Apparatus and method for continuously separating and purifying durene

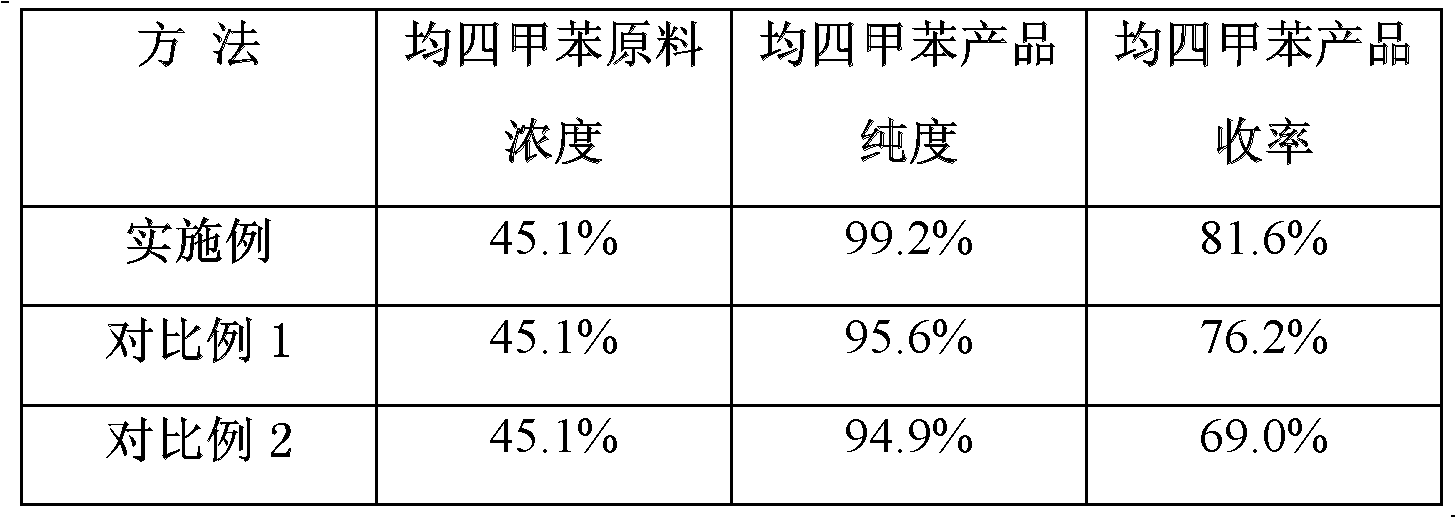

A technology of mesitylene and purification section is applied in the field of devices for continuous separation of mesitylene, which can solve the problems of high energy consumption and low continuous production capacity, and achieve the effects of reducing energy consumption, saving equipment and shortening the purification process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

