Coking wastewater treatment method with lignite and semi-coke used as novel adsorbent

A technology for coking wastewater and treatment methods, which is applied in the direction of adsorption water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems that lignite cannot be directly used, the effect of adsorption and removal is poor, and the treatment cost is high, so as to improve Wastewater treatment efficiency, low price, good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

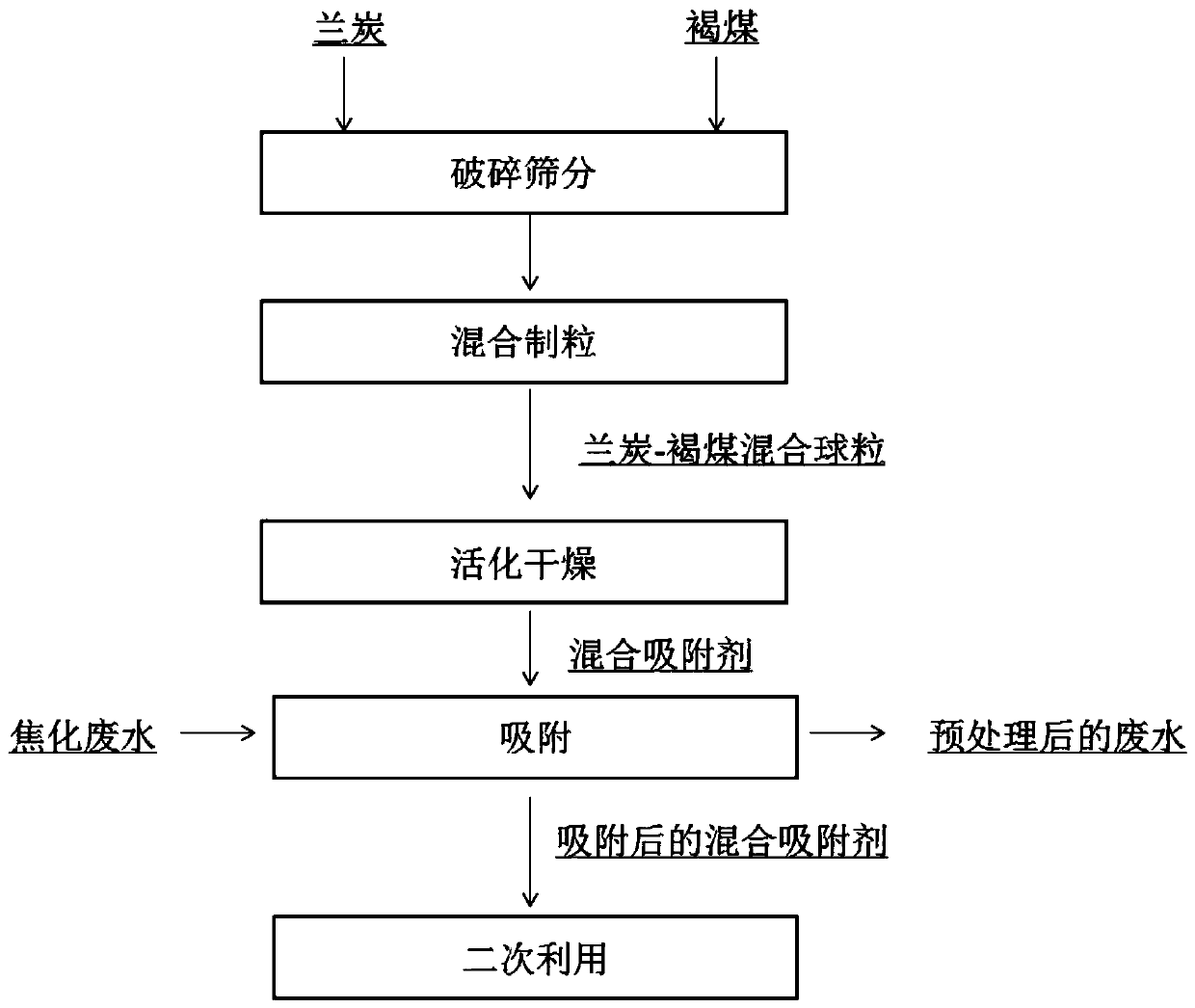

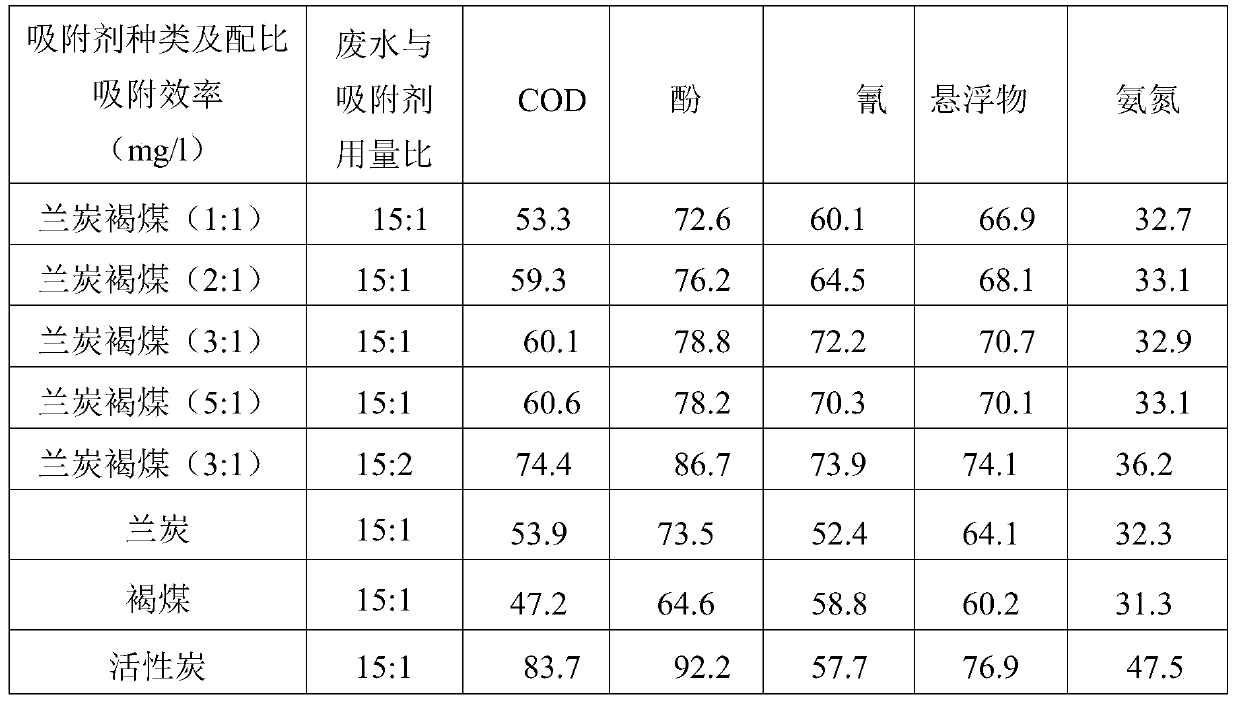

[0044] In this embodiment, a coking wastewater treatment method using lignite and semi-coke as a novel adsorbent comprises the following steps:

[0045] (1) Brown coal is pulverized to 3mm in the roller crusher, and semi-coke is crushed to 5mm in the roller crusher, and semi-coke and lignite powder meeting the requirements are obtained by screening;

[0046] (2) According to the ratio of 1:1, semi-coke and lignite are used to carry out continuous countercurrent relative movement and high-intensity full mixing of semi-coke and lignite powder with a strong mixer, in order to achieve mixed granulation of the original powder of semi-coke lignite, Obtain semi-coke-brignite mixed pellets;

[0047] (3) Activate the semi-coke-lignite mixed pellets obtained in step (2) under water vapor at 130°C, and use the surplus 130°C low-temperature hot air in iron and steel enterprises for drying treatment to make a mixed adsorbent to replace the existing coking Activated carbon as traditional a...

Embodiment 2

[0053] In this embodiment, a coking wastewater treatment method using lignite and semi-coke as a novel adsorbent comprises the following steps:

[0054] (1) Brown coal is pulverized to 3mm in the roller crusher, and semi-coke is crushed to 5mm in the roller crusher, and semi-coke and lignite powder meeting the requirements are obtained by screening;

[0055] (2) The semi-coke and lignite are mixed according to the ratio of 2:1, and the semi-coke and lignite powder are continuously mixed with high-intensity countercurrent relative motion by a powerful mixer, in order to achieve the mixed granulation of the original powder of the semi-coke lignite, Obtain semi-coke-brignite mixed pellets;

[0056] (3) Activate the semi-coke-brignite mixed pellets obtained in step (2) under 130 DEG C of water vapor, and use the surplus hot air of 180 DEG C in iron and steel enterprises to carry out drying treatment to make a mixed adsorbent;

[0057] (4) Put the mixed adsorbent into the adsorpti...

Embodiment 3

[0062] In this embodiment, a coking wastewater treatment method using lignite and semi-coke as a novel adsorbent comprises the following steps:

[0063] (1) Brown coal is pulverized to 3mm in the roller crusher, and semi-coke is crushed to 5mm in the roller crusher, and semi-coke and lignite powder meeting the requirements are obtained by screening;

[0064] (2) semi-coke and lignite are mixed and granulated according to a ratio of 3:1 to obtain semi-coke-lignite mixed pellets;

[0065] (3) Activate the semi-coke-brignite mixed pellets obtained in step (2) under 130°C water vapor, and use the surplus 130°C low-temperature hot air in iron and steel enterprises to carry out drying treatment to make a mixed adsorbent;

[0066] (4) Put the mixed adsorbent into the adsorption column, the effective adsorption height of the adsorption column is 1.5m, and pass coking wastewater into the adsorption column (control the mass ratio of coking wastewater and adsorbent to be 15:1; 2L / min), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com