Low-temperature rectisol process and device

A low-temperature methanol washing and process technology, which is applied in the petroleum industry, combustible gas purification, and separation of dispersed particles, to achieve the effect that the output will not decrease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further understand the present invention, the preferred embodiments of the present invention are described below in conjunction with the examples, but it should be understood that these descriptions are only to further illustrate the features and advantages of the present invention, rather than limiting the claims of the present invention.

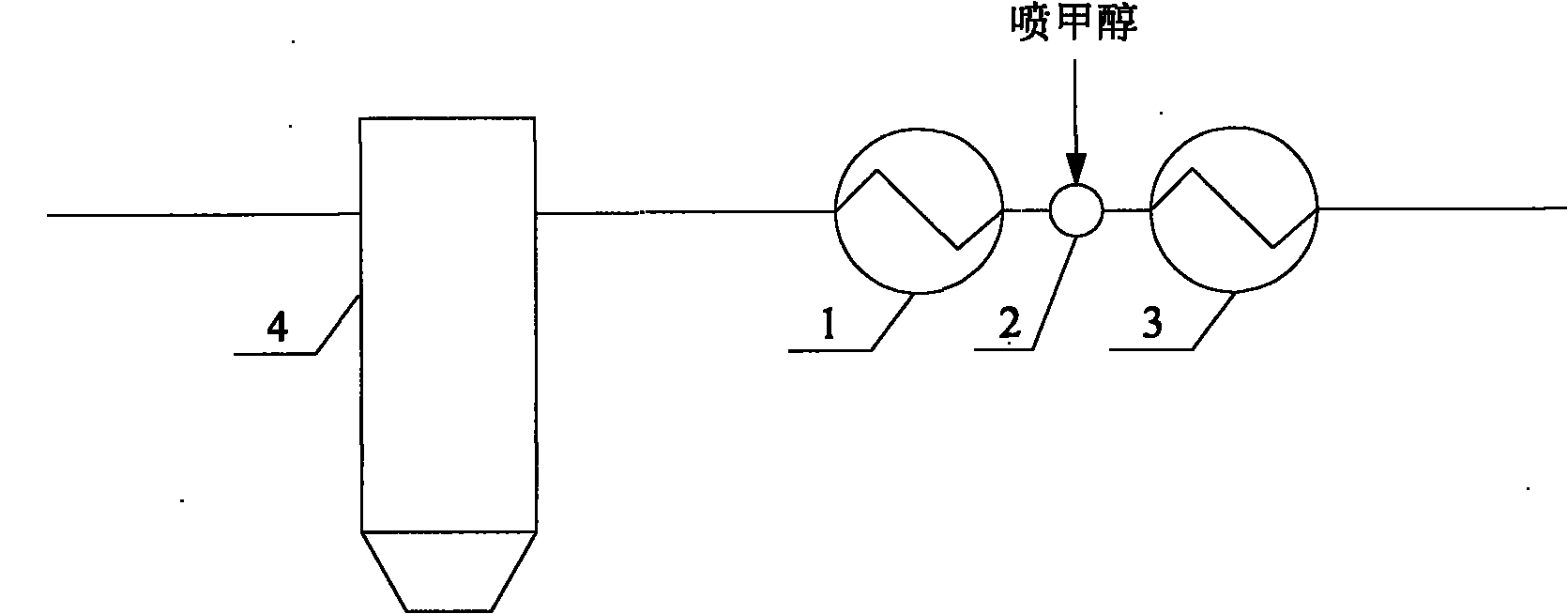

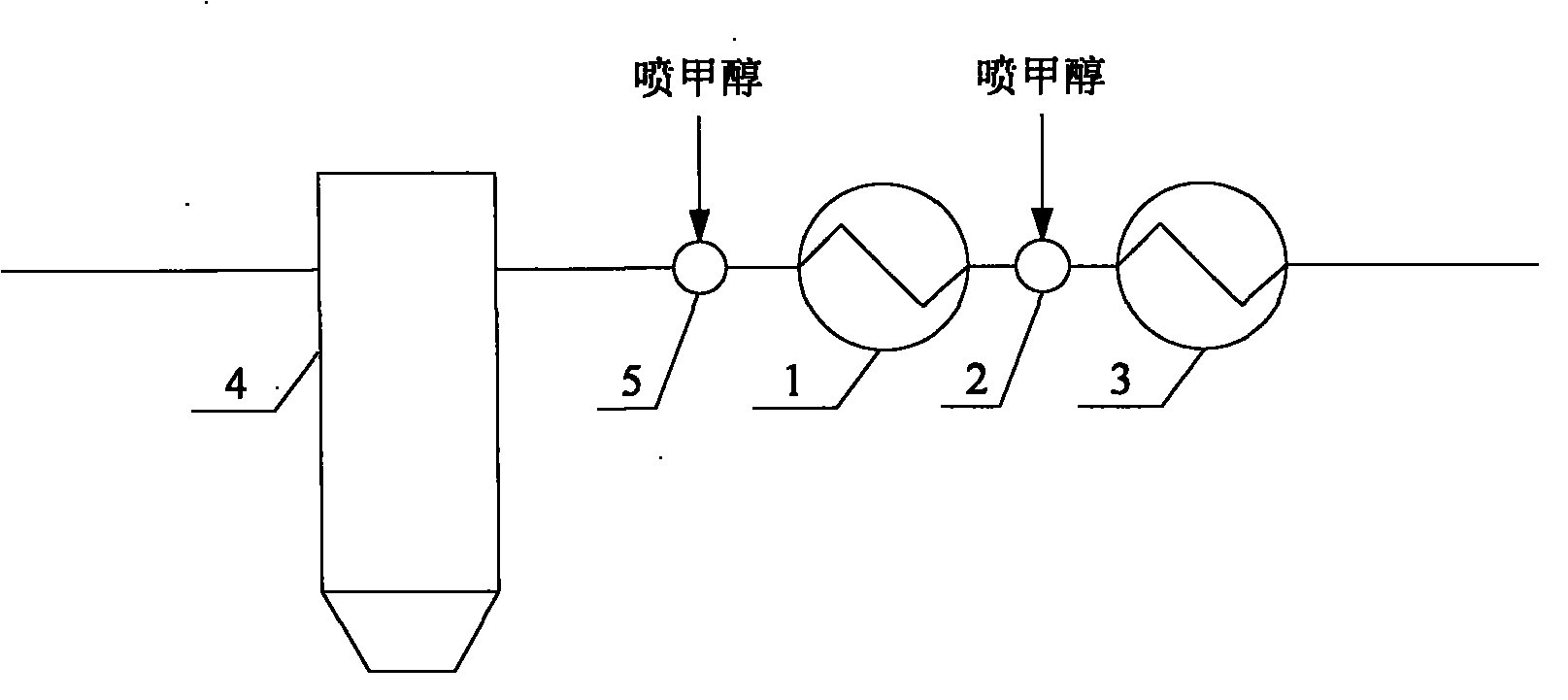

