New T type micro mixer

A micro-mixer, a new type of technology, applied in the field of micro-systems, can solve the problems of low mixing efficiency, achieve the effect of improving mixing intensity, wide application range, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

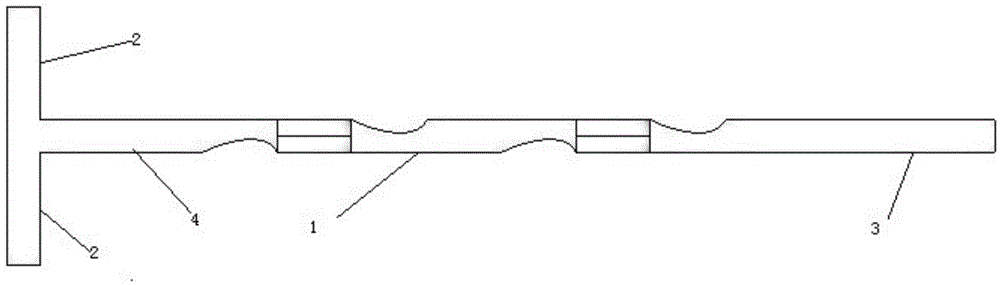

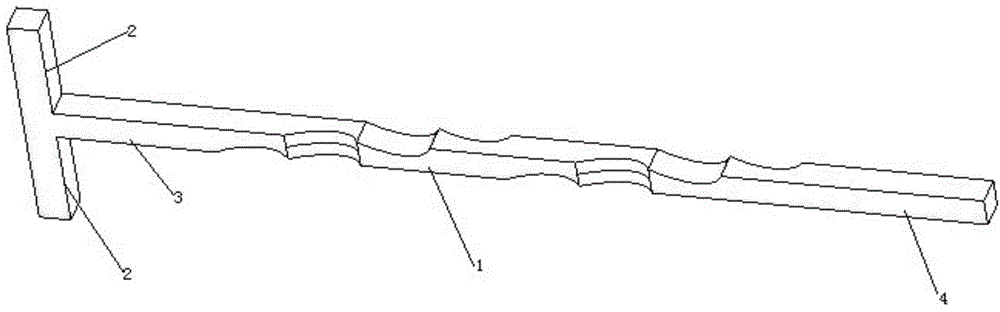

[0026] Example 1: Use ANSYS Workbench software to simulate two different fluids with a density of 1000kg m -3 、1100kg·m -3 , the diffusion coefficient is 10 -9 m 2 ·s -1 . The mixer is modeled in 3D, such as figure 2 As shown, the method used is the multi-component transport of FLUENT under the Workbench integrated environment. The density and viscosity coefficient change with the occurrence of mixing. The flow direction of the two fluids can be determined by observing the direction of the velocity. The mass fraction of the components is used to determine the mixing status.

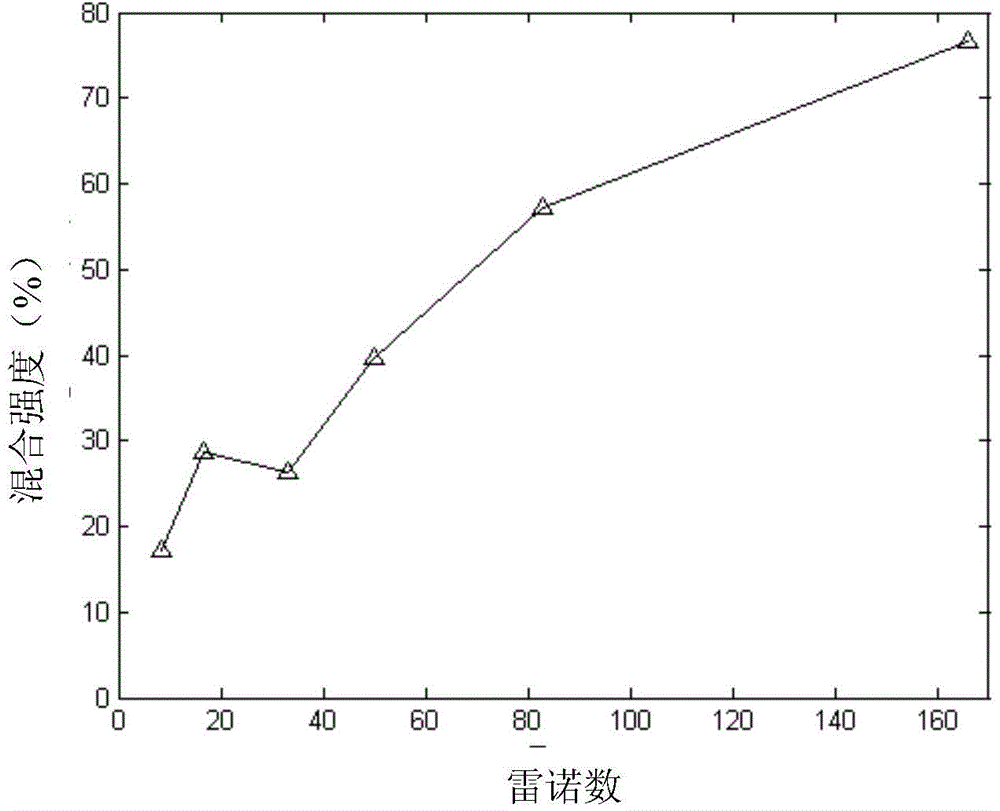

[0027] The main reason why microfluidics are difficult to mix is low flow rate, so there are two reasonable and practical criteria for evaluating a micro-mixer: mixing at low flow rate and high mixing intensity. The feasibility of the T-type micro-mixer is verified by FLUENT simulation of the mixing condition of the T-type micro-mixer at low flow rate.

[0028] Mixing intensity is an important i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com