Heat exchanger tube, method of manufacturing heat exchanger tube, and fluidized-bed furnace

A manufacturing method and technology for heat transfer tubes, applied in the field of heat transfer tubes, can solve the problems of wear, cracks, corrosion of heat transfer tubes, etc., and achieve the effect of reducing inspections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

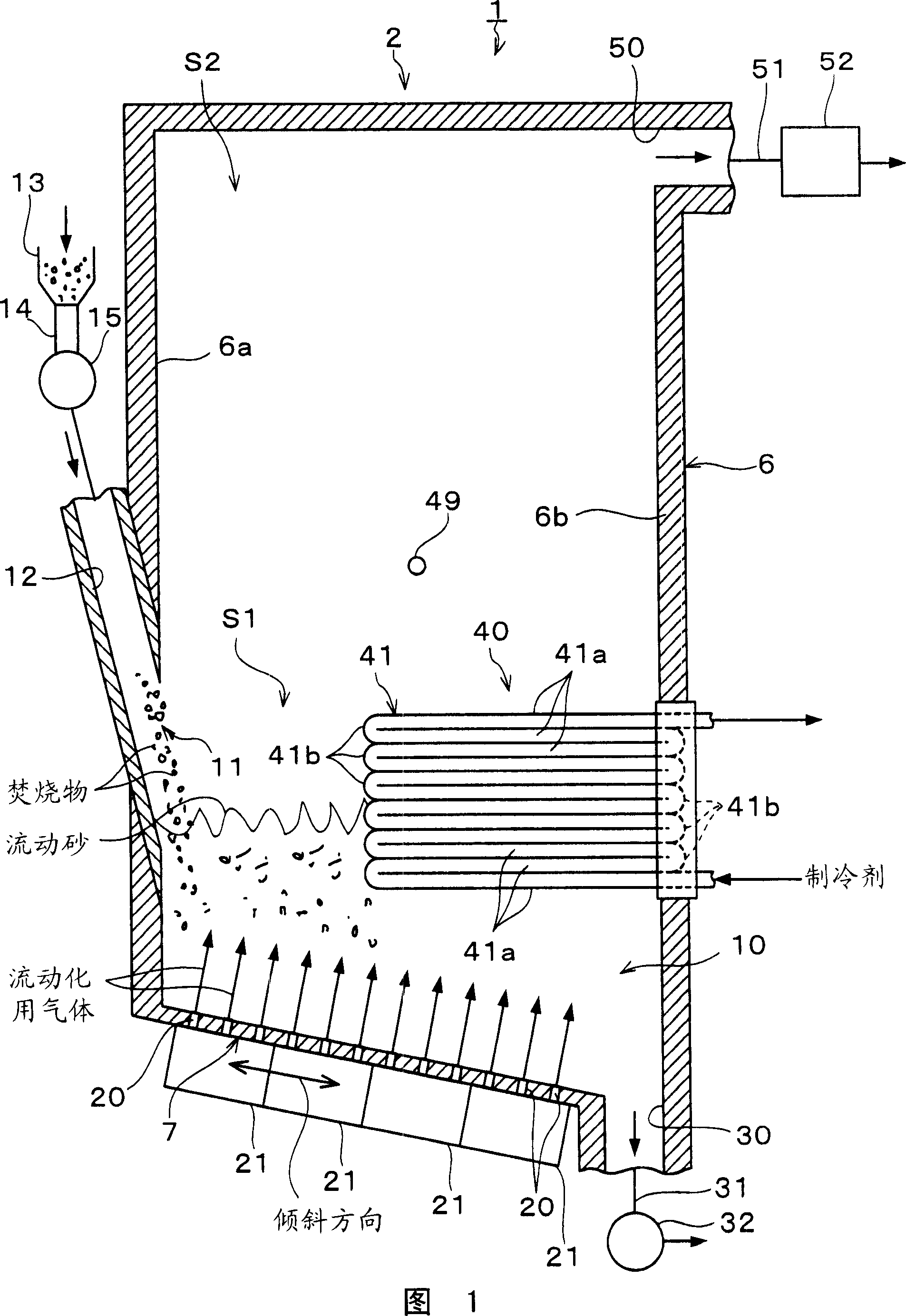

[0023] Next, preferred embodiments of the present invention will be described based on a fluidized bed furnace that incinerates shredder dust of discarded automobiles as incineration products (incineration raw materials). The fluidized bed furnace 1 shown in FIG. 1 is an inclined dispersed fluidized bed combustion furnace, and has a furnace body 2 that is approximately square. In the inner space of the furnace body 2, the lower part becomes the primary combustion chamber S1 for burning the incinerated material (primary combustion), and the upper part becomes the secondary combustion chamber for burning the exhaust gas generated by the primary combustion of the incinerated material (secondary combustion). (free space) S2.

