Method and apparatus for removing sulfate in high-salt petrochemical wastewater

A technology for petrochemical sewage and sulfate radicals, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of no industrial application examples, single ingredients, long inoculation and acclimation period, etc. , to achieve the effect of improving stability, improving removal rate and reducing scaling tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

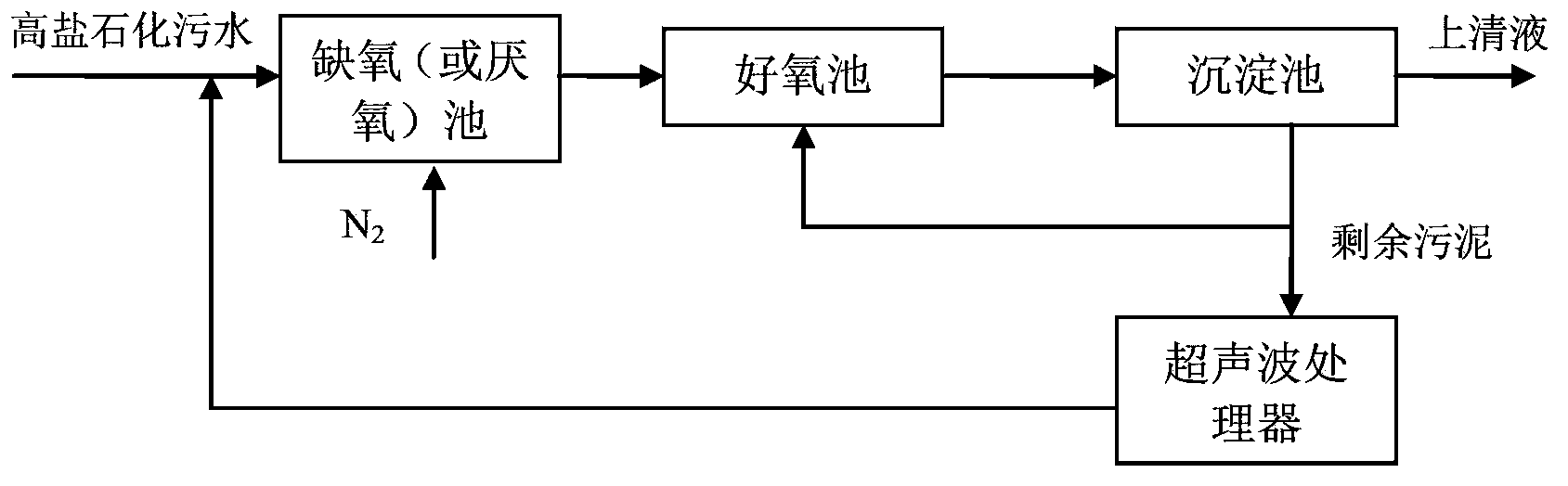

[0034] The residual sludge with a solid content of 3.2% produced by the high-salinity petrochemical sewage biochemical treatment system was treated by a double-headed ultrasonic processor. 40% of the remaining sludge enters the ultrasonic processor, the frequency of the remaining sludge is 20-30kHz, and the sound intensity is 20W / cm 2 After ultrasonic treatment for 5 minutes, the obtained sludge was mixed with high-salt petrochemical sewage to make the COD / SO in high-salt petrochemical sewage 4 2- =1.5, and then return to the anoxic pool of the sewage treatment system. The dissolved oxygen in the anoxic pool is controlled at 0.5mg / L, the pH value is 6.5-8.5, the water temperature is 25-35°C, the reflux ratio is 200%, and the residence time is maintained at 8.6h. The initial concentration of sulfate in high-salinity petrochemical wastewater was 556 mg / L. After anoxic treatment, the concentration of sulfate in the effluent was reduced to 221 mg / L, and the removal rate of sulfa...

Embodiment 2

[0037] The residual sludge with a solid content of 3.2% produced by the high-salinity petrochemical sewage biochemical treatment system was treated by a double-headed ultrasonic processor. 40% of the remaining sludge enters the ultrasonic processor, the frequency of the remaining sludge is 20-30kHz, and the sound intensity is 20W / cm 2 After 5 minutes of ultrasonic treatment, the obtained sludge supernatant was mixed with high-salt petrochemical sewage to make the COD / SO in high-salt and refractory sewage 4 2- =1.5, and then return to the anaerobic tank of the sewage treatment system. The dissolved oxygen in the anaerobic tank is controlled at 0.2mg / L, the pH value is 6.5-8.5, the water temperature is 25-35°C, the reflux ratio is 200%, and the residence time is maintained at 8.6h. The initial concentration of sulfate radicals in high-salt petrochemical wastewater was 583 mg / L. After anaerobic treatment, the sulfate radical concentration in the effluent was reduced to 215 mg / L...

Embodiment 3

[0040] The residual sludge with a solid content of 3.8% produced by the high-salinity petrochemical sewage biochemical treatment system was treated by a double-headed ultrasonic processor. 60% of the remaining sludge enters the ultrasonic processor, the frequency of the remaining sludge is 20-30kHz, and the sound intensity is 25W / cm 2 After 8 minutes of ultrasonic treatment, the obtained sludge was mixed with high-salt petrochemical sewage to make the COD / SO in high-salt petrochemical sewage 4 2- =2.0, and then return to the anoxic pool of the sewage treatment system. The dissolved oxygen in the anoxic pool is controlled at 0.5mg / L, the pH value is 6.5-8.5, the water temperature is 25-35°C, the reflux ratio is 300%, and the residence time is maintained at 8.6h. The initial concentration of sulfate in high-salinity petrochemical wastewater was 776mg / L. After anoxic treatment, the concentration of sulfate in the effluent was reduced to 186mg / L, and the removal rate of sulfate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com