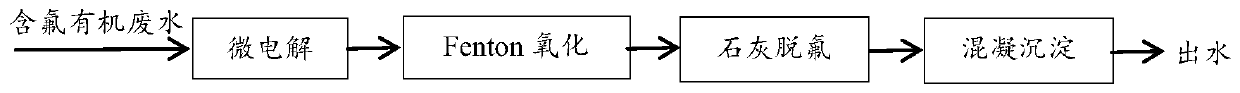

Process for treating chemical fluorine-containing wastewater by combining micro-electrolysis, Fenton and lime coagulation

A combined treatment and micro-electrolysis technology, applied in the direction of flocculation/sedimentation water/sewage treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the level and requirements of industrial production application, harmful and difficult to meet standards and other issues to achieve the effect of improving the efficiency of wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

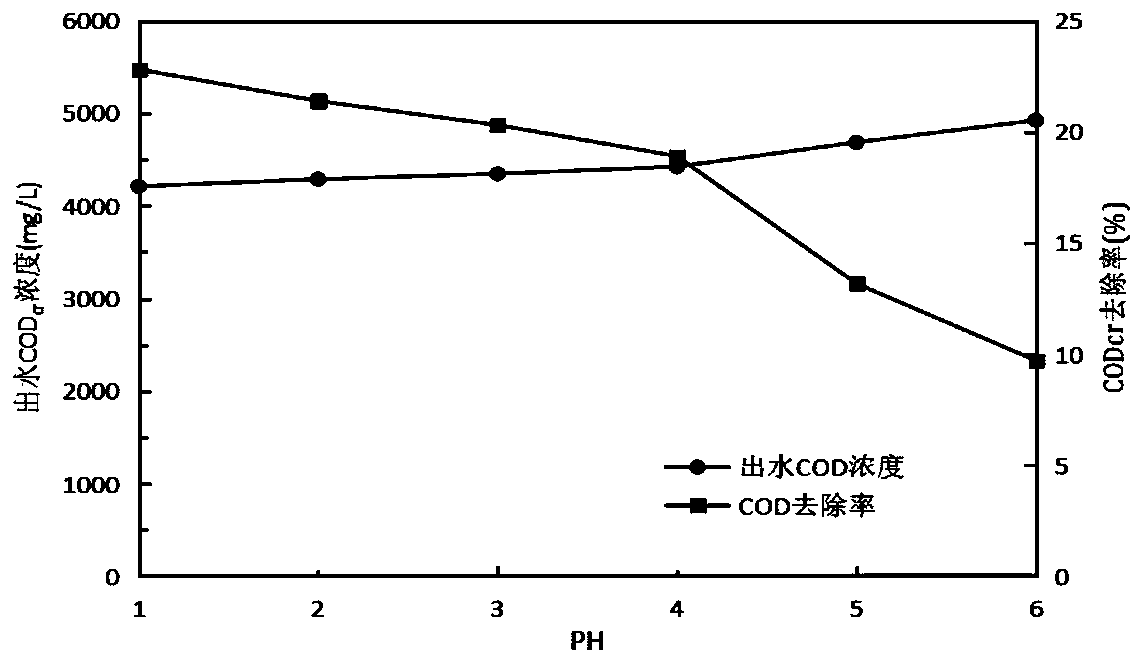

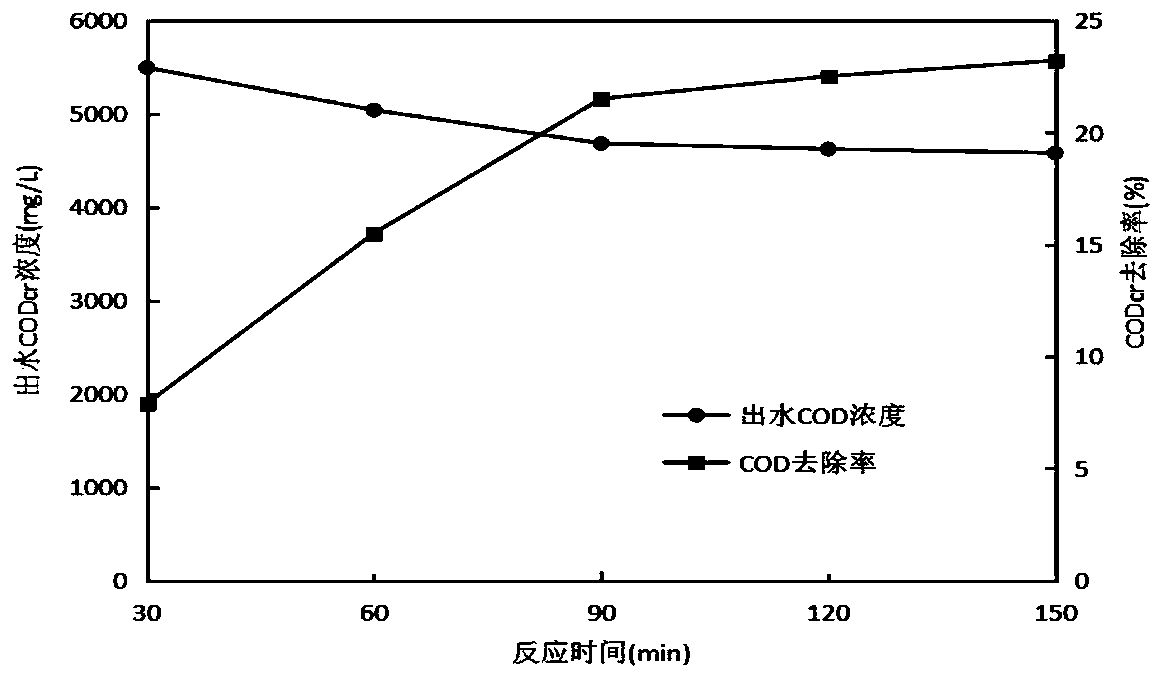

[0037] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing, and it is as a part of this specification, and the principle of the present invention is illustrated through the embodiment, and other aspects, features and advantages of the present invention will become clear at a glance through this detailed description. In the figures referred to, the same or similar parts in different figures are denoted by the same reference numerals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com