Energy-saving and emission-reducing method applied to sintering flue gas SCR denitration and system thereof

A technology for sintering flue gas, energy saving and emission reduction, which is applied in the field of air pollution control and can solve environmental pollution and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

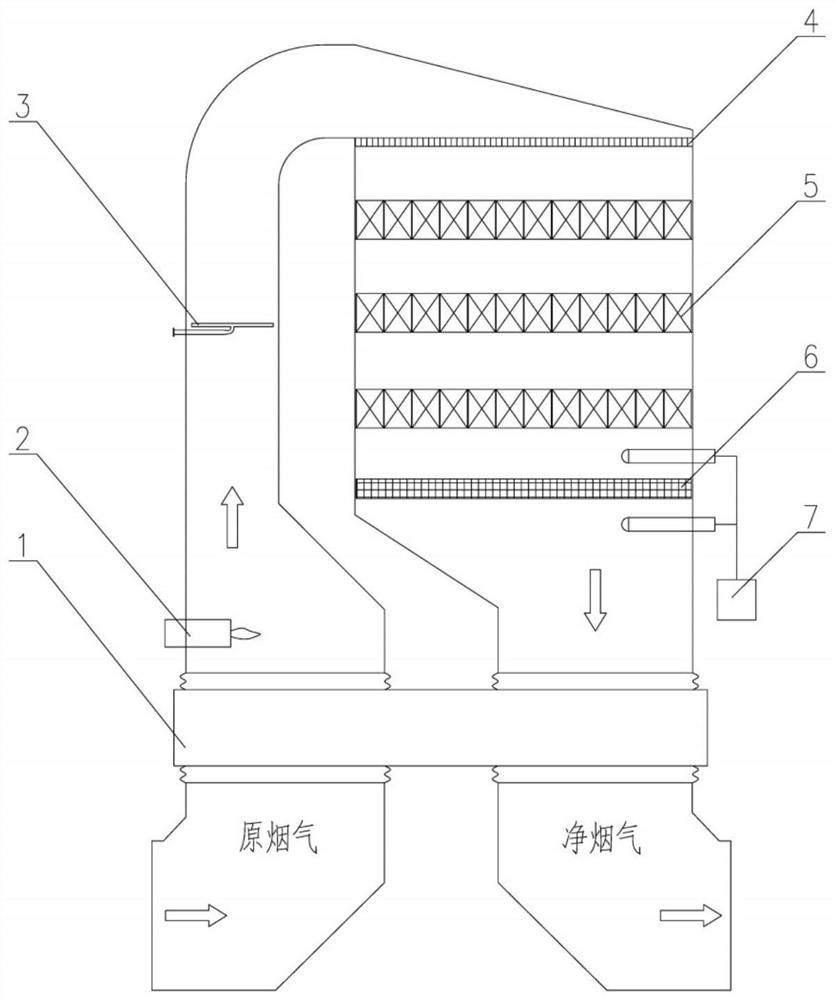

Embodiment 1

[0025] The flue gas temperature at the inlet of the denitrification system is 90°C, and the CO concentration is 5000ppm. After heat exchange in the heat exchanger 1, the temperature rises to 280°C. 3 After mixing, enter the SCR denitration catalyst bed layer 5 for denitration reaction, in which there is 2.5ppm unreacted NH 3 Enter the downstream CO catalytic combustion catalyst bed 6. Simultaneous CO catalytic combustion and NH on the CO catalytic combustion catalyst 3 Catalytic oxidation reaction, CO reduced from 5000ppm to 1000ppm, NH 3 From 2.5ppm to 0.5ppm, the flue gas temperature rises from 280°C to 310°C. Then the temperature of the clean flue gas is exchanged with the raw flue gas through a heat exchanger, and the temperature drops to 120°C before entering the downstream process.

Embodiment 2

[0027] The flue gas temperature at the inlet of the denitrification system is 80°C, and the CO concentration is 10,000ppm. After heat exchange in the heat exchanger, the temperature rises to 280°C. 3 After mixing, it enters the SCR denitrification catalyst bed for denitrification reaction, in which there is 3ppm unreacted NH 3 Enter the downstream CO catalytic combustion catalyst bed. Simultaneous CO catalytic combustion and NH on the CO catalytic combustion catalyst 3 Catalytic oxidation reaction, CO reduced from 10000ppm to 1500ppm, NH 3 From 3ppm to 0.6ppm, the flue gas temperature rises from 280°C to 330°C. Then the temperature of the clean flue gas is exchanged with the raw flue gas through a heat exchanger, and the temperature drops to 130°C before entering the downstream process.

[0028] To sum up, the present invention aims at energy saving and emission reduction. On the one hand, the catalytic combustion of CO can be used to generate heat, so as to greatly reduce ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com