External filtering system for hollow fiber porous membrane bundle and technology thereof

A filtration system and porous membrane technology, which is applied in the field of filtration systems of external hollow fiber membrane porous membrane bundles, can solve the problems that the membrane filaments are not easy to swing or vibrate, unfavorable vibration cleaning effect, uneven force, etc., to achieve good water quality , small footprint and long operating cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

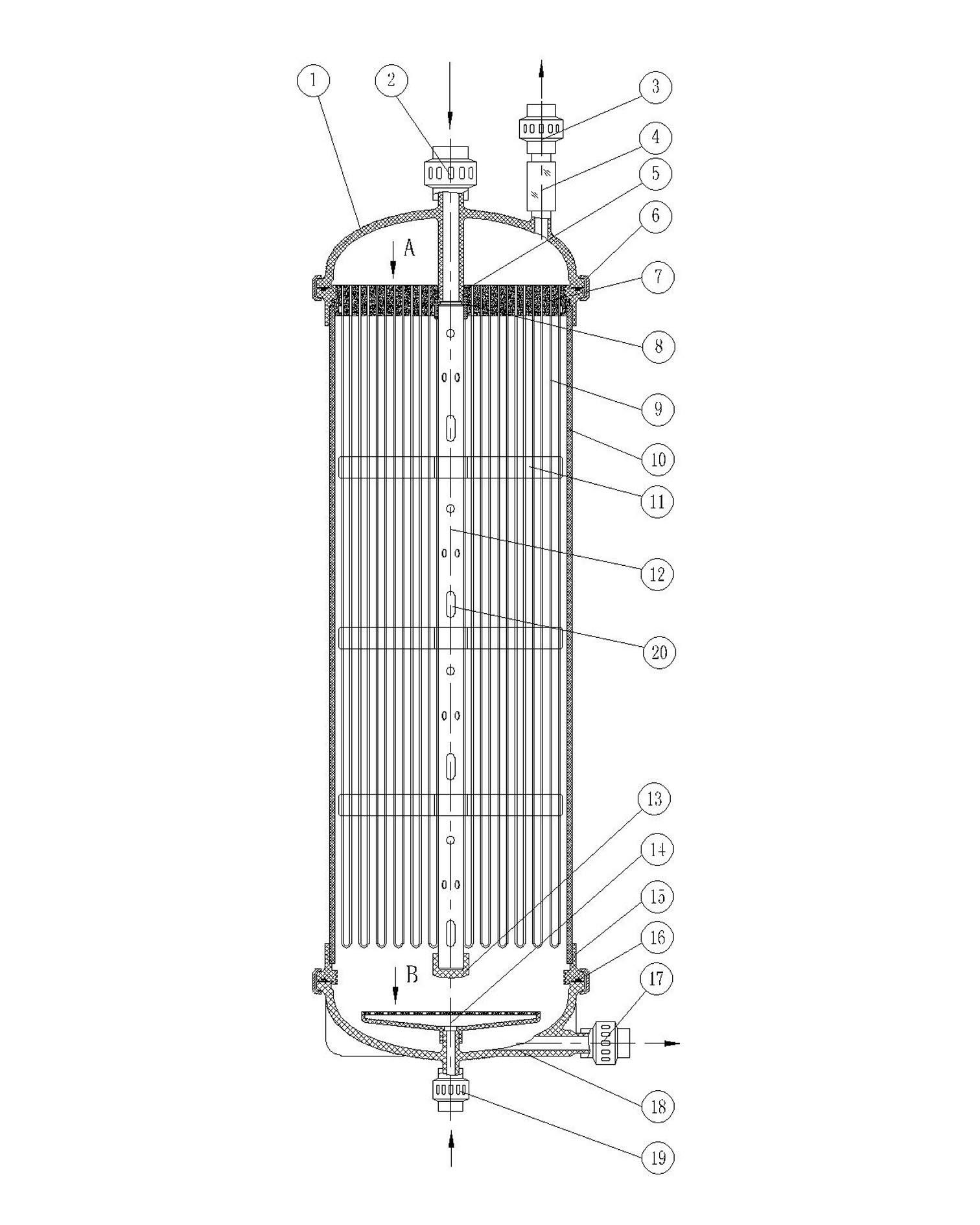

[0038] Such as figure 1 As shown, a filter system of an external hollow fiber porous membrane bundle includes an upper head 1, a lower head 18 and a cylinder body 10, the upper and lower heads are respectively located at the two ends of the cylinder body 10, and the upper and lower sides of the cylinder body There is a cylinder end ring 15 at both ends, and there is an O-ring 16 between the upper head 1, the lower head and the cylinder end ring, which is fixed by the hoop 6 after being sealed by the O-ring. The upper and lower heads and the cylinder body 10 are connected to form a shell with a cavity. There is a central pipe 12 fixed in the center of the shell, the upper end of the central pipe 12 is connected with a water inlet, the water inlet is connected with external equipment through the water inlet joint 2, the water inlet is located at the upper end of the upper head 1, and the water inlet is connected through the water distribution connecting pipe 8 is connected on t...

