Heat-conducting polyformaldehyde composite material and preparation method thereof

A composite material, polyoxymethylene technology, applied in the field of polymer material processing, can solve the problems of difficult composite and functionalization, poor compatibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

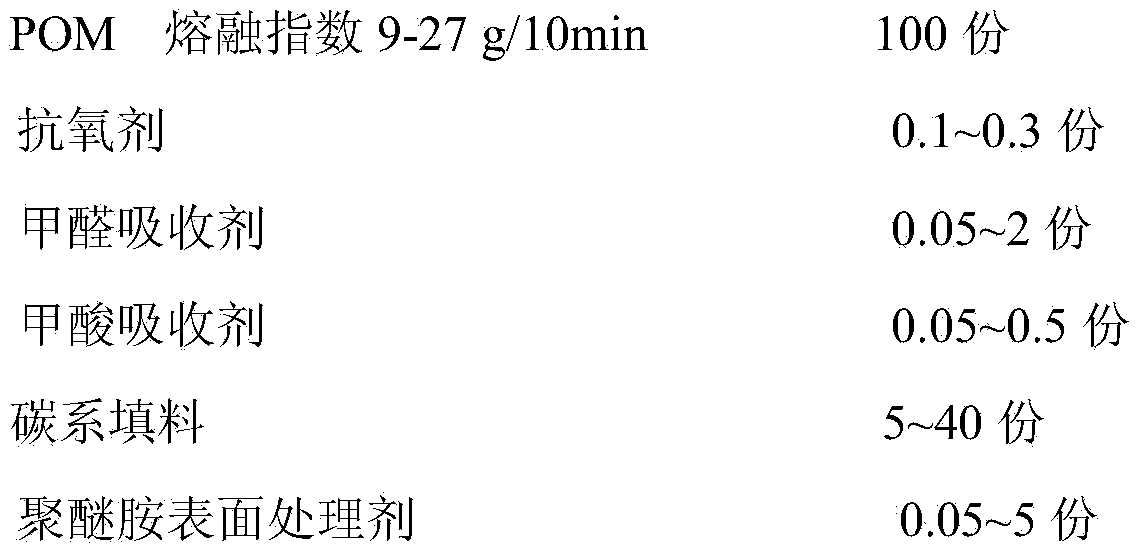

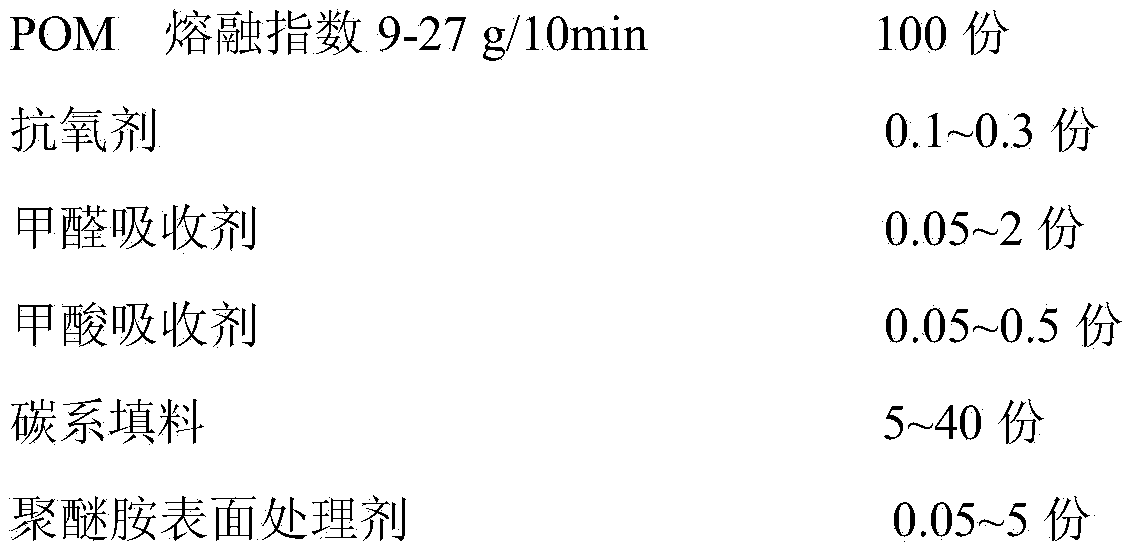

Method used

Image

Examples

Embodiment 1

[0023] Disperse 150g of polyetheramine surface treatment agent (n=5, m=18) and 3Kg of carboxylated multi-walled carbon nanotubes in a mixed solution of ethanol and water with a volume ratio of 1:9, with a mass fraction of 5%, at 50°C Ultrasonic treatment for 0.5h (frequency: 20kHz, power: 400w), then suction filtration and drying to obtain surface-modified multi-walled carbon nanotubes for use.

[0024] Mix polyoxymethylene resin 10Kg with surface-modified multi-walled carbon nanotubes 2Kg, tetrakis-[3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol 30g, melamine 20g, carbonic acid Add 20 g of calcium into a high-speed mixer for mixing, melt and knead with a vented twin-screw extruder, and extrude to granulate. Screw speed, 50 rpm; barrel temperature, 140-200°C.

[0025] The prepared thermally conductive POM / multi-armed carbon nanotube composite material has a thermal conductivity of 1.05W / (m K), a tensile strength of 58MPa, and a notched impact strength of 5....

Embodiment 2

[0027] Disperse 90g of polyetheramine surface treatment agent (n=10, m=12) and 3Kg of graphite oxide in a mixed solution of ethanol and water with a volume ratio of 1:9, with a mass concentration of 5%, and ultrasonically treat it at 50°C for 1h ( frequency: 20kHz, power: 400w), and then suction filtered and dried to obtain surface-modified graphite oxide for use.

[0028] POM resin 10Kg and surface modified graphite oxide 3Kg, N,N'-bis-[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl]hexamethylenediamine 40g, dicyandiamide Add 10 g of amine and 10 g of magnesium oxide into a high-speed mixer for mixing, use a vented twin-screw extruder to melt and knead, and extrude to granulate. Screw speed, 100 rpm; barrel temperature, 160-220°C.

[0029] The thermally conductive POM / graphite oxide composite material prepared has a thermal conductivity of 1.21W / (m K), a tensile strength of 53MPa, and a notched impact strength of 5.4KJ / m 2 .

Embodiment 3

[0031] Disperse 60g of polyetheramine surface treatment agent (n=10, m=12) and 3Kg of hydroxylated multi-walled carbon nanotubes in a mixed solution of ethanol and water with a volume ratio of 1:9, with a mass concentration of 5%, at 50°C Under ultrasonic treatment for 1.5h (frequency: 20kHz, power: 400w), then suction filtration and drying to obtain surface-modified hydroxylated multi-walled carbon nanotubes for use.

[0032] 10Kg of POM resin, 2Kg of hydroxylated multi-walled carbon nanotubes after surface modification, 10g of stearyl propionate, 70g of urea, and silicic acid Add 7g of calcium into a high-speed mixer for mixing, use a vented twin-screw extruder to melt and knead, and extrude to granulate. Screw speed, 200 rpm; barrel temperature, 180-220°C.

[0033] The prepared thermally conductive POM / hydroxylated carbon nanotube composite material has a thermal conductivity of 1.15W / (m K), a tensile strength of 60MPa, and a notched impact strength of 5.0KJ / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Notched impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com