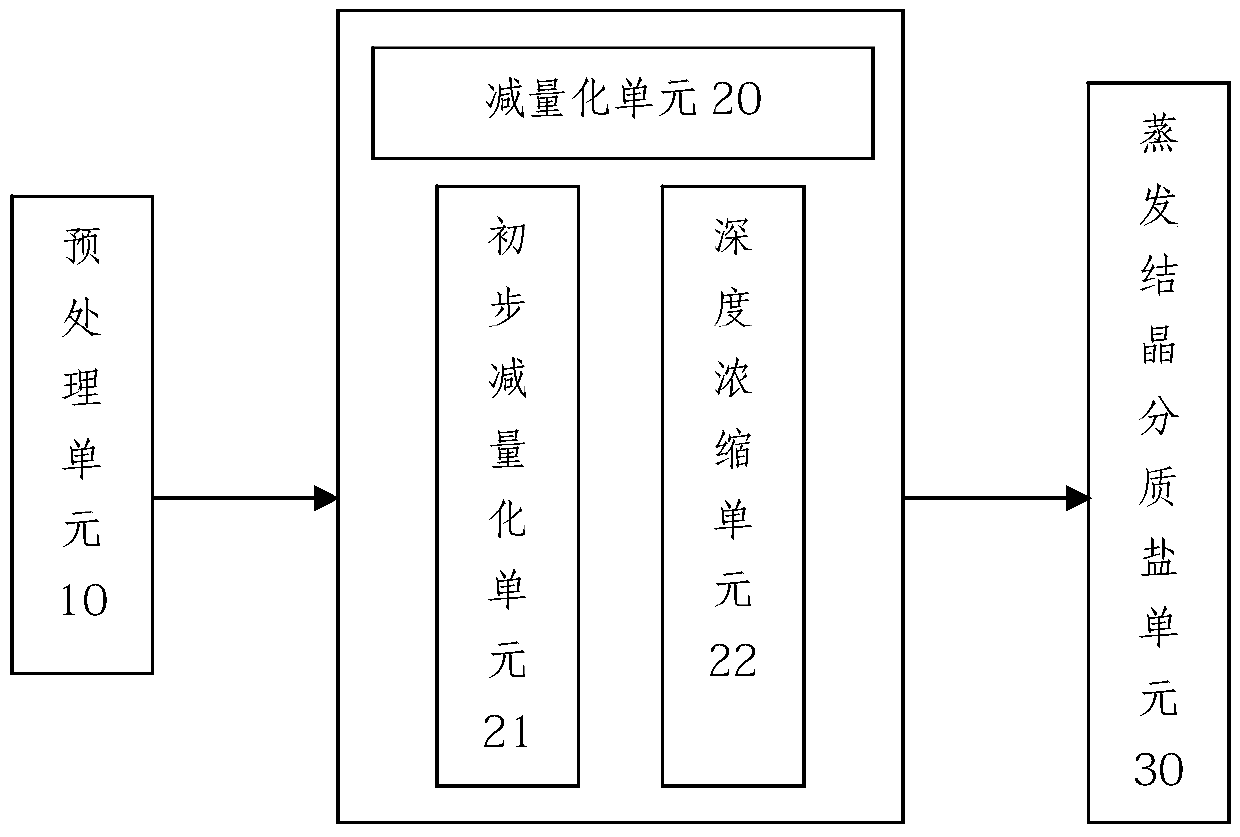

Zero emission treatment method of high-salinity wastewater

A treatment method, high salt content technology, applied in water/sewage treatment, heating water/sewage treatment, multi-stage water/sewage treatment, etc., can solve the problems of increased energy consumption, fouling of membrane elements and organic fouling, and reliability Low-level problems, to achieve the effect of reducing processing costs, reducing consumption, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Take the structure of the one-stage electrically driven ion membrane device 224 and the two-stage electrically driven ion membrane device 226 used in the present invention as an example.

[0065] The first-stage electrically driven ion membrane device 224 and the second-stage electrically driven ion membrane device 226 include an anode and a cathode arranged at intervals. Between the anode and the cathode are regularly arranged a plurality of membrane pairs composed of positive membranes, negative membranes and separators. The positive and negative membranes are homogeneous membranes with low membrane resistance and high performance. Between the two membranes is a separator with uniform flow state. The power supply of the first-level electric-driven ion membrane device 224 and the second-level electric-drive ion membrane device 226 adopts a high-frequency direct current power supply with positive and negative polarity automatic switching, and uses a digital program to ...

