Resourceful treatment and recycling method of circuit board wastewater

A circuit board and recycling technology, which is applied in the field of circuit board wastewater recycling, can solve the problems that cannot be fully realized, and achieve the effects of simple process, weakened poisonous effect, and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

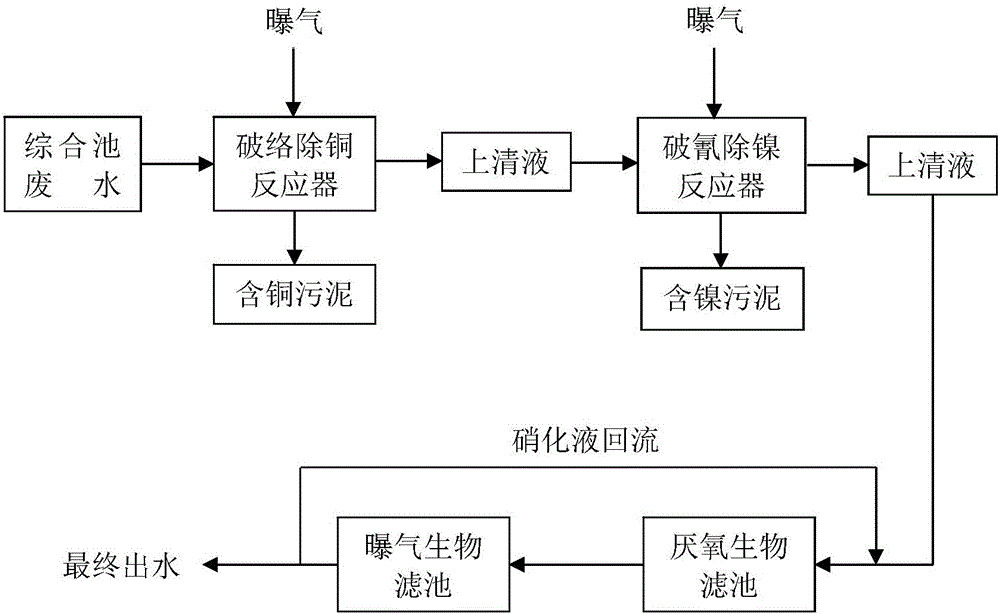

[0038] Taken from the waste water of a comprehensive pool of a circuit board factory (total copper = 180-200mg / L, total nickel = 0.9-1.5mg / L, COD Cr =450~550mg / L, ammonia nitrogen=35~45mg / L, total nitrogen=65~75mg / L, total phosphorus=3.8~4.5mg / L), press figure 1 process as shown.

[0039] First, adjust the pH of wastewater from a comprehensive pool of a circuit board factory to 3 to 4, pump it into the copper-breaking reactor with a metering pump, add Pall ring fillers to the reactor according to the effective volume of the reactor at 0.1kg / L, and react There is an aerator at the bottom of the tank for aeration to control the concentration of dissolved oxygen in the water to 2.5-4.0mg / L, and the residence time is 1h;

[0040] Add 10% sodium hydroxide solution to the effluent of the copper removal reactor to adjust the pH=8~9, then add commercially available anionic flocculant polyacrylamide (PAM), the dosage of PAM is 0.5mg / L, stir After 10 minutes of coagulation reaction (r...

Embodiment 2

[0046] Taken from the waste water of a comprehensive pool of a circuit board factory (total copper = 180-200mg / L, total nickel = 0.9-1.5mg / L, COD Cr =450~550mg / L, ammonia nitrogen=35~45mg / L, total nitrogen=65~75mg / L, total phosphorus=3.8~4.5mg / L), press figure 1 process as shown.

[0047] First, adjust the pH of wastewater from a comprehensive pool of a circuit board factory to 3 to 4, pump it into the decomplexation and copper removal reactor with a metering pump, and add Pall ring fillers to the reactor according to the effective volume of the reactor at 0.05kg / L, and react There is an aerator at the bottom of the device for aeration, and the dissolved oxygen concentration in the water is controlled to 2.5-4.0mg / L, and the residence time is 1.5h;

[0048] Add 10% sodium hydroxide solution to the effluent of the copper removal reactor to adjust the pH=8~9, then add commercially available anionic flocculant polyacrylamide (PAM), the dosage of PAM is 0.8mg / L, stir After 20 mi...

Embodiment 3

[0057] Taken from the waste water of a comprehensive pool of a circuit board factory (total copper = 180-200mg / L, total nickel = 0.9-1.5mg / L, COD Cr =450~550mg / L, ammonia nitrogen=35~45mg / L, total nitrogen=65~75mg / L, total phosphorus=3.8~4.5mg / L), press figure 1 process as shown.

[0058] First, adjust the pH of the waste water from a comprehensive pool of a circuit board factory to 3~4, pump it into the copper removal reactor with a metering pump, add Pall ring fillers to the reactor according to the effective volume of the reactor of 0.15kg / L, and react There is an aerator at the bottom of the device for aeration, and the dissolved oxygen concentration in the water is controlled to 2.5-4.0mg / L, and the residence time is 0.5h;

[0059] Add 10% sodium hydroxide solution to the effluent of the copper removal reactor to adjust the pH=8~9, then add commercially available anionic flocculant polyacrylamide (PAM), the dosage of PAM is 0.3mg / L, stir After 10 minutes of coagulation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com