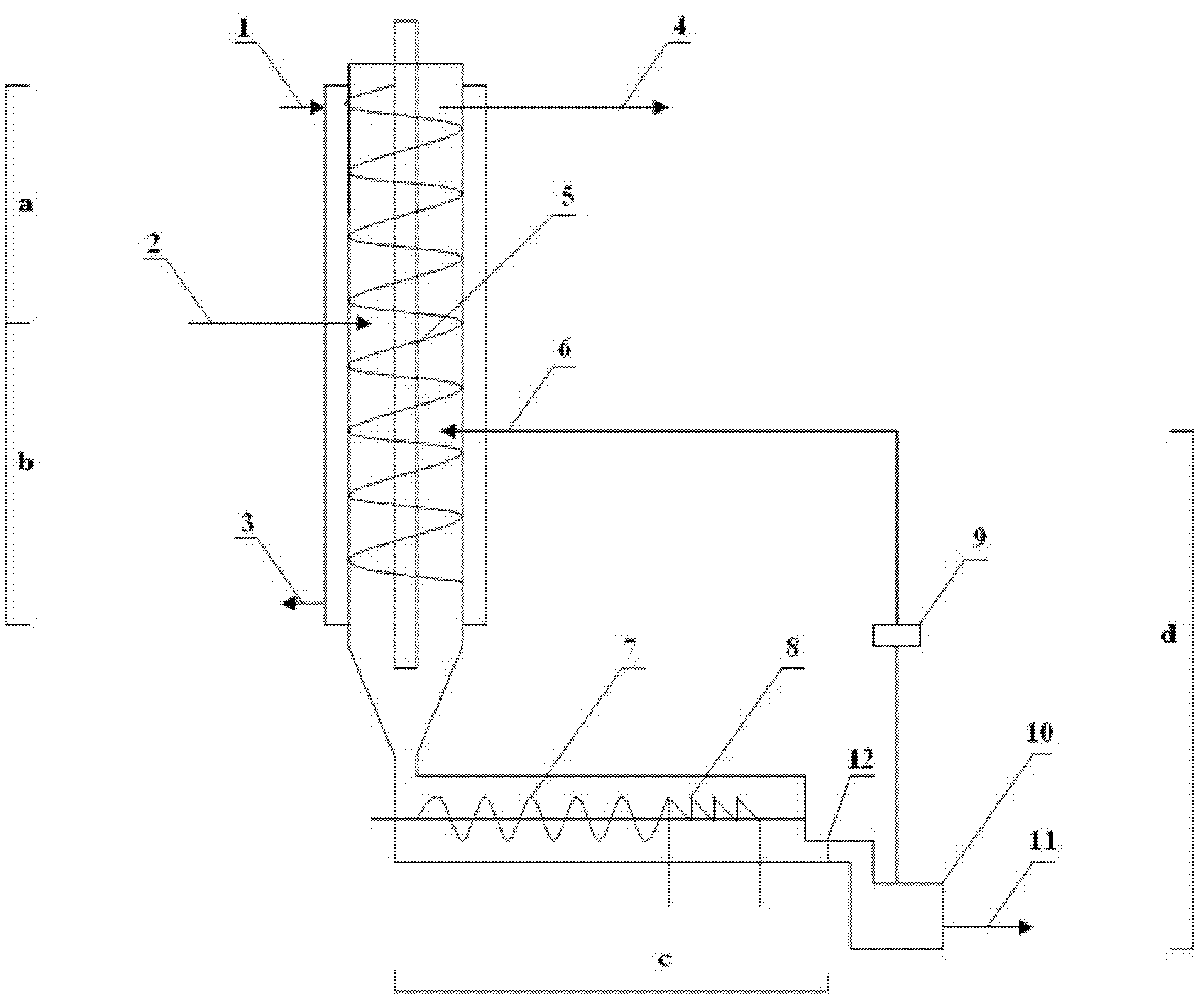

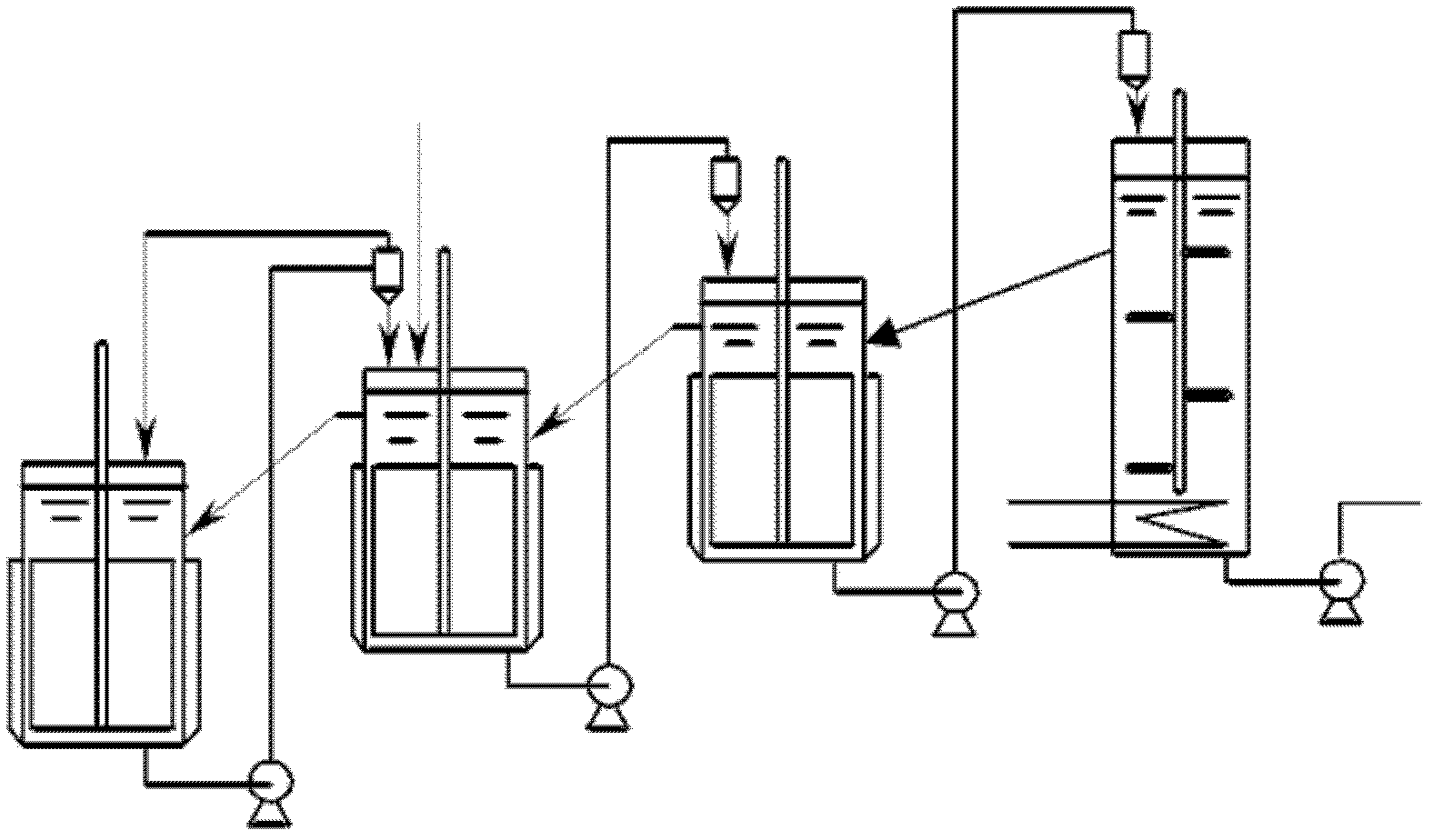

[0043] Such as figure 1 Shown, a device for continuous separation and purification of durene.

[0044] The device includes a vertical tower body and a horizontal tower body, and a rotating scraper is arranged in the vertical tower body and the horizontal tower body;

[0045] There is a constant temperature feed inlet on the outside of the vertical tower body. The vertical tower body includes from top to bottom: raffinate recovery section a and crystal purification section b. Above the constant temperature feed inlet of the vertical tower body is the raffinate recovery section. a, below the constant temperature feeding port is the crystal purification section b;

[0046] The horizontal tower body includes a crystal collection section c and a molten crystal reflux section d; the position of the rotary scraper in the horizontal tower body is the crystal collection section c, and the horizontal tower body without the rotary scraper is the molten crystal reflux section d;

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com