Patents

Literature

58results about How to "Low thermal inertia" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

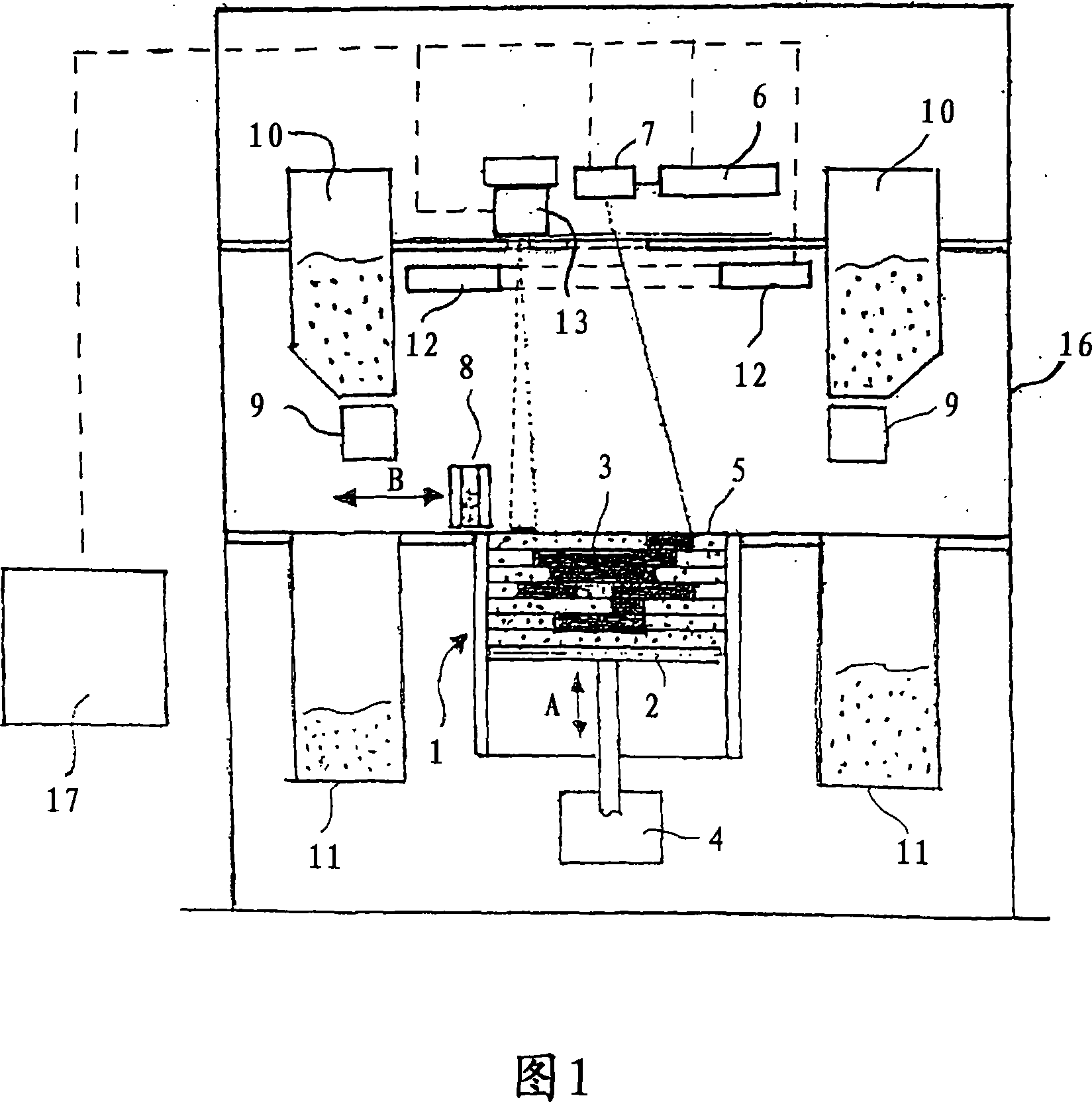

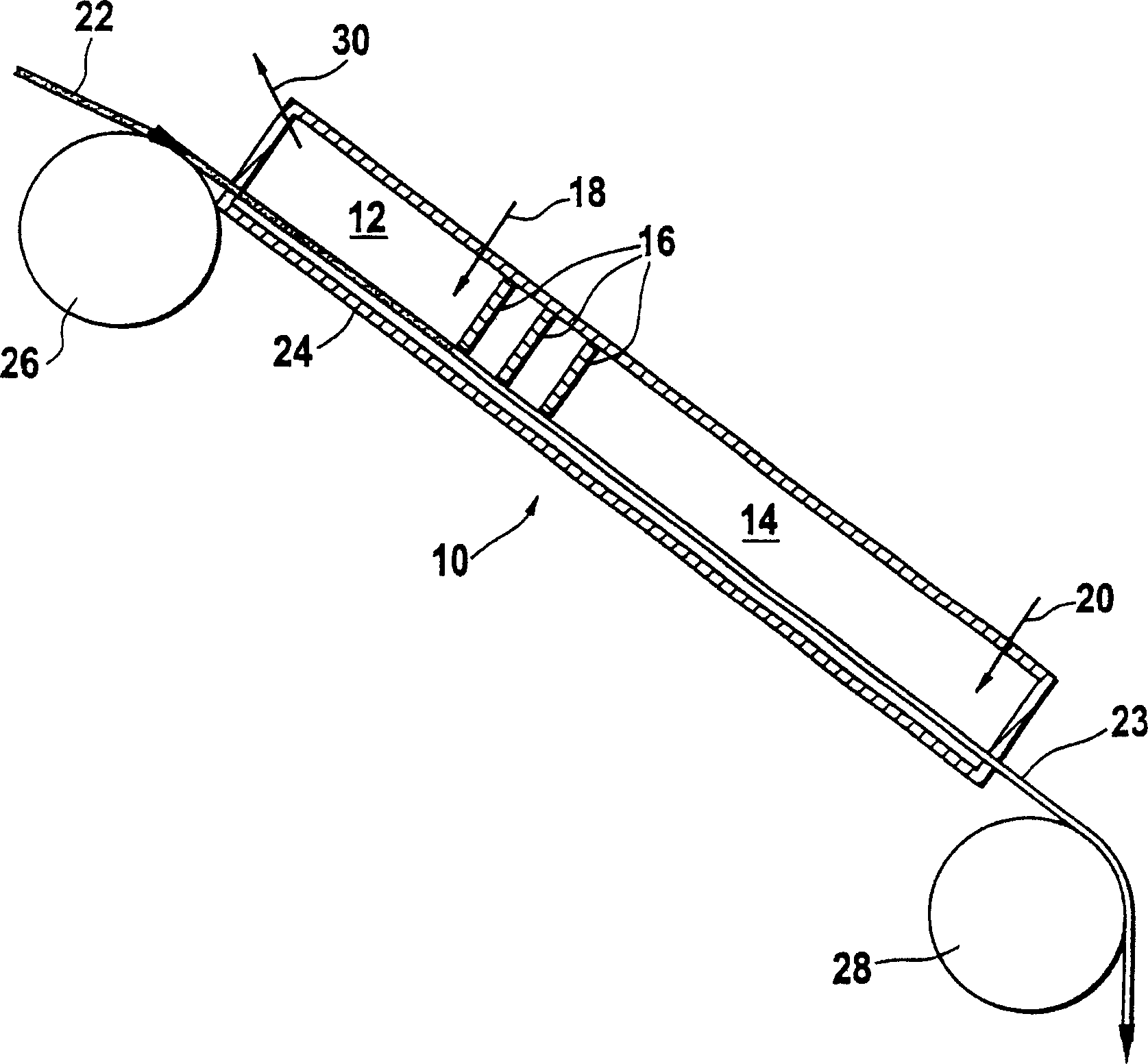

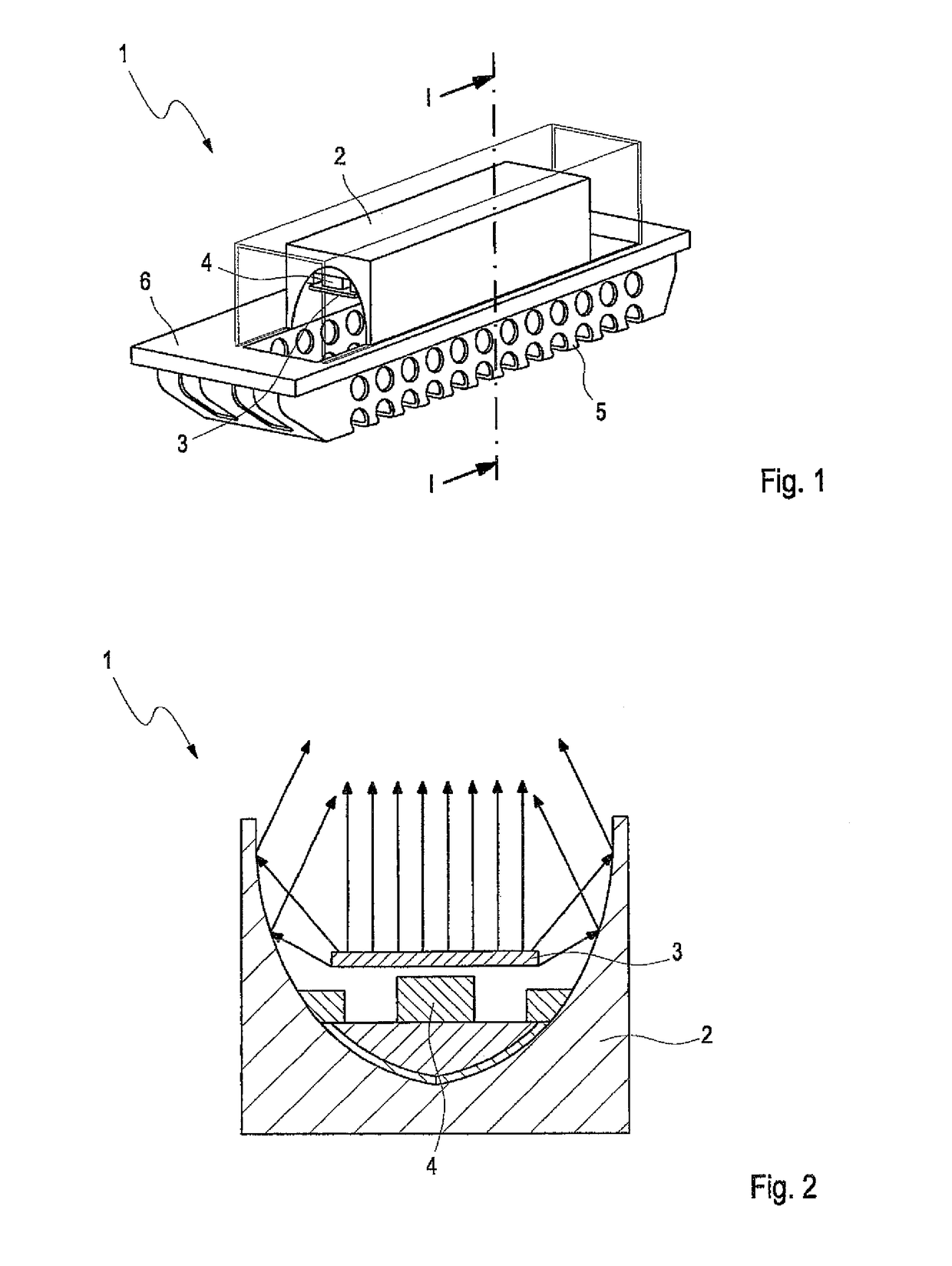

Radiant heater for heating the building material in a laser sintering device

InactiveUS8073315B2Reduce the temperatureThermal inertiaDomestic stoves or rangesDrying solid materials with heatRadiant heaterMetallurgy

