Method of recovering methanol from acidic gas in Rectisol unit

A low-temperature methanol washing and recovery device technology, applied in separation methods, chemical instruments and methods, separation/purification of hydroxyl compounds, etc., can solve problems such as increased energy consumption of methanol washing devices, failure to reach purification indicators, and affecting absorption effects, etc. Achieve the effect of reducing cooling energy consumption, ensuring regeneration effect, and reducing cooling energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

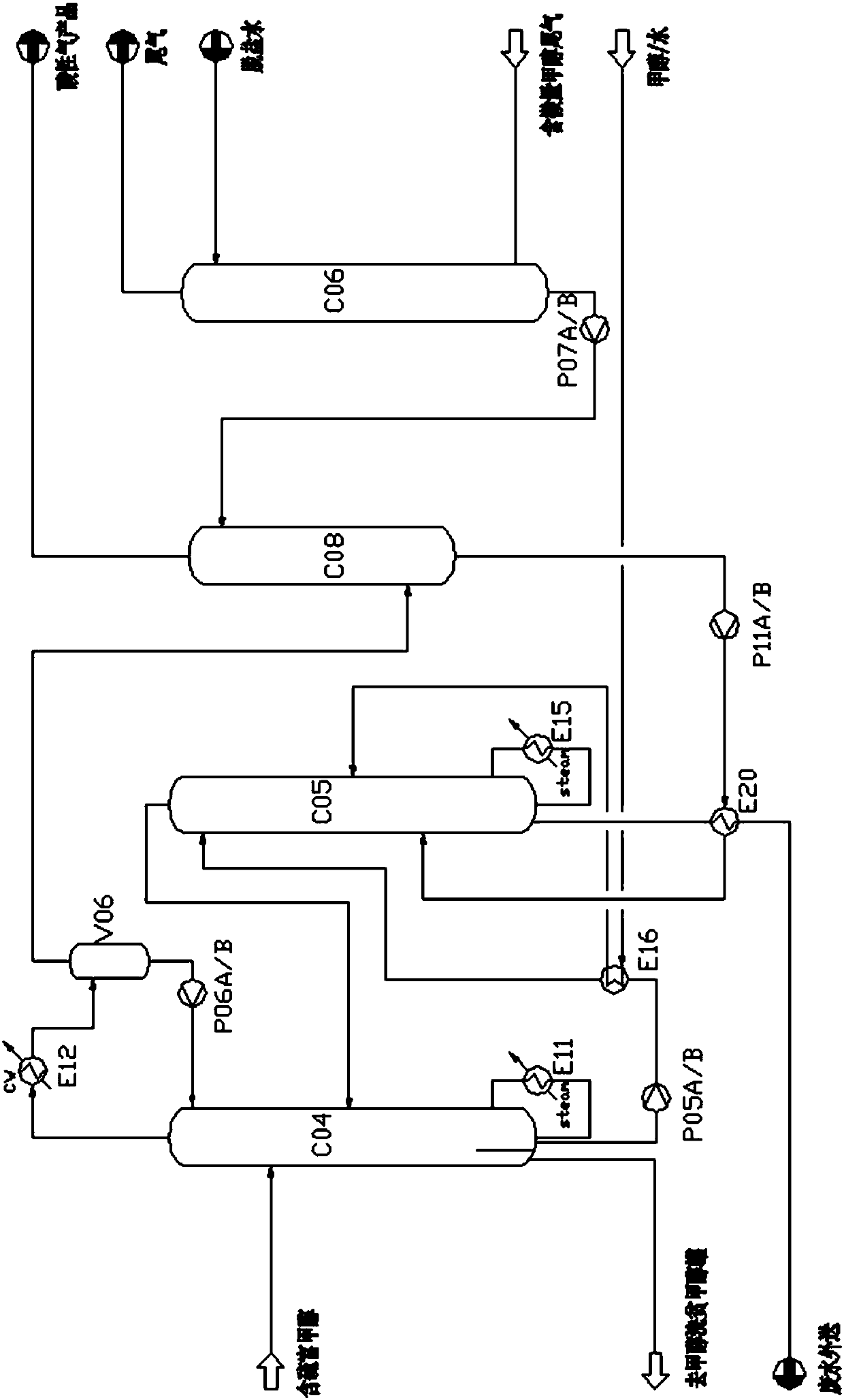

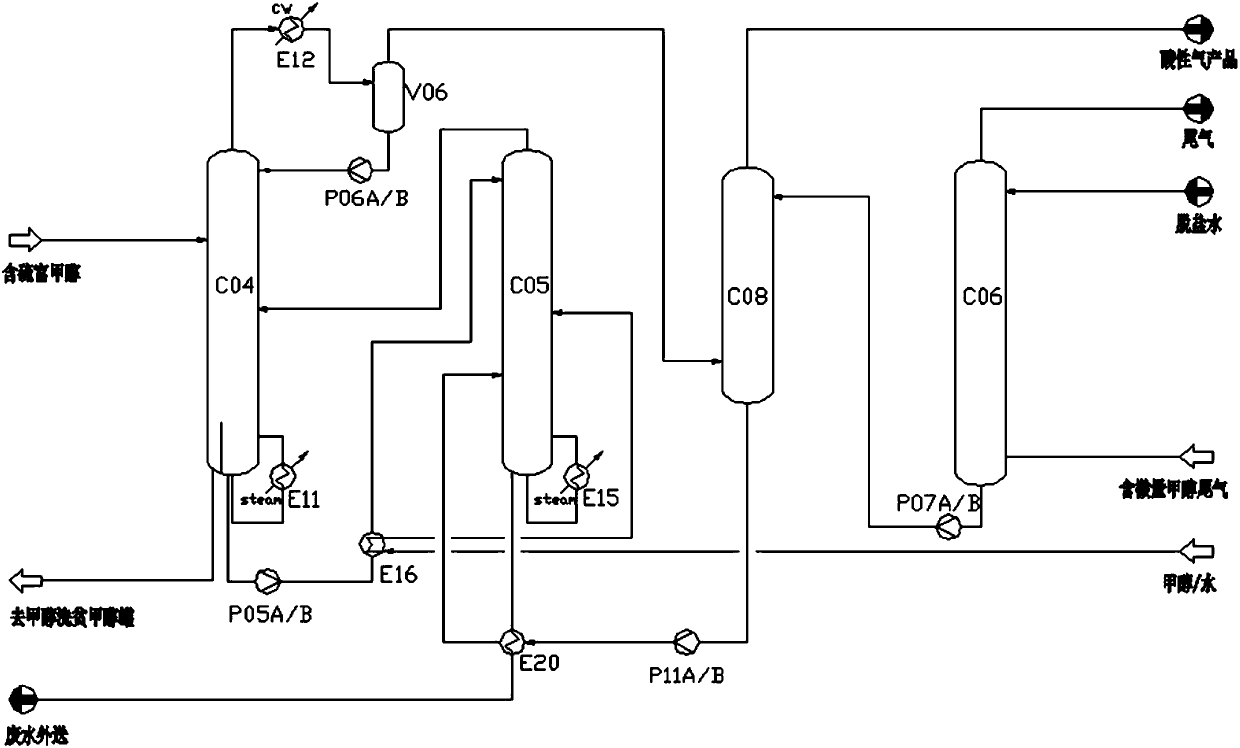

[0086] The sulfur-rich methanol produced in the low-temperature methanol washing device is flashed under reduced pressure and stripped, and then enters the thermal regeneration tower C04 for regeneration to obtain methanol lean liquid and acid gas;

[0087] The methanol barren solution is recycled;

[0088] The acid gas enters the heat regeneration tower reflux tank V06 through the water cooler E12 at the top of the heat regeneration tower, and then enters the lower part of the acid gas scrubber C08. The upper part of the gas scrubber C08 is washed to absorb methanol to obtain washed acid gas and washed waste water;

[0089] The acid gas after the washing is sent to the recovery device;

[0090] The washed waste water is boosted by the acid gas scrubber bottom pump P11 at the bottom of the acid gas scrubber C08, and then passes through the waste water heat exchanger E20 to exchange heat with the high-temperature wastewater at the bottom C05 of the methanol-water separation to...

