Method for treating reverse osmosis concentrates of petrochemical wastewater

A technology of reverse osmosis concentrate and petrochemical wastewater, applied in the direction of oxidized water/sewage treatment, etc., can solve the problems of immature research on the standard treatment of reverse osmosis concentrate, and achieve the effect of simple method and good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

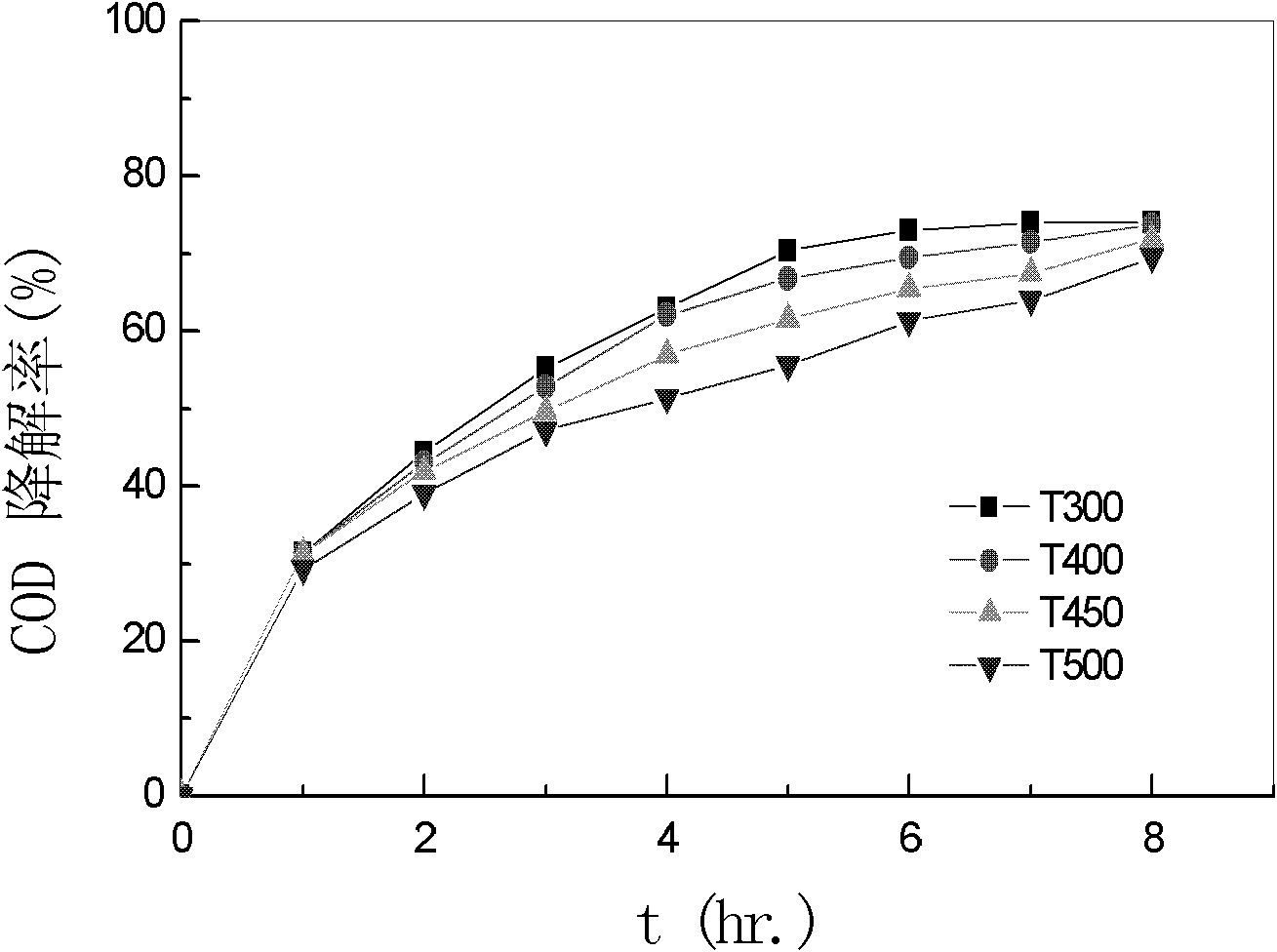

[0034] Example 1. Preparation and Application of Single Manganese Catalyst for Ozone Multiphase Catalytic Oxidation Treatment of Reverse Osmosis Concentrate

[0035] 1. Preparation of single manganese catalyst

[0036] Prepare a certain concentration of manganese nitrate solution, take 150 grams of alumina carrier (particle size 3 ~ 5mm) dry impregnation with the above solution, the impregnation solution is basically blotted; after standing for 12 hours to dry, then dry at 80 ° C for 12 hours, Then roasting at a certain temperature for 4 hours, the nitrates are decomposed into metal oxides, which are fixed on the carrier to make a finished solid catalyst, and the loading capacity of the prepared catalyst active component is 6%.

[0037] In this example, the catalysts were calcined at 300° C., 400° C., 450° C. and 500° C. to prepare finished single manganese catalysts at different calcination temperatures.

[0038] 2. Ozone multi-phase catalytic oxidation treatment method for ...

