Neutral chemical cleaning agent for eliminating hard scales of air pre-heater of desulfurization system and preparation method of neutral chemical cleaning agent

A desulfurization system and cleaning agent technology, applied in the field of chemical cleaning, can solve the problems of more hard scale formation, poor effect, blockage, etc., and achieve the effect of improving the desulfurization efficiency, removing the hard scale thoroughly, and improving the operation rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

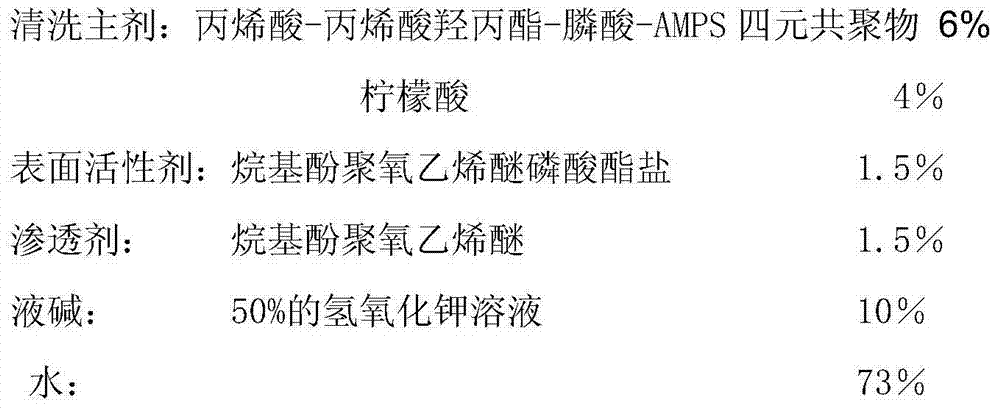

[0025] The present invention is a kind of neutral chemical cleaning agent for removing the hard scale of the air preheater of the desulfurization system, and the formula is as follows:

[0026]

[0027] The preparation method of the above-mentioned neutral chemical cleaning agent: according to the above ratio, first add water, then add the main cleaning agent, then slowly add liquid caustic soda, (the temperature is controlled below 50°C) and stir evenly, then add surfactant, infiltrate agent, stir evenly.

Embodiment 2

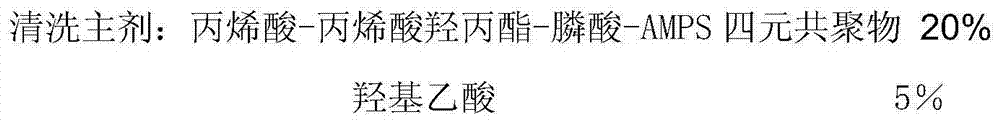

[0032] The present invention is a kind of neutral chemical cleaning agent for removing the hard scale of the air preheater of the desulfurization system, and the formula is as follows:

[0033]

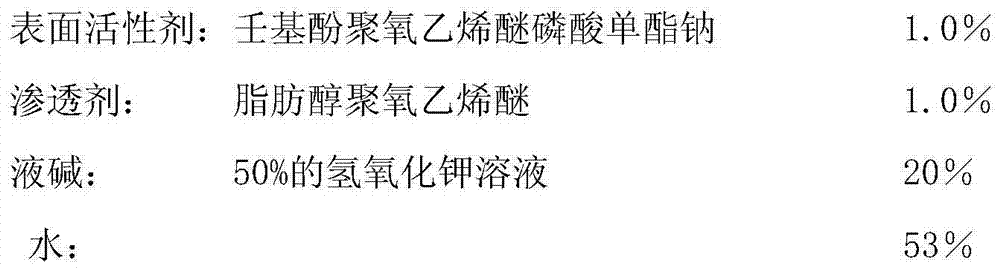

[0034]

[0035] The preparation method of the above-mentioned neutral chemical cleaning agent: according to the above ratio, first add water, then add the main cleaning agent, then slowly add liquid caustic soda, (the temperature is controlled below 50°C) and stir evenly, then add surfactant, infiltrate agent, stir evenly.

[0036] Corrosion test of the above-mentioned neutral chemical cleaning agent:

[0037] Test method: Spray the above cleaning agent on the scaled 20# carbon steel and ceramic cutting discs respectively.

[0038] Test results: At room temperature, the static wet time is 8 hours, and the scale with a thickness of about 1.5cm will completely expand and melt. The average corrosion rate of 20# carbon steel is 0.00105g / m 2 h, the average corrosion rate of cerami...

Embodiment 3

[0040] The present invention is a kind of neutral chemical cleaning agent for removing the hard scale of the air preheater of the desulfurization system, and the formula is as follows:

[0041]

[0042] The preparation method of the above-mentioned neutral chemical cleaning agent: according to the above ratio, first add water, then add the main cleaning agent, then slowly add liquid caustic soda, (the temperature is controlled below 50°C) and stir evenly, then add surfactant, infiltrate agent, stir evenly.

[0043] Corrosion test of the above-mentioned neutral chemical cleaning agent:

[0044] Test method: Spray the above cleaning agent on the scaled 20# carbon steel and ceramic cutting discs respectively.

[0045] Test results: At room temperature, the static wet time is 4 hours, and the scale with a thickness of about 1.5cm will completely expand and melt. The average corrosion rate of 20# carbon steel is 0.00105g / m 2 h, the average corrosion rate of ceramic cutting disc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com