A driving and guiding mechanism of a numerical control cutting machine

A guiding mechanism and cutting machine technology, applied in metal processing and other directions, can solve problems such as the reduction of the life of the rack and pinion, the poor meshing of the rack and pinion, and the easy vibration of the bracket, so as to prolong the service life, ensure cutting accuracy, and prevent jamming. effect of death

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

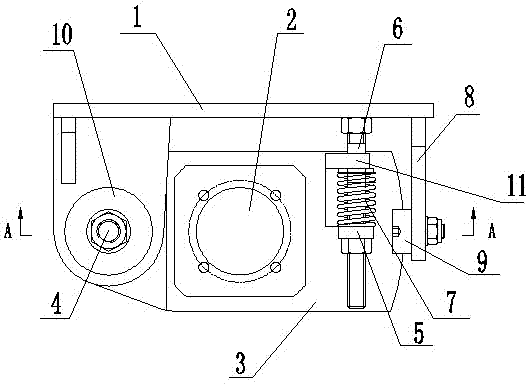

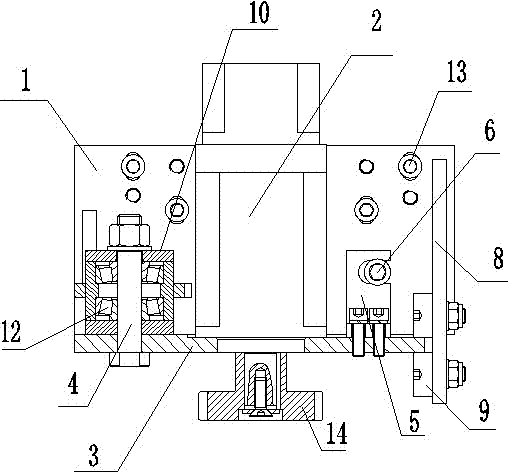

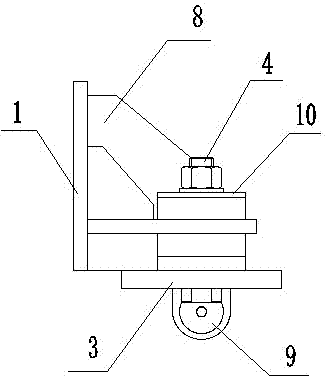

[0011] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

[0012] It can be seen from the accompanying drawings that the driving and guiding mechanism of the CNC cutting machine of this program includes a connecting plate 1, and the connecting plate 1 is provided with a supporting plate 3 for fixing the driving mechanism 2, and one end of the supporting plate 3 is connected to The shaft 4 is connected to the connecting plate 2, and the supporting plate 3 can rotate around the connecting shaft 4. An adjusting plate 5 is arranged at the end of the supporting plate 3 away from the connecting shaft 4, and the adjusting plate 5 is connected with the pre-tightened adjusting screw 6. The plate 1 is fixed, a spring 7 is provided on the pre-tightening adjusting screw 6, and a limit plate 8 is provided on the end of the connecting plate 1 far away from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com