Solid waste innocent treatment device and method

A technology of harmless treatment and solid waste, applied in the direction of solid waste removal, combustion methods, incinerators, etc., can solve the problems of necessary discharge of harmful smoke, substandard exhaust emissions, incomplete combustion of gas, etc. Stabilization, suppression of NOX formation, low thermal inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

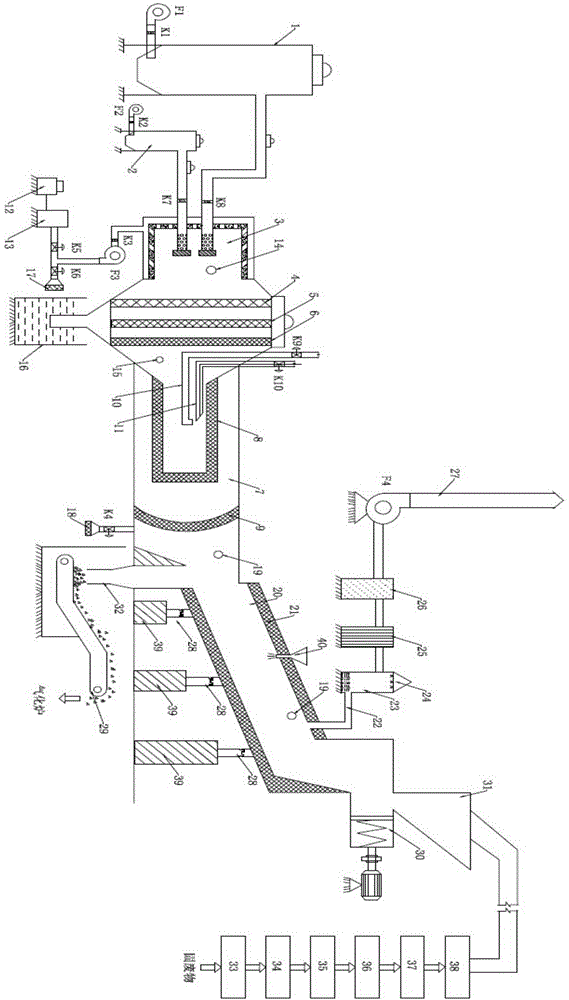

[0025] see figure 1 , the solid waste harmless treatment device includes a solid waste pyrolysis gasification furnace 1, a gas oxygen distribution premixed filter chamber 3, a gas combustion chamber 7, a dechlorination and desulfurization drying device 20, and a solid waste pretreatment device connected in sequence The solid waste harmless treatment device also includes a biomass pyrolysis gasifier 2 communicated with the gas oxygen distribution premixed filter chamber 3, and a tail gas treatment device communicated with the top of the dechlorination and desulfurization drying device 20; the gas The filter chamber in the oxygen distribution premixing filter chamber 3 is provided with a filter screen; the gas combustion chamber 7 is provided with a cylindrical metal fiber burner 8 with an open end, and the diesel pipe 10 and the igniter 11 extend into the cylindrical metal fiber burner 8. Inside the fiber burner 8; the gas combustion chamber 7 is also provided with a planar or ...

Embodiment 2

[0031] Based on the solid waste harmless treatment method of the solid waste harmless treatment device described in embodiment 1, the steps are as follows:

[0032] (1) After the solid waste is broken through the wire rope bag breaking machine to break plastic bags, woven bags, and cloth bags, it is sent to the vibrating screen to remove large non-combustible materials, and then sent to the magnetic separator to remove metal substances, and then sent to the crushing and crushing machine into lumps below 30cm, and then sent to the drum sieve to screen out small granular non-combustibles, and then sent to the crawler-type rolling dehydrator to squeeze out the internal moisture of the organic matter, so that the moisture content of the solid waste is reduced from more than 45%. After reaching below 30%, it is sent to the dechlorination and desulfurization drying device;

[0033] (2) The solid waste is in full contact with the hot air sent from the gas combustion chamber in the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com