Embodiment 2

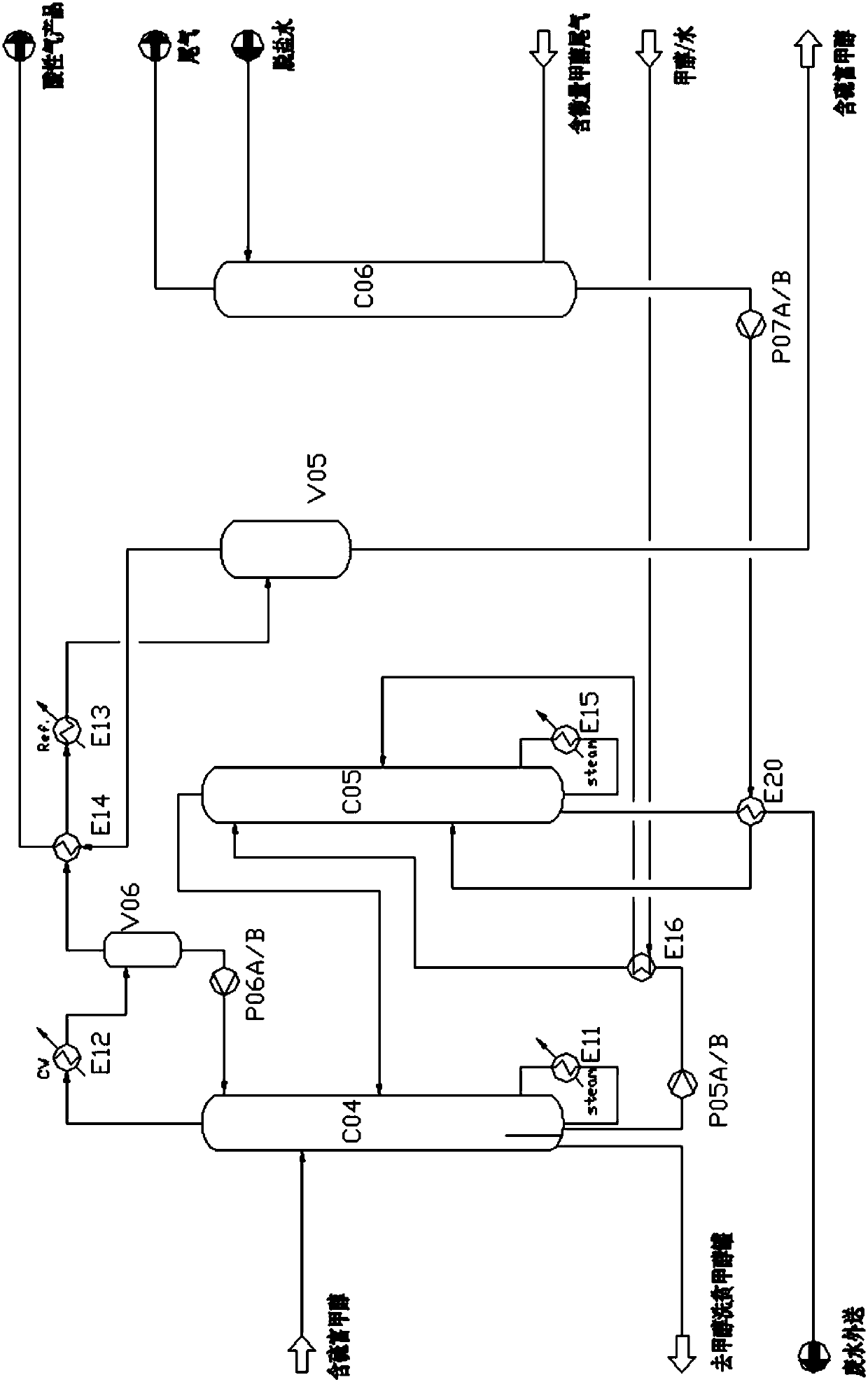

[0095] The sulfur-rich methanol produced in the low-temperature methanol washing device is flashed under reduced pressure and stripped, and then enters the thermal regeneration tower C04 for regeneration to obtain methanol lean liquid and acid gas;

[0096] The methanol barren solution is recycled;

[0097] The acid gas enters the reflux tank V06 of the thermal regeneration tower through the top water cooler E12 of the thermal regeneration tower, and then enters the lower part of the acid gas scrubber C08. The upper part of the gas scrubber C08 is washed to absorb methanol to obtain washed acid gas and washed waste water;

[0098] The acid gas after the washing is sent to the recovery device;

[0099] The washed waste water is boosted by the acid gas scrubber bottom pump P11 at the bottom of the acid gas scrubber C08, and then passes through the waste water heat exchanger E20 to exchange heat with the high-temperature wastewater at the bottom C05 of the methanol-water separat...

Embodiment 3

[0109] The sulfur-rich methanol produced in the low-temperature methanol washing device is flashed under reduced pressure and stripped, and then enters the thermal regeneration tower C04 for regeneration to obtain methanol lean liquid and acid gas;

[0110] The methanol barren solution is recycled;

[0111] The acid gas enters the heat regeneration tower reflux tank V06 through the water cooler E12 at the top of the heat regeneration tower, then passes through the acid gas heat exchanger E14 and the low-temperature acid gas at the outlet of the separation tank V05 for heat exchange and cooling, and then is further cooled by the deep cooler E13 After entering the separation tank V05, the methanol content of the separated low-temperature acid gas is 0.1% mol.

[0112] Using the above device, the cooling capacity consumed in the process of separating methanol from acidic gas is 500KW, which is 500KW higher than that in Example 1, which increases energy consumption by 10%, and red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com