Biomembrane treatment method of two-step wet-spun acrylic fiber wastewater

A treatment method and biofilm technology, applied in textile industry wastewater treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as increasing wastewater treatment costs, affecting water quality, and substandard sulfate radicals. Achieve the effect of reducing the cost of secondary treatment, avoiding sludge bulking, and reducing the amount of excess sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

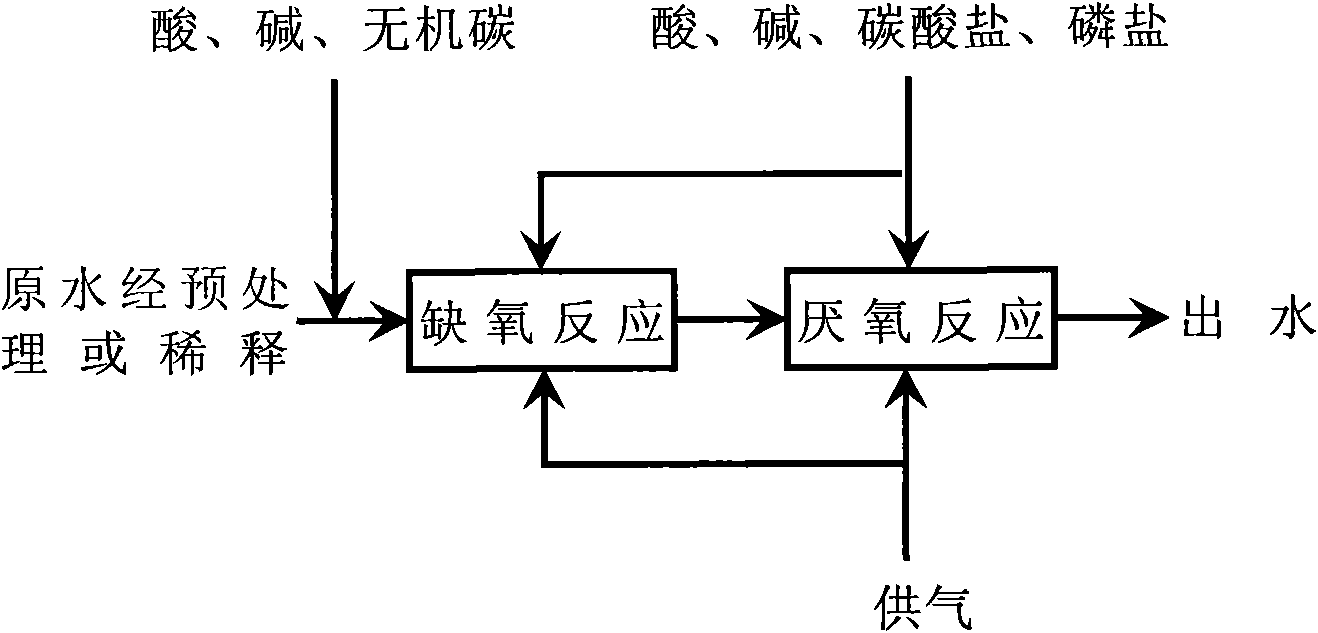

Method used

Image

Examples

specific Embodiment 1-

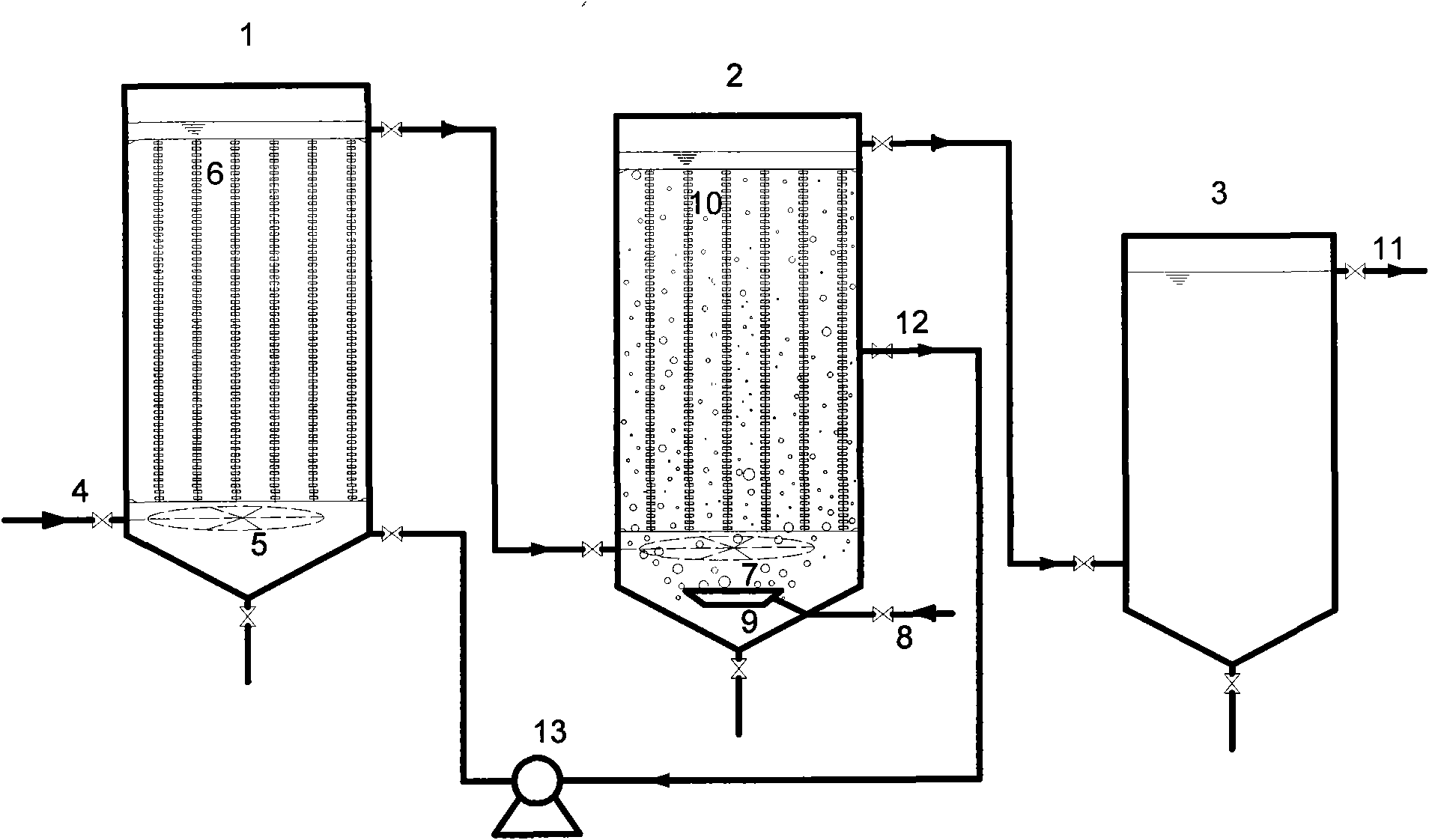

[0047] The acrylic fiber production line of a chemical fiber factory has an annual production capacity of 100,000 tons. The raw materials of the polymerization unit are vinyl acetate, acrylonitrile and desalinated water. The auxiliary materials include ammonium persulfate, sulfuric acid, ferrous sulfate, sodium bisulfate, etc.; Amine synthesis DMAC ready-to-use. The wastewater mainly comes from the polymerization unit, and some wastewater is also generated from the spinning unit and solvent recovery unit. The regulating tank of the wastewater treatment plant receives all production wastewater and domestic wastewater from the polymerization unit, spinning unit, solvent recovery unit, etc. This mixed wastewater is treated by the following method.

