Engine capable of directly injecting natural gas for multiple times under high pressure in cylinder and layered rapid combustion method thereof

A natural gas and engine technology, which is applied in the field of natural gas engines and their combustion control, can solve the problem that the combustion optimization ignition and combustion chamber structure optimization matching methods of in-cylinder high-pressure direct injection natural gas engines are not proposed, and the requirements for high engine efficiency and low emissions cannot be taken into account. High load conditions cannot be applied to achieve the effect of shortening the flame propagation distance, improving the distribution of the concentration field, and increasing the flame propagation speed and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in more detail below in conjunction with accompanying drawing example:

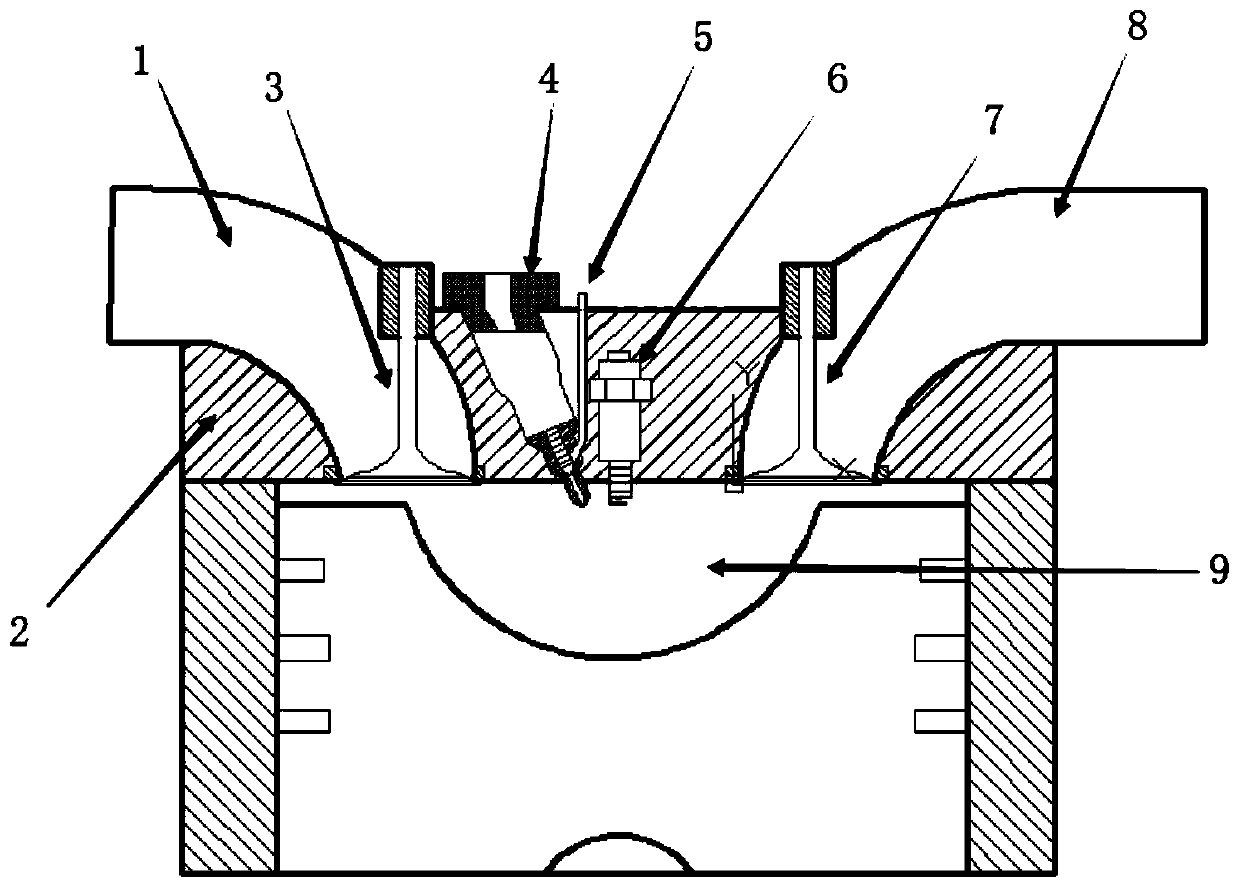

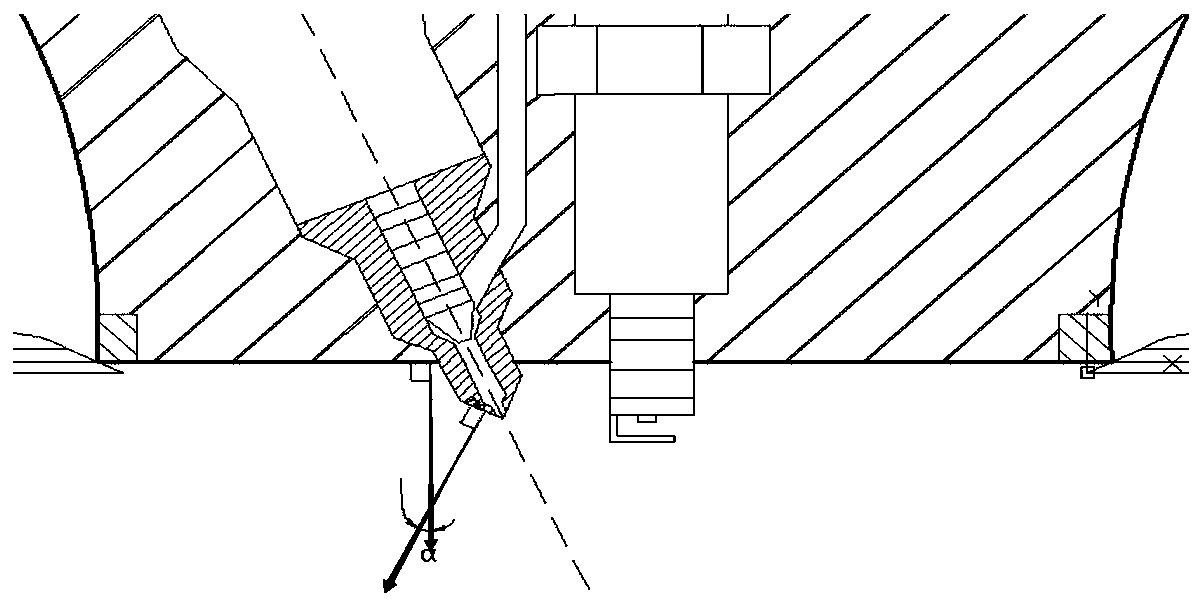

