Method and device for producing sulfolane

A technology of sulfolane and equipment, which is applied in the field of production of sulfolane and its equipment, can solve problems such as easy accidents, increased investment, and limited reaction effect, and achieve the effects of ensuring production safety, increasing mixing intensity, and facilitating process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

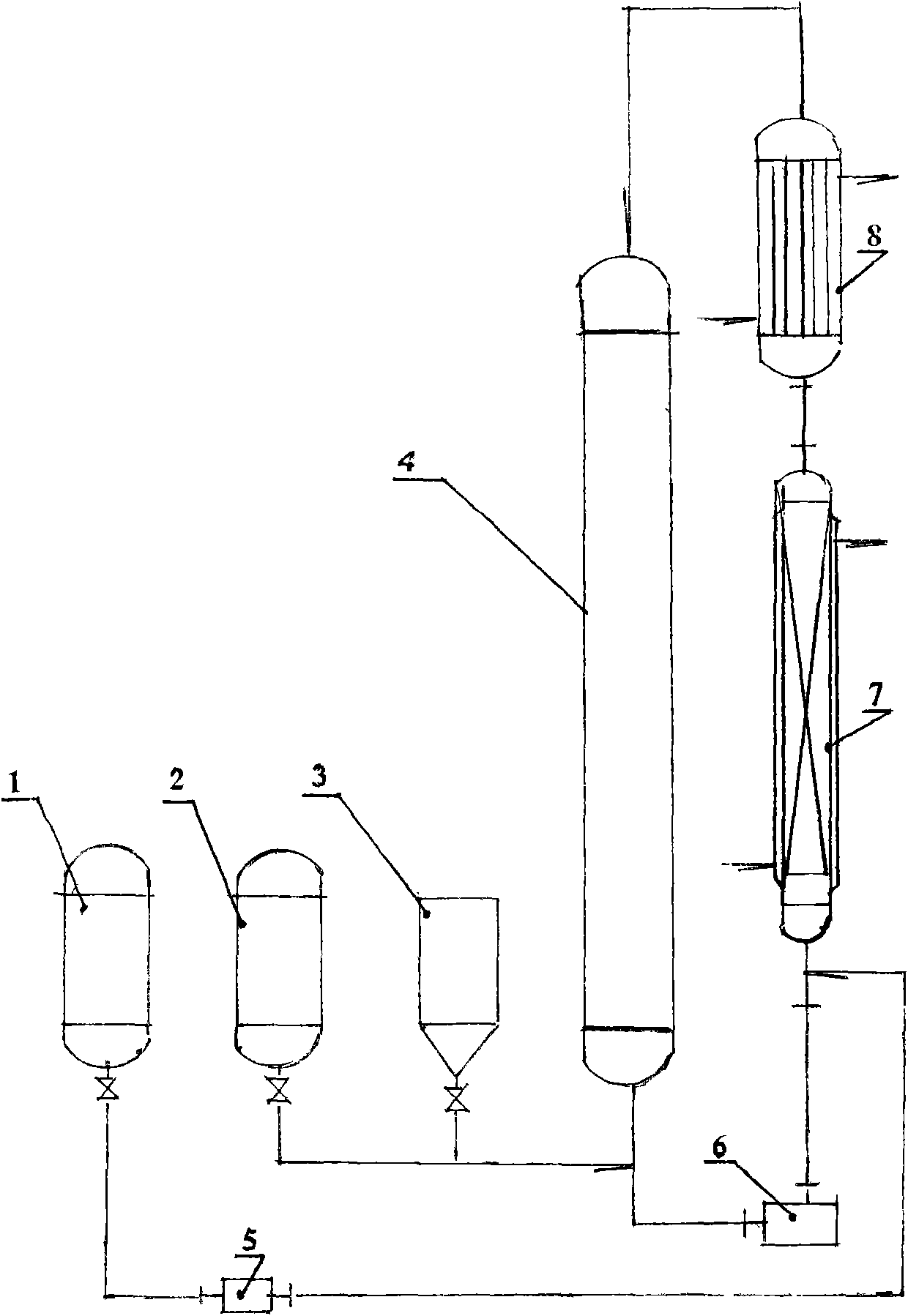

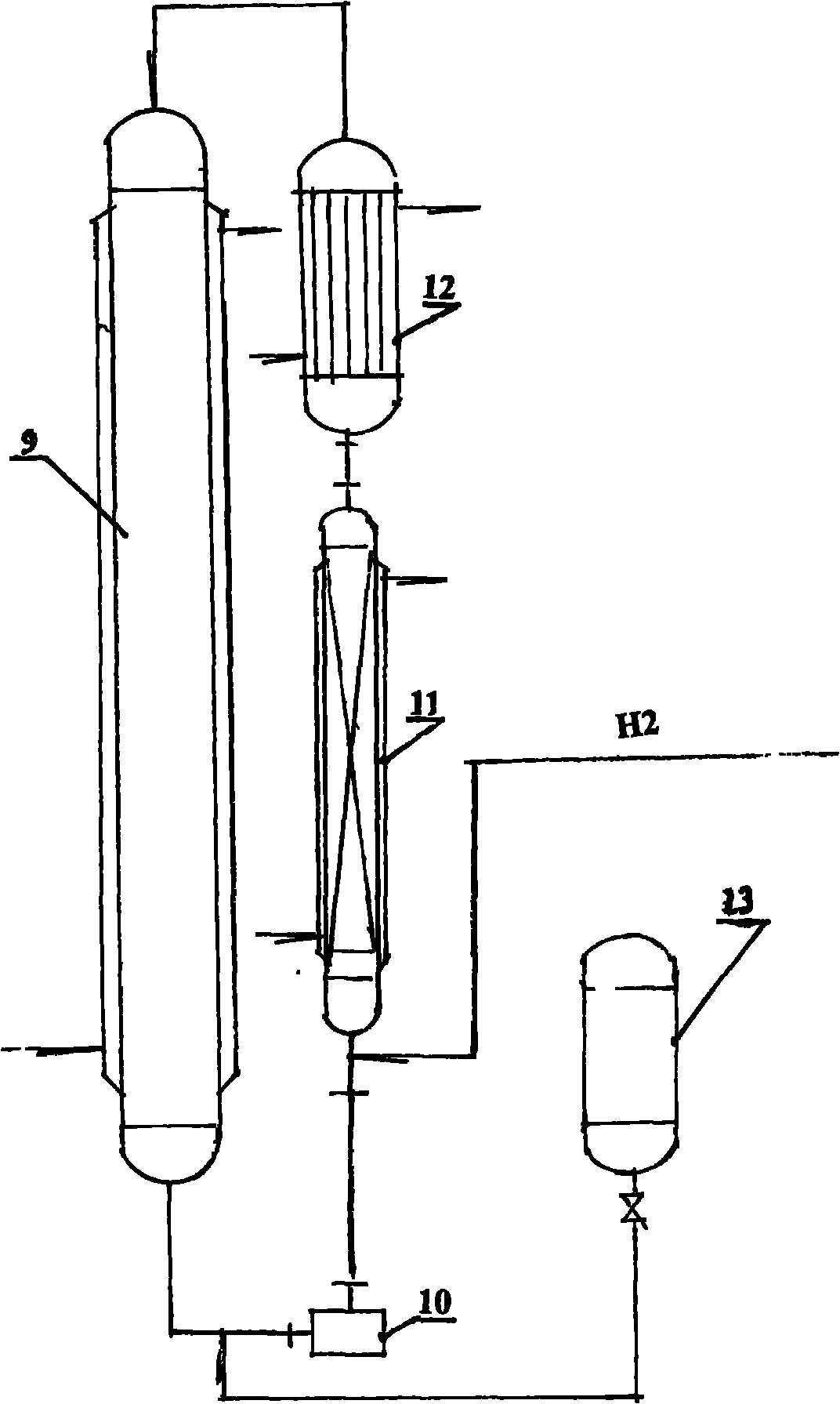

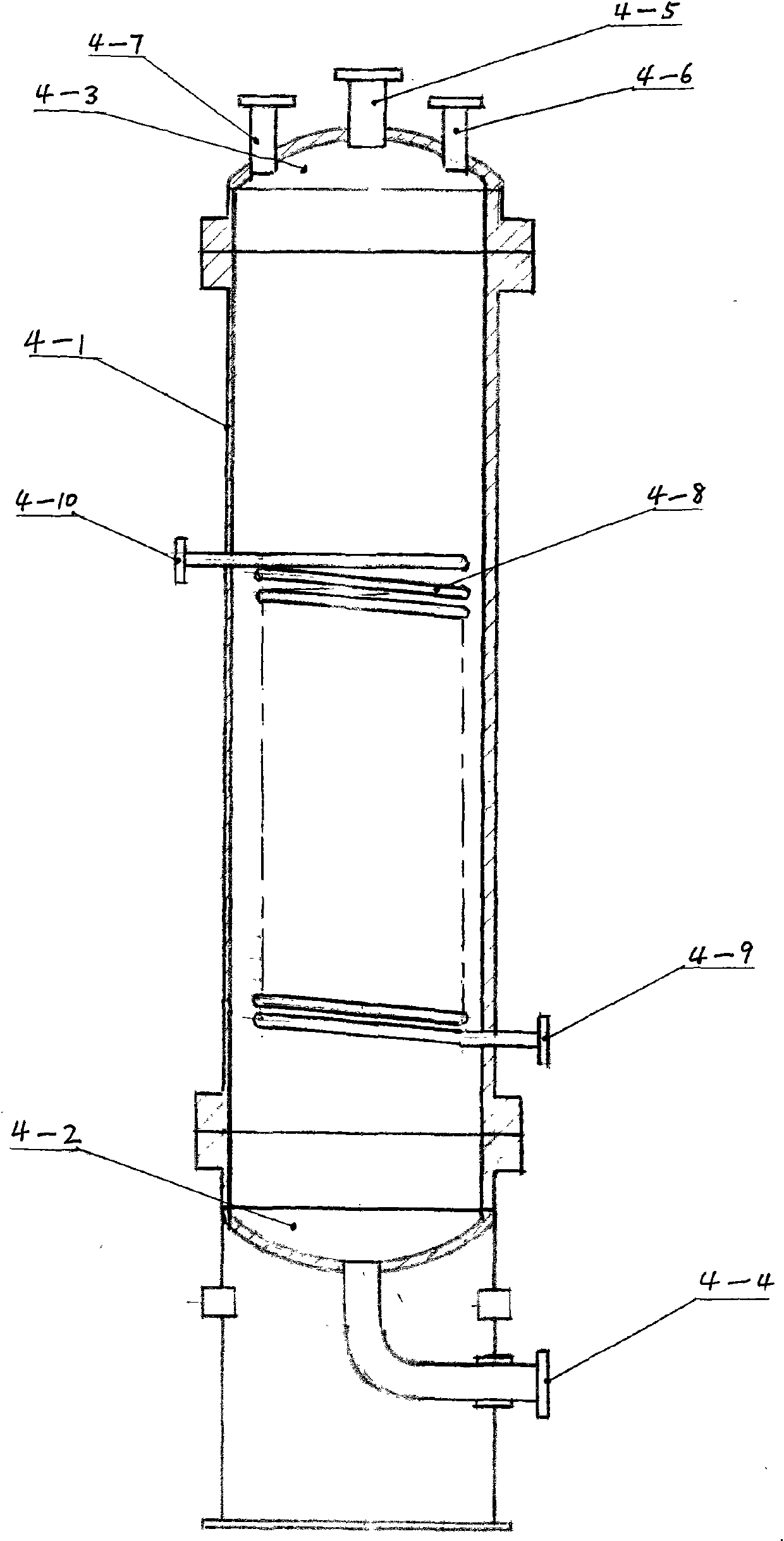

[0017] The method for producing sulfolane is: first put sulfur dioxide and polymerization inhibitor into the synthetic mixed reactor in a ratio of 240:1 by weight, and when the temperature reaches the process requirements, continuously inject butadiene (sulfur dioxide and butadiene) by a quantitative pump. The weight ratio of alkene is 1.2: 1), continuously injected into the continuous reaction, in the reaction process, it is injected into the synthetic static mixer and the synthetic heating and cooling device with the circulating pump, and then returns to the synthetic mixing reactor for mixed reaction (i.e. in vitro circulation system) to generate sulfolene; the sulfolene generated after the mixed reaction is diluted with benzene to a concentration of 60% and sent to the hydrogenation mixing reactor, and then the liquid catalyst (such as nickel-aluminum complex catalyst) Put it into the hydrogenation mixed reactor, then continuously inject hydrogen into the hydrogenation stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com