Device and method for treating petrochemical wastewater by using anaerobic hydrolysis acidification-A/O biological membrane method

A technology for hydrolyzing acidification and petrochemical wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

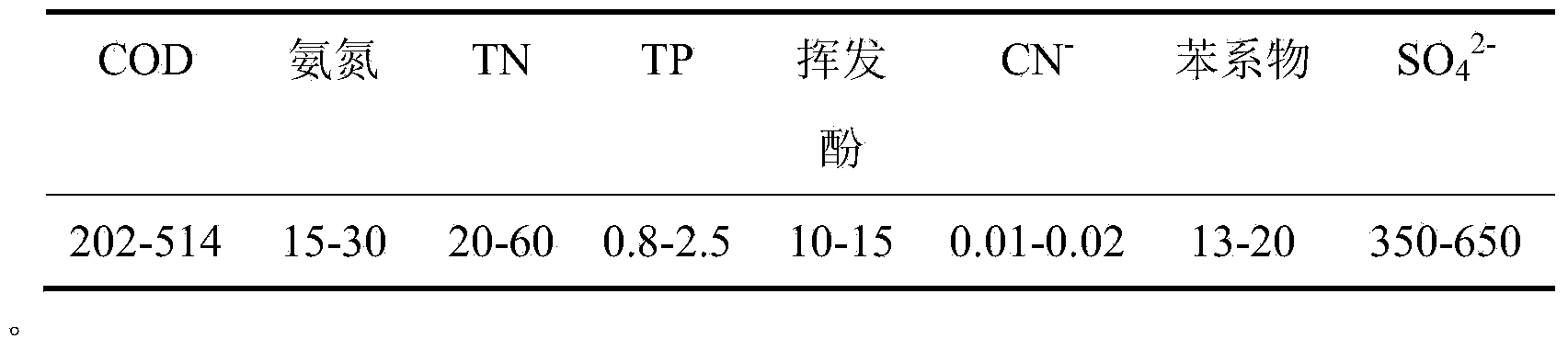

Embodiment 1

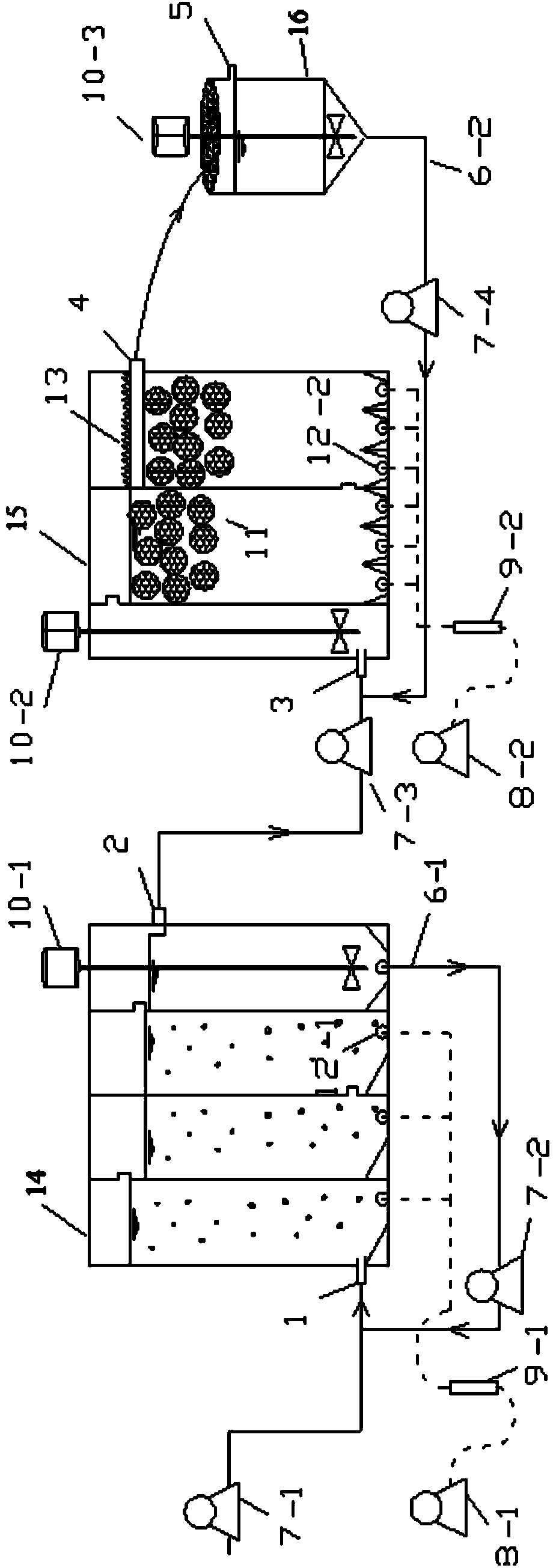

[0028] A device for treating petrochemical wastewater by microaerobic hydrolytic acidification-A / O biofilm method, which is composed of a hydrolytic acidification tank, an A / O biofilm reactor and a secondary sedimentation tank connected in sequence; an aeration tube is arranged at the bottom of the hydrolysis acidification tank , by controlling the amount of aeration to make it in the state of microaerobic hydrolysis and acidification; the O section of the A / O biofilm reactor is filled with biological fillers, and the volume filling rate is 30%.

[0029] The biological filler is a porous plastic ball carrier filled with polyurethane foam; each porous plastic ball is filled with four polyurethane foams of 1 cm square.

[0030] A sedimentation tank is provided at the end of the hydrolytic acidification tank for sludge reflux.

[0031] A sludge return pipe is set between the secondary settling tank and section A of the A / O biofilm reactor, and the sludge from the secondary settli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com