Multi-fuel universal reforming hydrogen production system and method for SOFC

A general-purpose technology for hydrogen production by reforming, applied in fuel cells, chemical instruments and methods, hydrogen, etc., can solve the problems of increased equipment cost, complexity, lack of versatility, etc., and achieve the effect of reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

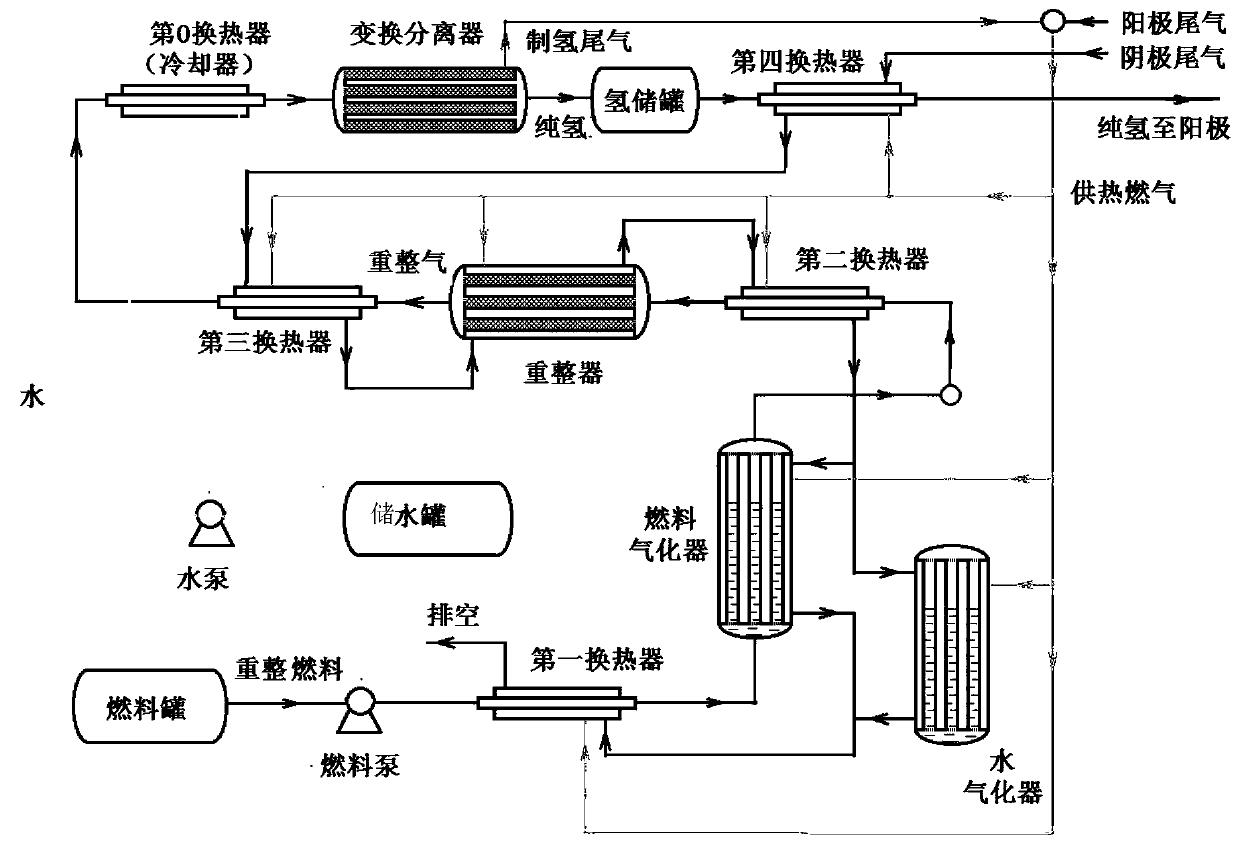

[0076] When reforming gaseous fuels such as natural gas, the multi-fuel general-purpose reforming hydrogen production system for SOFC includes water storage tanks, fuel tanks, water gasifiers, reformers, shift separators, hydrogen storage tanks and multiple heat exchangers;

[0077] The water storage tank is connected to the water vaporizer through the zeroth heat exchanger, and the fuel in the fuel tank passes through the first heat exchanger; the water vaporizer and the first heat exchanger The discharged gas streams are combined in the pipeline, and then pass through the second heat exchanger, the reformer, the zeroth heat exchanger, the shift separator, the hydrogen storage tank, the fourth heat exchanger The heater is connected to the fuel cell anode;

[0078] The cathode tail gas of the fuel cell passes through the fourth heat exchanger, the reformer, and the second heat exchanger in sequence, and then communicates with the water vaporizer through a pipeline, and the ex...

Embodiment 2

[0087] Multi-fuel general-purpose reforming hydrogen production system for SOFC, including fuel tank, fuel gasifier, reformer, shift separator, hydrogen storage tank and multiple heat exchangers when reforming methanol water vapor ;

[0088] The fuel tank is connected to the fuel gasifier through the first heat exchanger, and then passes through the second heat exchanger, the reformer, the third heat exchanger, the shift separator, The hydrogen storage tank and the fourth heat exchanger are connected to the fuel cell anode;

[0089] The cathode tail gas of the fuel cell passes through the fourth heat exchanger, the third heat exchanger, the reformer, and the second heat exchanger in sequence, and then communicates with the fuel gasifier through a pipeline, and is discharged The airflow is evacuated through the first heat exchanger.

[0090] The hydrogen production tail gas discharged from the shift separator is mixed with the anode tail gas of the fuel cell to form heating g...

Embodiment 3

[0099] When reforming fuels that can only be reformed under high temperature conditions such as diesel and gasoline, the multi-fuel general-purpose reforming hydrogen production system for SOFC includes water storage tanks, fuel tanks, water vaporizers, and fuel gasification reactors, reformers, shift separators, hydrogen storage tanks and multiple heat exchangers;

[0100] The water storage tank is connected to the water gasifier through the zeroth heat exchanger, and the fuel tank is connected to the fuel gasifier through the first heat exchanger; the water gasifier is connected to the fuel gasifier The gas streams discharged from the reformer are combined in the pipeline, and then pass through the second heat exchanger, the reformer, the zeroth heat exchanger, the shift separator, the hydrogen storage tank, the first Four heat exchangers connected to the fuel cell anode;

[0101] The cathode tail gas of the fuel cell passes through the fourth heat exchanger, the reformer, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com