Advanced treatment technology of petrochemical wastewater

A petrochemical and advanced treatment technology, applied in natural water treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of high equipment cost and treatment cost, low sludge operating cost, and poor operation Stability and other issues, to achieve the effect suitable for large-scale industrial application, cheap raw materials, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

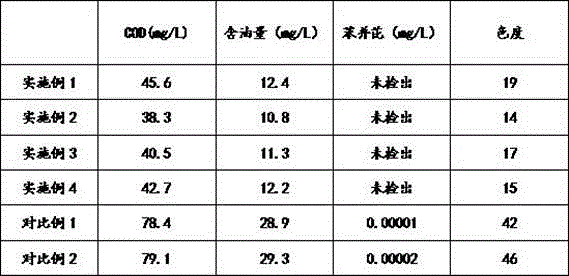

Examples

Embodiment 1

[0026] (1) Discharge the industrial wastewater into the adsorption tank, add an appropriate amount of cinder for adsorption treatment, the particle size of the cinder is 1.5mm, then pass the wastewater through the grid to remove solid impurities, and then send it to the sedimentation tank for sedimentation treatment;

[0027] (2) Collect the supernatant after the precipitation treatment, and add a composite treatment agent according to the dosage of 20mg / L of wastewater. The composite treatment agent is composed of the following components: 50 parts of modified starch, 45 parts of silicon carbonate, hydrogen 40 parts of alumina, 35 parts of polyferric sulfate, 30 parts of polysilicon aluminum sulfate, 20 parts of calcite powder, 15 parts of opal powder, 10 parts of sodium hypochlorite, 8 parts of polyaluminum calcium chloride, 4 parts of sodium hydroxide, glacial acetic acid 4 parts, 3 parts of 3-oxo-1-cyclopentanecarboxylic acid, 1 part of potassium ethoxide, 1 part of pilocar...

Embodiment 2

[0034](1) Discharge industrial wastewater into the adsorption tank, add an appropriate amount of cinder for adsorption treatment, the particle size of the cinder is 2 mm, then pass the wastewater through the grid to remove solid impurities, and then send it to the sedimentation tank for sedimentation treatment;

[0035] (2) Collect the supernatant after precipitation treatment, and add a composite treatment agent according to the dosage of 25 mg / L wastewater. The composite treatment agent is composed of the following components: 55 parts of modified starch, 50 parts of silicon carbonate, 45 parts of aluminum hydroxide, 40 parts of polyferric sulfate, 35 parts of polysilicon aluminum sulfate, 25 parts of calcite powder, 20 parts of opal powder, 15 parts of sodium hypochlorite, 10 parts of polyaluminum calcium chloride, 5 parts of sodium hydroxide tablet alkali, ice 5 parts of acetic acid, 4 parts of 3-oxo-1-cyclopentanecarboxylic acid, 2 parts of potassium ethylate, 2 parts of p...

Embodiment 3

[0042] (1) Discharge industrial wastewater into the adsorption tank, add an appropriate amount of cinder for adsorption treatment, the particle size of cinder is 2.5mm, then pass the wastewater through the grid to remove solid impurities, and then send it to the sedimentation tank for sedimentation treatment;

[0043] (2) Collect the supernatant after the precipitation treatment, and add a composite treatment agent according to the dosage of 30mg / L wastewater. The composite treatment agent is composed of the following components: 60 parts of modified starch, 55 parts of silicon carbonate, hydrogen 50 parts of alumina, 45 parts of polyferric sulfate, 40 parts of polysilicon aluminum sulfate, 30 parts of calcite powder, 25 parts of opal powder, 20 parts of sodium hypochlorite, 12 parts of polyaluminum calcium chloride, 6 parts of sodium hydroxide, glacial acetic acid 6 parts, 5 parts of 3-oxo-1-cyclopentanecarboxylic acid, 3 parts of potassium ethoxide, 3 parts of pilocarpine, 25...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com