Embodiment 2

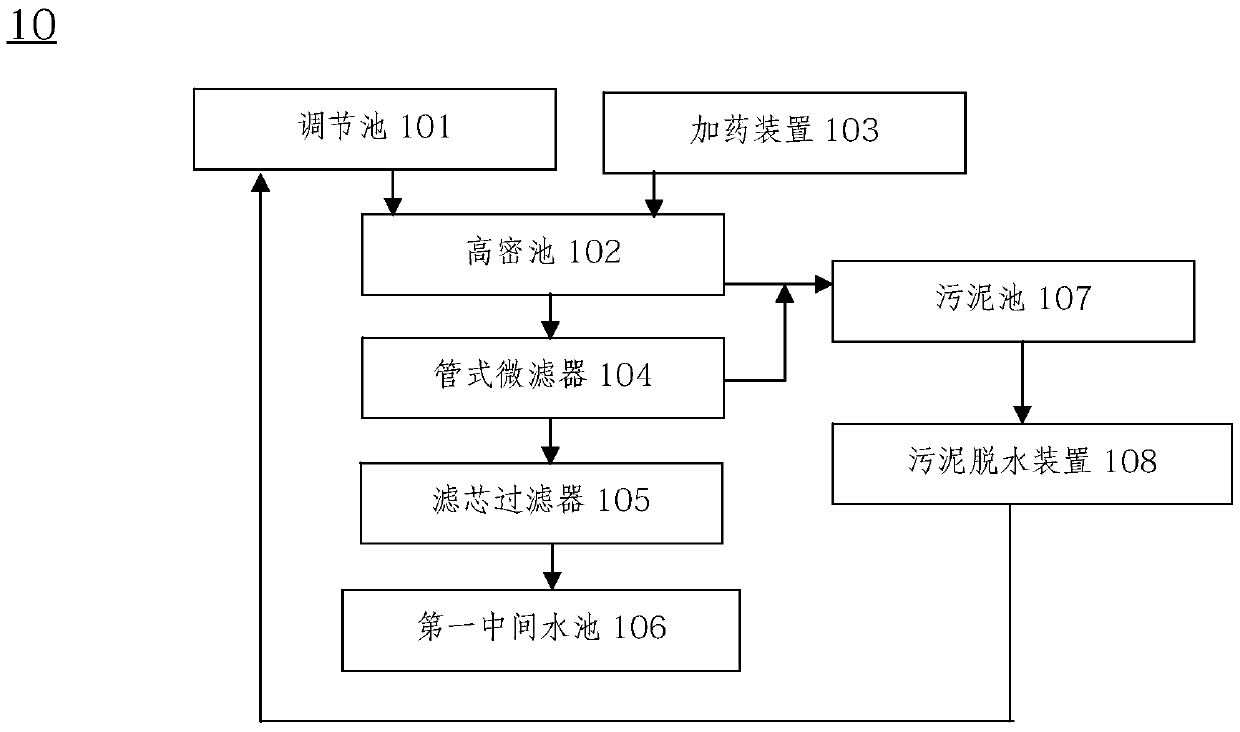

[0069] Take the wastewater pretreatment process as an example.

[0070] Such as figure 2 As shown, the device of the pretreatment process of wastewater at least includes a regulating tank 101, a high-density tank 102, a dosing device 103, a tubular microfilter 104, a cartridge filter 105, a first intermediate tank 106, a sludge tank 107 and a sludge dewatering device 108.

[0071]The regulating pool 101 regulates the homogeneity and equalization of the wastewater sent by each pipeline. The homogeneous and uniformly regulated waste water is sent into the high-density pool 102 through a lift pump. Add lime or sodium hydroxide, sodium carbonate, polyaluminum chloride and polyacrylamide to the wastewater in the high-density pool 102 through the dosing device 103 . Preferably, the amount of chemical added should not be too large, and it needs to be adjusted accordingly according to the actual water quality, otherwise it will easily cause membrane pollution and affect the servic...

