High-salt waste water treatment method

A technology for high-salt wastewater and wastewater, applied in seawater treatment, return water treatment, water/sewage treatment, etc., can solve the problems of no treatment method, ecological environment troubles, etc., to extend continuous and stable operation time, the method is simple and easy The effect of low running and running costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

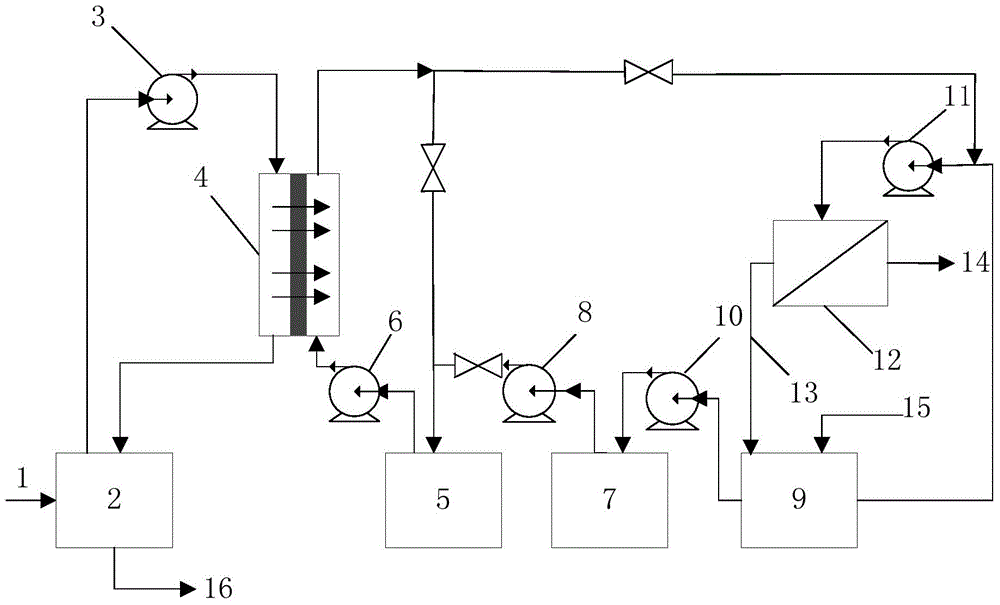

[0049] For a schematic diagram of the process, see figure 1 . The water quality characteristics of high-salt wastewater 15 in the figure are: wastewater pH6.5-8.5, conductance 9000-13000μs / cm, COD cr 0~100mg / L, Cl - 2000~5000mg / L, Ca 2+ 0~70mg / L, Mg 2+ 0~100mg / L, soluble silicon 0~50mg / L, NH 4 -N0~5mg / L. Forward osmosis raw water 1 is a glucose solution with a mass concentration of 5%.

[0050] The forward osmosis membrane module used is a cellulose acetate plate-and-frame membrane module; the membrane distillation module used is a polytetrafluoroethylene (PTFE) hollow fiber hydrophobic membrane module with a membrane pore size of 0.2 μm, and the membrane distillation form is an internal pressure vacuum membrane distillation.

[0051] The steps are as follows: (1) The high-salt wastewater 15 enters the membrane distillation heating pool 9, and the high-salt wastewater 15 is heated to 60° C. in the membrane distillation heating pool. After that, the heated high-salt waste...

Embodiment 2

[0057] For a schematic diagram of the process, see figure 1 . The water quality characteristics of the high-salt wastewater 15 are the same as those in Example 1. Forward osmosis raw water 1 is a whey protein solution with a mass concentration of 5%.

[0058] The forward osmosis membrane module used is a cellulose acetate plate-and-frame membrane module; the membrane distillation module used is a polypropylene (PP) hollow fiber hydrophobic membrane module with a membrane pore size of 0.2 μm, and the membrane distillation form is an internal pressure vacuum membrane distillation.

[0059] In the operation steps, the difference from Example 1 is that the high-salt wastewater 15 is heated to 70°C in the membrane distillation heating pool; when the conductivity of the membrane distillation concentrated water in the membrane distillation heating pool 9 reaches 180,000 μs / cm, the The distilled concentrated water raw water pump 10 is pumped into the membrane distillation concentrat...

Embodiment 3

[0065] For a schematic diagram of the process, see figure 1 . The water quality characteristics of the high-salt wastewater 15 are the same as those in Example 1. Forward osmosis raw water 1 is a whey protein solution with a mass concentration of 5%.

[0066] The forward osmosis membrane module used is a cellulose acetate plate-and-frame membrane module; the membrane distillation module used is a polypropylene (PP) hollow fiber hydrophobic membrane module with a membrane pore size of 0.2 μm, and the membrane distillation form is an internal pressure vacuum membrane distillation.

[0067] In the operation steps, the difference from Example 1 is that the high-salt wastewater 15 is heated to 70°C in the membrane distillation heating pool; when the conductivity of the membrane distillation concentrated water in the membrane distillation heating pool 9 reaches 200,000 μs / cm, the The distilled concentrated water raw water pump 10 is pumped into the membrane distillation concentrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductance | aaaaa | aaaaa |

| Membrane pore size | aaaaa | aaaaa |

| Conductance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com