Embodiment 2

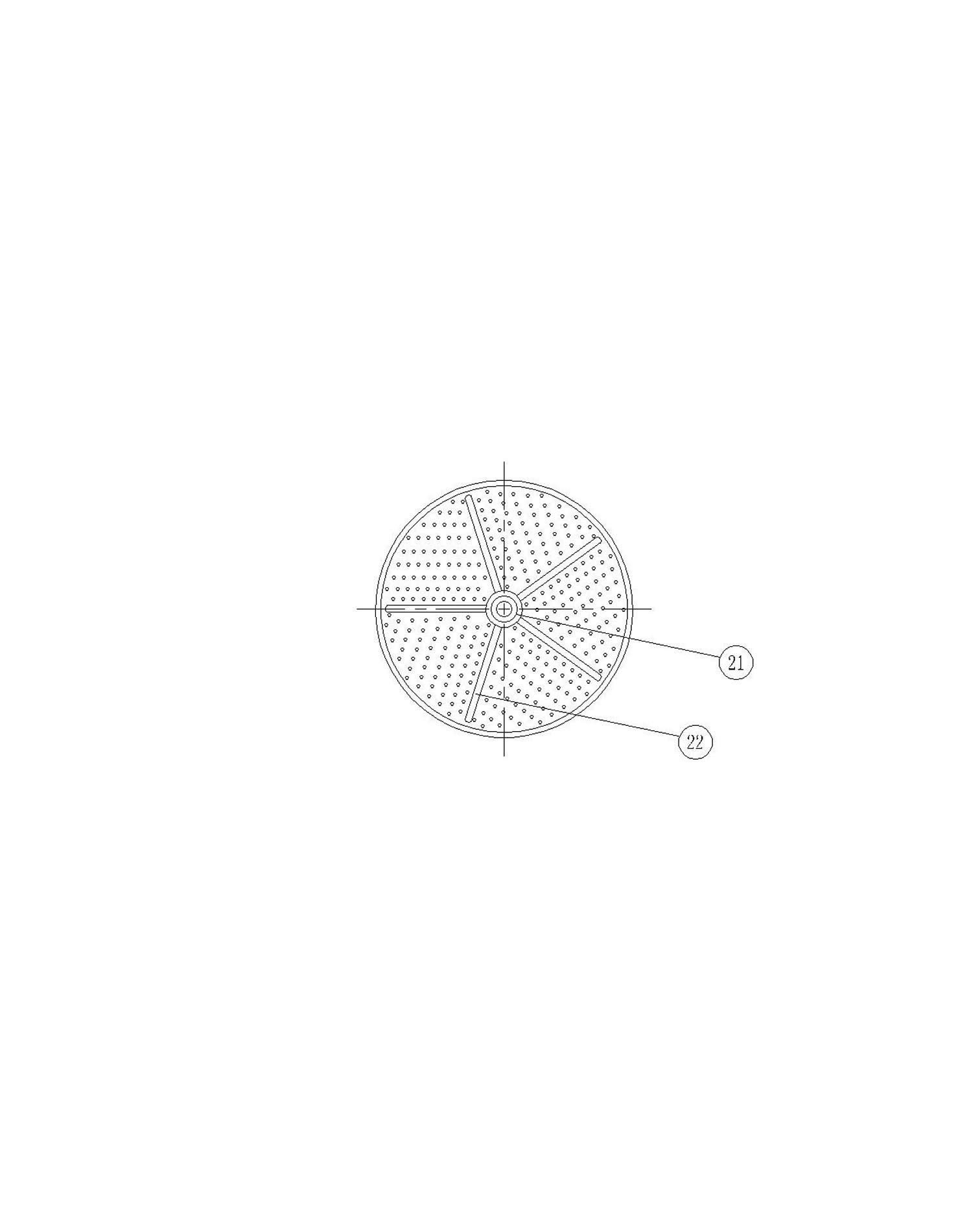

[0041] Such as Figure 4 As shown, the difference from Embodiment 1 is that the air distribution tray 14 includes a central part 25 that overlaps with the center of the central tube, and a plurality of symmetrically arranged ribs 26 are integrally formed on the central part 25. Cloth air hole 24.

