Method for producing coal tar and synthesis gas from oil-rich coal using pyrolysis gasification coupling device and oil gas purification device

A technology of pyrolysis gasification and coupling device, which is applied in the fields of combustible gas purification, combustible gas purification/transformation, petroleum industry, etc. The effect of reducing the amount of separation, reducing the difficulty of separation, and reducing the difficulty of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

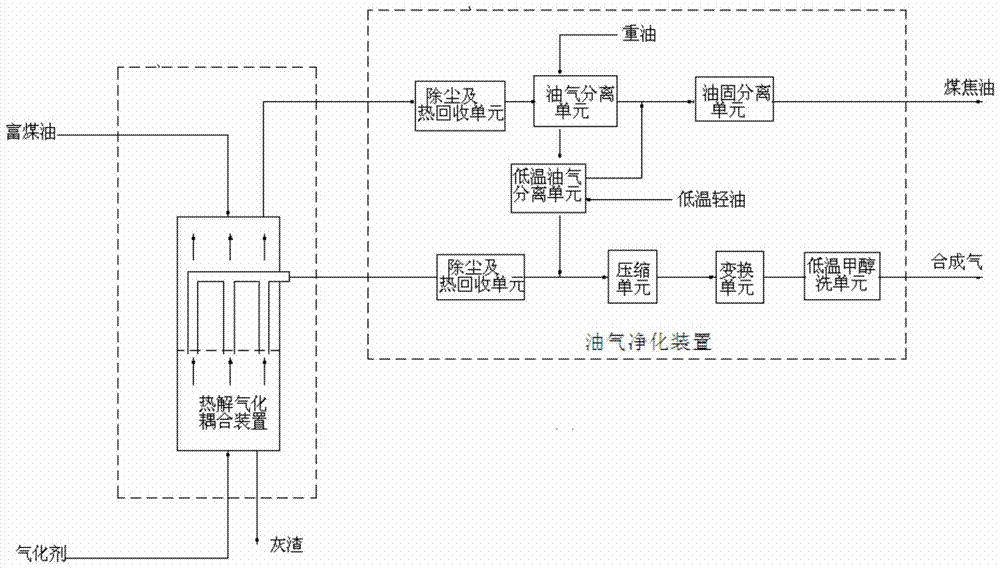

[0022] The present invention uses oil-rich coal as a raw material, and firstly obtains pyrolysis gas and crude synthesis gas through a pyrolysis gasification coupling device, and realizes separate collection of the two gases in the same device. Then, in view of the problems of difficult oil and gas separation, low recovery rate of coal tar, and large amount of waste water, an oil and gas purification device was installed to recover coal tar through dust removal and heat recovery, oil and gas separation, oil-solid separation, and low-temperature oil and gas separation to obtain coal Tar products, improve the recovery rate of coal tar, and reduce the waste water discharge in the separation process. At the same time, the synthesis gas is further purified through conversion, low-temperature methanol washing and other units to obtain synthesis gas products.

[0023] Concrete preparation method of the present invention is as follows:

[0024] (1) Using oil-rich coal as raw material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com