Embodiment 2

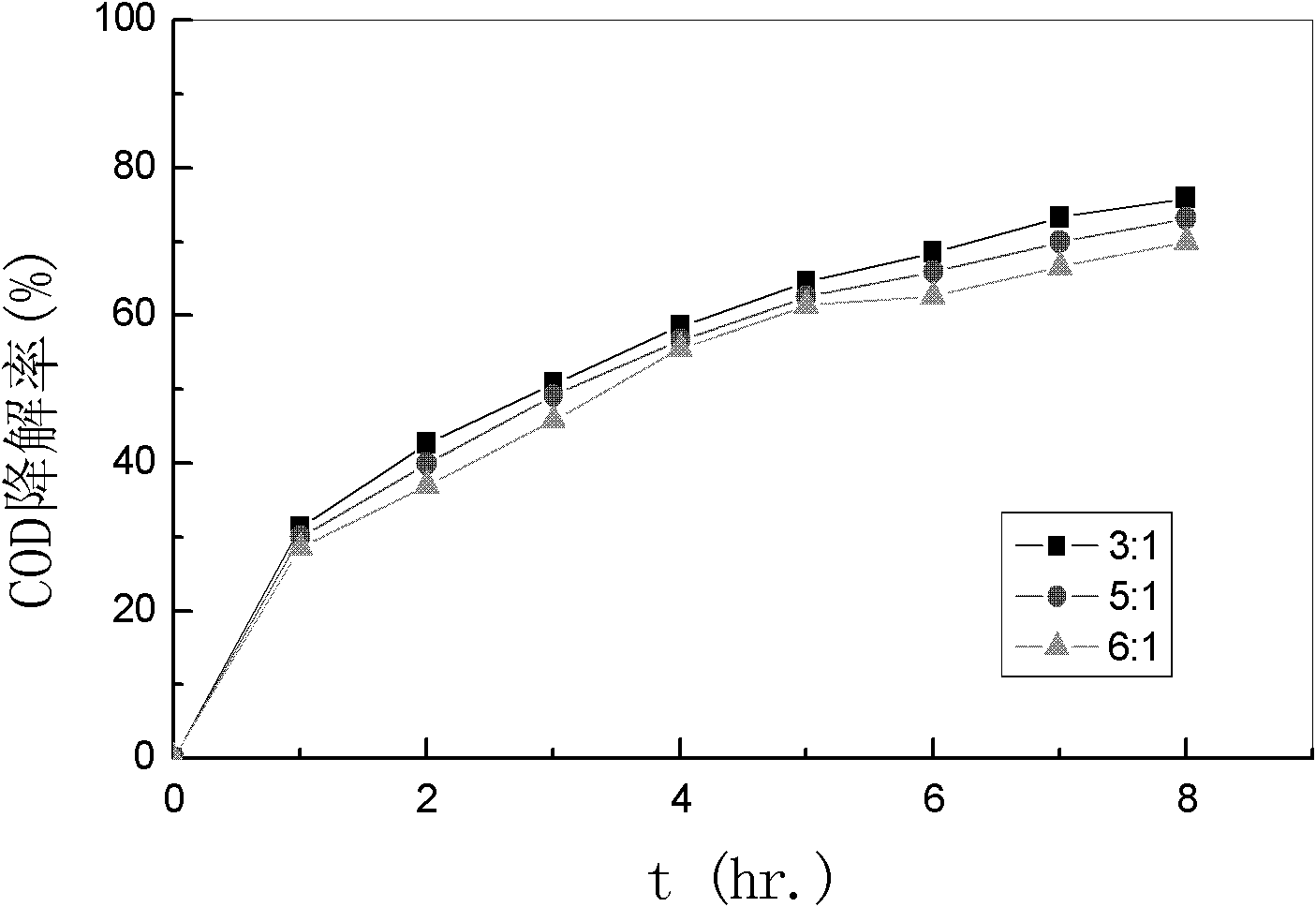

[0044] Example 2. Preparation and Application of Copper-Manganese Two-Component Catalyst for Ozone Multiphase Catalytic Oxidation Treatment of Reverse Osmosis Concentrate

[0045] Some copper components are infiltrated into the single Mn catalyst to prepare the copper-manganese two-component catalyst. According to the ratio of manganese and copper, prepare a mixed solution of manganese nitrate and copper nitrate with a certain concentration, take 150 grams of activated carbon carrier (particle size 3 ~ 5mm) and dry impregnate with the above solution, and the impregnating solution is basically blotted dry; after standing for 12 hours to dry, then After drying at 80°C for 12 hours, and then roasting at 450°C for 4 hours, the nitrates are decomposed into metal oxides and fixed on the carrier to make a finished solid catalyst. The prepared catalyst active component has a loading capacity of 6 %.

[0046] In this example, the prepared copper-manganese dual-component catalyst was u...

Embodiment 3

[0049] Example 3. Ozone multi-phase catalytic oxidation treatment of reverse osmosis concentrated solution under different initial pH conditions of water samples

[0050] Select the manganese-copper 3:1 (mass ratio) catalyst prepared in Example 2, abbreviated as ZYW-1. The initial pH value of the water sample was adjusted to 5, 7 and 11 with sodium hydroxide or sulfuric acid solution, respectively, and the reverse osmosis concentrated solution was treated with ozone multiphase catalytic oxidation. The results are shown in Table 3 and Figure 5 , Figure 6 . It can be seen that the initial pH value of the water sample has little difference in the degradation rate of COD under acidic and neutral conditions, although the degradation rate under alkaline conditions is slightly higher, but the difference is not significant (see Table 3, Figure 5 ). On ozone depletion, alkaline under O 3 The consumption is much greater than that of acidic and neutral lower O 3 consumption (see ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com