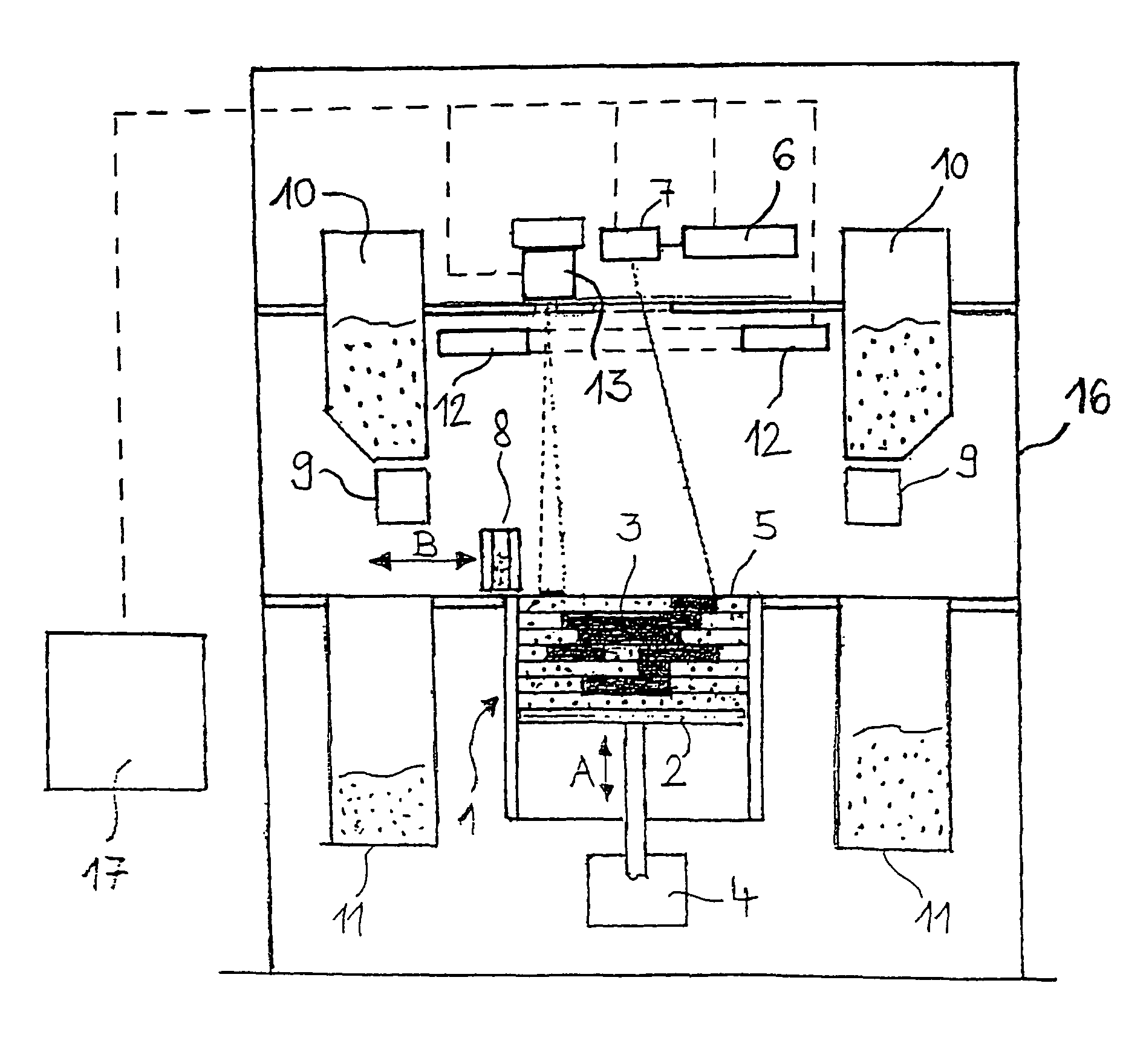

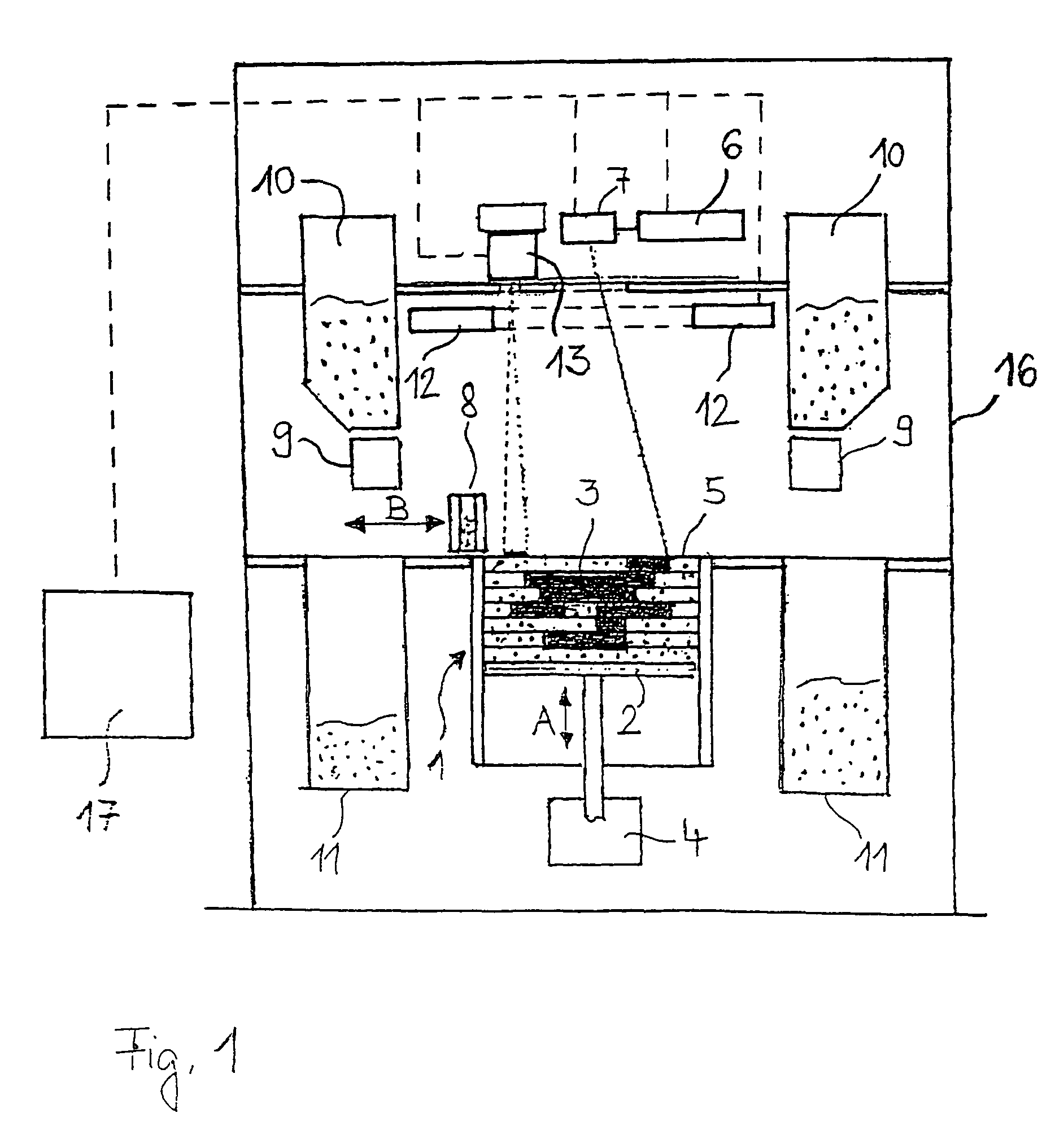

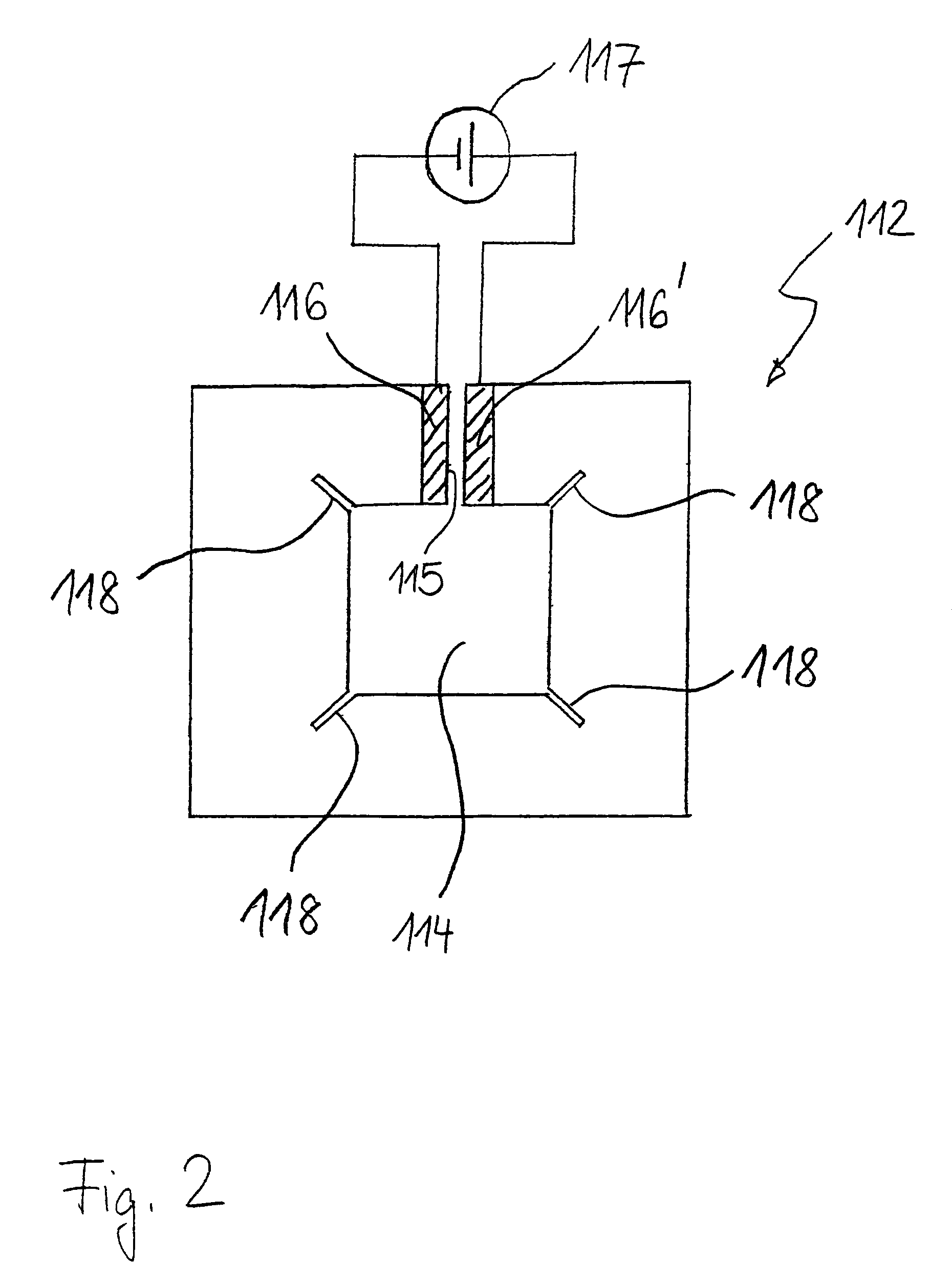

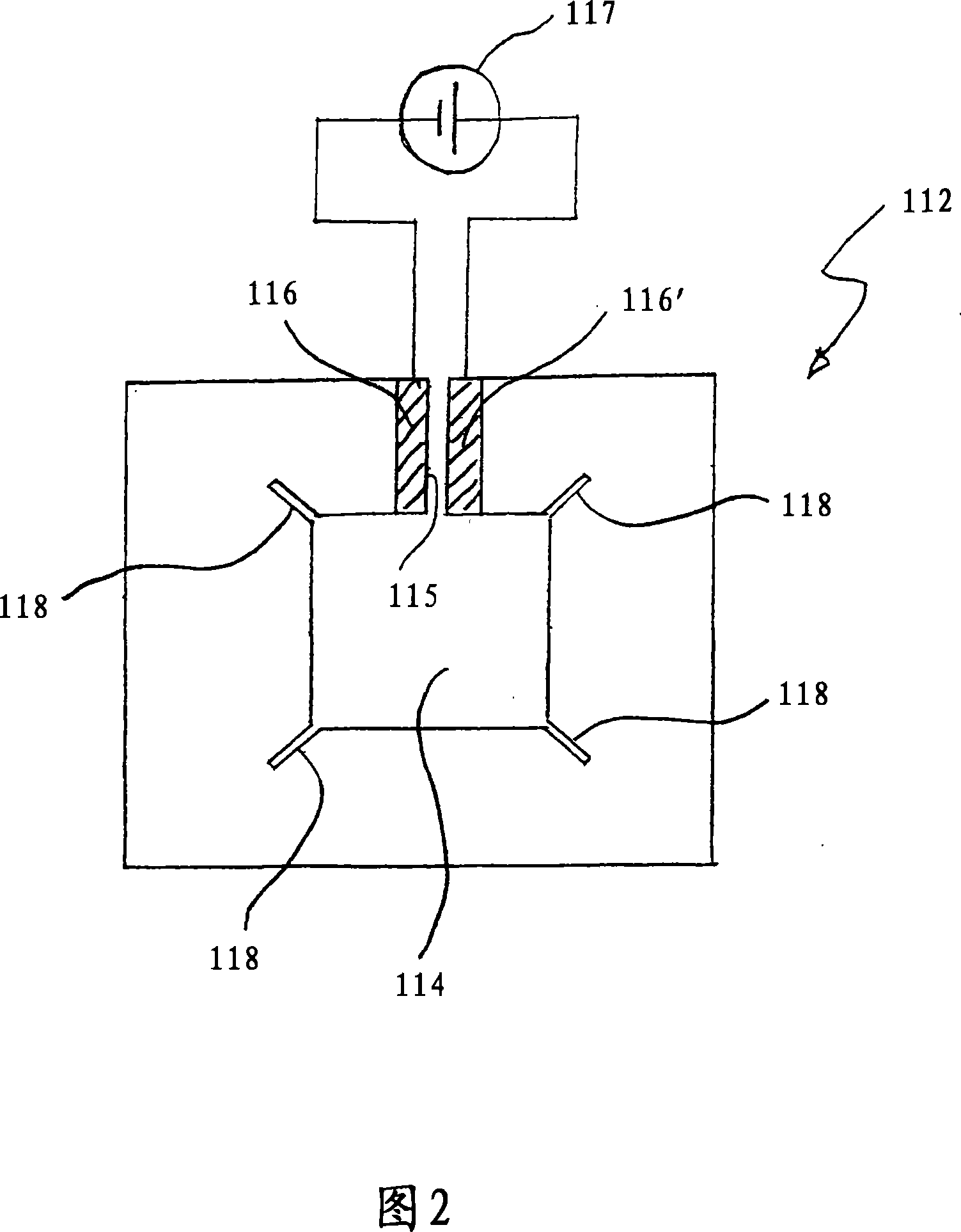

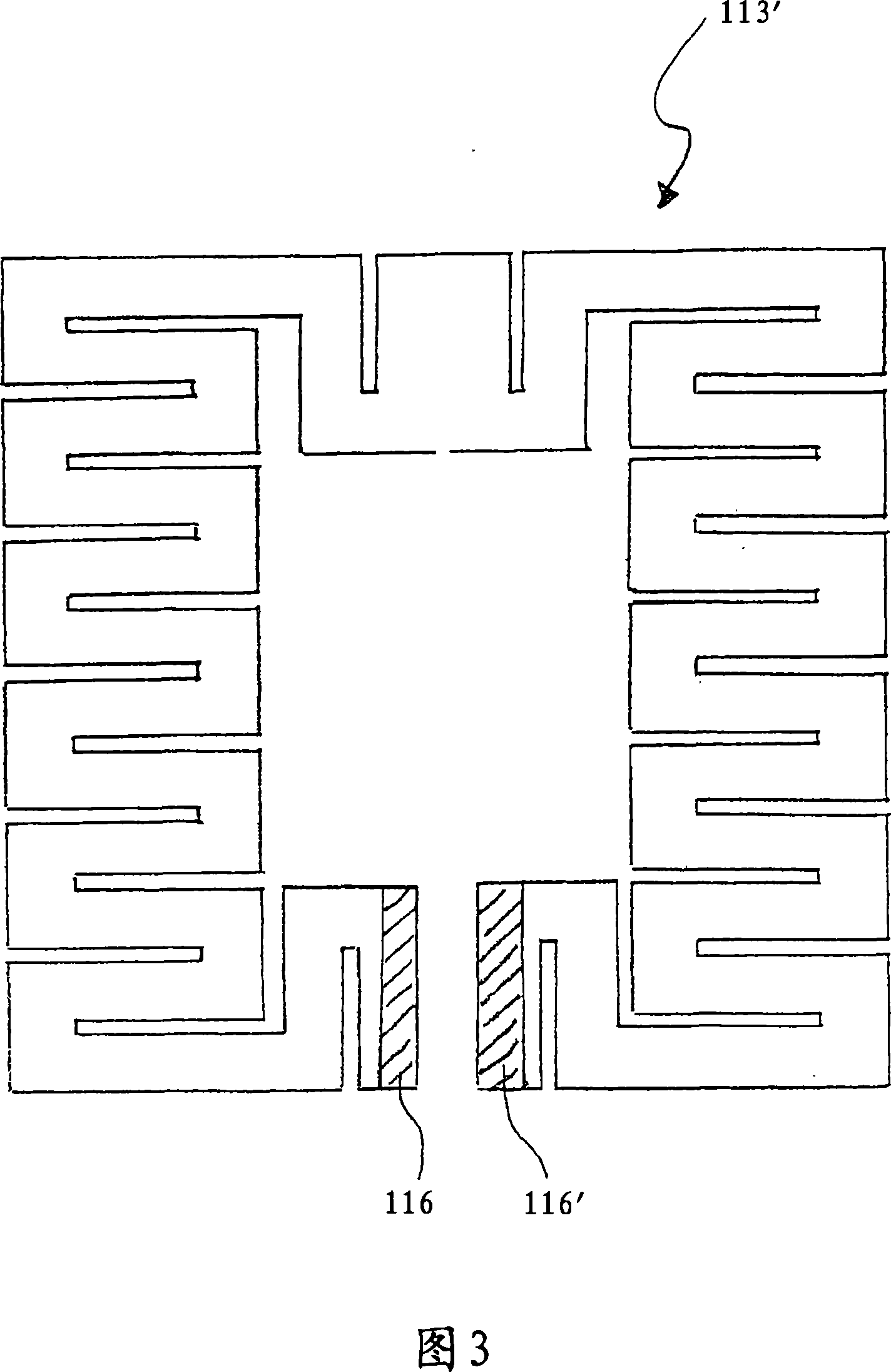

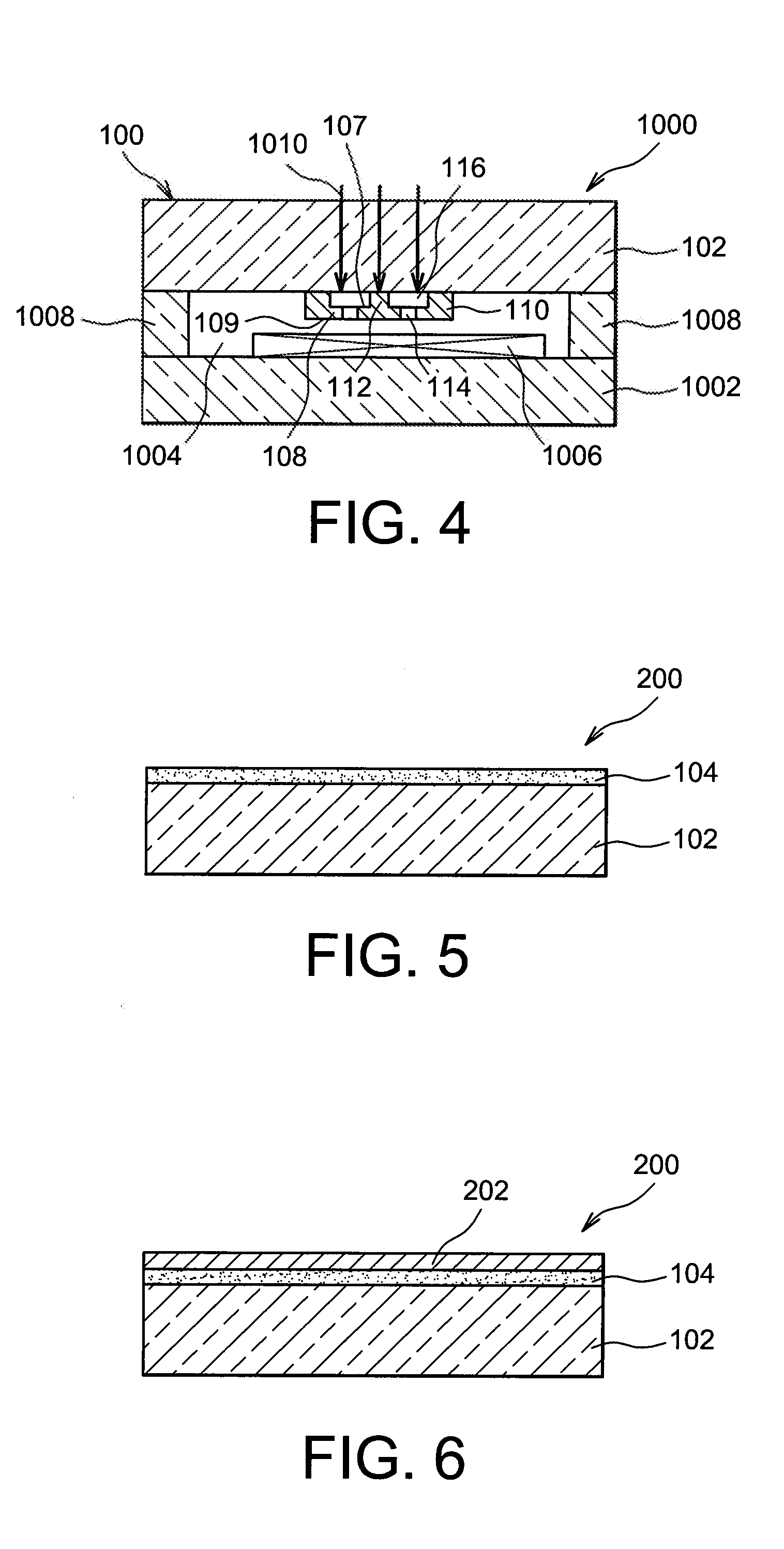

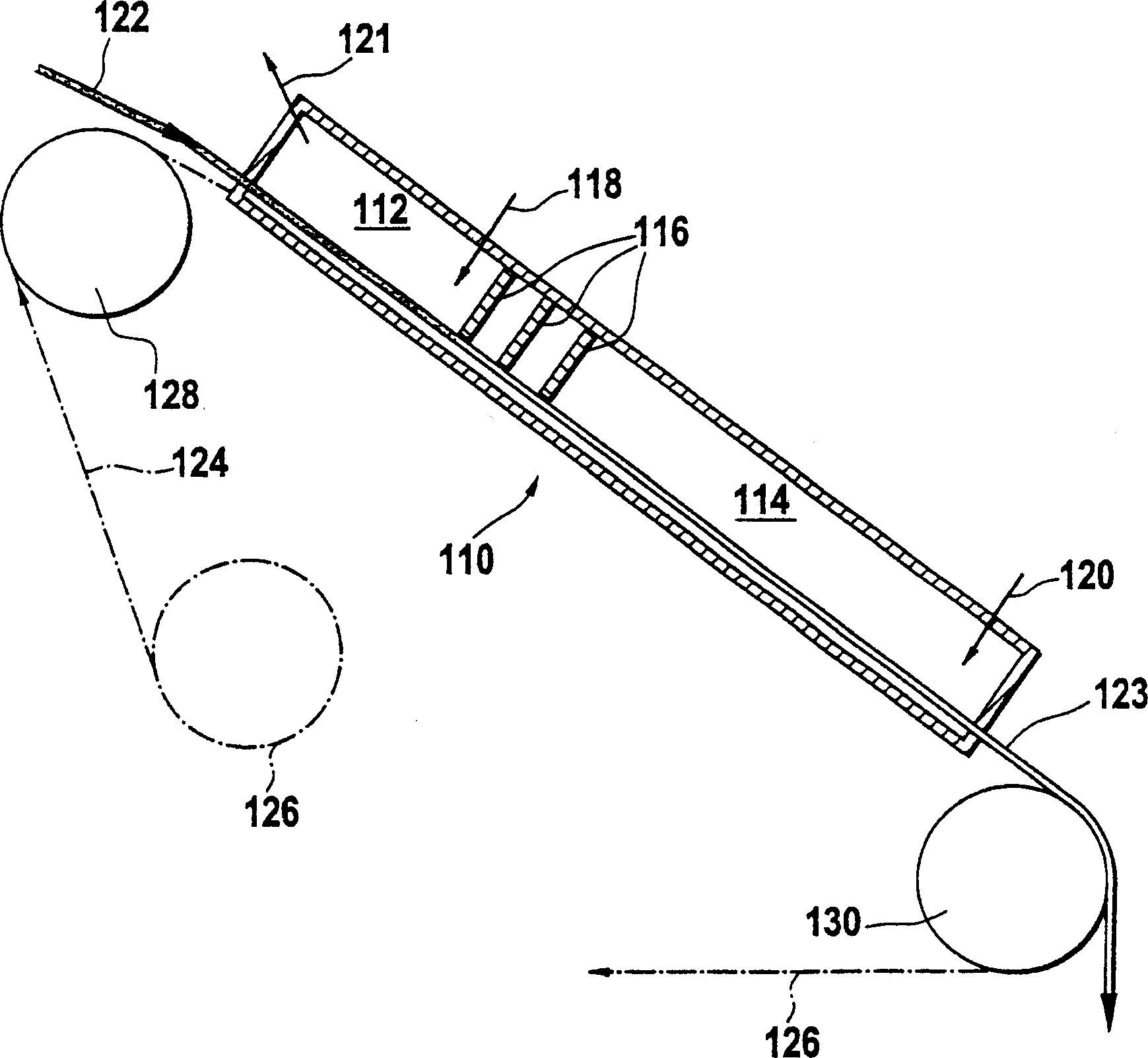

A radiant heating for heating the building material in a laser sintering device and a laser sintering device having such a radiant heating are described. The radiant heating has a sheet-like heat radiating element (113, 213, 313), which is characterized in that it is made of a material, that has a low thermal inertia with a thermal diffusivity of preferably more than 1.5·10−4 m2 / s and preferably has a thickness of 2 mm or less.

Owner:EOS ELECTRO OPTICAL SYST

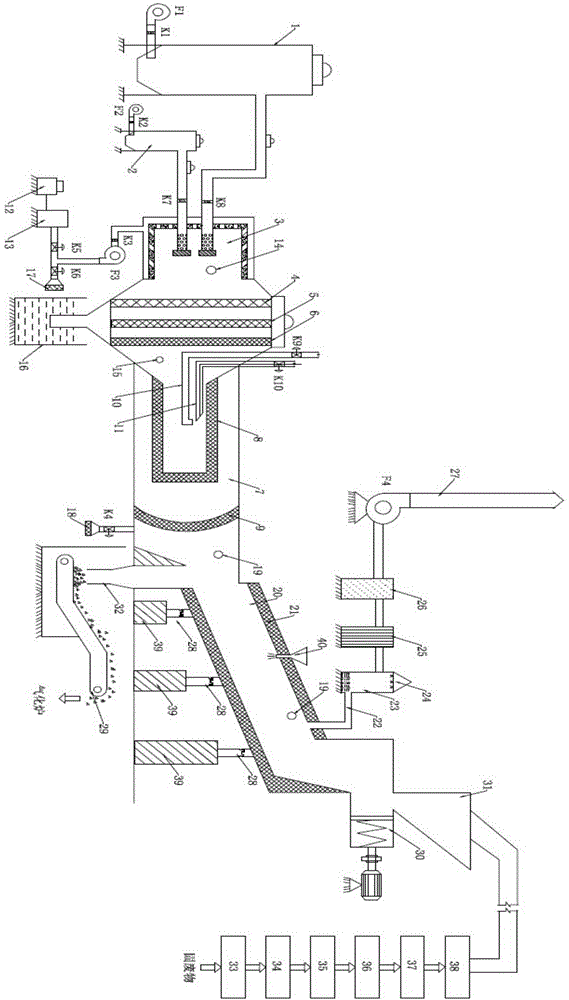

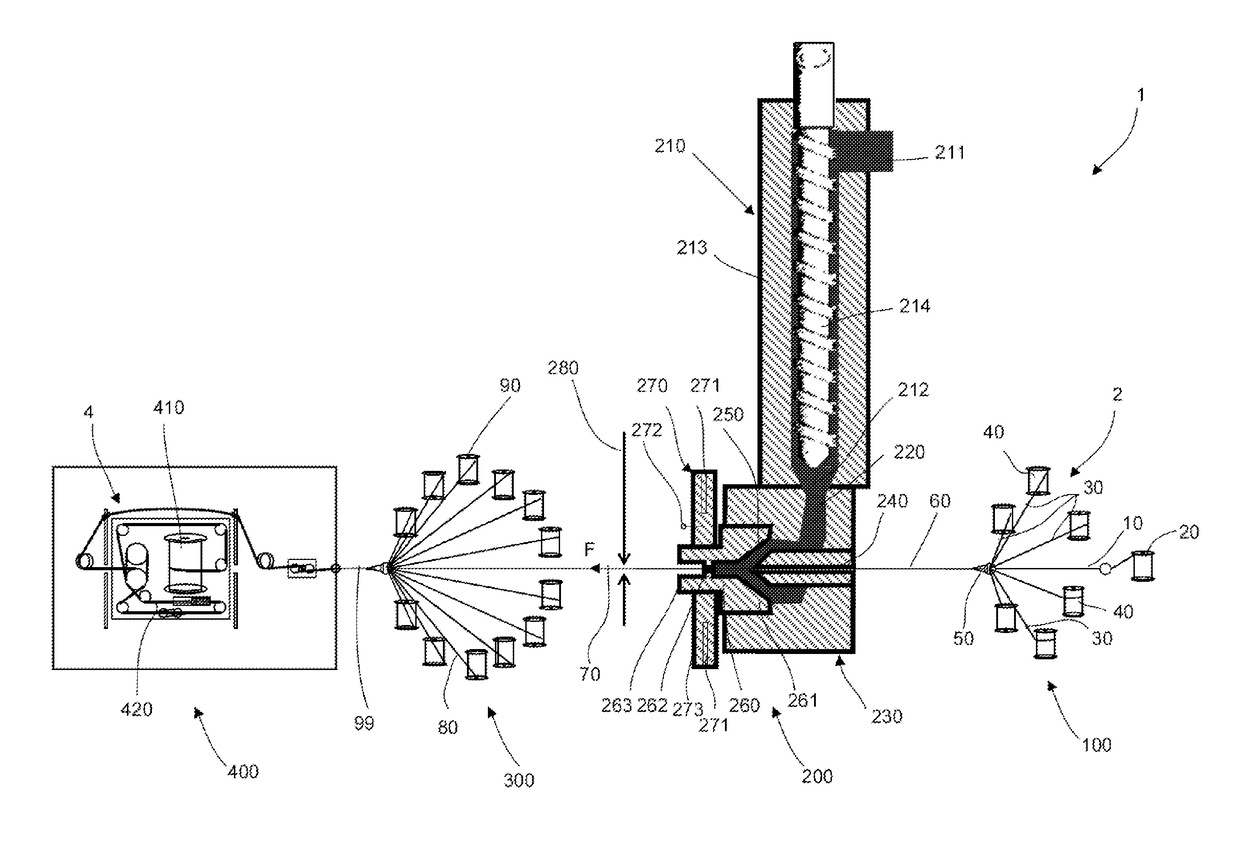

Solid waste innocent treatment device and method

ActiveCN104588402AExcellent emission indicatorsMeet environmental protection requirementsSolid waste disposalIncinerator apparatusCombustion chamberEmission standard

The invention discloses a solid waste innocent treatment device and a solid waste innocent treatment method. The solid waste innocent treatment device comprises a solid waste pyrolysis gasifier, a fuel gas oxygen replenishment premixing and filtering chamber, a fuel gas combustion chamber, a dechloridation and desulfurization drying device and a solid waste pretreatment device which are sequentially communicated; the solid waste innocent treatment device also comprises a biomass pyrolysis gasifier and a tail gas treatment device, wherein the biomass pyrolysis gasifier is communicated with the fuel gas oxygen replenishment premixing and filtering chamber; the tail gas treatment device is communicated with the top of the dechloridation and desulfurization drying device. When the method and the device are used for treating solid waste, the content of Dioxin in a detected emitted tail gas is lower than 0.023ng / m<3>, and the emission allowances of other gases, such as CO, SO2, HC1 and NOx, are also highly superior to the emission standard (GB18485-2014) issued by the nation in July 1st, 2014, and can completely meet the requirement of environment-friendliness.

