Method for preparing thermally conductive composite material with directivity

A heat-conducting composite material and directional technology, which is applied in the field of preparation of directional heat-conducting composite materials, can solve problems such as poor thermal conductivity, and achieve the effects of simple operation, expanded application fields, and short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

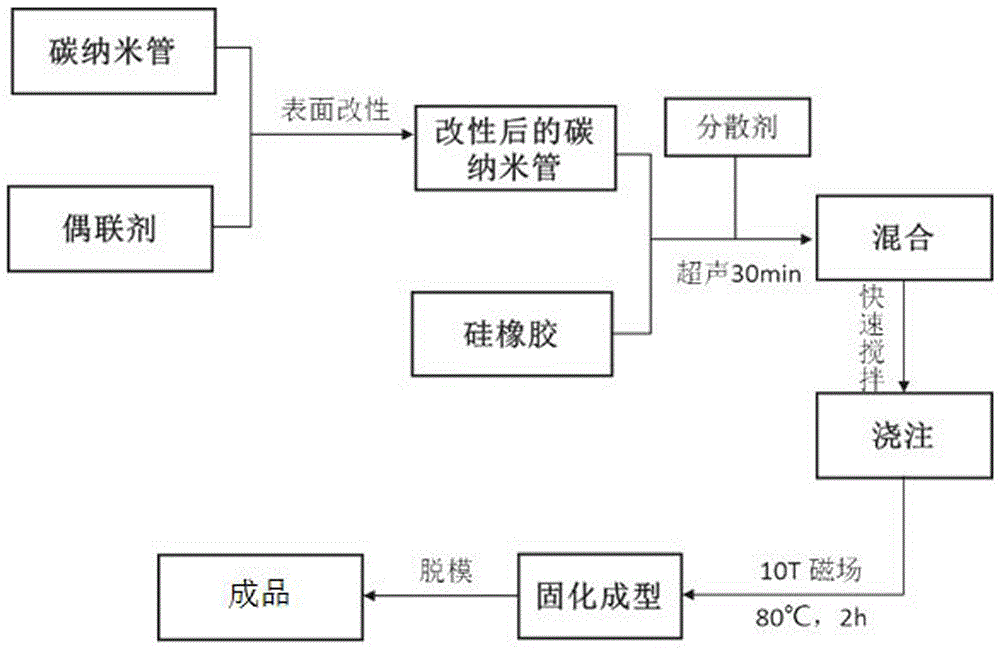

[0025] see figure 1 , in an embodiment of the present invention, a method for preparing a directional thermally conductive composite material, the specific steps are as follows:

[0026] (1) Surface treatment of carbon nanotubes: Mix the surfactant and deionized water at a weight ratio of 0.1:10 to obtain an aqueous solution of the surfactant, stir evenly, then add 1 mg of carbon nanotubes, and perform ultrasonic dispersion at room temperature 0.5h, to obtain carbon nanotube suspension, 3000r / min centrifugation for 2min, wash 3 times with deionized water, then wash 2 times with absolute ethanol, dry at 60°C in a vacuum oven for 10h, to obtain surface-treated carbon nanotube;

[0027] (2) Dissolve 0.1wt% of the surface-treated carbon nanotubes obtained in step (1) in 5 parts of dispersant, ultrasonically disperse for 20 minutes, then add 10 parts of silicone rubber matrix, perform mechanical uniform stirring for 10 minutes, and ultrasonically disperse again until The dispersa...

Embodiment 2

[0029] A method for preparing a directional thermally conductive composite material, the specific steps are as follows:

[0030] (1) Surface treatment of carbon nanotubes: Mix the surfactant and deionized water at a weight ratio of 2:10 to obtain an aqueous solution of the surfactant, stir evenly, then add 6 mg of carbon nanotubes, and perform ultrasonic dispersion at room temperature After 0.8h, the carbon nanotube suspension was obtained, centrifuged at 3500r / min for 3min, washed 4 times with deionized water, and then washed 3 times with absolute ethanol, and dried in a vacuum oven at 65°C for 17h to obtain surface-treated carbon nanotubes. nanotube;

[0031] (2) Dissolve 0.5wt% of the surface-treated carbon nanotubes obtained in step (1) in 8 parts of dispersant, ultrasonically disperse for 25 minutes, then add 10 parts of silicone rubber matrix, perform mechanical uniform stirring for 20 minutes, and ultrasonically disperse again until The dispersant is completely volatil...

