Liquid sulfur collection method for sulfur recovery

A sulfur recovery and collection method technology, applied in chemical instruments and methods, sulfur compounds, inorganic chemistry, etc., can solve problems such as soil pollution, reduce emission concentration and total emission, process technology is safe and reliable, and reduce leakage and pollution sources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

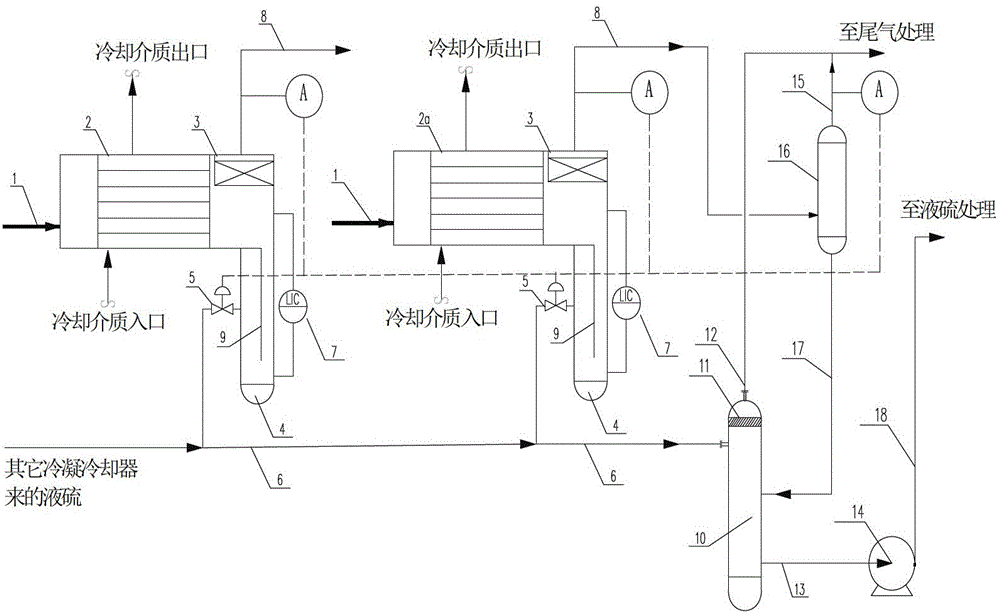

[0036] like figure 1The liquid sulfur collection device of the sulfur recovery device shown includes a sulfur condensation cooling and collection facility consisting of a process gas condensation cooler 2 and a liquid sulfur collection device 4, a liquid sulfur intermediate tank 10, a liquid sulfur pump 14, and a tail gas separator tank 16. The process gas outlet of the process gas condensing cooler 2 is provided with a liquid sulfur trap 3, the process gas outlet is connected to the process gas outlet line 8, and the process gas outlet line 8 is connected to the next-stage reaction or condensing cooling system or tail gas separator tank 16 , the top of the tail gas liquid separation tank 16 is connected to the tail gas treatment device through the tail gas discharge line 15, and the bottom of the tail gas liquid separation tank 16 is connected to the liquid sulfur intermediate tank 10 through the liquid sulfur pipeline 17; the liquid sulfur collector 4 is directly connected to...

Embodiment 2

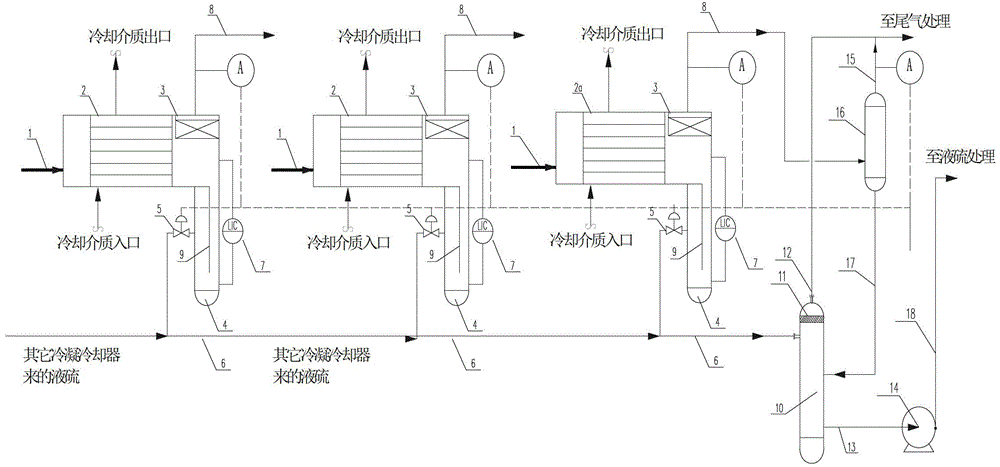

[0044] like figure 2 The liquid sulfur collection device of the sulfur recovery device shown includes a sulfur condensation cooling and collection facility consisting of a process gas condensation cooler 2 and a liquid sulfur collection device 4, a liquid sulfur intermediate tank 10, a liquid sulfur pump 14, and a tail gas separator tank 16. The process gas outlet of the process gas condensing cooler 2 is provided with a liquid sulfur trap 3, the process gas outlet is connected to the process gas outlet line 8, and the process gas outlet line 8 is connected to the next-stage reaction or condensing cooling system or tail gas separator tank 16 , the top of the tail gas liquid separation tank 16 is connected to the tail gas treatment device through the tail gas discharge line 15, and the bottom of the tail gas liquid separation tank 16 is connected to the liquid sulfur intermediate tank 10 through the liquid sulfur pipeline 17; the liquid sulfur collector 4 is directly connected ...

Embodiment 3

[0052] like figure 2 The liquid sulfur collection device of the sulfur recovery device shown includes a sulfur condensation cooling and collection facility consisting of a process gas condensation cooler 2 and a liquid sulfur collection device 4, a liquid sulfur intermediate tank 10, a liquid sulfur pump 14, and a tail gas separator tank 16. The process gas outlet of the process gas condensing cooler 2 is provided with a liquid sulfur trap 3, the process gas outlet is connected to the process gas outlet line 8, and the process gas outlet line 8 is connected to the next-stage reaction or condensing cooling system or tail gas separator tank 16 , the top of the tail gas liquid separation tank 16 is connected to the tail gas treatment device through the tail gas discharge line 15, and the bottom of the tail gas liquid separation tank 16 is connected to the liquid sulfur intermediate tank 10 through the liquid sulfur pipeline 17; the liquid sulfur collector 4 is directly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com