Embodiment 3

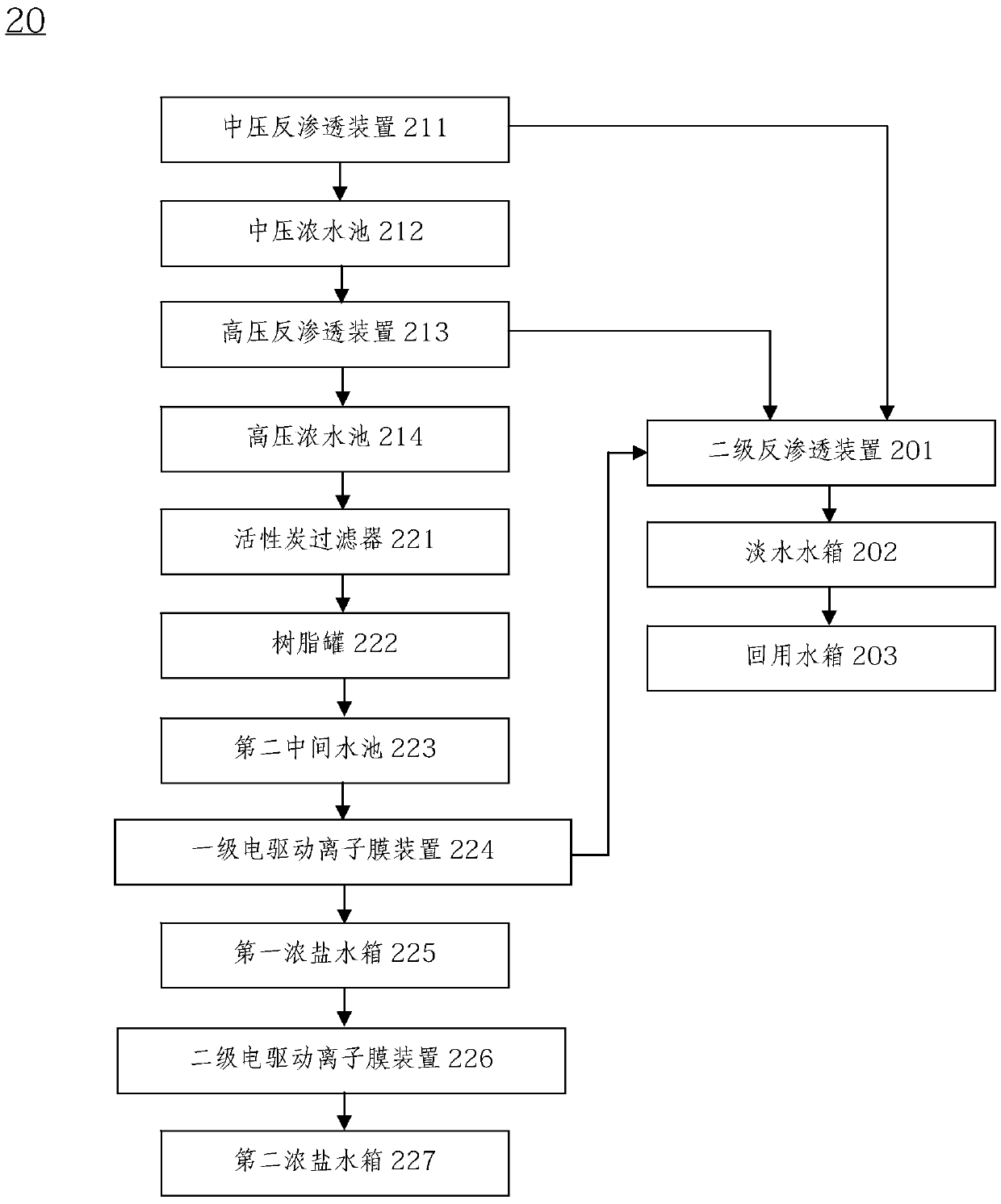

[0074] Take waste water reduction treatment process as an example.

[0075] Wastewater reduction process includes primary reduction process and deep concentration process. Such as image 3 As shown, the devices of the preliminary reduction process include at least a medium-pressure reverse osmosis device 211 , a medium-pressure concentrated water tank 212 , a high-pressure reverse osmosis device 213 and a high-pressure concentrated water tank 214 . The device of the deep concentration process at least includes an activated carbon filter 221, a resin tank 222, a second intermediate pool 223, a first-stage electric drive ion membrane device 224, a first concentrated brine tank 225, a second electric drive ion membrane device 226 and a second concentration Brine tank 227 . The devices of the reduction process also include a secondary reverse osmosis device 201 , a fresh water tank 202 and a recycled water tank 203 .

[0076] The pretreated waste water collected in the first in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com