Owner:深鹏环保工程有限公司

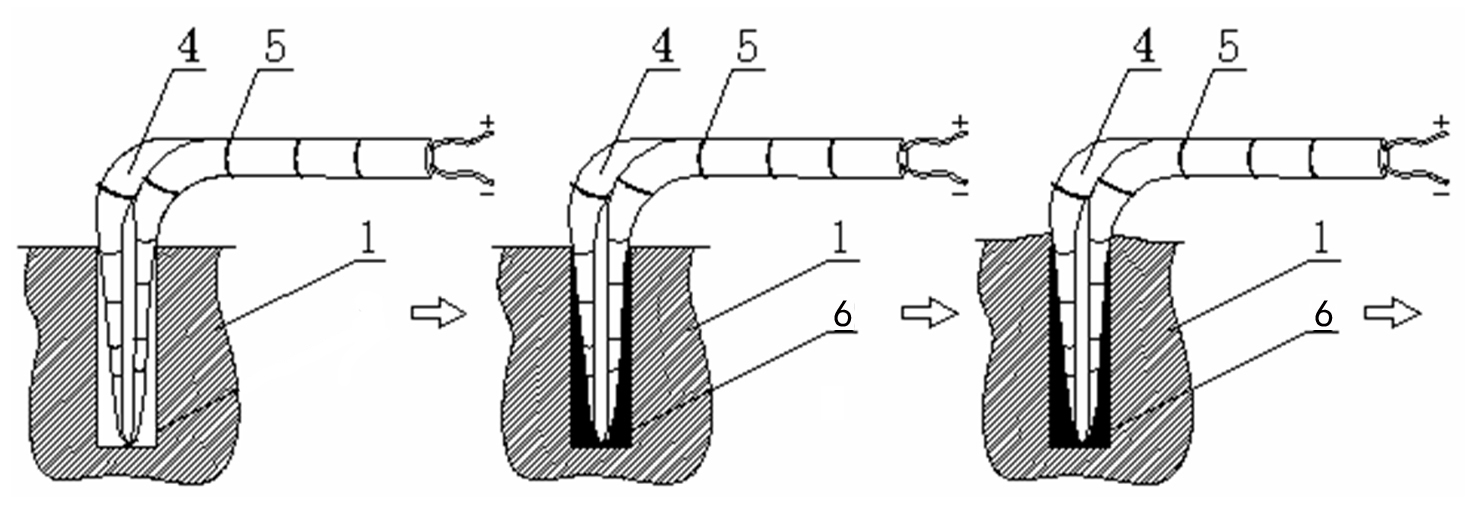

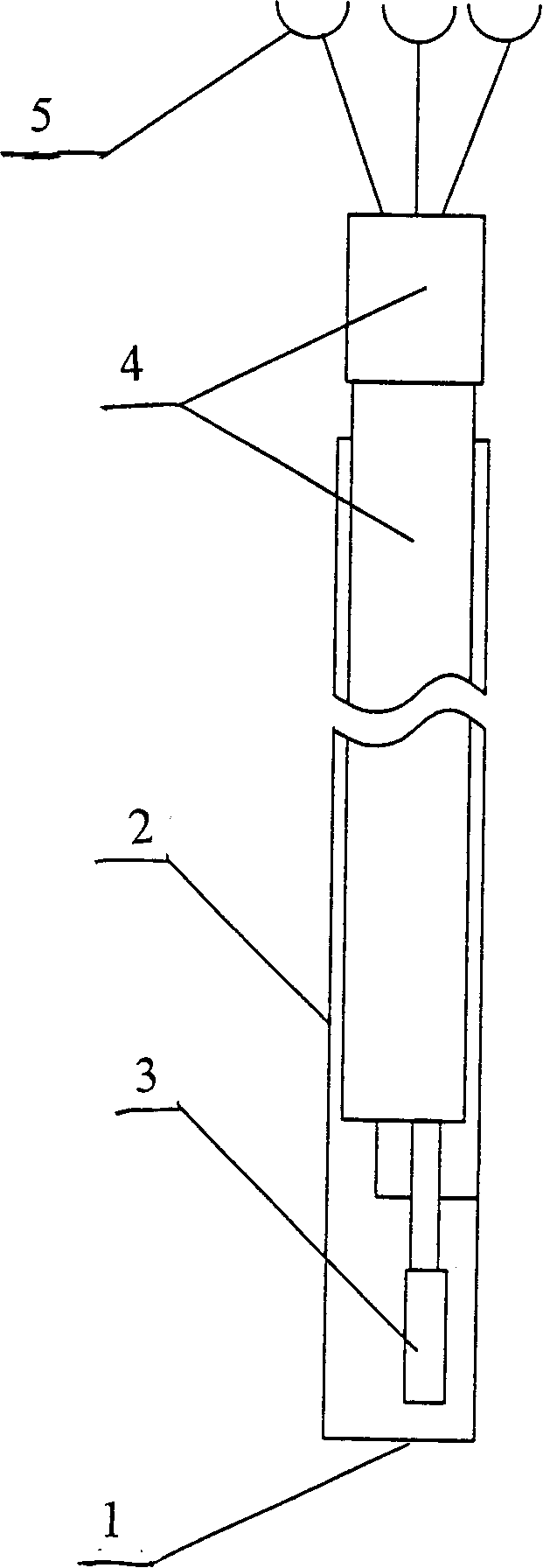

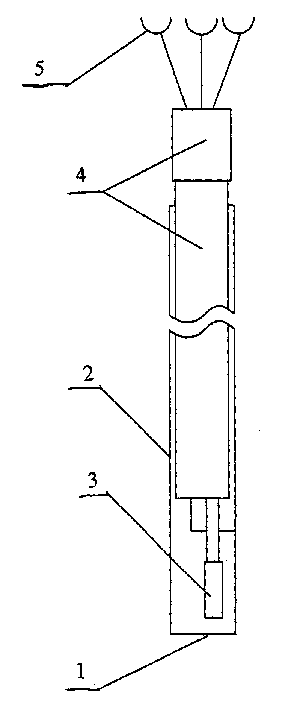

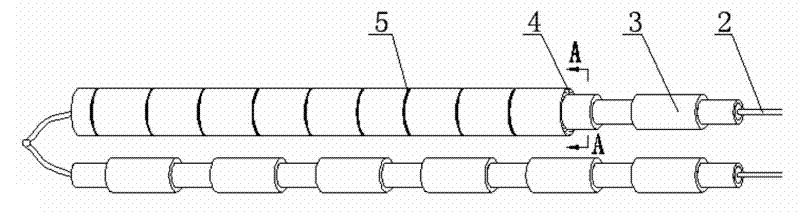

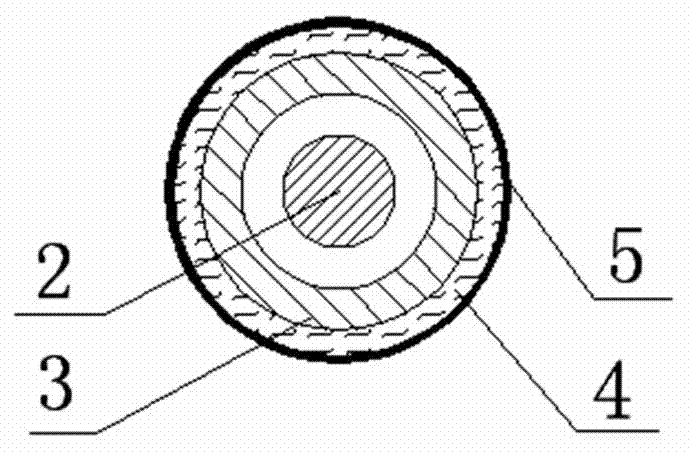

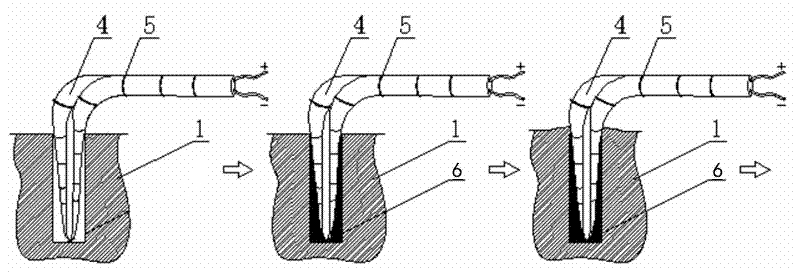

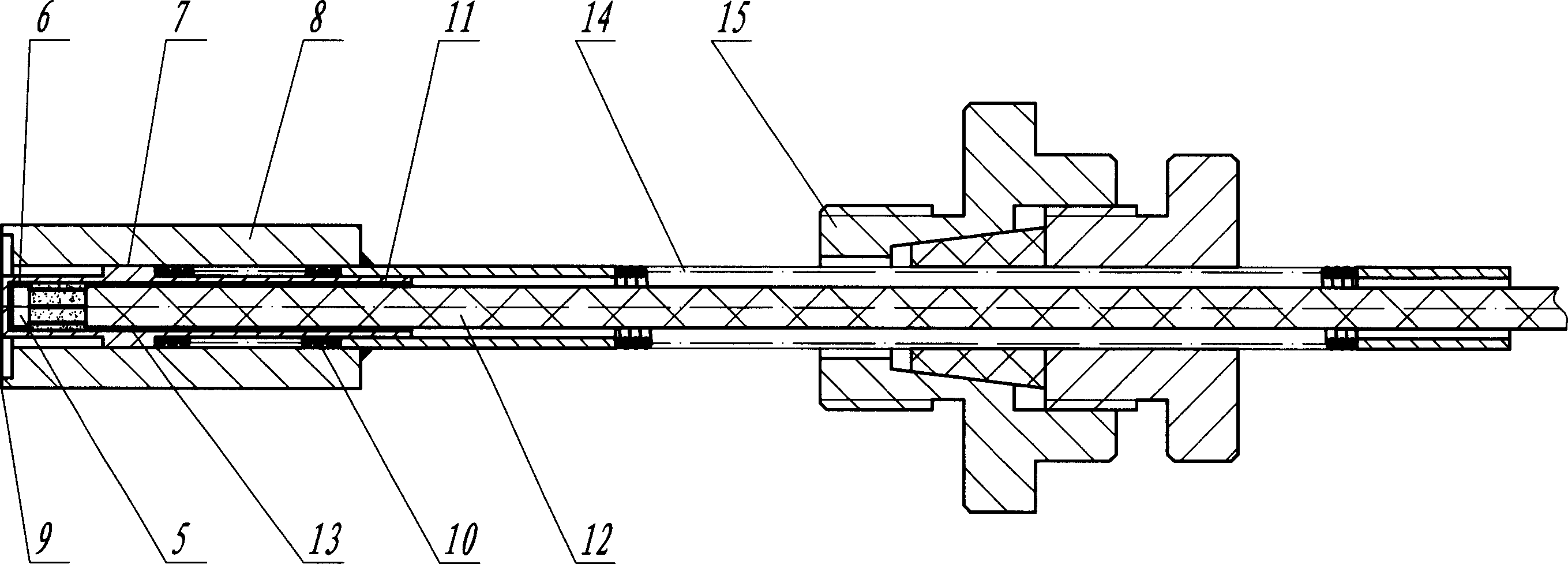

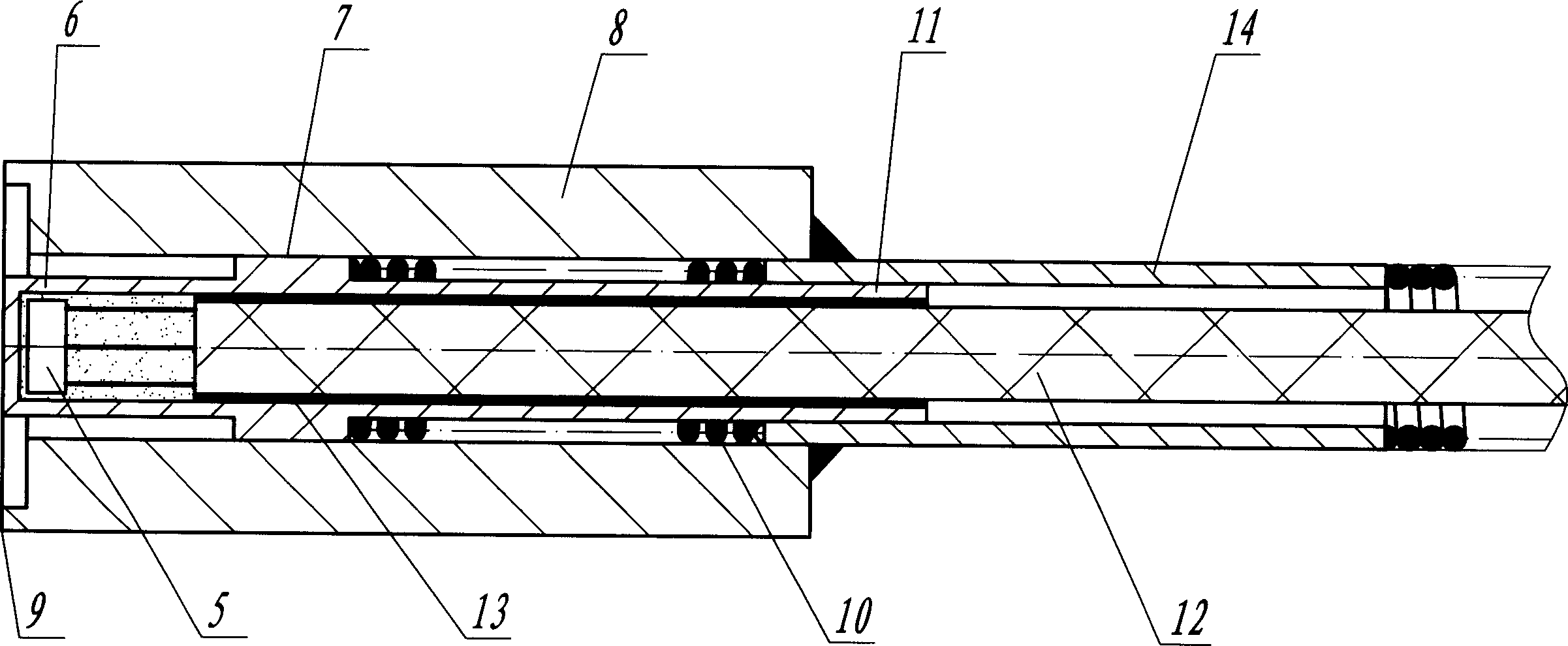

Method for follow-up testing of temperature of steel billet in furnace

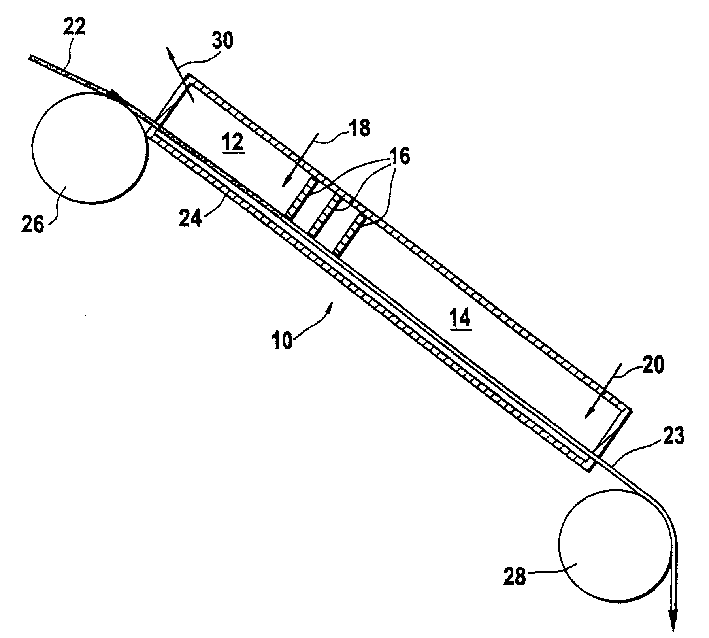

InactiveCN101968385AAvoid damageImprove accuracyThermometers using electric/magnetic elementsUsing electrical meansIron powderThermocouple

The invention relates to a method for follow-up testing of temperature of a steel billet in a furnace, which comprises the steps of primary preparation and the steps of follow-up testing in the furnace. The primary preparation comprises the following concrete steps: (1) drilling a hole on the steel billet to be tested; (2) inserting the hot end part of a thermocouple into the hole drilled in the step (1), and enabling the hot end of the thermocouple to be in contact with the bottom of the hole; filling and compressing the residual space in the hole by the iron powder of which the material is the same as the material of the steel billet to be tested; and (3) connecting the measuring end of the thermocouple to a temperature recorder, enabling the temperature recorder and the steel billet to together enter the furnace, and then, carrying out the steps of follow-up testing in the furnace. The method of the invention can improve the accuracy and the reliability of temperature testing of the steel billet.

