Treatment method of petrochemical wastewater

A petrochemical and treatment method technology, applied in the field of petrochemical wastewater treatment, can solve the problems of low treatment efficiency, difficult to meet the standard discharge wastewater treatment system design and operation, complex and other problems, achieve high pollutant removal rate, good economic benefits, reduce The effect of usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

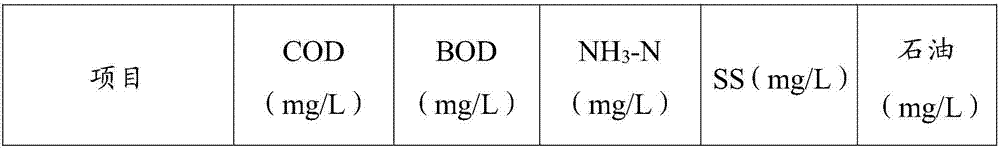

[0034] A treatment method for petrochemical wastewater, comprising the steps of:

[0035] Step 1, oil separation treatment: collect petrochemical wastewater, pass it into the grease trap, and use the oil scraper to scrape the oil on the water surface to obtain the effluent from the grease trap;

[0036] Step 2, air flotation treatment: the water from the oil separation tank enters the air flotation tank to remove SS, oil slick and COD. The air flotation tank adopts pressurized dissolved air flotation, the pressure of the pressurized dissolved air is 0.5Mpa, the volume ratio of steam to water is 0.5:1, and the reflux The ratio is 20%, the waste gas residence time is 50min, and the air flotation scum is processed by the chain scraper machine to obtain the effluent of the air flotation tank;

[0037] Step 3, advanced oxidation and flocculation treatment: the effluent from the air flotation tank enters the advanced oxidation tank, and the advanced oxidation tank is equipped with a...

Embodiment 2

[0044] A treatment method for petrochemical wastewater, comprising the steps of:

[0045] Step 1, oil separation treatment: collect petrochemical wastewater, pass it into the grease trap, and use the oil scraper to scrape the oil on the water surface to obtain the effluent from the grease trap;

[0046] Step 2, air flotation treatment: the water from the grease trap enters the air flotation tank to remove SS, oil slick and COD. The air flotation tank adopts pressurized dissolved air flotation, the pressure of the pressurized dissolved air is 0.6Mpa, the volume ratio of steam to water is 0.1:1, and the reflux The ratio is 30%, the waste gas residence time is 60min, and the air flotation scum is processed by the chain scraper machine to obtain the effluent of the air flotation tank;

[0047] Step 3, advanced oxidation and flocculation treatment: the effluent from the air flotation tank enters the advanced oxidation tank, and the advanced oxidation tank is equipped with a pH onli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com