Embodiment 3

[0034] A method for preparing a directional thermally conductive composite material, the specific steps are as follows:

[0035] (1) Surface treatment of carbon nanotubes: Mix the surfactant and deionized water at a weight ratio of 3:10 to obtain an aqueous solution of the surfactant, stir evenly, then add 10 mg of carbon nanotubes, and perform ultrasonic dispersion at room temperature 1h, get carbon nanotube suspension, centrifuge at 4000r / min for 5min, wash 5 times with deionized water, then wash 4 times with absolute ethanol, dry in vacuum oven at 70°C for 24h, get surface-treated carbon nanotubes Tube;

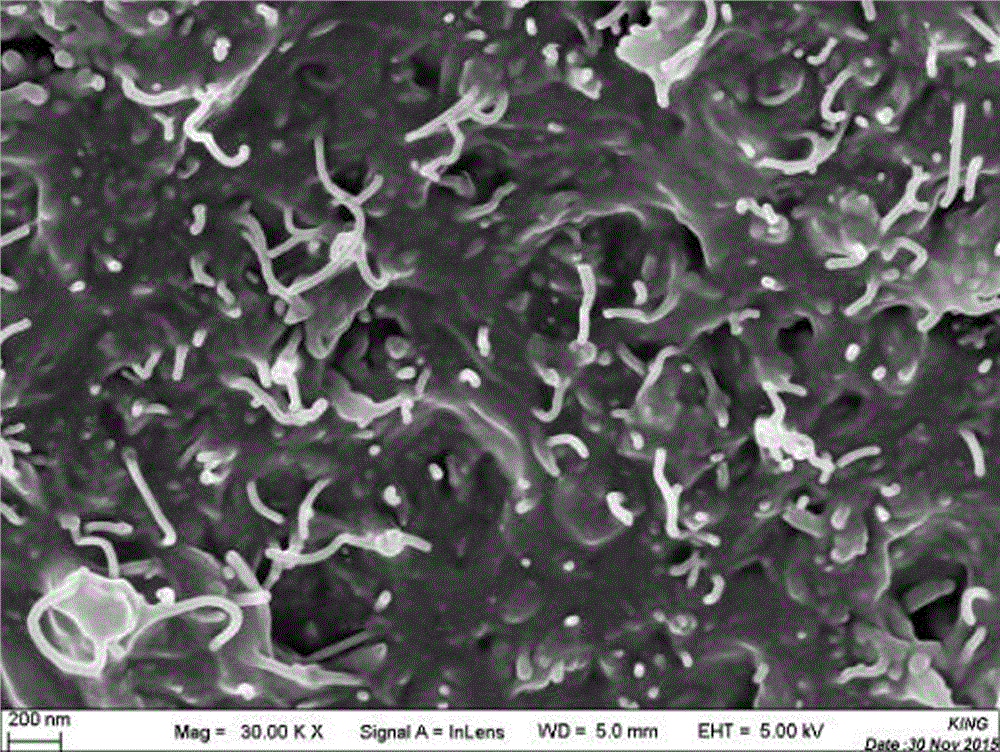

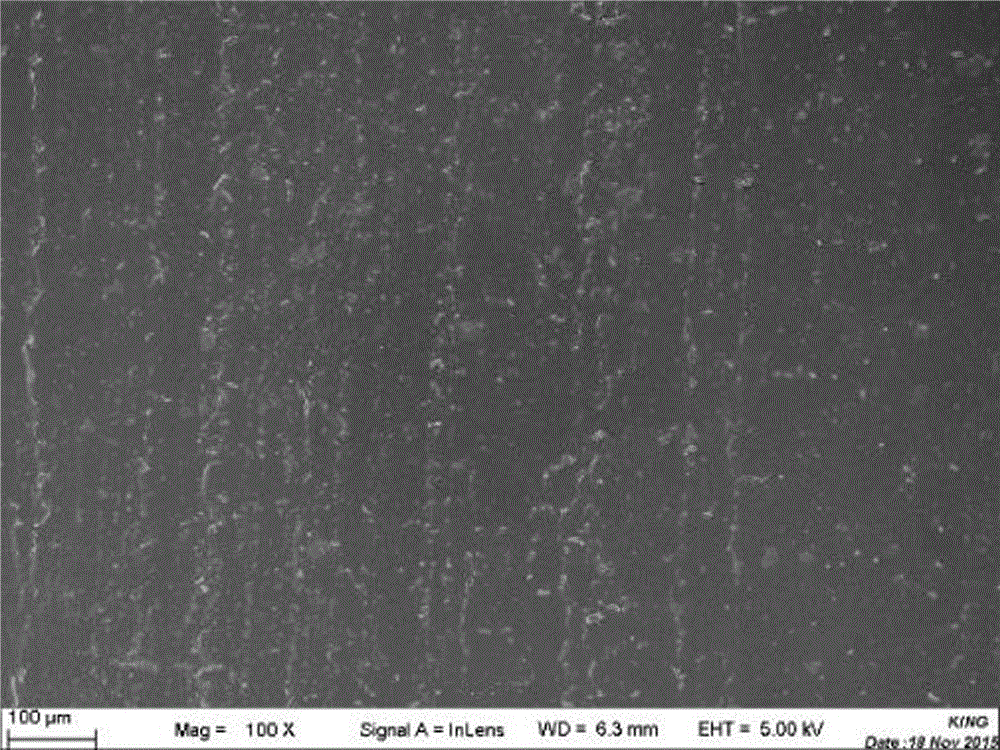

[0036] (2) Dissolve 1wt% of the surface-treated carbon nanotubes obtained in step (1) in 10 parts of dispersant, ultrasonically disperse for 30 minutes, then add 10 parts of silicone rubber matrix, perform mechanical uniform stirring for 30 minutes, and ultrasonically disperse again until dispersed The agent is completely volatilized, vacuumed to remove air bubbles, poure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com