Owner:武钢集团有限公司

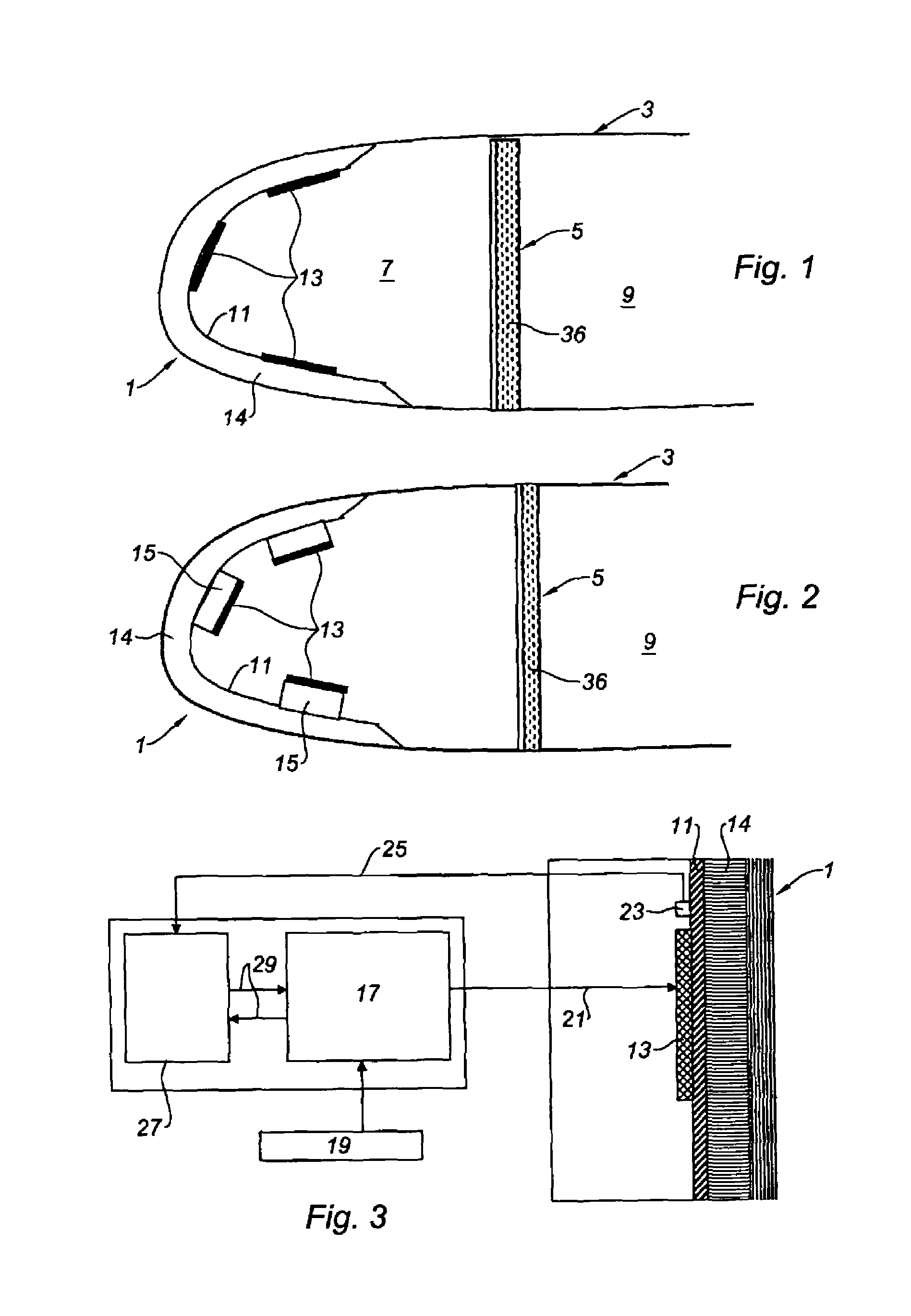

Radiant heater for heating the building material in a laser sintering device

InactiveCN101107882ALess lateral radiationLow thermal inertiaAdditive manufacturing apparatusIncreasing energy efficiencyRadiant heaterThermal diffusion coefficient

The invention relates to a radiant heater for heating the building material in a laser sintering device and to a laser sintering device comprising a radiant heater of this type. The radiant heater comprises a flat heat-emission element (113, 213, 313), which is characterised in that it consists of a material with low thermal inertia and a thermal diffusivity preferably in excess of 1.5 10-4 m2 / s and preferably a thickness less than or equal to 2 mm.

Owner:EOS ELECTRO OPTICAL SYST

Rare earth electrode slurry of rare earth thick film circuit based on metal plate and its preparation technology

ActiveCN1909748AIntermolecular bonding strength and improved manufacturabilitySolid combinationOhmic-resistance electrodesNon-conductive material with dispersed conductive materialSolid phasesYttrium

The invention relates to a rare-earth electrode slurry of rare-earth circuit, based on the metal base board and a relative production, wherein it is characterized in that: said slurry is formed by solid material and organic solvent carrier, while their mass ratio is 70-90:30-10; the solid component comprises: silver, palladium, and yttrium composite power and micro-crystal glass powder, while their mass percentage is 99.4-94:0.6-6; said composite power is formed by silver, palladium, and yttrium powders at the ratio as 0.6-10:99-82:0.4-8; said micro-crystal glass is the one in SiO2-Al2O3-CaO-B2O3-Bi2O3-La2O3 group. And the production comprises: (1), preparing rare-earth micro-crystal glass powder; (2), preparing silver, palladium, and yttrium composite powder; (3), preparing organic solvent carrier; (4), mixing material in three-dimension and rolling with three rollers; (5), preparing the rare-earth slurry; (6), bottling. The invention is environment friendly and better humidity compatibility.

Owner:GUANGDONGSHENG YUCHEN ELECTRONICS & TECH CO LTD

Suspended getter material-based structure

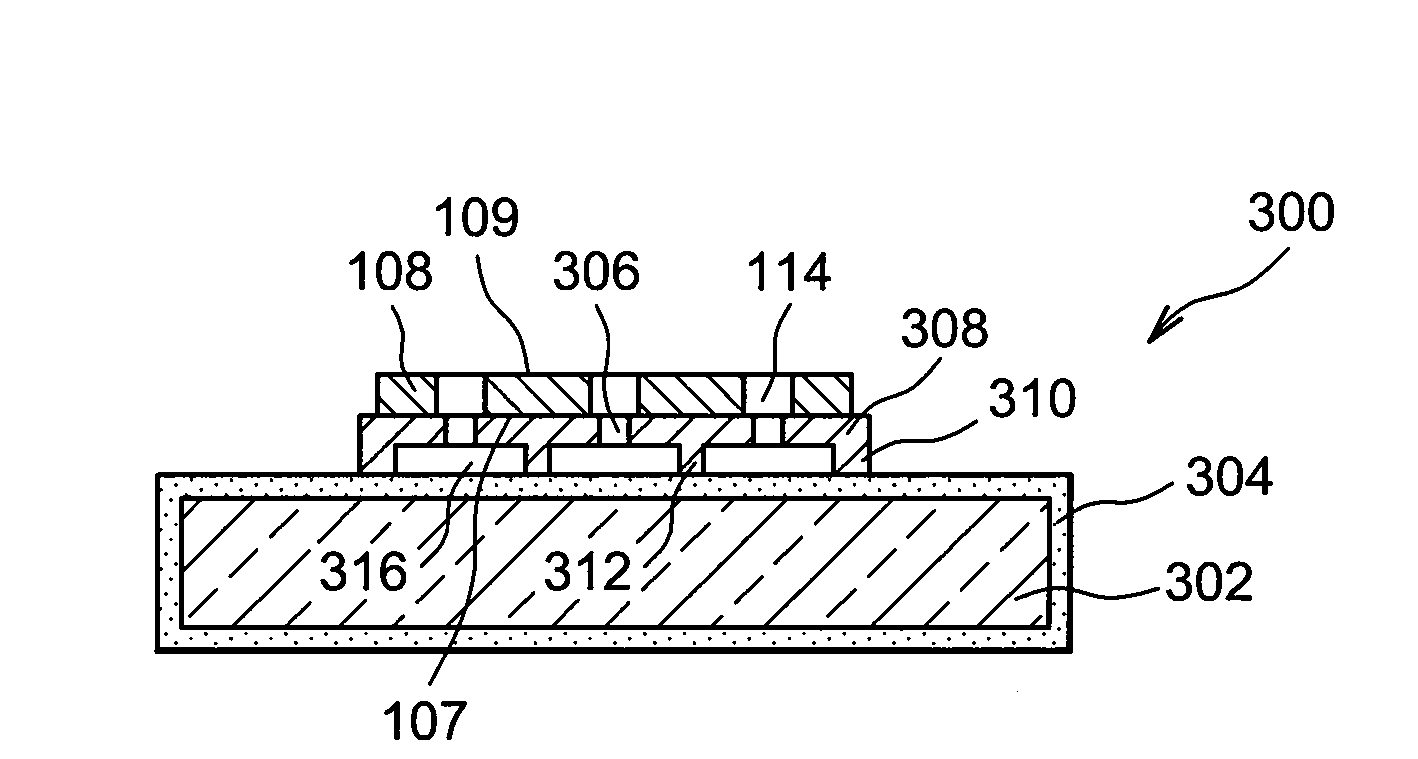

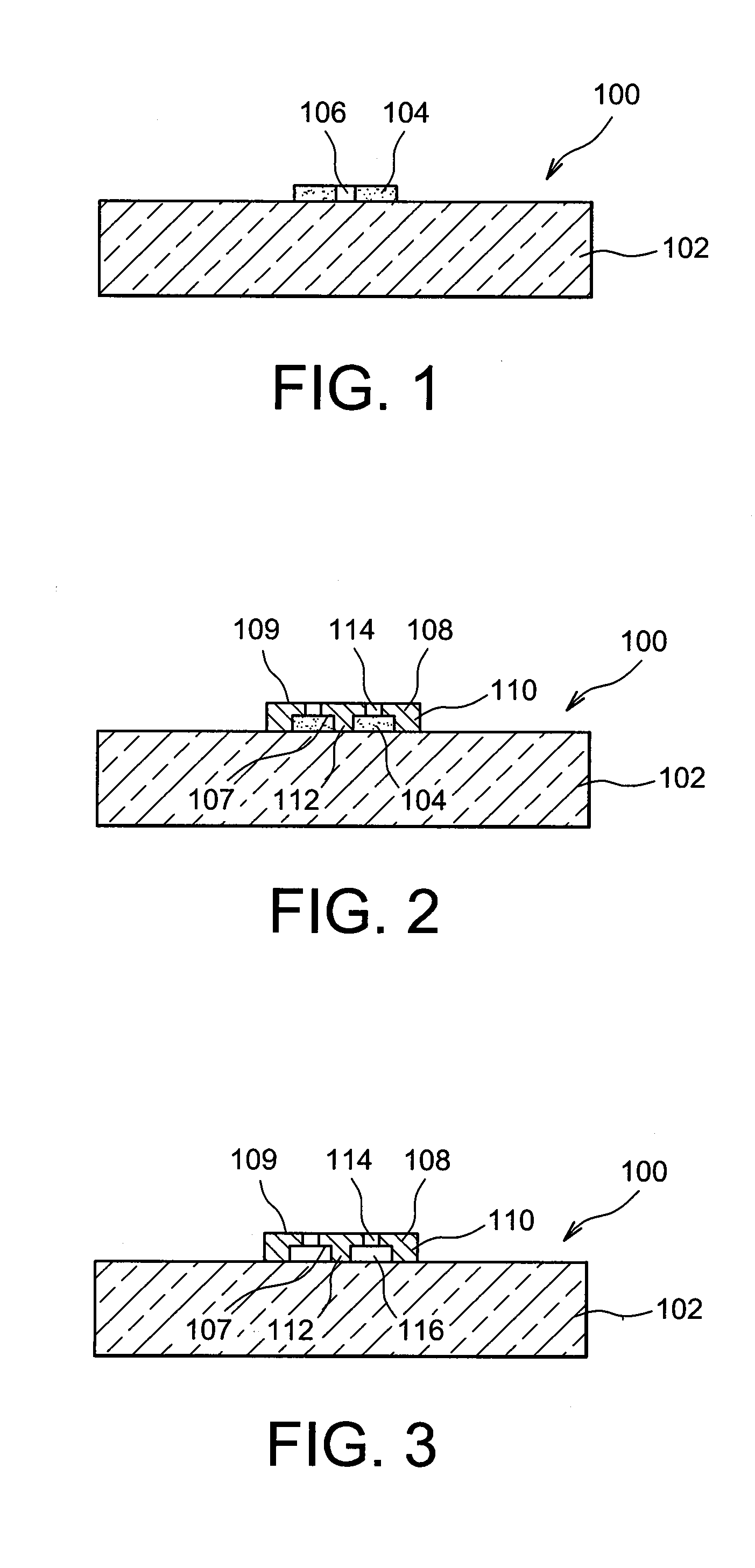

ActiveUS20100001361A1Thermal activation powerIncrease the areaLayered productsSemiconductor/solid-state device detailsMaterials scienceGetter

