Method for recycling and comprehensively utilizing reverse osmosis concentrated water produced after treatment of coking wastewater

A technology for reverse osmosis concentrated water and coking wastewater, applied in chemical instruments and methods, oxidized water/sewage treatment, reverse osmosis, etc. Harsh environment and other problems, to achieve good separation ability, avoid organic pollution and fouling, and the effect of dense surface activation layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

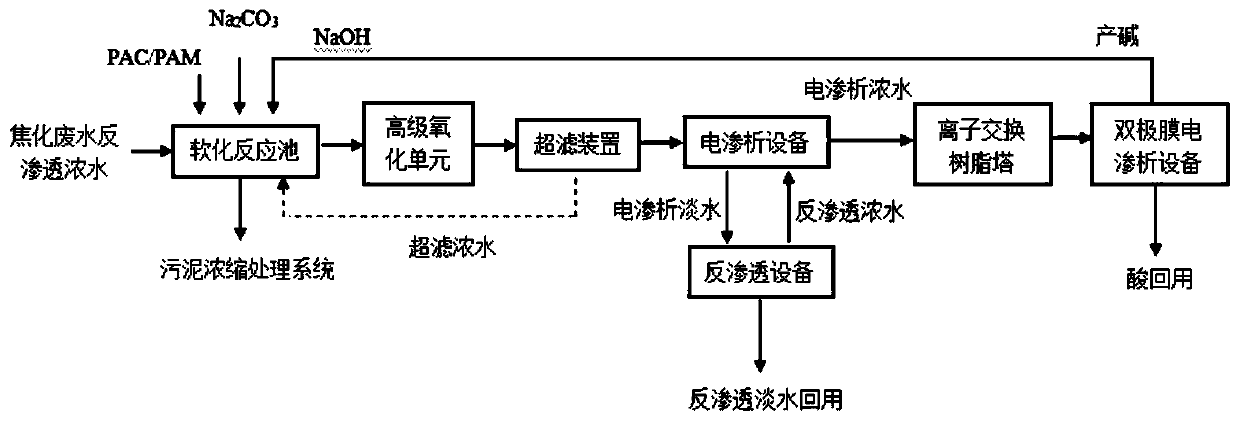

[0060] Refer to attached figure 1 , 100L coking wastewater reverse osmosis concentrated water contains 21.8g / L Na in the present embodiment + , 6.074g / L of Cl - , 2.755g / L SO 4 2- , 152.49ppm Ca 2+ , 114.79ppm of Mg 2+ , COD of 469ppm. In this embodiment, the method for comprehensive utilization of coking wastewater reverse osmosis concentrated water resources includes the following steps:

[0061] S1. Pass the reverse osmosis concentrated water into the softening reaction tank, and add 40.4g of sodium carbonate solid and 2mol / L sodium hydroxide solution to the tank to remove Ca in the water 2+ , Mg 2+ To reduce the hardness of the concentrated water, add 100g of flocculant polyaluminum chloride (PAC) and 50g of coagulant polyacrylamide (PAM) to the reaction tank at the same time, and Ca in the effluent after softening 2+ , Mg 2+ Total content <10mg / L;

[0062] S2, the lower layer of sludge after dehardening is discharged through the control of the sludge discharge v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com