Ablation-resistant rubber type thermal insulation layer and preparation method thereof

A rubber-type, ablation-resistant technology, applied in the field of heat-resistant materials, to achieve the effect of improving ablation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

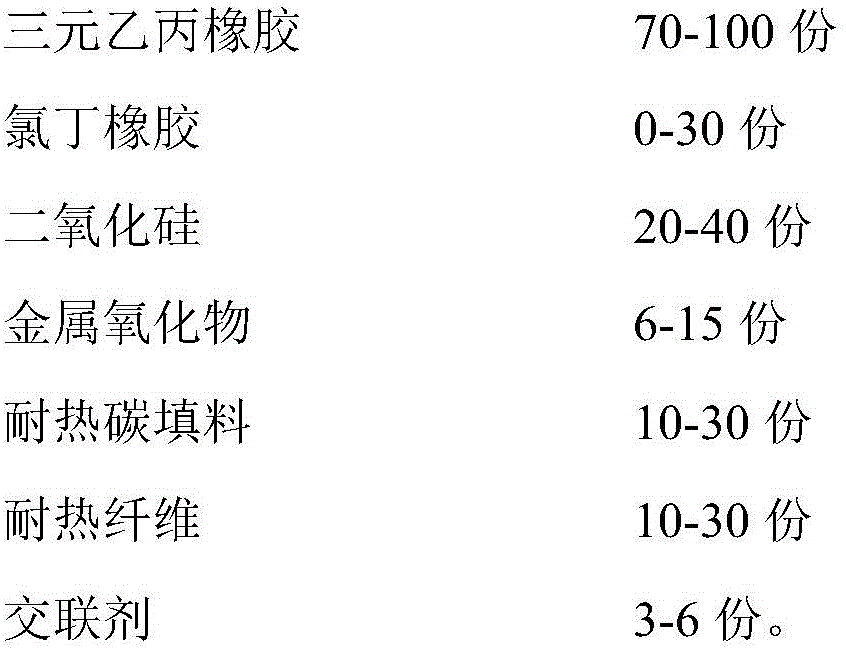

Method used

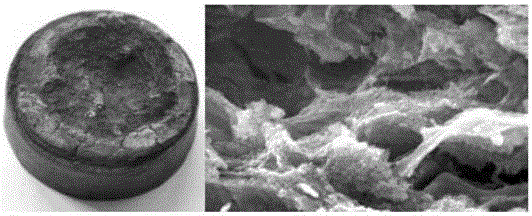

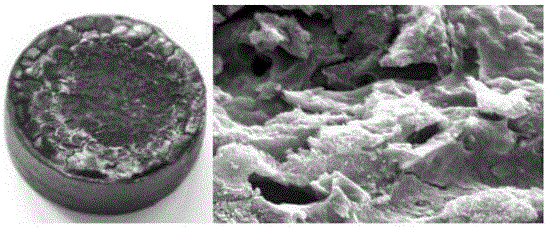

Image

Examples

Embodiment 1

[0029] Embodiment 1: Add 85 parts of EPDM rubber, 15 parts of chloroprene rubber, gas-phase method Si in 25 ℃ of double-roll mills successively. 2 35 parts, 6 parts of zinc oxide, 4 parts of magnesium oxide, 15 parts of PPS fiber, 10 parts of aramid fiber, 20 parts of carbon black, knead until uniformly mixed, and finally add 3.5 parts of dicumyl peroxide, knead, thin pass Uniform, out of the film. Vulcanize for 40 minutes in a flat vulcanizer at 160° C. to obtain the ablation-resistant rubber-type heat insulating layer of the present invention.

[0030] Oxyacetylene wire ablation rate: 0.075mm / s

Embodiment 2

[0031] Embodiment 2: Add 80 parts of EPDM rubber, 20 parts of chloroprene rubber, precipitation method Si in 25 ℃ of double-roll mills successively. 2 40 parts, 5 parts of zinc oxide, 2 parts of magnesium oxide, 20 parts of PPS fiber, 10 parts of aramid fiber, 30 parts of carbon black, knead until uniformly mixed, and finally add 5 parts of dicumyl peroxide, knead, thin pass Uniform, out of the film. Vulcanize for 40 minutes in a flat vulcanizer at 160° C. to obtain the ablation-resistant rubber-type heat insulating layer of the present invention.

[0032] Oxyacetylene wire ablation rate: 0.067mm / s

Embodiment 3

[0033] Embodiment 3: Add 90 parts of EPDM rubber, 10 parts of chloroprene rubber, gas-phase method Si in 25 ℃ of double-roll mills successively. 2 30 parts, 5 parts of zinc oxide, 3 parts of magnesium oxide, 25 parts of PPS fiber, 5 parts of aramid fiber, knead until evenly mixed, finally add 25 parts of carbon fiber, 4 parts of dicumyl peroxide, knead, thin and even , out of the film. Vulcanize for 40 minutes in a flat vulcanizer at 160° C. to obtain the ablation-resistant rubber-type heat insulating layer of the present invention.

[0034] Oxyacetylene wire ablation rate: 0.072mm / s

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire ablation rate | aaaaa | aaaaa |

| Wire ablation rate | aaaaa | aaaaa |

| Wire ablation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com