Getter structure comprising a substrate and at least one getter material-based layer mechanically connected to the substrate by means of at least one support, in which the surface of the support in contact with the substrate is smaller than the surface of a first face of the getter material layer, in which said first face is in contact with the support, and a second face of the getter material layer, opposite said first face is at least partially exposed.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

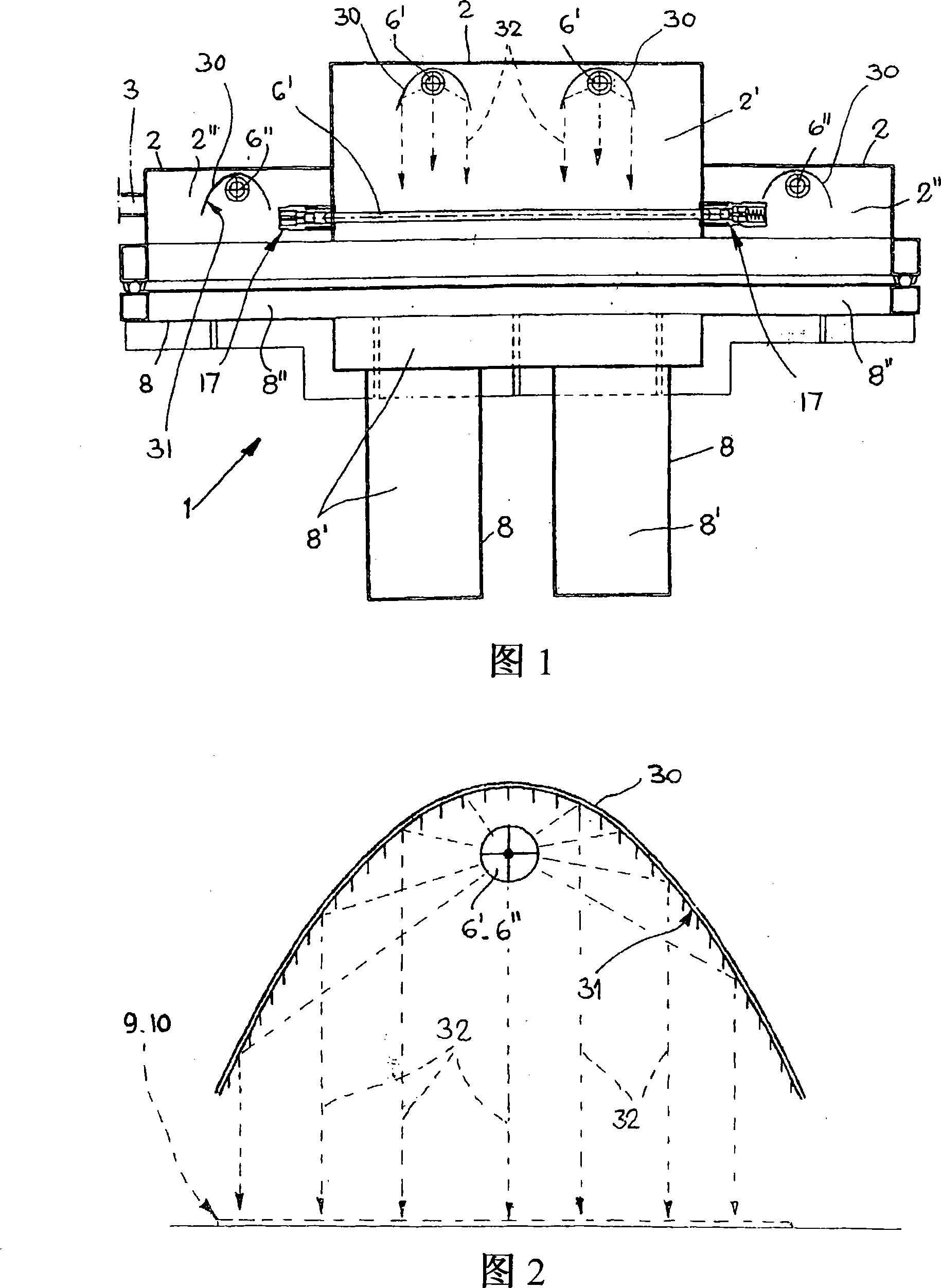

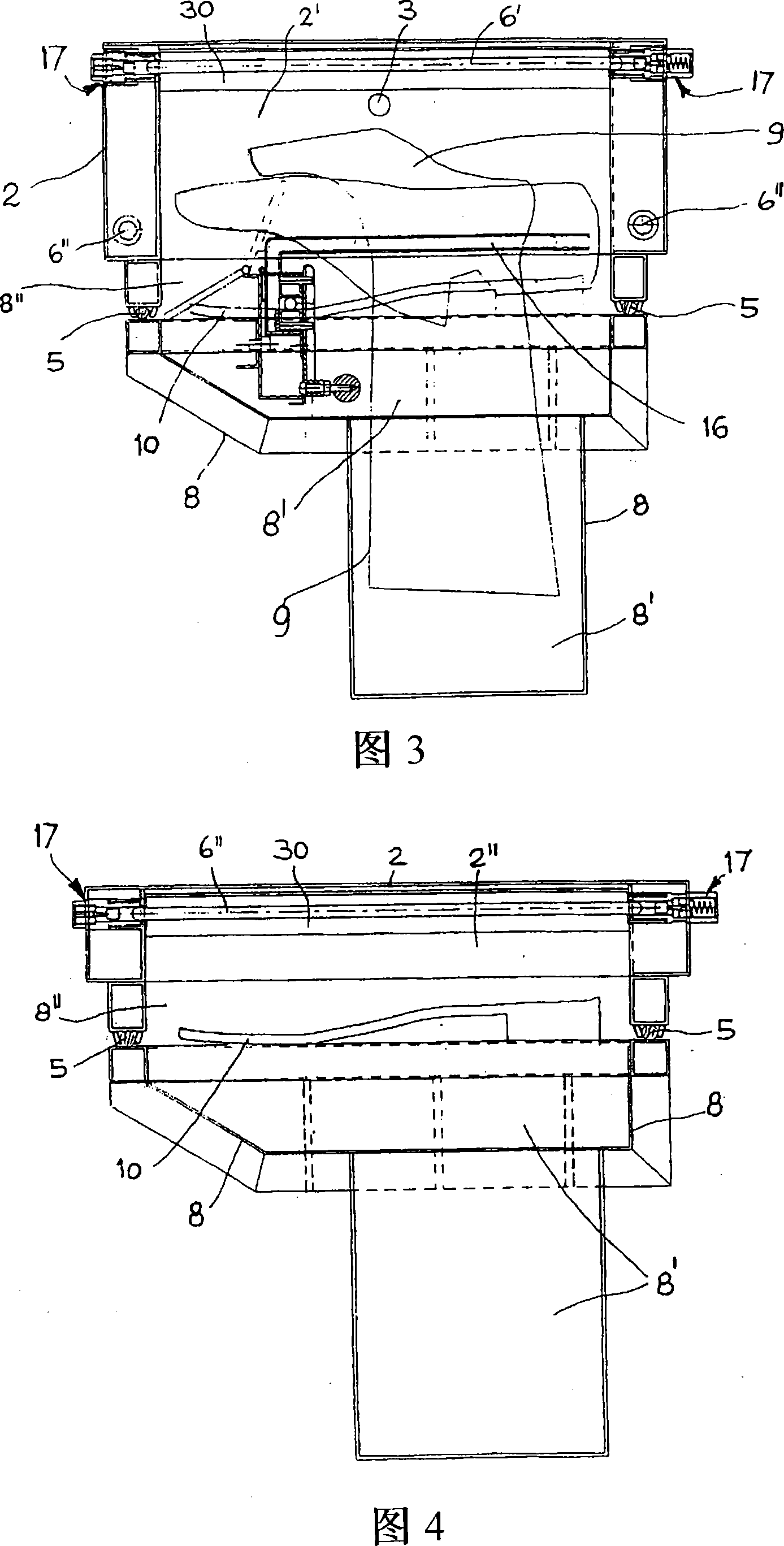

