Dry-process flue gas desulfurizing method using combined gas jet

A dry-process flue gas desulfurization and flue gas technology, which is applied in the direction of separation methods, chemical instruments and methods, and dispersed particle separation, can solve problems such as not being able to meet the fluidization requirements of large-scale flue gas desulfurization reactions, and achieve widening load changes The effect of adaptability, improving utilization rate and enhancing mass transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

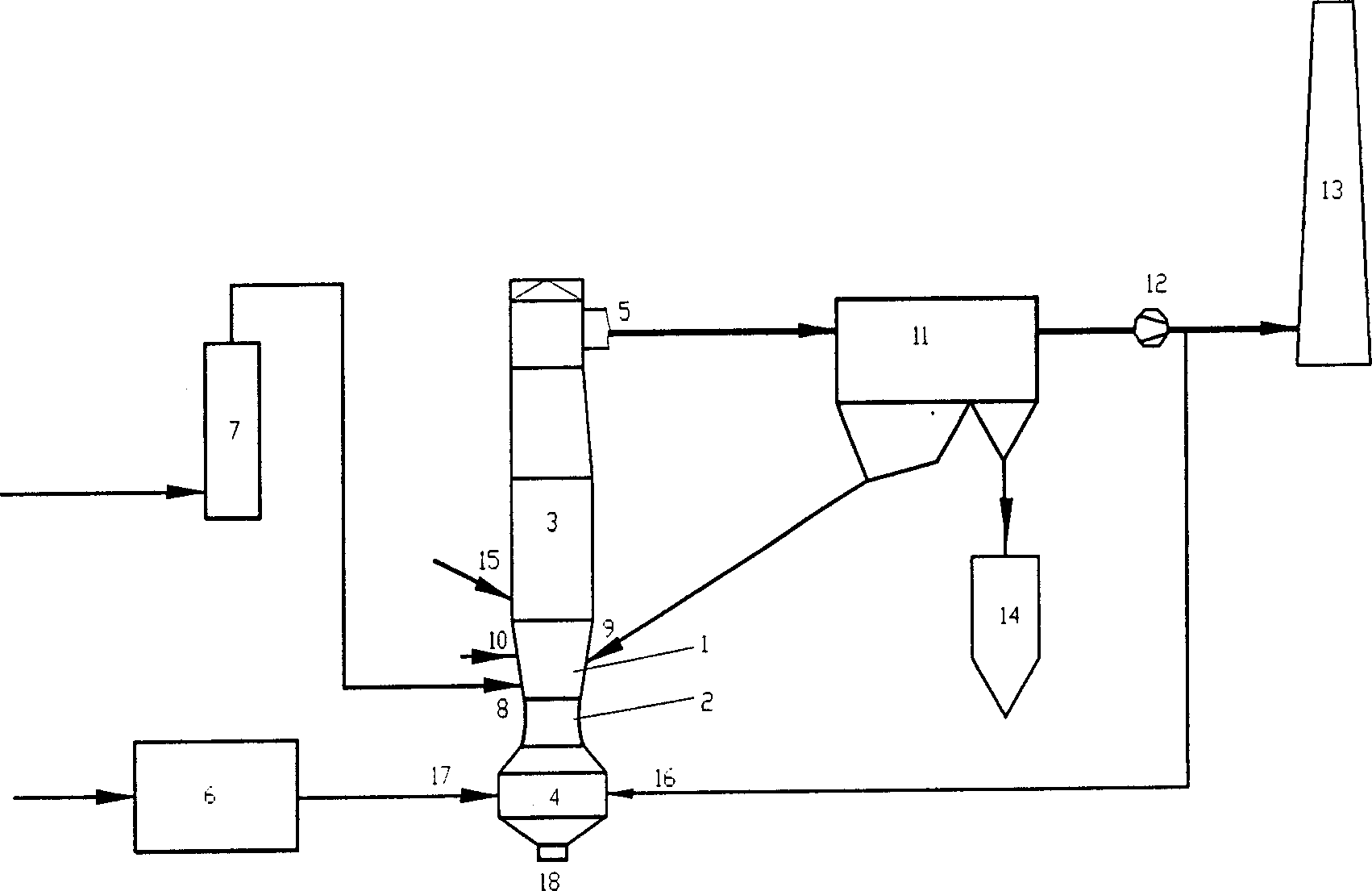

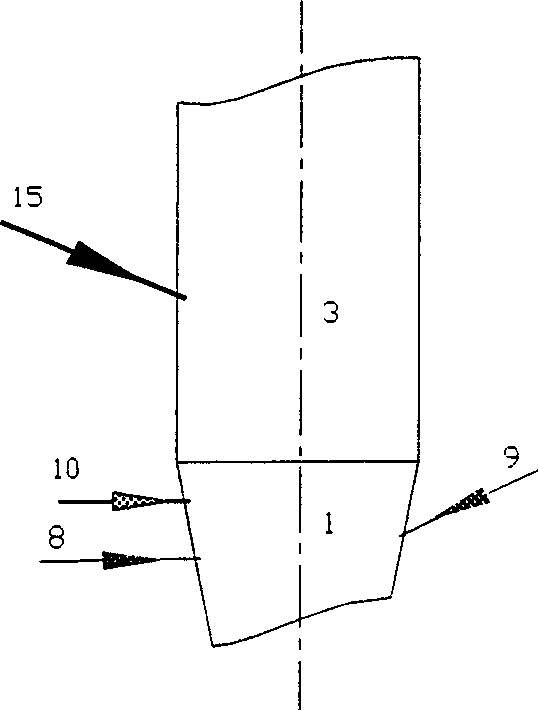

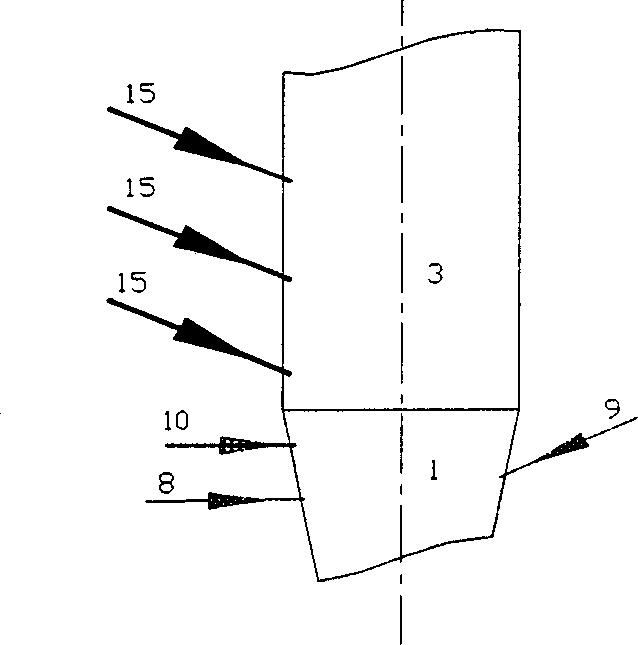

[0028] General application The desulfurization reaction tower of the present invention includes: a flue gas mixing chamber at the bottom of the tower, a flue gas injection device (Venturi nozzle, air distribution device) in the flue gas mixing chamber, a water supply atomizing nozzle, a feeding device, and a feeding device , flue gas jet nozzle, desulfurization reaction tower body, separation (static, cloth bag, inertia, etc.) device outside the desulfurization reaction tower, desulfurization tower flue gas recirculation device. In the present invention, the combined flue gas jet is sprayed into the middle or upper part of the desulfurization reaction tower, thereby changing the flow characteristics of the middle and upper regions of the desulfurization tower, strengthening the turbulence intensity, and forming a new vortex area, so as to effectively organize the gas, solid and gas in the desulfurization reaction tower. Full mixing of liquid three phases and speed slip.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com