Smoke purifying and residual heat deep recycling integrated device

A flue gas purification and waste heat technology, which is applied in the types of heat exchangers, the use of liquid separation agents, lighting and heating equipment, etc., can solve the problems of deep recovery of flue gas waste heat, secondary pollution, etc., and achieves a simple structure and a floor space. Small, the effect of improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

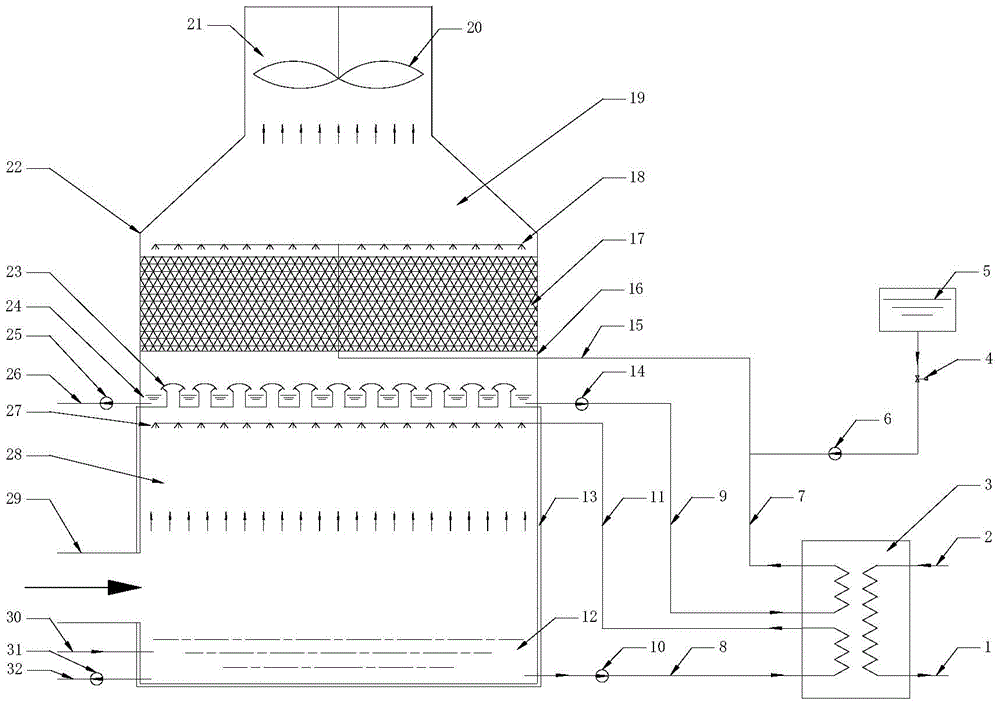

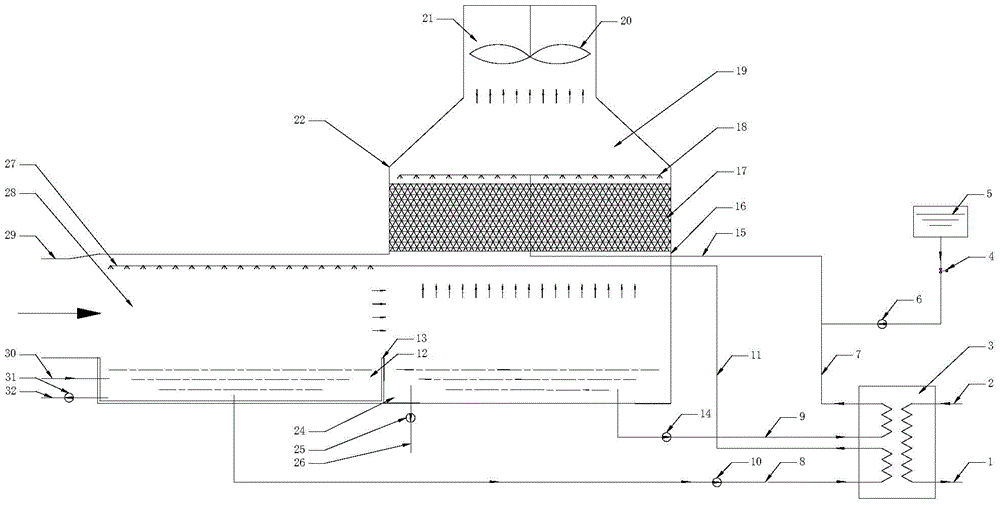

[0027] Such as figure 1 As shown, the flue gas purification and waste heat deep recovery integrated device includes a purification heat exchange tower 22, a heat exchanger 3, a slurry replenishment tank 5 and the pipes, valves and pumps connected between them. The external interface has a cooling medium outlet 1 and a cooling medium. Medium inlet 2, slurry treatment system 26, flue gas inlet 28, water supply system 29, water quality treatment system 32.

[0028] The purification heat exchange tower 22 is the core equipment of the whole device, and its wind cap layer formed by the wind cap 23 is divided into a spray chamber 28 and a stuffing chamber 19 . The spray chamber 28 is composed of a slurry pool 12 , a spray layer 27 and a flue gas inlet 29 , and the outer wall of the spray chamber 19 needs to be covered with an insulating layer 13 . The packing chamber 19 is composed of a slurry pool 24 , a packing layer 17 and a slurry distribution layer 18 . The shape of the purifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com