Rotary iron-carbon micro-electrolysis reactor and wastewater treatment method

A technology for iron-carbon micro-electrolysis and wastewater treatment, which is applied in sterilization/microdynamic water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc. The problem of slow reaction speed, etc., can speed up the internal electrolysis reaction process, improve the processing efficiency, and improve the reaction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

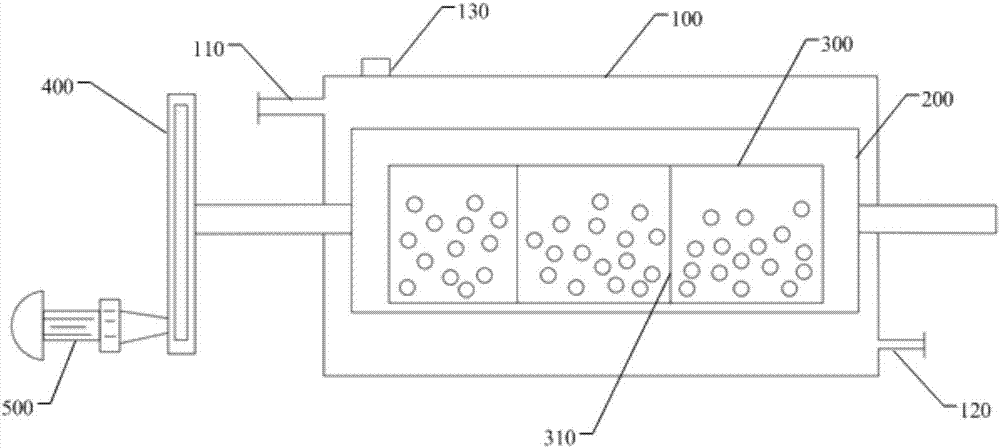

[0069] A rotary iron-carbon micro-electrolysis reactor and wastewater treatment method, the rotary iron-carbon micro-electrolysis reactor comprises a shell 100 with a cover, an inlet pipe 110 and an outlet pipe 120 arranged on both sides of the shell 100 with a cover, a set The vent 130 on the shell with cover 100, and the drum 200; holes are evenly opened on the drum 200, the drum 200 is horizontally arranged in the shell with cover 100, and the two ends of the drum 200 have a rotating shaft, and the rotating shaft Protrude out of the cover housing 100; one end of the rotating shaft is connected to the motor 500 through the transmission device 400; the drum 200 is provided with a cover that can be lifted, and the drum 200 is provided with a cylinder 300 composed of a screen, and the cylinder 300 Contains iron carbon filler. The iron-carbon filler is a spheroid formed by sintering iron fine powder and coking coal at a volume ratio of 1:1 at 1100 ° C. The volume of the iron-car...

Embodiment 2

[0078]A rotary iron-carbon micro-electrolysis reactor and wastewater treatment method, the rotary iron-carbon micro-electrolysis reactor comprises a shell 100 with a cover, an inlet pipe 110 and an outlet pipe 120 arranged on both sides of the shell 100 with a cover, a set The vent 130 on the shell with cover 100, and the drum 200; holes are evenly opened on the drum 200, the drum 200 is horizontally arranged in the shell with cover 100, and the two ends of the drum 200 have a rotating shaft, and the rotating shaft Protrude out of the cover housing 100; one end of the rotating shaft is connected to the motor 500 through the transmission device 400; the drum 200 is provided with a cover that can be lifted, and the drum 200 is provided with a cylinder 300 composed of a screen, and the cylinder 300 Contains iron carbon filler. The iron-carbon filler is a spheroid formed by sintering iron fine powder and coking coal at a volume ratio of 1:3 at 1000 ° C. The volume of the iron-carb...

Embodiment 3

[0087] A rotary iron-carbon micro-electrolysis reactor and wastewater treatment method, the rotary iron-carbon micro-electrolysis reactor comprises a shell 100 with a cover, an inlet pipe 110 and an outlet pipe 120 arranged on both sides of the shell 100 with a cover, a set The vent 130 on the shell with cover 100, and the drum 200; holes are evenly opened on the drum 200, the drum 200 is horizontally arranged in the shell with cover 100, and the two ends of the drum 200 have a rotating shaft, and the rotating shaft Protrude out of the cover housing 100; one end of the rotating shaft is connected to the motor 500 through the transmission device 400; the drum 200 is provided with a cover that can be lifted, and the drum 200 is provided with a cylinder 300 composed of a screen, and the cylinder 300 Contains iron carbon filler. The iron-carbon filler is a spheroid formed by sintering iron fine powder and coking coal at a volume ratio of 1:2 at 900°C, and the volume of the iron-ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com