Wet-type electric precipitator and electric precipitation desulfurization device comprising same

A wet electrostatic precipitator and wet electrostatic precipitator technology, applied in combined devices, external electrostatic separators, electrode cleaning, etc., can solve the problems of affecting the dust collection effect, reducing the purification efficiency, frequent electric sparks, etc., and improve the efficiency of the dust removal system , reduce emission concentration, and save floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

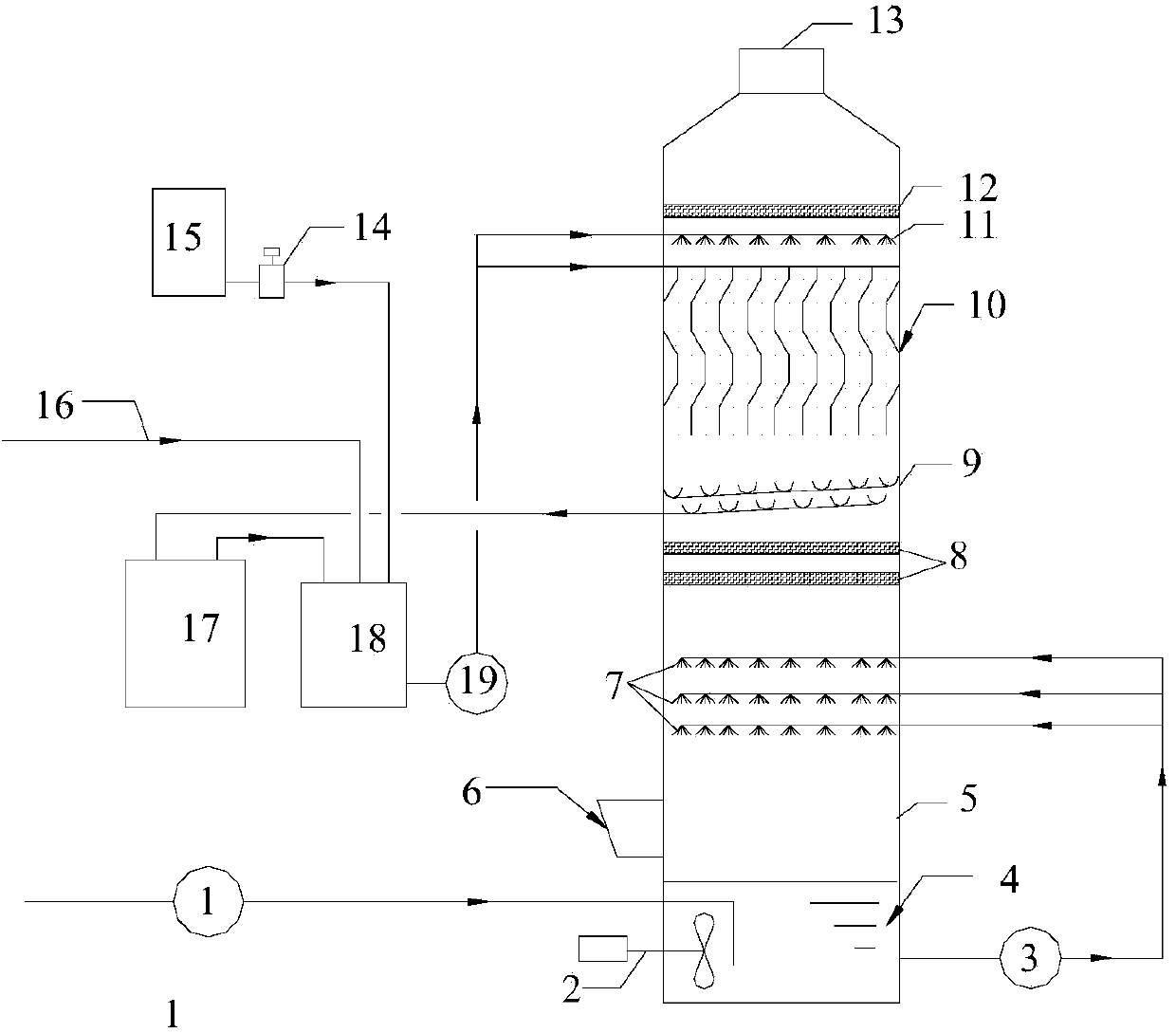

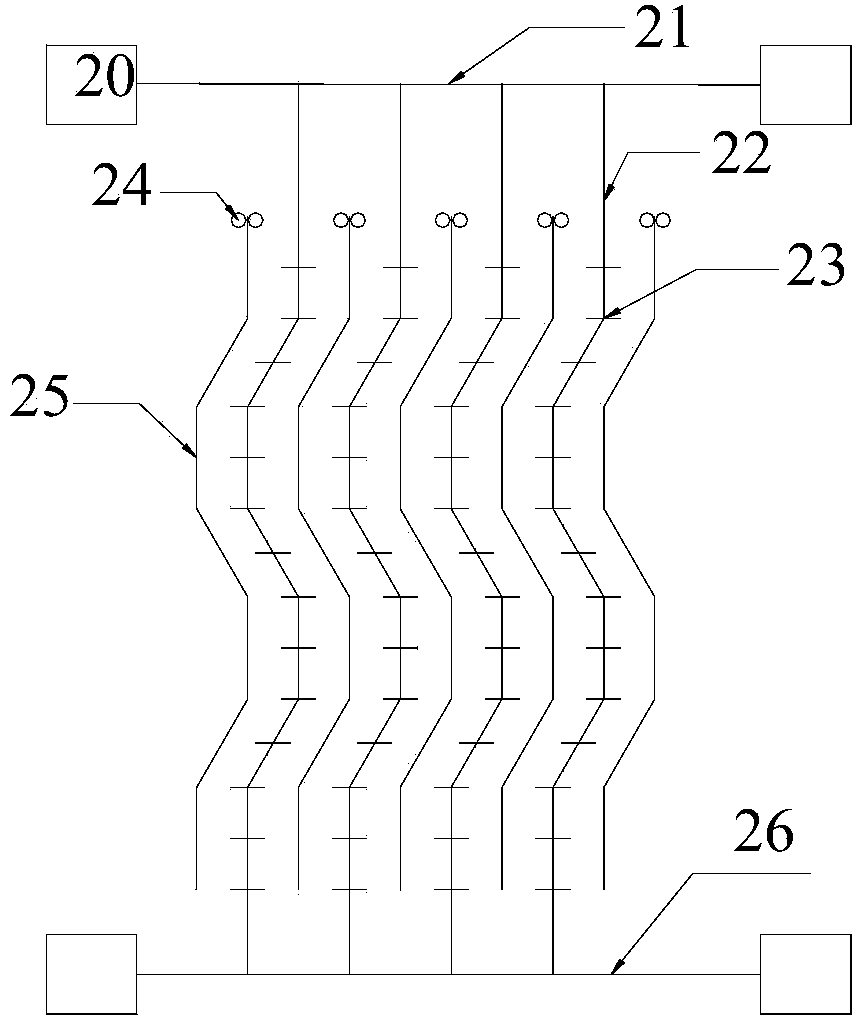

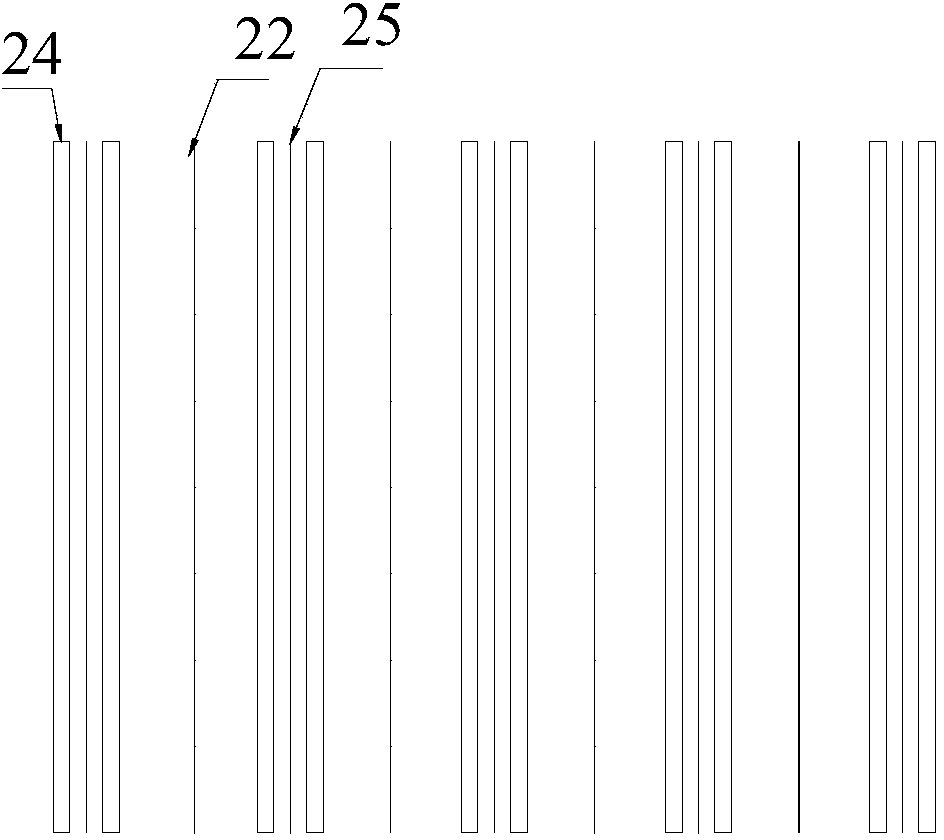

Embodiment 1

[0085] Using the above-mentioned self-designed wet electrostatic precipitator and desulfurization device, the length of the bent plate of the wet electrostatic precipitator is 8m, the distance between the two creases is 300mm, and the angle of the bend is 140°. Two adjacent bent plates The distance between them is 280mm, the length of the burrs is 25mm, the distance between adjacent burrs is 50mm, and the distance between several cathode lines between two adjacent bent plates is 250mm.

