Large-cylinder-diameter gas engine turbulent jet ignition system, gas supply system and method

A gas engine, turbulent jet technology, applied in gaseous engine fuels, combustion engines, engine components, etc., can solve the problems of poor combustion stability, engine ignition, and high concentration of residual combustion exhaust gas, and achieve improved ignition capability, increased ignition energy, and shortened The effect of flame spread distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

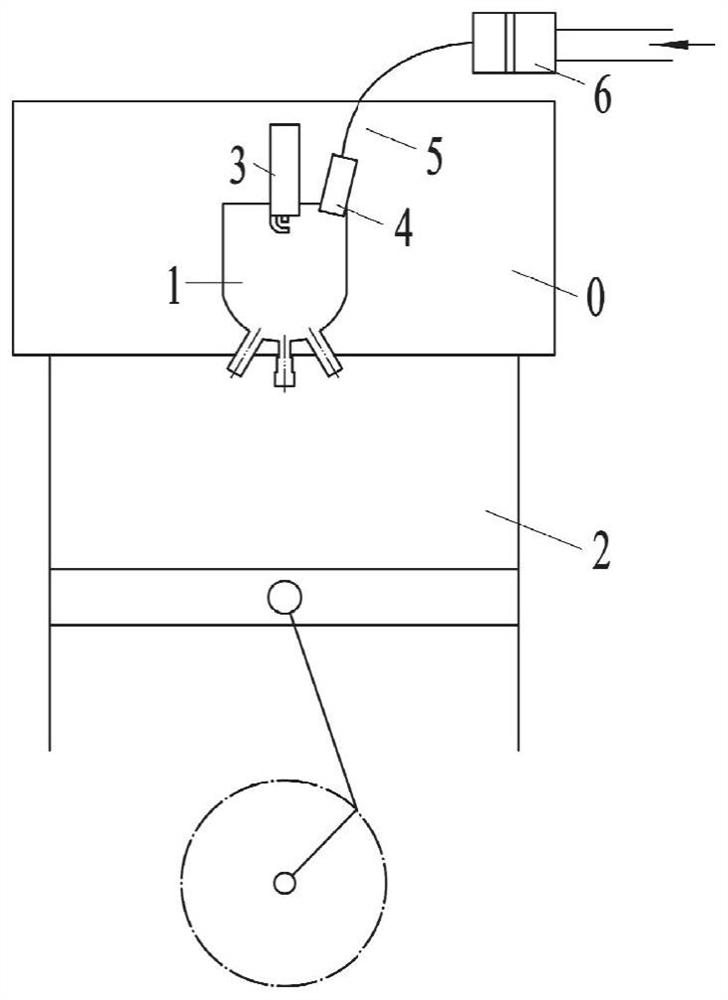

[0044] In one or more embodiments, a turbulent jet ignition system for a large bore gas engine is disclosed, such asfigure 1 shown, including:

[0045] a pre-combustion chamber 1, the pre-combustion chamber 1 is respectively communicated with the main combustion chamber 2 through a plurality of fluid passages;

[0046] The pre-combustion chamber gas injection valve 6 is connected to the pre-combustion chamber 1 through the gas delivery pipeline 5 and the one-way valve 4, and is used to inject auxiliary gas into the pre-combustion chamber 1 in a timed and quantitative manner;

[0047] The spark plug 3 is arranged on the pre-combustion chamber 1 , and the ignition electrode of the spark plug 3 is inserted into the pre-combustion chamber 1 for igniting the combustible mixture in the pre-combustion chamber 1 .

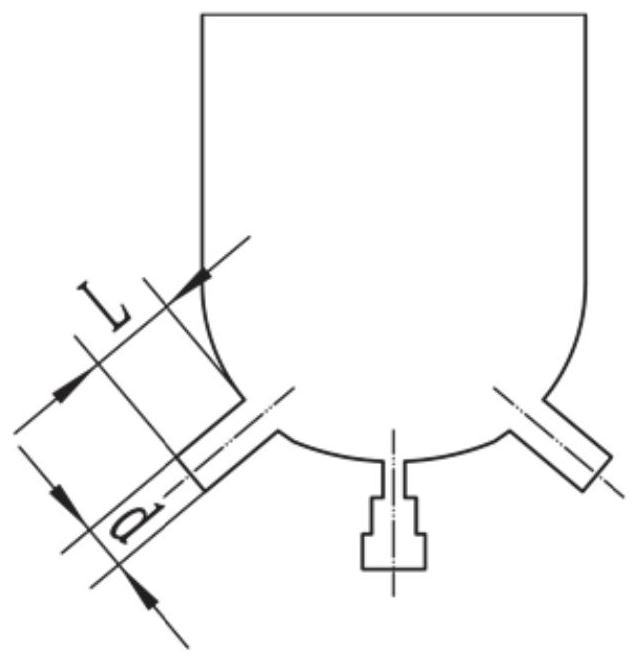

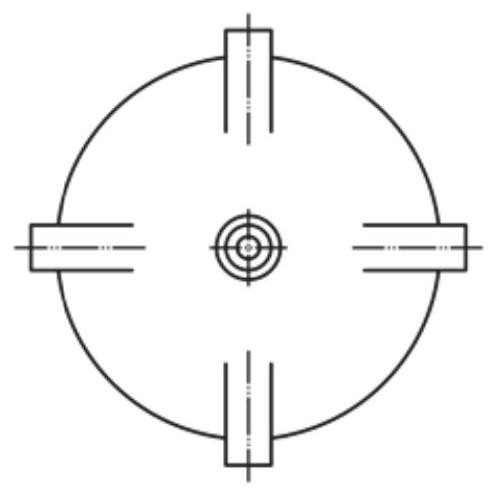

[0048] At least one fluid passage is provided at the bottom center of the pre-chamber 1 , and the central axis of the fluid passage is parallel to the central axis of the ...

Embodiment 2

[0056] In one or more embodiments, an air supply system for a large bore gas engine is disclosed, incorporating Figure 4 , including: the controller 20 and the turbulent jet ignition system of the large-bore gas engine described in the first embodiment; the main combustion chamber 2 is provided with an intake passage 16 and an exhaust passage 19 respectively, and the intake passage 16 passes through the pre-combustion chamber gas. The injection valve 6 is connected with the gas delivery pipeline 5; the intake passage 16 is connected with the gas intake passage; the intake passage 16 is also connected with the supercharger through the intercooler 15; The supercharger is connected; the controller 20 is used to control the pre-combustion chamber gas injection valve 6, the exhaust bypass valve 14 and the gas intake passage.

[0057] Specifically, the intake passage 16 and the exhaust passage 19 are connected with the main combustion chamber 2 to organize the intake and exhaust of...

Embodiment 3

[0064] In one or more embodiments, a gas supply method for a large bore gas engine is disclosed, the method comprising the following processes:

[0065] Control the gas intake passage to be closed, and control the air to enter the main combustion chamber 2 and the pre-combustion chamber 1 at the set pressure for scavenging;

[0066] The gas inlet passage is controlled to open, and the gas and air are controlled to enter the inlet passage 16 of the main combustion chamber 2 at a set pressure to form a mixture with a set concentration; the mixture is controlled to enter the main combustion chamber 2 and pre-combustion respectively. room 1;

[0067] The gas injection pressure is reduced, and the pre-combustion chamber gas injection valve 6 is closed, so that the gas concentration of the mixture in the intake passage 16 is reduced and only enters the main combustion chamber 2 to complete the set gas injection amount and air intake amount.

[0068] The specific method steps are as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com