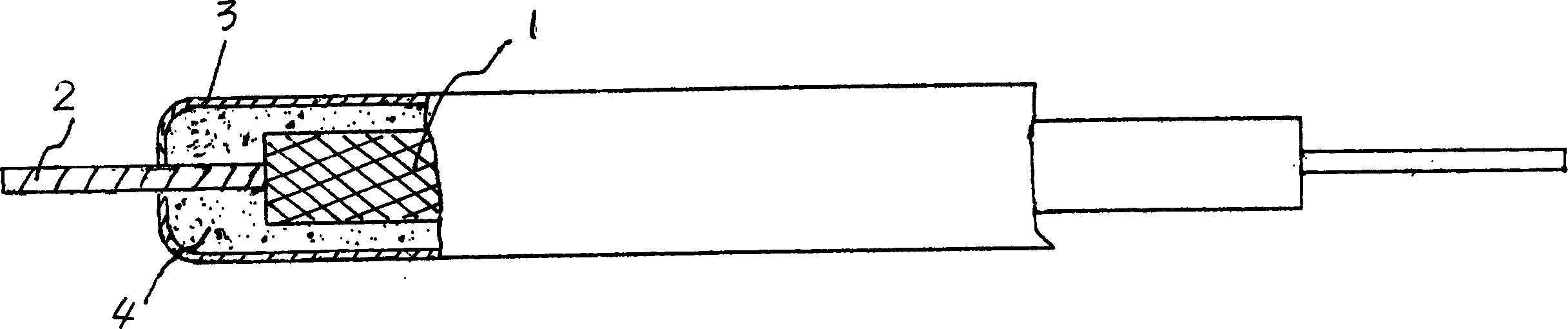

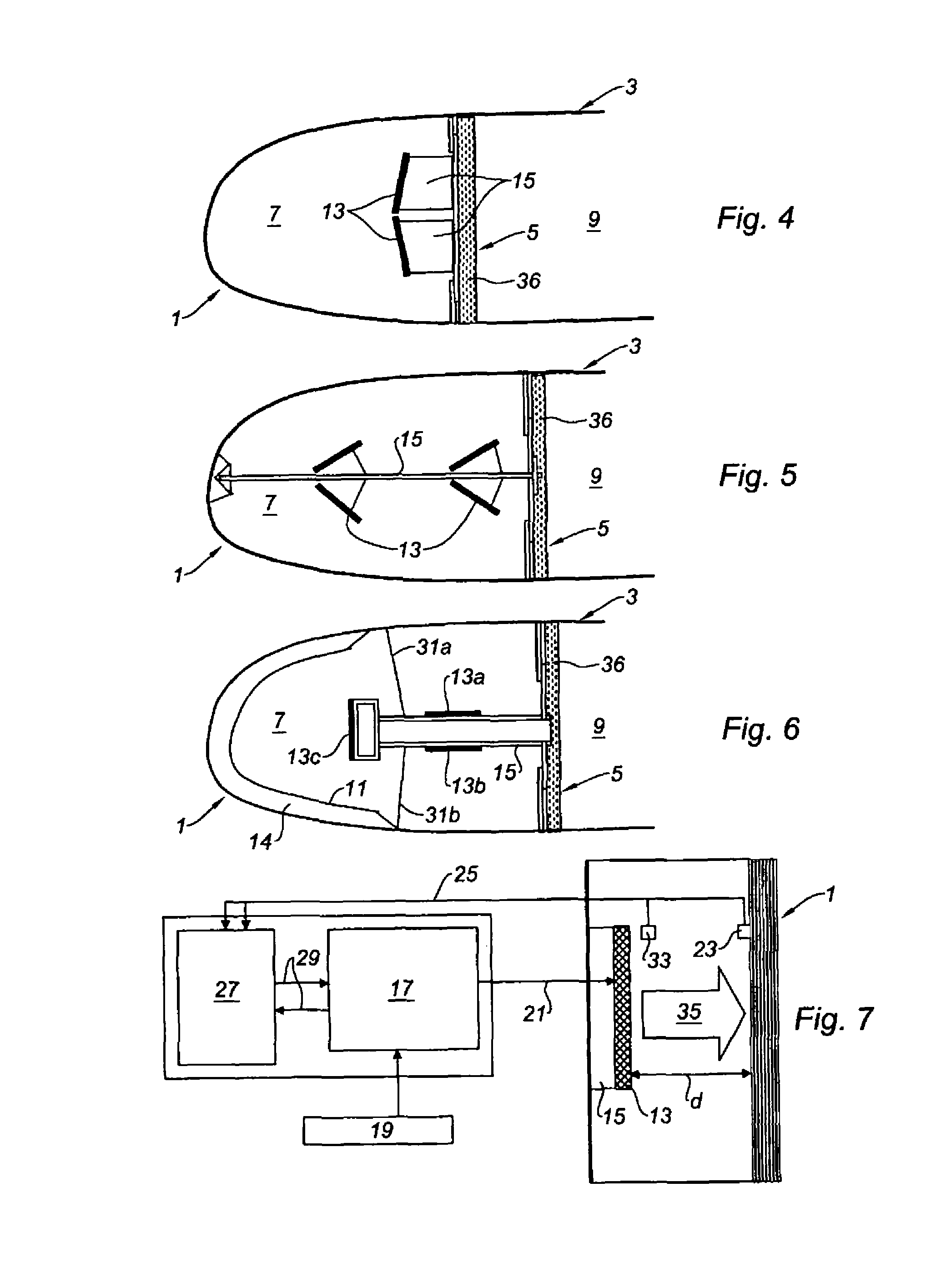

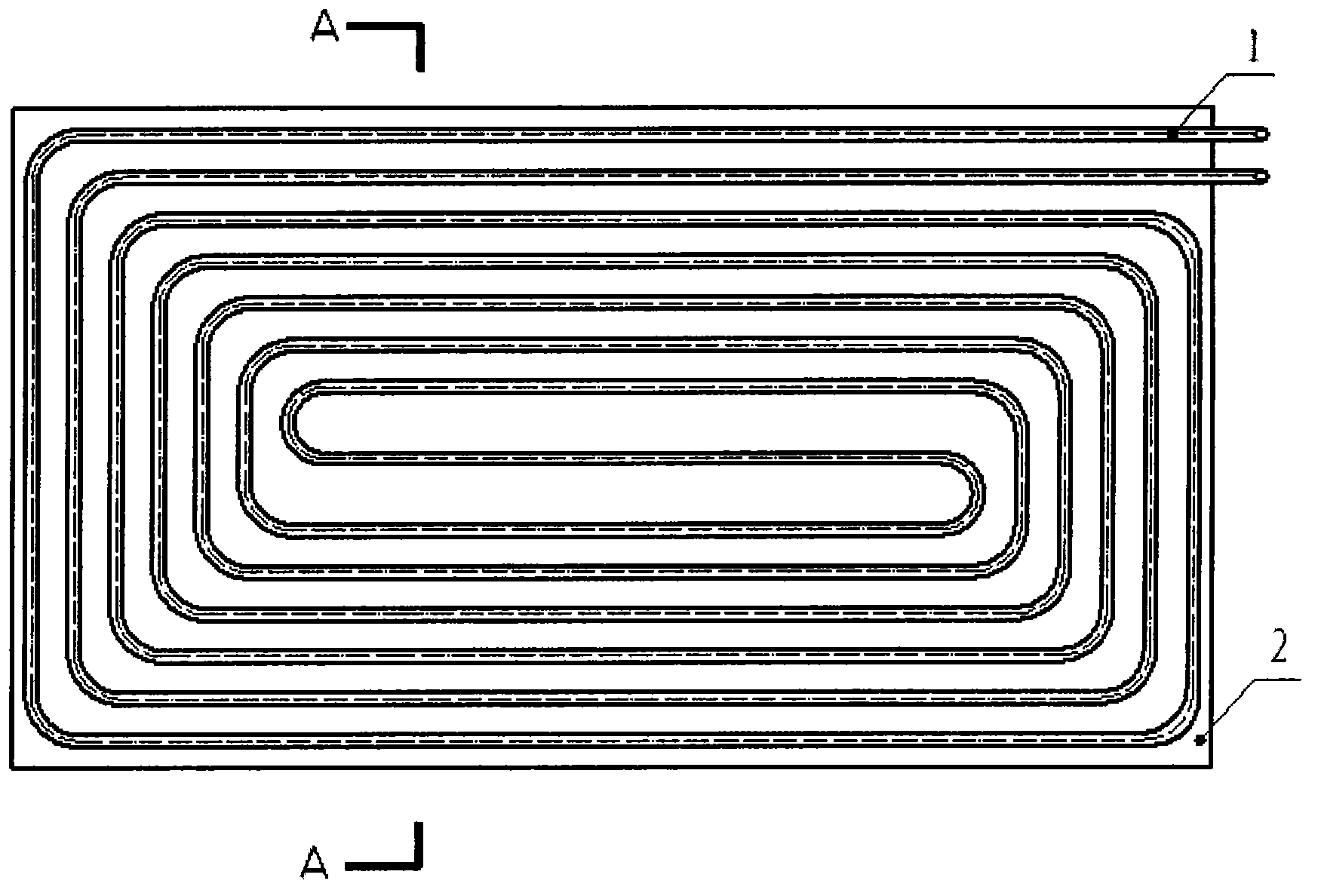

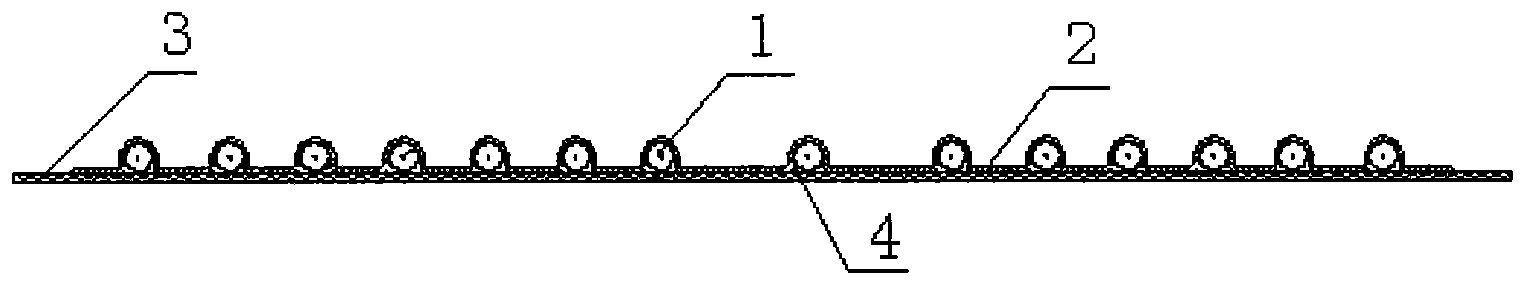

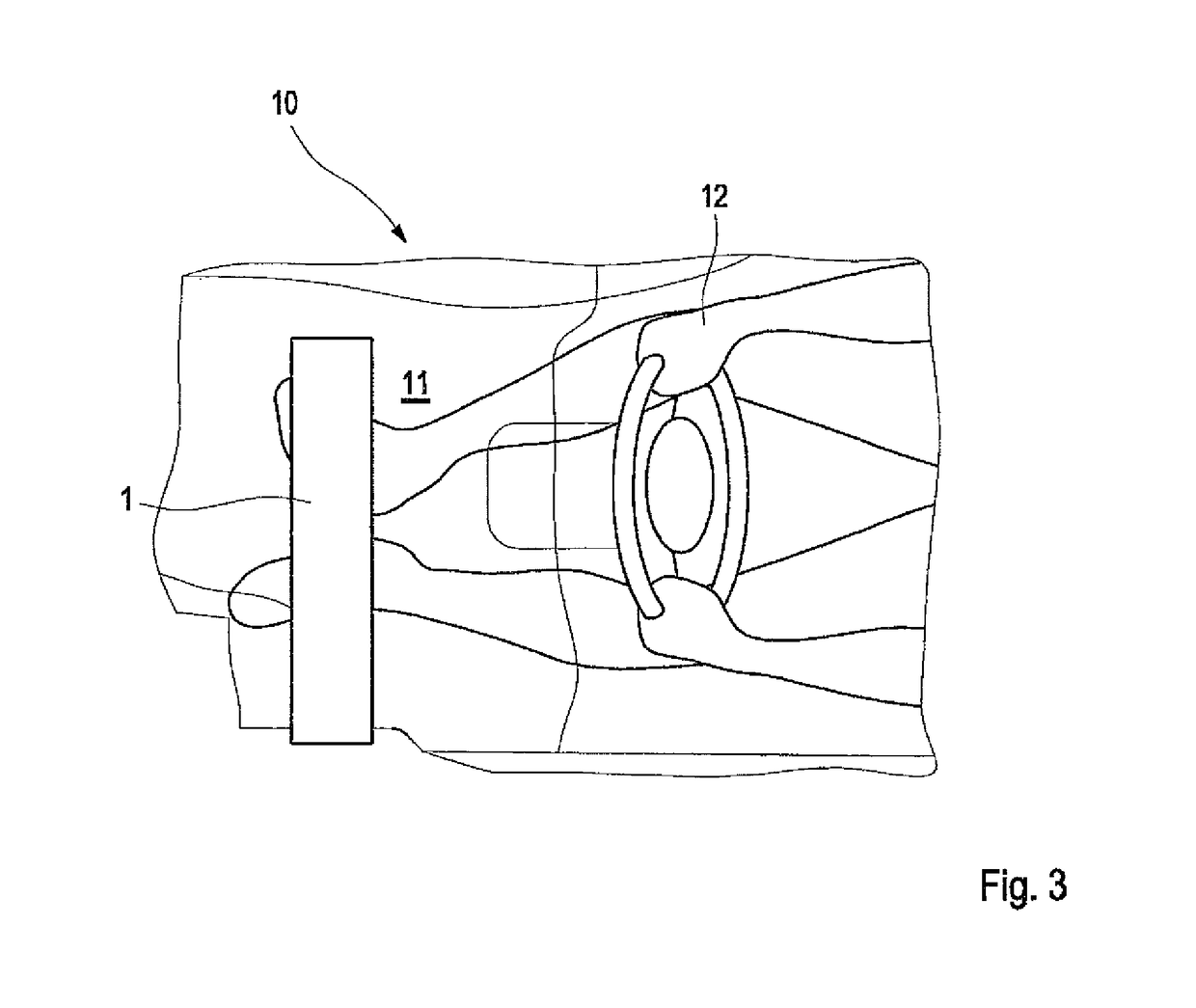

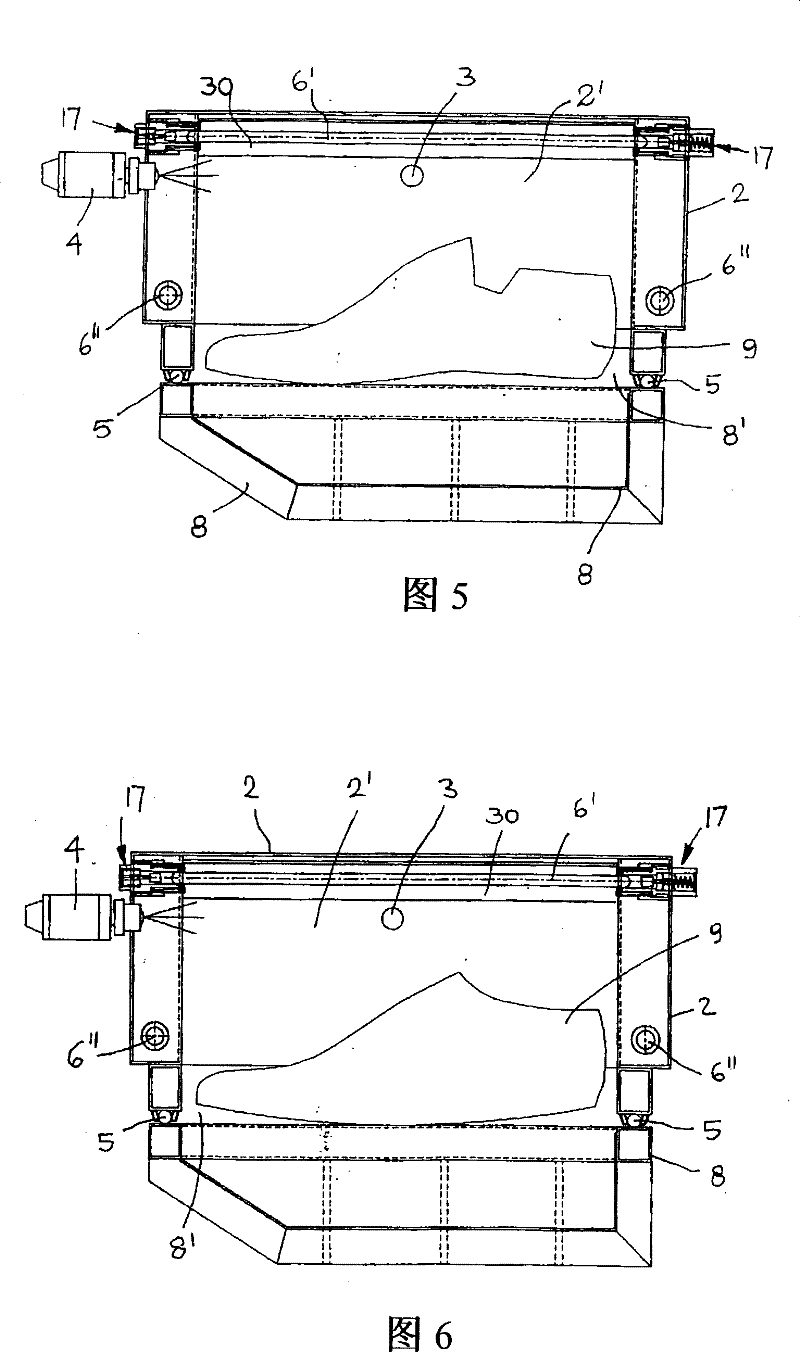

De-icing and/or Anti-icing system for the leading edge of an aircraft wing

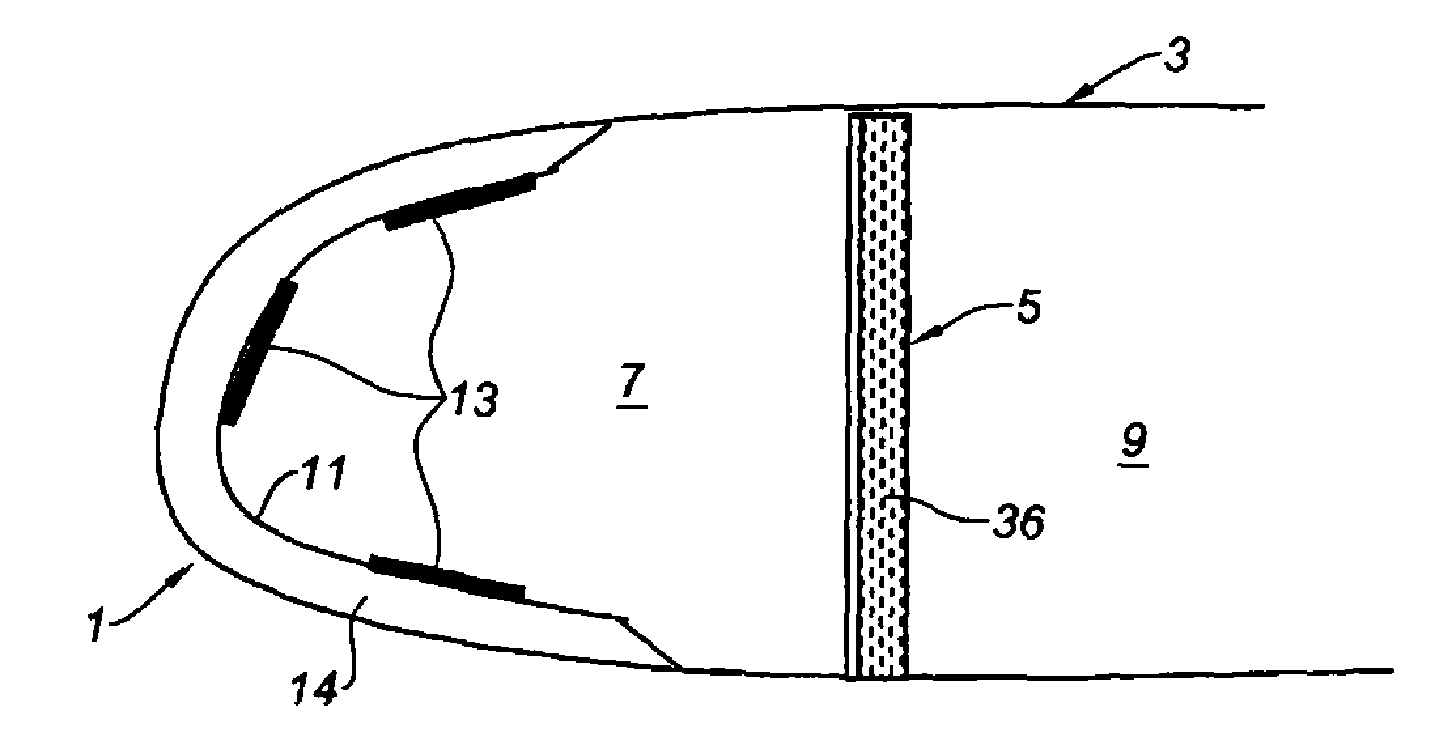

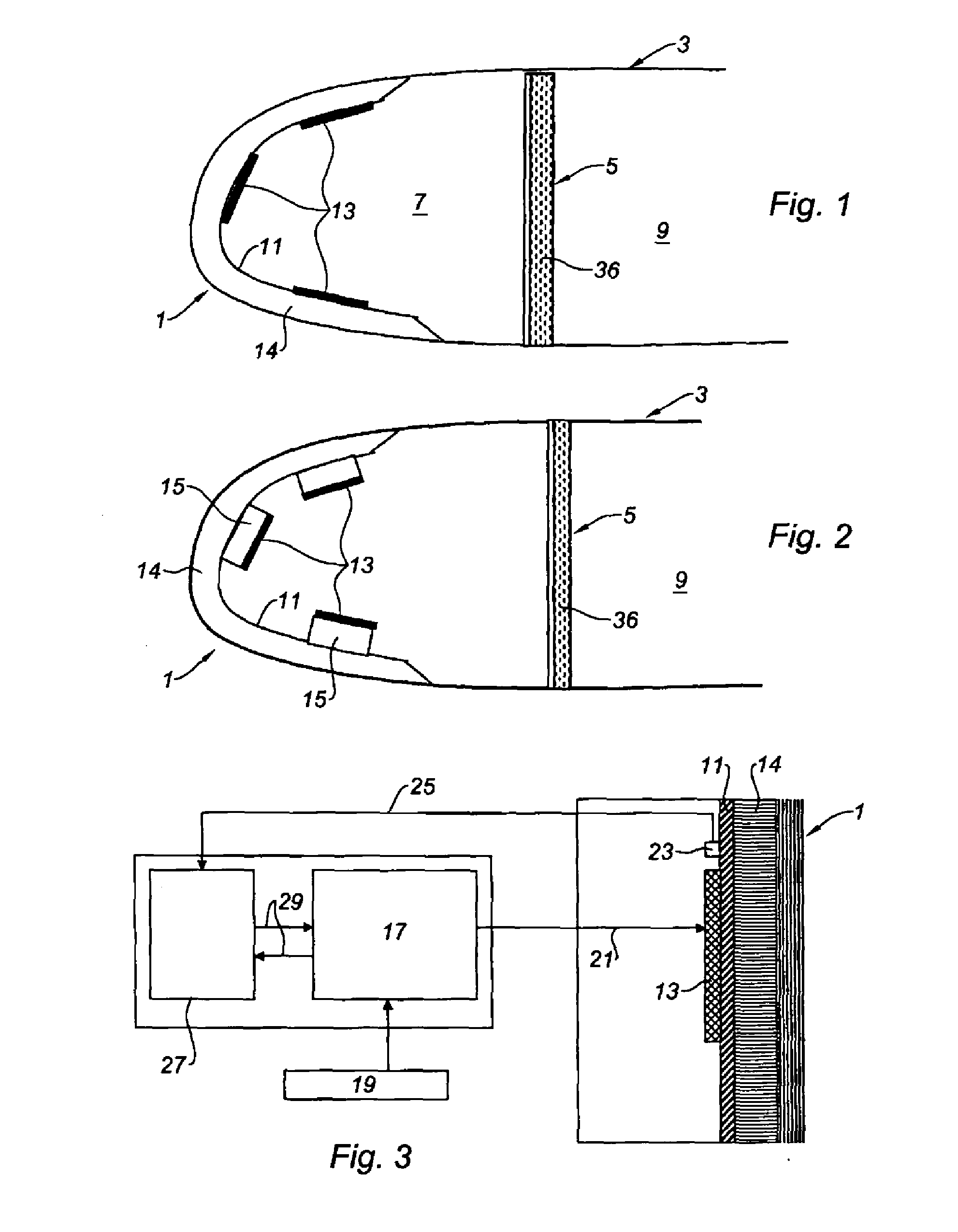

InactiveUS20110036950A1Eliminate withdrawalLow thermal inertiaPower plant arrangements/mountingDe-icing equipmentsLeading edgeLeading-edge slats