[0086] There is a gypsum slurry atomizing nozzle at the lower end of the pilot test device to simulate the water mist and dust in the flue gas. The atomized slurry enters the wet electrostatic precipitator through the blower of the fan. The water mist content and slurry dust at the inlet of the wet electrostatic precipitator are controlled and the voltage is adjusted. , to measure the removal efficiency of water mist and dust at the outlet of the wet electrostatic precipitator.

[0087]

Embodiment 2

[0089]Using the above self-designed and manufactured wet electrostatic precipitator and desulfurization device, the length of the bent plate of the wet electrostatic precipitator is 2m, the distance between the two creases is 800mm, and the angle of the bend is 170°. Two adjacent bent plates The distance between them is 400mm, the length of the burrs is 5mm, the distance between adjacent burrs is 150mm, and the distance between several cathode lines between two adjacent bent plates is 500mm.

[0090] There is a gypsum slurry atomizing nozzle at the lower end of the pilot test device to simulate the water mist and dust in the flue gas. The atomized slurry enters the wet electrostatic precipitator through the blower of the fan. The water mist content and slurry dust at the inlet of the wet electrostatic precipitator are controlled and the voltage is adjusted. , to measure the removal efficiency of water mist and dust at the outlet of the wet electrostatic precipitator.

[0091] ...

Embodiment 3

[0093] Using the above self-designed and manufactured wet electrostatic precipitator and desulfurization device, the length of the bent plate of the wet electrostatic precipitator is 4m, the distance between the two creases is 600mm, and the angle of the bend is 155°. Two adjacent bent plates The distance between them is 350mm, the length of the burrs is 10mm, the distance between adjacent burrs is 100mm, and the distance between several cathode lines between two adjacent bent plates is 400mm.

[0094] There is a gypsum slurry atomizing nozzle at the lower end of the pilot test device to simulate the water mist and dust in the flue gas. The atomized slurry enters the wet electrostatic precipitator through the blower of the fan. The water mist content and slurry dust at the inlet of the wet electrostatic precipitator are controlled and the voltage is adjusted. , to measure the removal efficiency of water mist and dust at the outlet of the wet electrostatic precipitator.

[0095...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com