Filtrating and squeezing process and system for desulphurization wastewater

A desulfurization wastewater and process technology, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of high moisture content of filter cake, blockage of filter cloth, affecting transportation, etc., to reduce energy consumption, avoid scaling, and avoid failures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

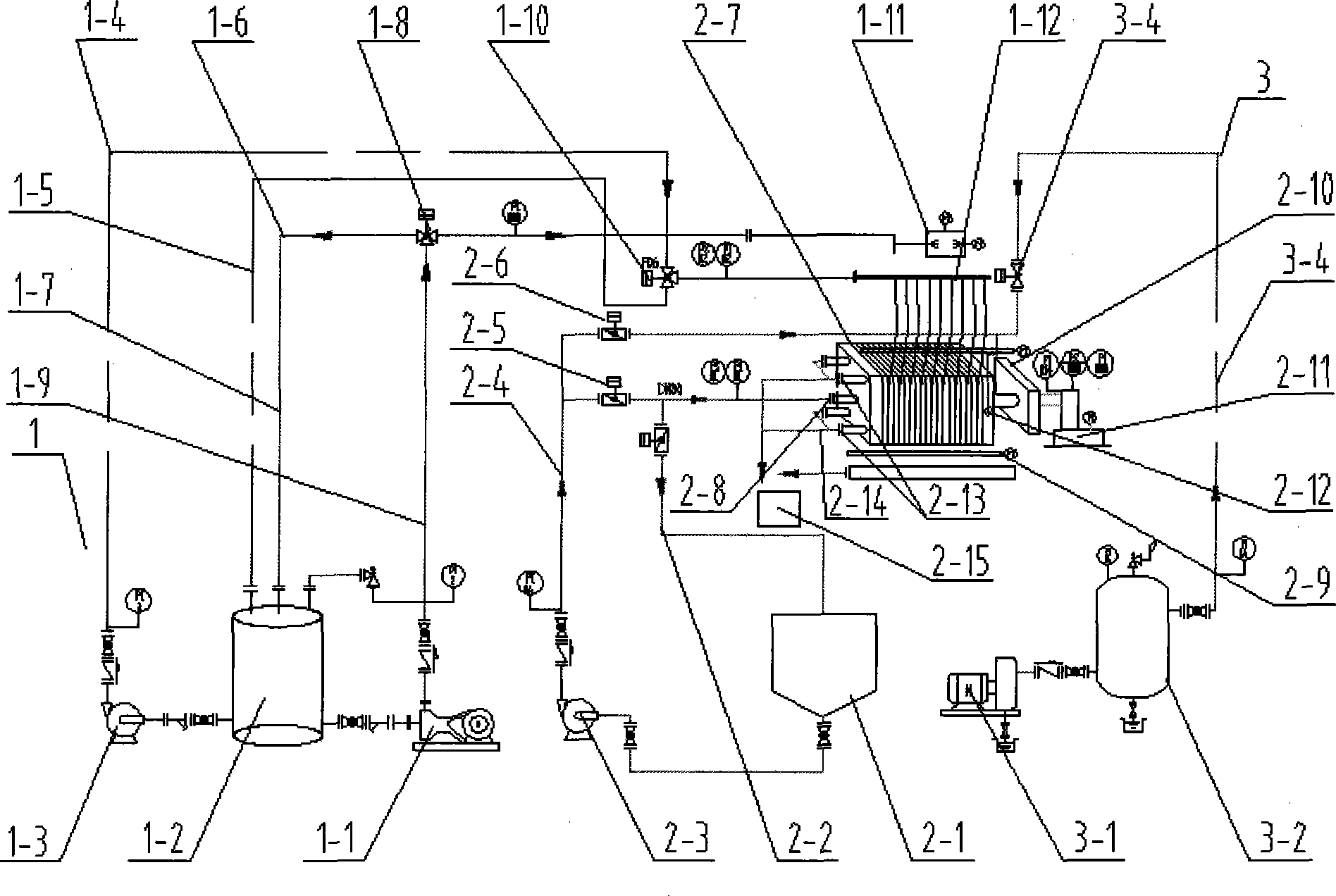

[0009] Embodiment 1: refer to figure 1 . Desulfurization waste water filtration and pressing process and system, which includes mud feeding system, sludge drying system, filter cake pressing system, filter cloth cleaning system and supporting electrical control system. The water inlet of the washing pump 1-1 in the filter cloth cleaning system 1 is connected with the water storage tank 1-2 through the washing water pipe 1-8, and the washing water return pipe 1-4 is connected with the washing water pipe 1-3 through the pneumatic three-way ball valve 1-5 And the water return port of the washing return pipe 1-4 is connected with the water storage tank 1-2, the water inlet of the washing water pipe 1-3 is connected with the water outlet of the flushing pump 1-1, and the valve between the water storage tank 1-2 and the washing water pipe 1-3 is connected. Connect with the water supply pipe 1-9, and the pneumatic three-way ball valve 1-5 communicates with the cloth washing device 1...

Embodiment 3

[0010] Embodiment 3: On the basis of Embodiment 1, the desulfurization waste water filtering and pressing process and system are characterized in that: the feed pump 2-3 passes the sewage pool 2-1 slurry through the pipeline 2-11 and 2- 12 is injected from both sides of the filter press 2-7 at the same time, because the pipeline is equipped with a pressure sensor 2-17, the signal end of the sensor is connected to the signal end of the PLC controller through the signal line, and the PLC controller There is a pressure upper and lower limit setting control circuit in the middle, and the required pressure control value can be easily set through the PLC control panel, so when the feeding pipe between the feed valve 2-5 and the filter press 2-7 When the pressure of the pressure sensor 2-17 on the upper reaches the set low pressure value (0.8MPa), the PLC controller instructs the actuator to cut off the power supply of the feed pump 2-3, the feed pump 2-3 stops working, and the air co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com