium acetate, hydrogen The mol ratio of barium oxide and lithium acetate is 1:1), drop into the dehydration kettle successively, then feed into nitrogen protection, turn on stirring, the stirring speed is controlled at 80rpm, and the temperature of the system kettle is from normal temperature with a heating rate of 1.5 ℃ / min After warming up to 202℃ for 10min, stop dehydration;

[...

Embodiment 3

[0054] A preparation method of low-ion precipitation polyphenylene sulfide resin, using sodium sulfide, sodium hydroxide, p-dichlorobenzene and lithium acetate composite catalyst as raw materials, in N-methylpyrrolidone solvent, polycondensation into low-ion precipitation poly Phenyl sulfide resin, the concrete technological process comprises the following steps:

[0055] (1) dehydration of sodium sulfide: 17.5kgN-methylpyrrolidone is added in the reactor, then add sodium sulfide pentahydrate 7.6kg, sodium hydroxide 0.2kg, composite catalyst 0.64kg (the composite catalyst is barium hydroxide and lithium acetate, hydrogen The mol ratio of barium oxide and lithium acetate is 1:1), drop into the dehydration kettle successively, then feed into nitrogen protection, turn on stirring, the stirring speed is controlled at 80rpm, and the temperature of the system kettle is from normal temperature with a heating rate of 1.5 ℃ / min After warming up to 202℃ for 10min, stop dehydration;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com