Composite slow-release scale inhibitor suitable for petrochemical wastewater reusing circulating water system

A technology for circulating water systems and petrochemical sewage, applied in water/sludge/sewage treatment, descaling and water softening, chemical instruments and methods, etc., can solve problems such as high cost, difficult operation of covering protective layer, complex internal structure, etc. , to achieve the effects of low production and use costs, good corrosion and scale inhibition effects, and easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

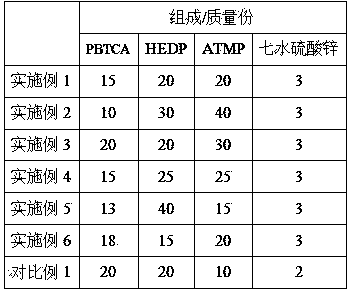

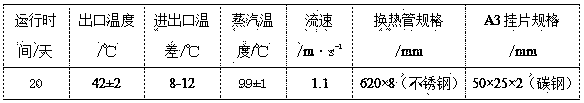

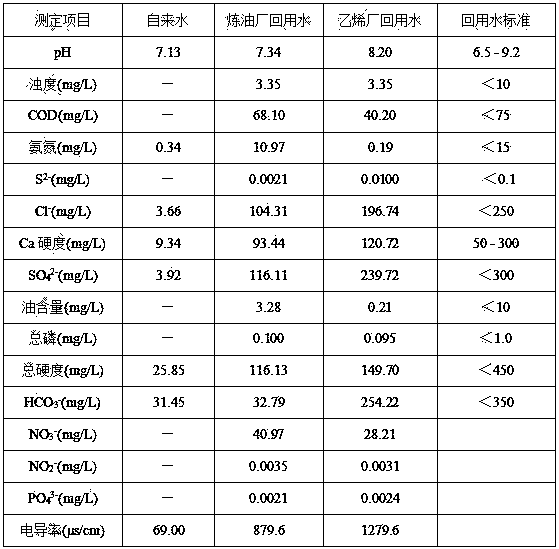

Method used

Image

Examples

Embodiment 1

[0030] The corrosion inhibitor in Example 1 has a scale inhibition rate of 87.42%. A dynamic simulation experiment was carried out on the reuse water of an oil refinery. The corrosion inhibition rate was 86.18%, and the corrosion rate had dropped to 0.0168 mm / a; a dynamic simulation experiment was carried out on the reuse water of an ethylene plant. , the corrosion inhibition rate is 86.44%, and the corrosion rate has dropped to 0.0091 mm / a, which meets the anti-corrosion requirement of Sinopec's circulating cooling water with a corrosion rate of less than 0.075 mm / a.

[0031] Taking the product RP-98 (polyphosphorus carboxylate compound slow-release scale inhibitor) of a chemical company in Maoming as a comparison, the scale inhibition rate of the agent is 90.34%, and when the dosage is 100mg / L, the dynamic simulation of the reuse water of the refinery is carried out In the experiment, the corrosion inhibition rate was 89.54%, and the corrosion rate was 0.0034 mm / a; the dynami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com