Gas firing or oil firing boiler using thin flameless burning mode

A flameless combustion, oil-fired boiler technology, applied in the combustion method, the use of multiple fuel combustion, the use of block fuel and liquid fuel combustion, etc., can solve the problems of unfavorable operation time boilers, high boiler costs, insufficient combustion and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

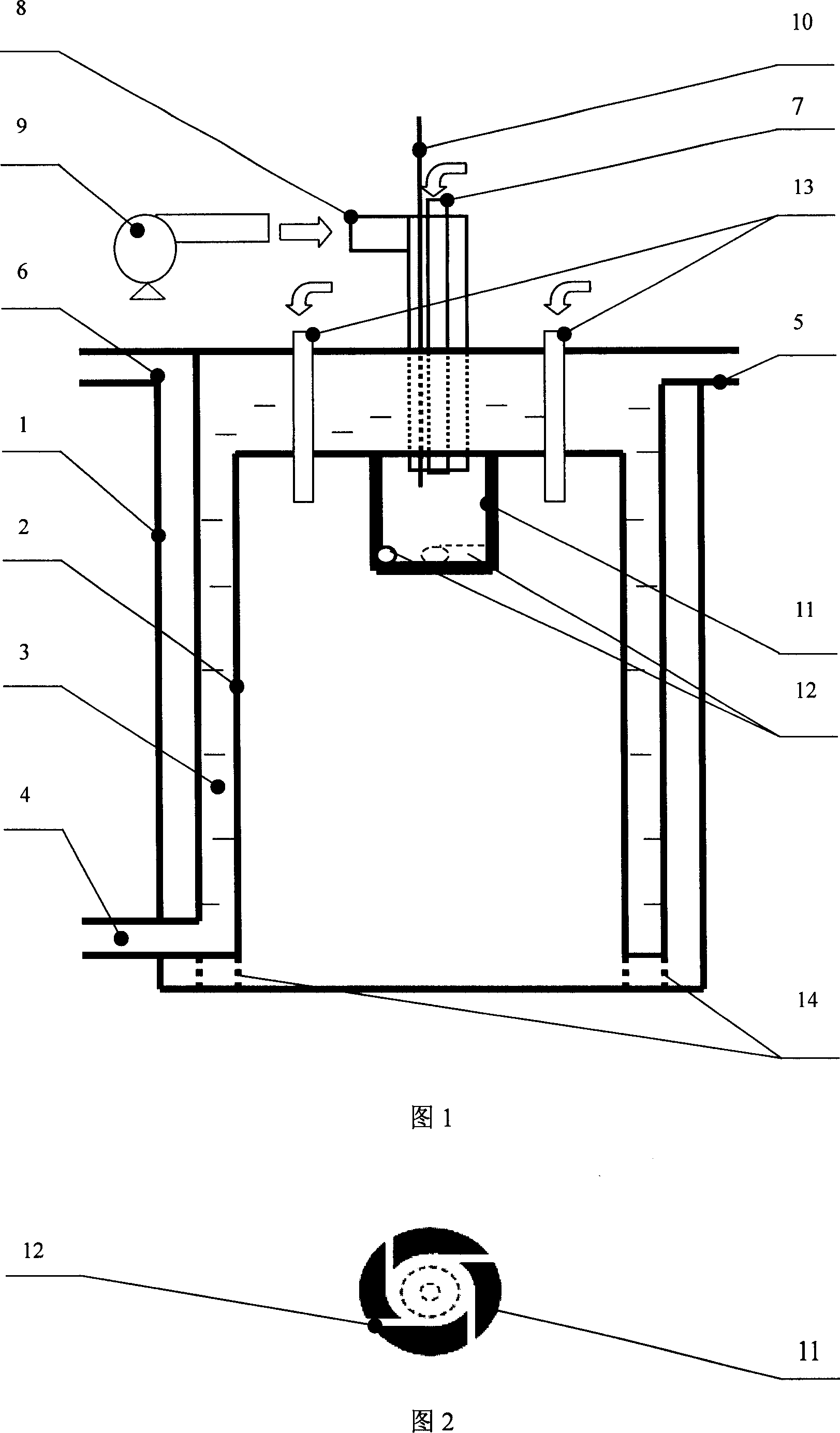

[0015] Example 1: A vertical gas boiler with a pre-combustion hood on top

[0016] In this embodiment, a gas-fired boiler with a boiler evaporation capacity of 0.5t / h is used. FIG. 1 is a schematic diagram of a longitudinal section structure of the gas boiler in this embodiment; FIG. 2 is a schematic bottom view of a transverse section of a pre-combustion hood and a swirling flow tube. As shown in the figure: the outer layer of the boiler is a barrel-shaped pot shell 1, the axis of the pot shell is perpendicular to the horizontal direction, the pot shell 1 is surrounded by refractory bricks, with a height of 3.5m and an outer diameter of 1.6m, and the inner layer is a barrel-shaped furnace liner 2 , between the furnace 2 and the boiler shell 1 is a water jacket 3, the water jacket 3 is assisted by the bracket 14 to be fixed on the boiler shell 1, and a layer of flue is sandwiched between the boiler shell 1 and the water jacket 3 to communicate with the furnace, and the boiler ...