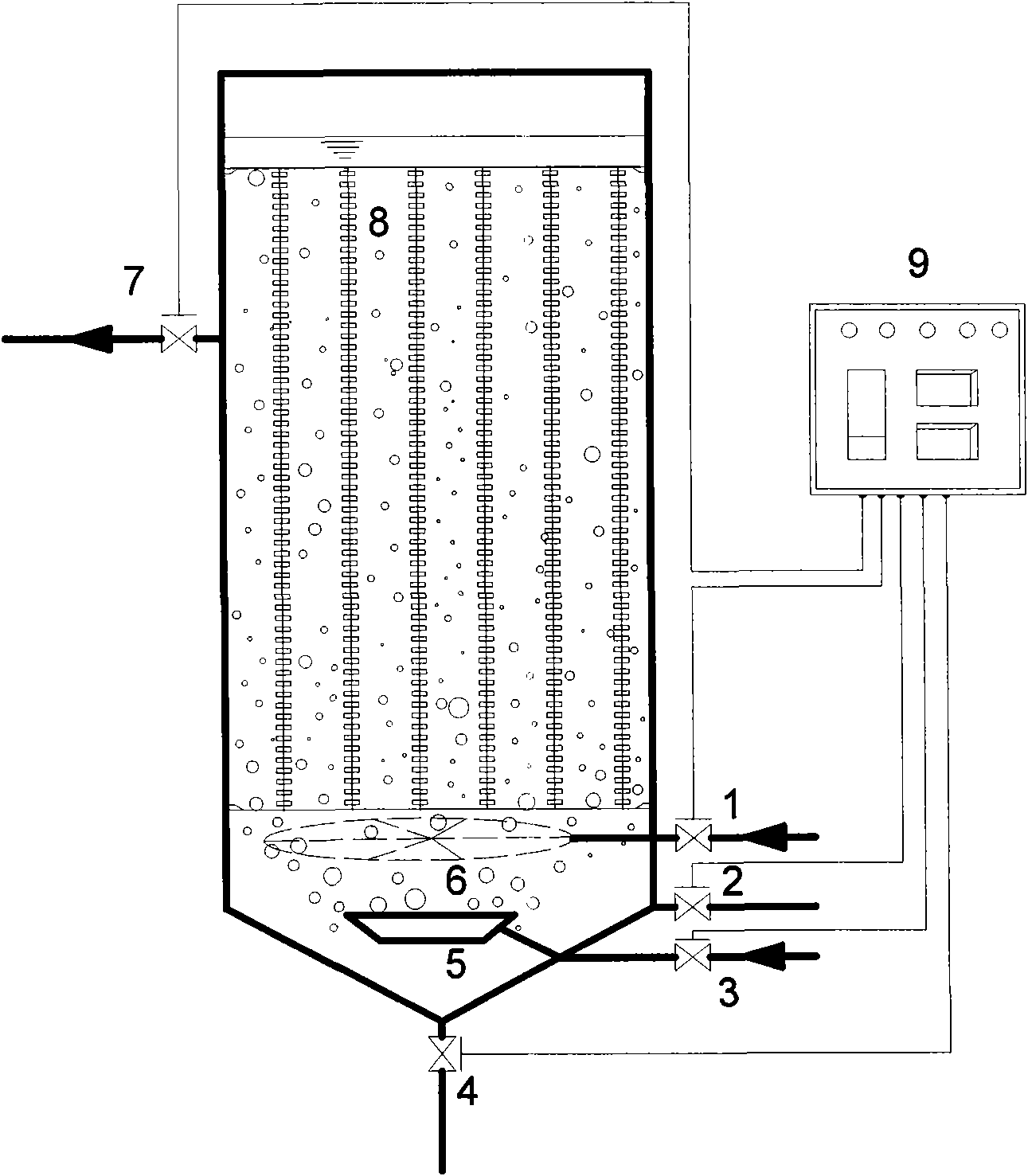

[0048]After the mixed wastewater meets the corresponding water quality requirements through physical and chemical pretreatment, it is lifted to the present invention with a pump. The waste water enters through the water inlet (1) an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com