Ternary electrolytic sewage treatment combined process

A combined process and electrolysis of sewage technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve time-consuming and labor-consuming, unstable water outlet indication, and secondary air pollution And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in combination with specific embodiments.

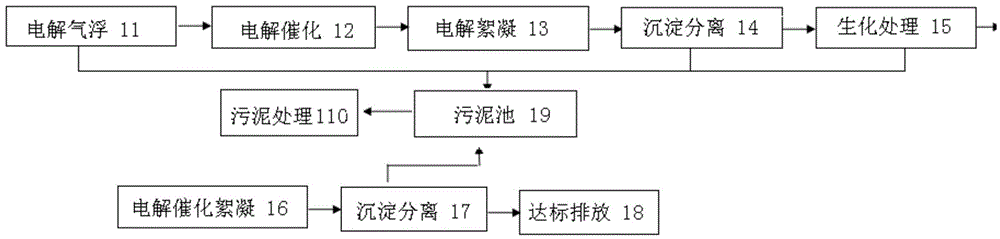

[0041] see figure 1 , a three-way electrolytic sewage treatment combined process embodiment 1, which is suitable for petroleum and petrochemical sewage treatment. The steps are: electrolytic air flotation 11, electrolytic catalysis 12, electrolytic flocculation 13, and sedimentation separation 14 for difficult sewage. , biochemical treatment 15, electrolytic catalytic flocculation 16 and precipitation separation 17 steps, the obtained water is tested and discharged 18, and at the same time, the electrolytic air flotation 11, precipitation separation 14, biochemical treatment 15, precipitation separation 16 steps obtained Sludge treatment 110 is performed after the sludge is transported to the sludge tank 19 .

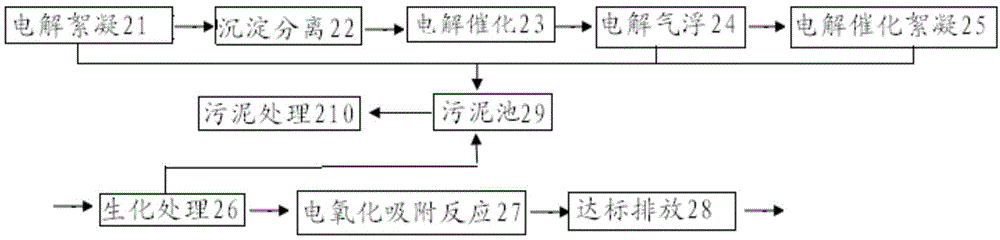

[0042] see figure 2 , a second embodiment of a three-element electrolytic sewage treatment combined process, which is suitable for waste water treatment such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com