Embodiment 2

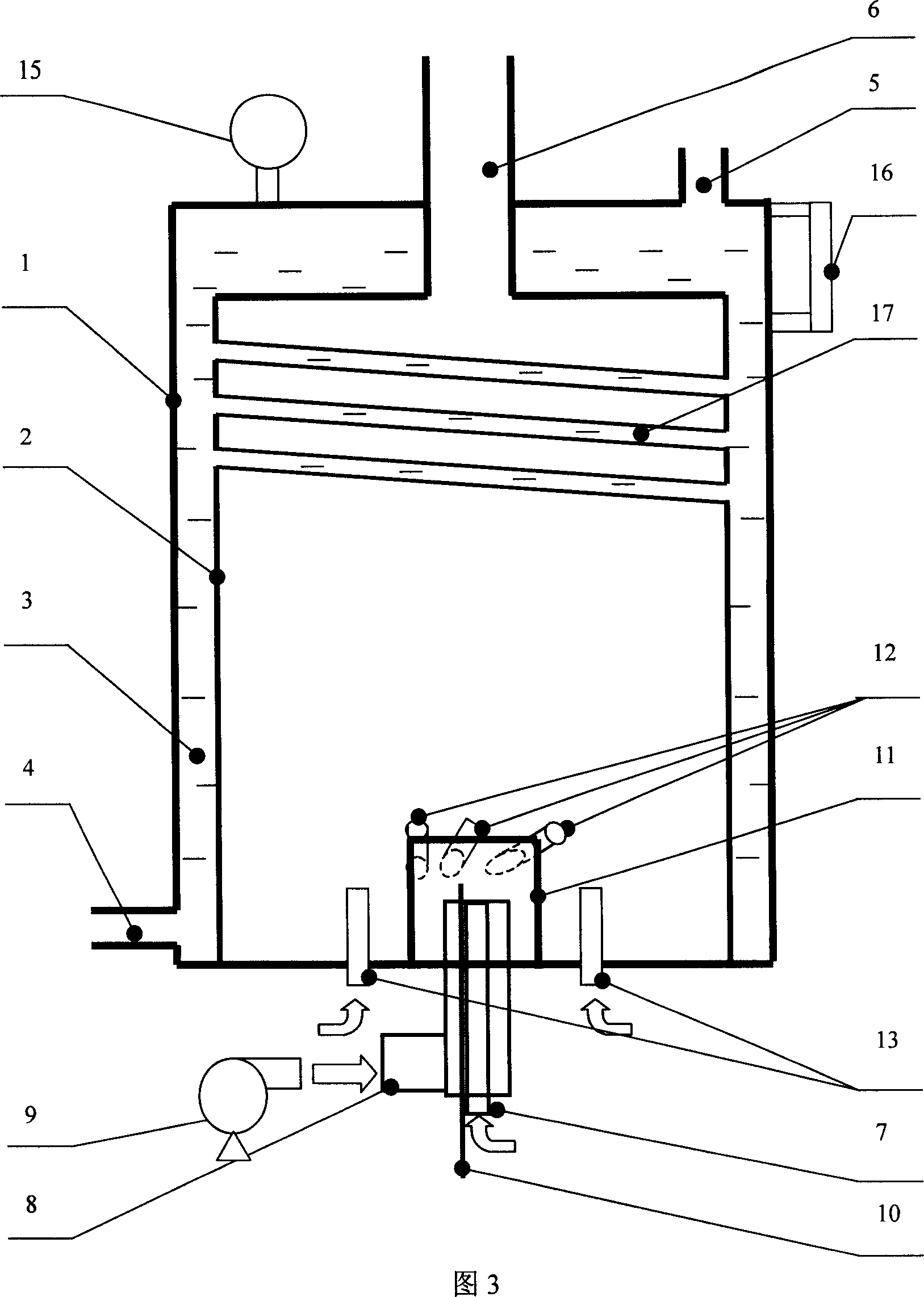

[0021] Example 2: An oil-fired boiler with a pre-combustion hood at the bottom

[0022]In this embodiment, an oil-fired boiler with a boiler evaporation of 0.3 t / h is used. FIG. 3 is a schematic diagram of the longitudinal cross-sectional structure of the oil-fired boiler of the present embodiment. As shown in the figure: the outer layer of the boiler is a square barrel-shaped shell 1, with a height of 2.8m and a cross-sectional dimension of 1.3m×1.3m. The inner layer is a square barrel-shaped furnace 2, which forms a water jacket 3 with the furnace shell 1. , a pressure gauge 15 is installed above the boiler shell 1 to connect with the water jacket 3, and a water level gauge 16 is installed above the boiler shell side to connect to the water jacket 3. In order to enhance heat exchange, the furnace chamber is arranged on the upper part of the furnace at an angle of 10 to 25 degrees. The pipe 17 is connected to the water jackets on both sides; the primary fuel pipe 7 and the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com