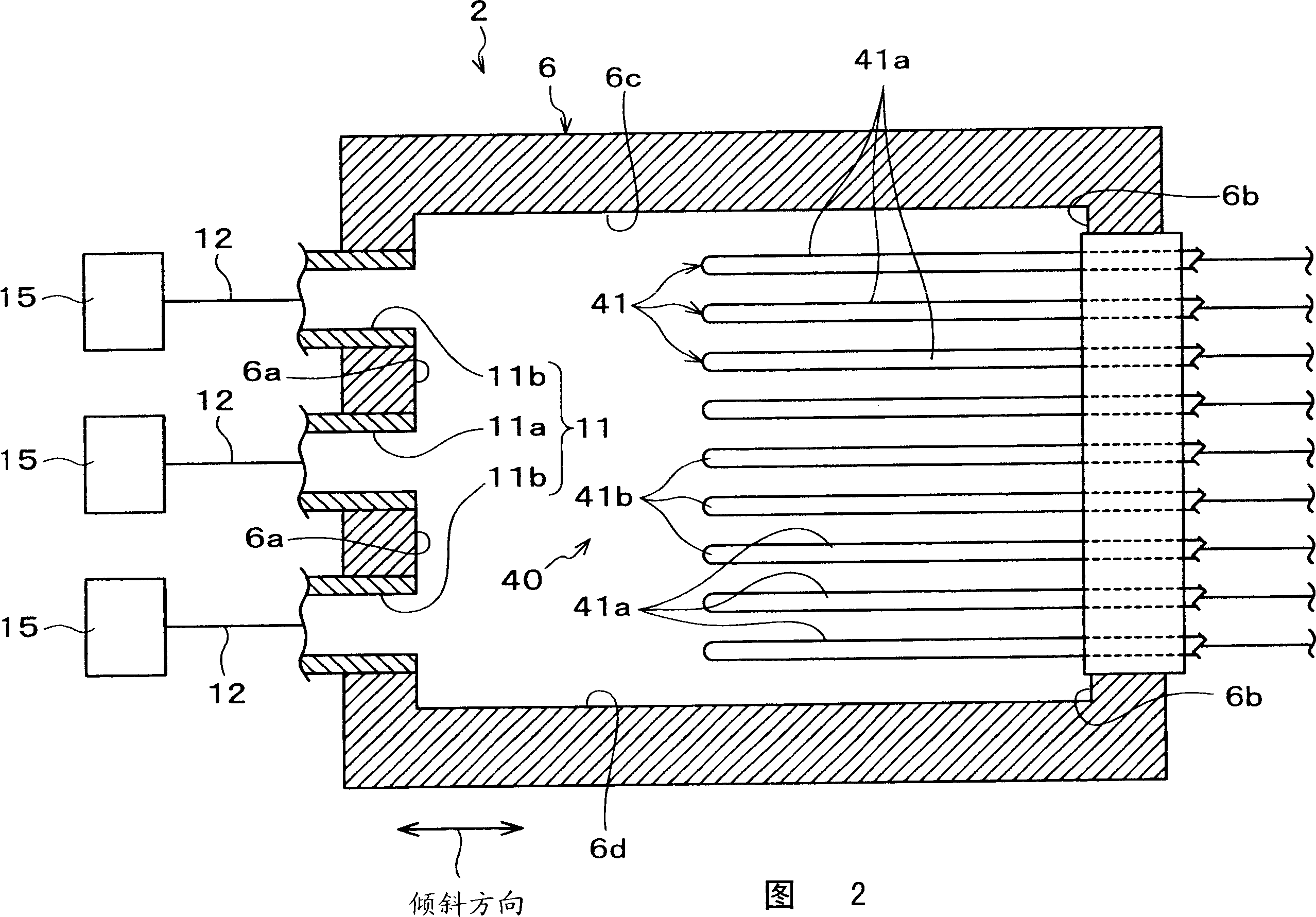

[0024] The side wall portion 6 of the furnace body 2 is approximately square cylindrical, has approximately the same cross-sectional shape as a rectangle, and has four inner sides erected in an approximately vertical direction, that is, the front inner side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com