Petrified waste water treatment process

A petrochemical wastewater treatment technology, applied in flotation water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. complex problems, to achieve good economic and social benefits, reduce environmental pollution, and simple equipment technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

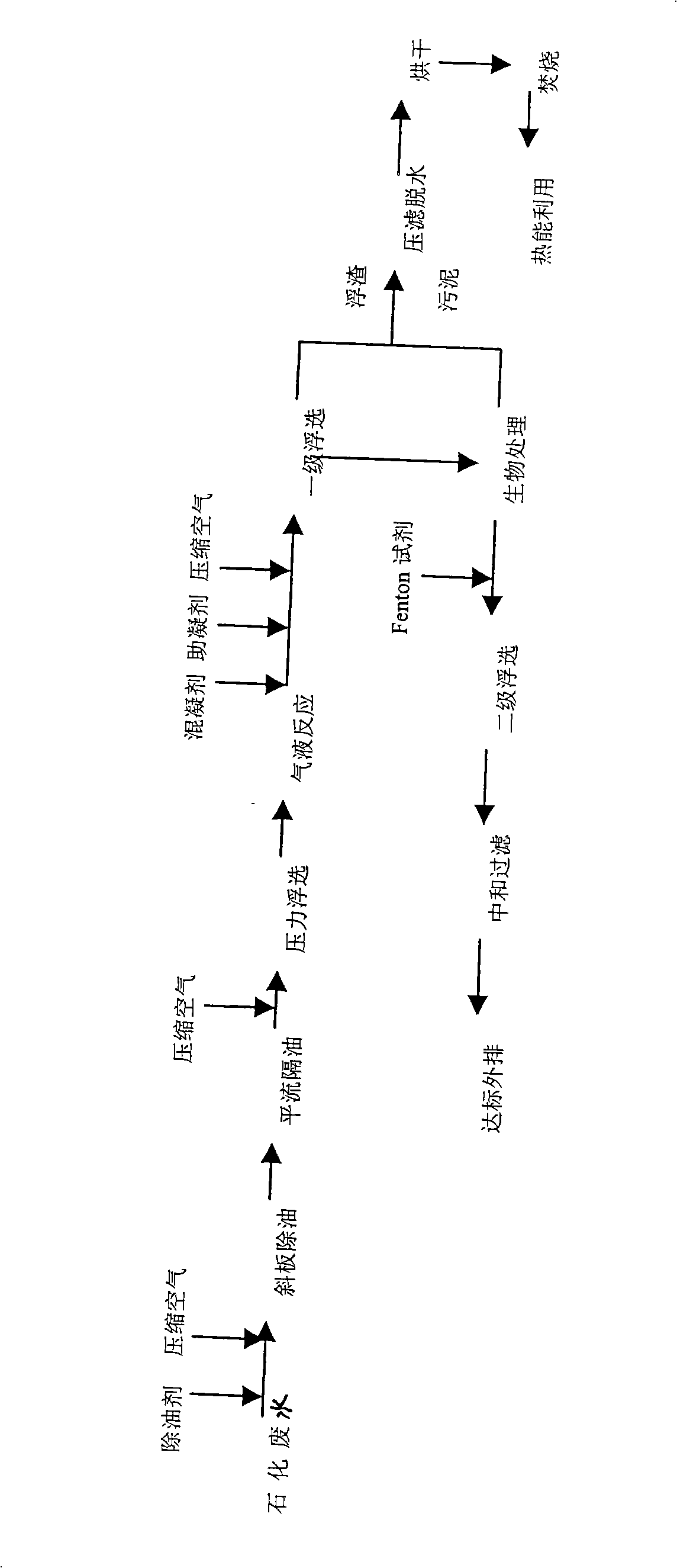

[0015] As shown in the figure, the petrochemical wastewater treatment process provided by the present invention includes inclined plate oil removal, advection oil separation, pressure flotation, gas-liquid reaction primary flotation, biological treatment, secondary flotation, neutralization filtration, scum, There are multiple processes for sludge treatment, and good effects can be obtained in terms of sewage treatment, oil recovery, and heat energy utilization according to the aforementioned implementation steps.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com