Technology of treating high-concentration organic wastewater with wet type catalytic oxidation

A technology for catalytic wet oxidation of organic wastewater, applied in the direction of oxidation water/sewage treatment, water/sewage treatment, water/sludge/sewage treatment, etc., to reduce process energy consumption and improve wastewater treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

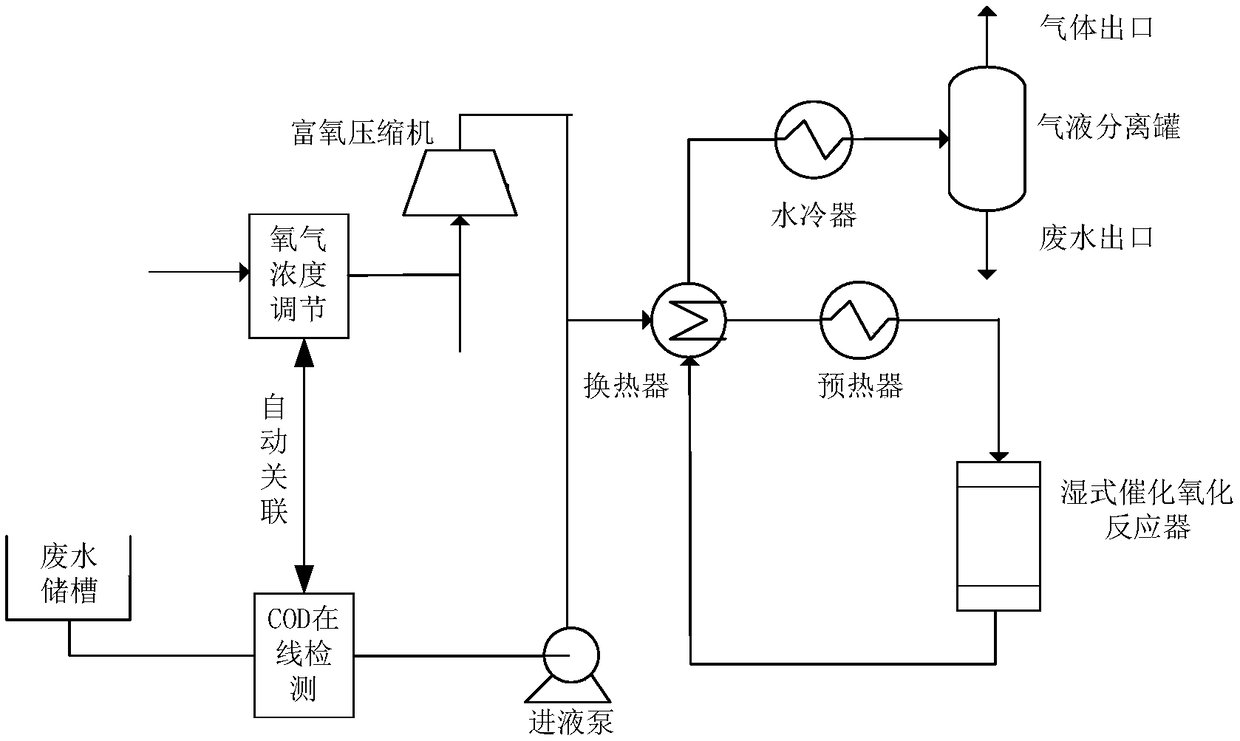

Image

Examples

Embodiment 1

[0019] The catalyst (Pd-Ag-Zn / TiO 2 , where Pd accounts for 0.44wt%, Ag accounts for 1.5wt%, Zn accounts for 0.35wt%, TiO 2 Accounting for 97.71wt%) 4ml was filled in the fixed bed reactor. The COD content of the wastewater is 10000mg / L, and the space velocity is 0.5h -1 , given that the space velocity of oxygen-enriched gas is 34 times the space velocity of wastewater (16.8h -1 ), the oxygen concentration is 1.2 times of the theoretical oxygen demand, and the oxygen generator automatically adjusts the oxygen concentration to 25%. The waste water is mixed with oxygen-enriched gas and enters the heat exchanger. After heat exchange, the gas-liquid mixture is sent to the waste water reactor for reaction at 250°C and 6.0 MPa; the water vapor after the oxidation reaction first passes through the heat exchanger and then water-cooled The temperature of the device is cooled, and then sent to the gas-liquid separation tank for gas-liquid separation, the treated water is directly dis...

Embodiment 2

[0021]The catalyst of Example 5 in CN201810389974.1 (Ru-Ag-La / molecular sieve, wherein Ru accounts for 0.3wt%, Ag accounts for 0.9wt%, La accounts for 0.05wt%, molecular sieve accounts for 98.75wt%) 4ml is packed in fixed bed reaction inside the device. The COD content of the wastewater is 30000mg / L, and the space velocity is 1h -1 , given that the space velocity of oxygen-enriched gas is 35 times the space velocity of wastewater (35h -1 ), the oxygen concentration is 1.15 times of the theoretical oxygen demand, and the oxygen generating device automatically adjusts the oxygen concentration to 69%. The waste water is mixed with oxygen-enriched gas and enters the heat exchanger. After heat exchange, the gas-liquid mixture is sent to the waste water reactor for reaction at 200°C and 5.0 MPa; the water vapor after the oxidation reaction first passes through the heat exchanger and then water-cooled After cooling down, it is sent to the gas-liquid separation tank for gas-liquid s...

Embodiment 3

[0023] The catalyst (Au-Ag-Mo / ZrO 2 , where Au accounts for 0.4wt%, Ag accounts for 1.2wt%, Mo accounts for 0.5wt%, ZrO 2 Accounting for 97.9wt%) 4ml was filled in the fixed bed reactor. The COD content of the wastewater is 20000mg / L, and the space velocity is 1.5h -1 , given that the space velocity of oxygen-enriched gas is 36 times the space velocity of wastewater (54h -1 ), the oxygen concentration is 1.2 times of the theoretical oxygen demand, and the oxygen generating device automatically adjusts the oxygen concentration to 47%. The waste water is mixed with oxygen-enriched gas and enters the heat exchanger. After heat exchange, the gas-liquid mixture is sent to the waste water reactor for reaction at 210°C and 4.0 MPa; the water vapor after the oxidation reaction first passes through the heat exchanger and then water-cooled After cooling down, it is sent to the gas-liquid separation tank for gas-liquid separation; the treated water is sent to the next treatment sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com