Embodiment 3

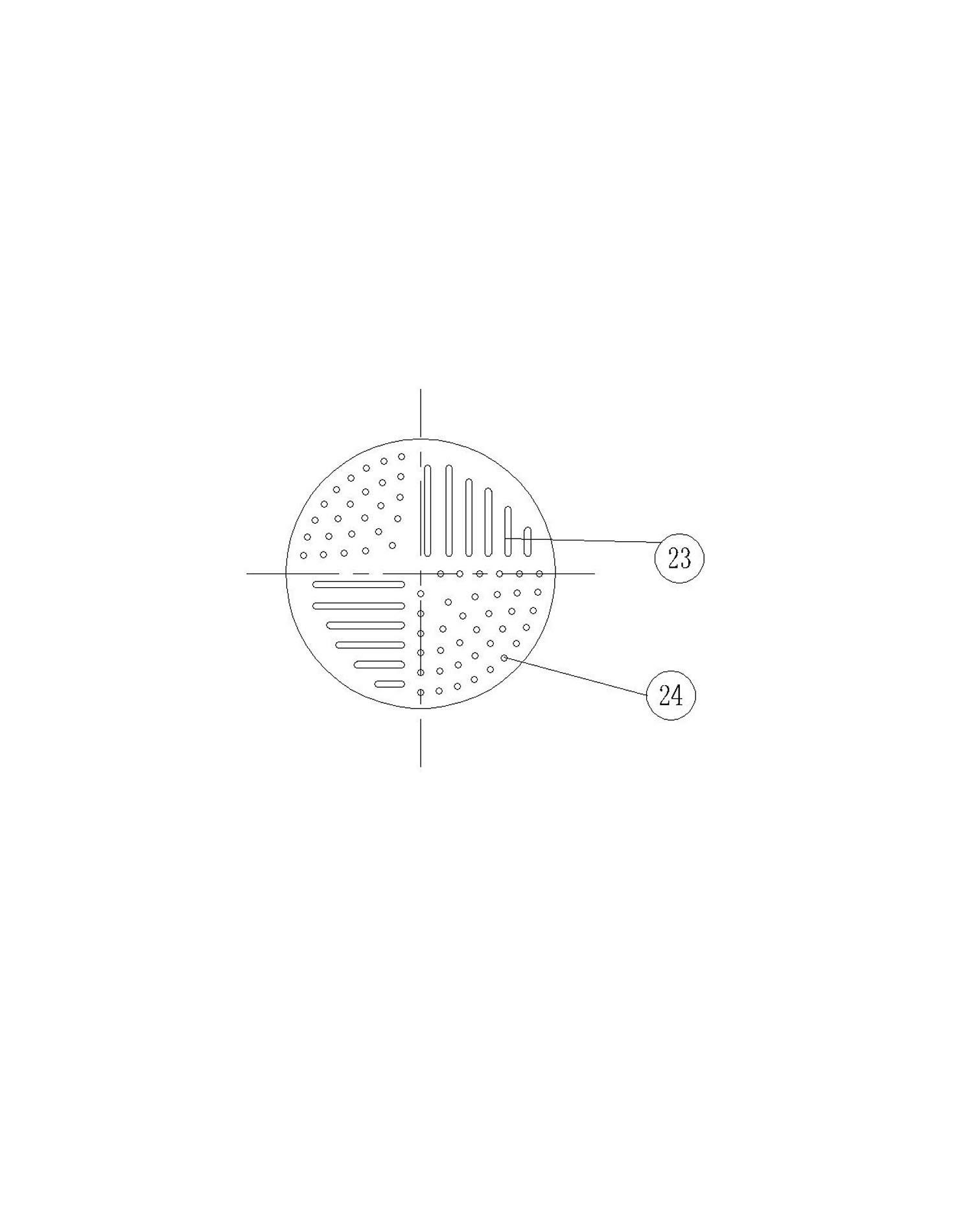

[0043] Such as Figure 5 and 6 As shown, the difference from Embodiment 1 is that the air inlet is connected with an air inlet pipe 27, and the air inlet pipe 27 pulls out two air inlet branches 28 to be connected to the central fixing portion 21 of each layer of support of the frame body 11, The central fixed part 21 is a hollow cavity, and the part of the air intake branch 28 passing through the central fixed part is provided with an opening, and the gas is introduced into the central fixed part 21. The outer surface of the ribs is provided with air holes 29, and the center of the gas is fixed in the supporting ribs, and then sprayed outwards from the air holes 29 on the supporting ribs, because the supporting ribs divide the membrane filaments into membrane filament bundles, and are close to the membrane filaments. The cleaning effect of membrane filament is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com