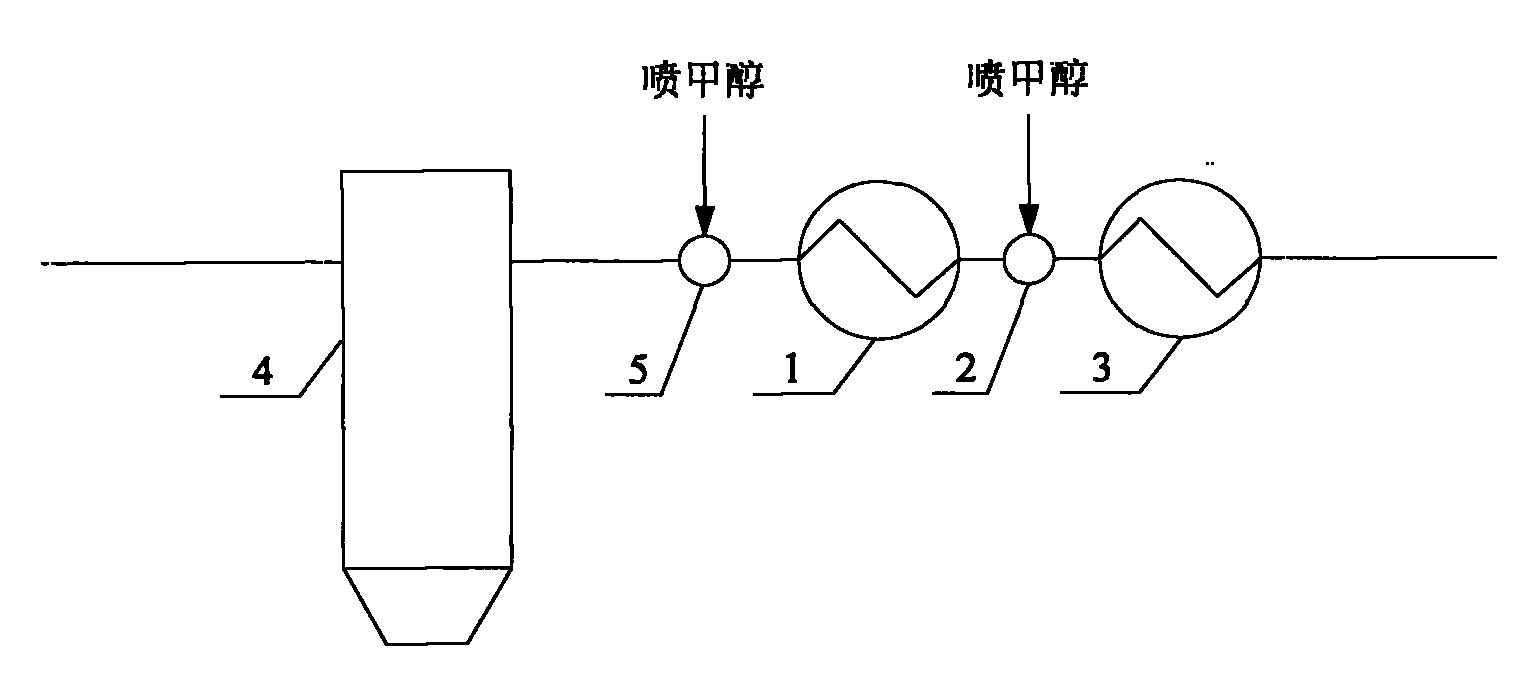

[0025] The low-temperature methanol washing process provided by the invention comprises the following steps:

[0026] Step a) spray methanol solution into the crude gas to be treated, so that the methanol atomizes and dissolves into the crude gas to lower the freezing point of the gas. The volume concentration of the injected methanol solution is preferably 98%-99.8%, and the amount of the methanol solution is preferably 180kg / h-190kg / h.

[0027] Step b) performing primary cooling on the crude gas sprayed into the methanol solution. Since methanol is dissolved in the crude gas, the freezing point of methanol is as low as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com