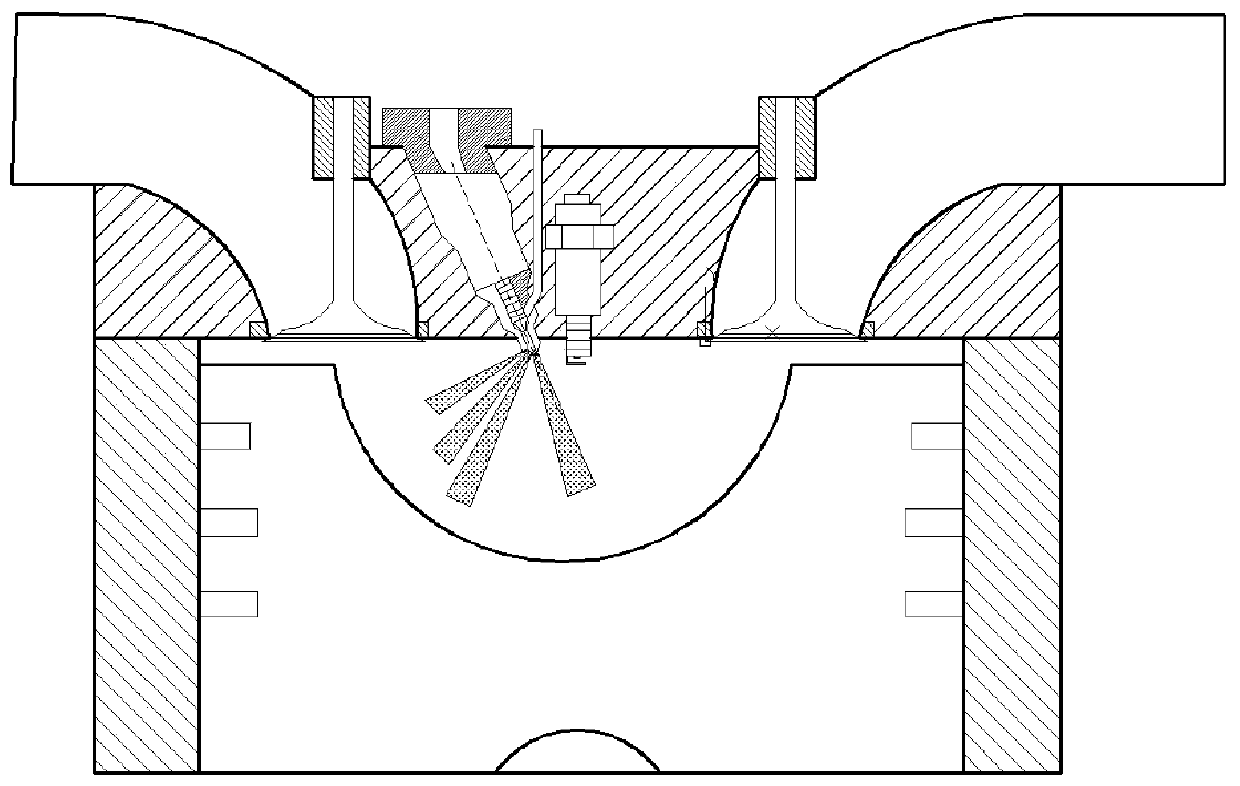

[0023] combine Figure 1-4f , the present invention is an engine with multiple high-pressure direct-injection natural gas in a cylinder, comprising: intake port 1, cylinder head 2, intake valve 3, high-pressure natural gas injection valve 4, high-pressure natural gas supply pipeline 5, spark plug 6, exhaust Valve 7, exhaust passage 8, combustion chamber 9, etc. The cylinder head of the high-pressure in-cylinder direct injection natural gas engine adopted is respectively equipped with a spark plug 6, a high-pressure natural gas injection valve 4, and a high-pressure natural gas supply pipeline 5, and the central axis of the spark plug 6 Coinciding with the central axis of the cylinder head 2, the high-pressure natural gas injection valve 4 is located between the intake port 1 and the spark plug 6, and the nozzle of the high-pressure natural gas injection valve 4 ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com