Highly effective pretreatment apparatus for refractory dyeing waste water

A pretreatment device, technology for printing and dyeing wastewater, applied in textile industry wastewater treatment, water/sewage treatment, water/sludge/sewage treatment, etc. Effective contact, low operating costs and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

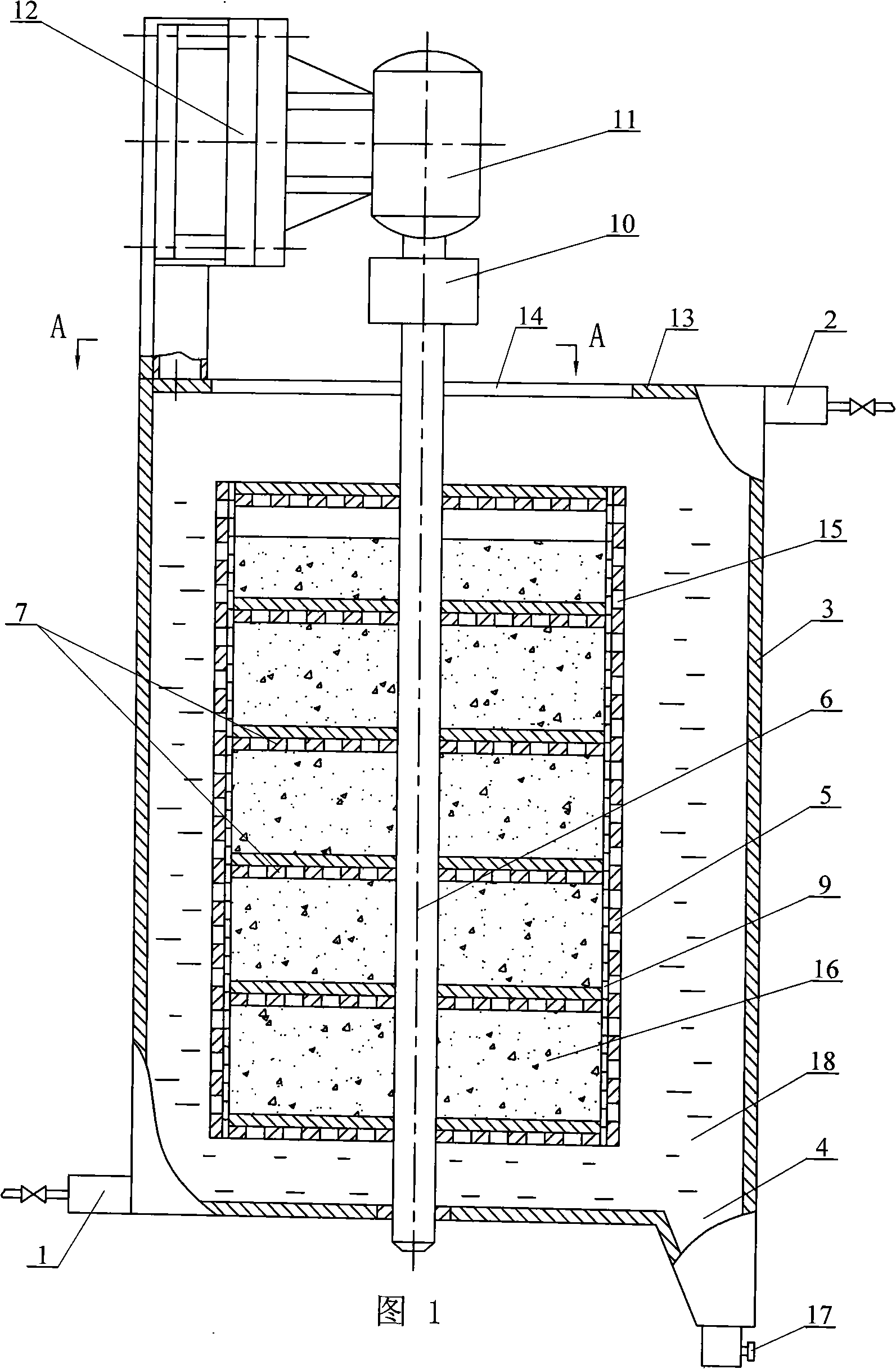

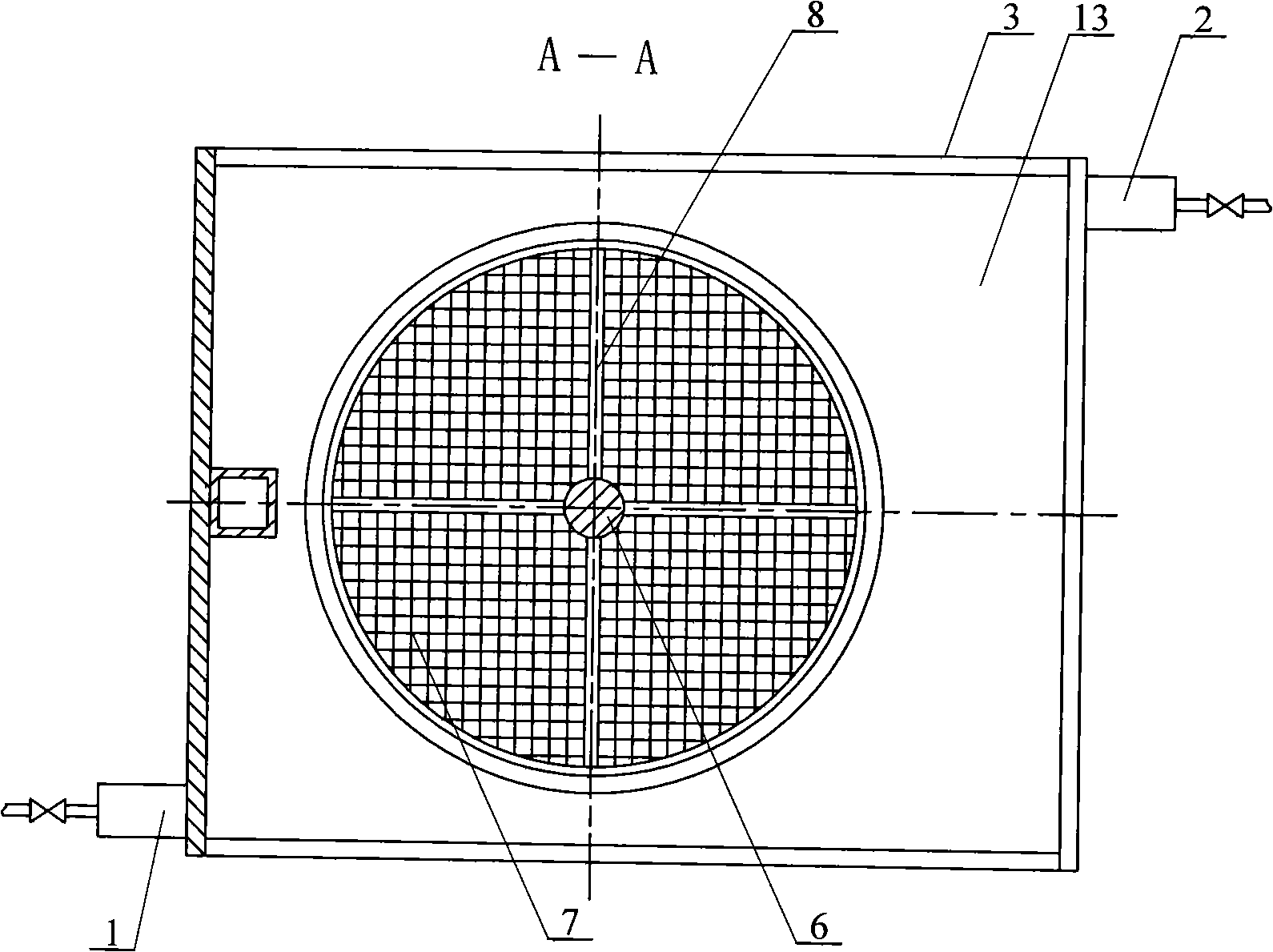

[0012] Specific implementation mode one: in conjunction with Fig. 1~ figure 2 Describe this embodiment, the pretreatment device of this embodiment includes water inlet water distribution device 1, water outlet water distribution device 2 and reactor 3; The lower end and the upper end are respectively communicated with the reactor 3 (i.e., the upflow type is adopted, the water is fed from the bottom, and the water is overflowed from the top); the pretreatment device also includes a rotating cylinder 5, a rotating shaft 6, a governor 10, and a motor 11 , support 12, end cap 13, iron-carbon filler 16, sludge discharge valve 17 and a group of mesh partitions 7; the rotating cylinder 5 is installed in the reactor 3, and the upper end of the reactor 3 is equipped with an end cap 13 (detachable), the end cover 13 has a central hole 14, the input end of the rotating shaft 6 is connected to the output end of the motor 11 through the governor 10, and the motor 11 is connected to the rea...

specific Embodiment approach 2

[0013] Specific Embodiment 2: This embodiment is described with reference to FIG. 1 . In this embodiment, the holes 15 on the outer wall of the rotating cylinder 5 are evenly distributed along the entire outer wall of the rotating cylinder 5 , which can improve the pretreatment efficiency. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0014] Specific embodiment three: the present embodiment is described in conjunction with Fig. 1, the filling ratio of the iron-carbon filler 16 of the present embodiment is 30%~80% of the effective volume of the rotating cylinder 5, and is completely submerged below the water surface of the reactor 3. Other components and connections are the same as those in the first embodiment.

[0015] Embodiment 4: This embodiment is described in conjunction with FIG. 1 . The iron-carbon filler 16 of this embodiment is filled in the rotating cylinder 5 according to the volume ratio of 1:3 to 5:4, which has a better adsorption effect. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com