Device and process for treating high-concentration organic wastewater containing PVA

An organic wastewater and high-concentration technology, which is applied in filtration treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of harsh reaction conditions, poor treatment effect, and low cost of physical methods, and achieve convenient operation and maintenance. Wide range and good processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

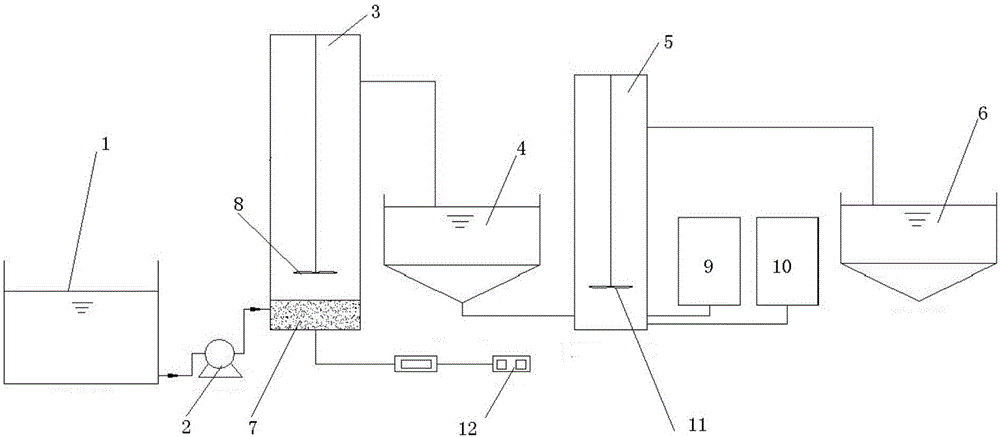

[0022] see figure 1 , a device for treating high-concentration organic wastewater containing PVA, including connected iron-carbon micro-electrolysis reaction pools 3, sedimentation tanks 4, Fenton reactors 5 and clear water pools 6 connected in sequence according to the wastewater entering, and the water storage tank 1 is metered Pump 2 links to each other with iron-carbon micro-electrolysis reaction cell 3, iron-carbon micro-electrolysis reaction cell 3 links to each other with oxygenator 12, is filled with iron-carbon filler 7 at the bottom of described iron-carbon micro-electrolysis reaction cell, in described iron-carbon A stirring device 8 is arranged in the upper part of the micro-electrolysis reaction pool, and the Fenton reactor 5 passes through the ferrous sulfate feeding pipe and the hydrogen peroxide feeding pipe and the ferrous sulfate replenishing tank 9 hydrogen peroxide replenishing tank 10 respectively.

[0023] Preferably, the Fenton reactor 5 is provided with...

Embodiment 2

[0025] A process utilizing the device described in Implementation 1 to process PVA-containing high-concentration organic wastewater, comprising the steps of:

[0026] 1) Add alkali to the water storage tank 1, and adjust the pH of the high-concentration organic wastewater containing PVA (COD is 2200mg / L) to 8-10;

[0027] 2) The pH-adjusted waste water is transported to the iron-carbon micro-electrolysis reaction tank 3 through the metering pump 2, and when it is aerated by the oxygenator 12, the ratio of gas to water is 6:1, and the stirring device is started at the same time 8. Carry out iron-carbon micro-electrolysis treatment for 5-8 hours;

[0028] 3) Enter the sedimentation tank 4 after iron-carbon micro-electrolysis treatment, and add CPAM to the sedimentation tank 4 for flocculation and precipitation;

[0029] 4) After flocculation and sedimentation, the effluent from the sedimentation tank 4 enters the Fenton reactor 5, adding acid to adjust the pH to 3-5, adding fer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com