The invention relates to a de-icing and / or anti-icing system for the leading edge of an aircraft wing or for the lip (1) of the air intake of an aircraft engine, characterised in that it includes a plurality of infrared emitting members (13) arranged inside said leading edge or said lip (1), power supply means (17) for said emitters (13), and means (27) for controlling said power supply means (17).

Owner:SAFRAN NACELLES

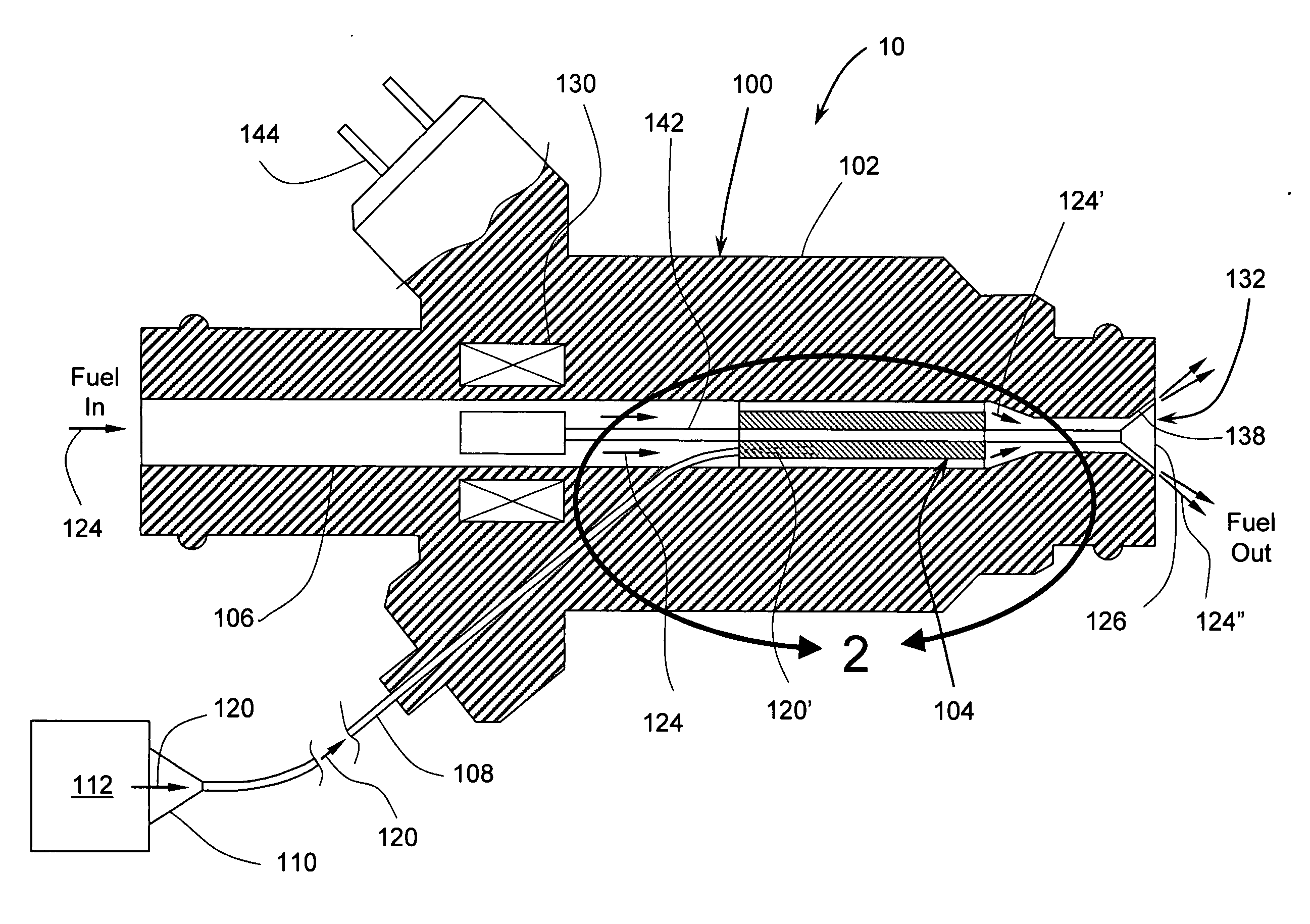

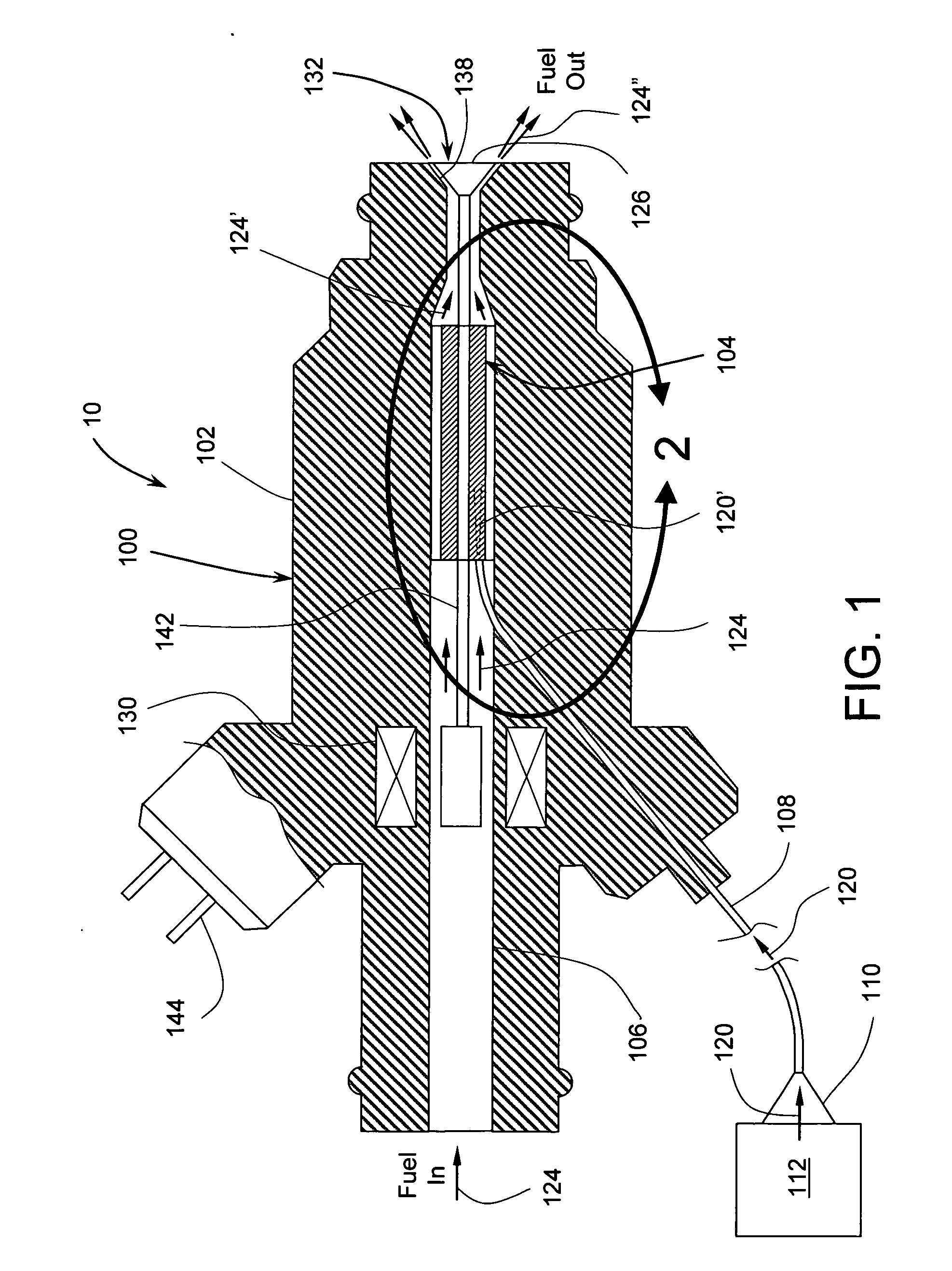

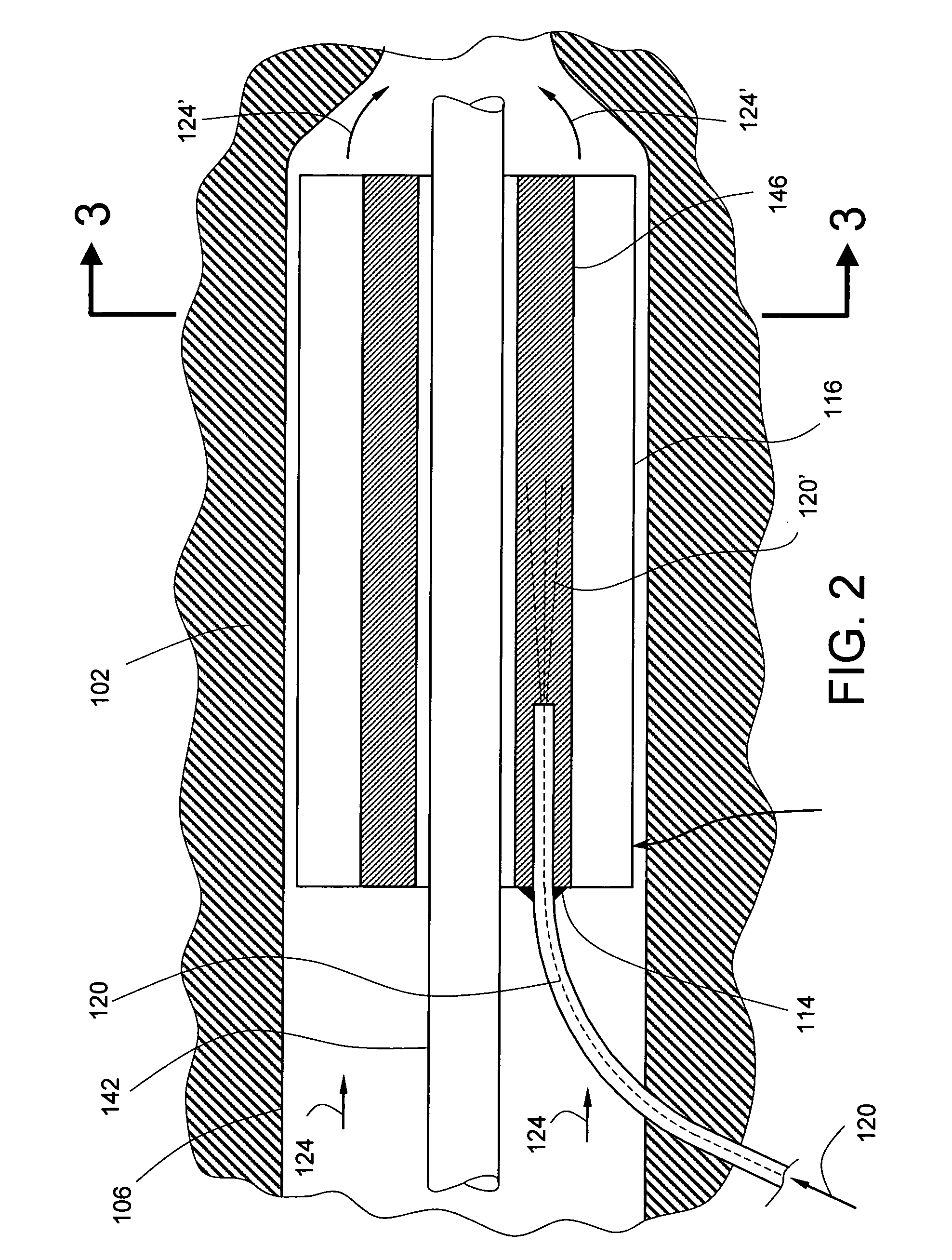

Fuel injector

InactiveUS20110100338A1Reduce emissionPromote combustionFuel injection apparatusMachines/enginesInjectorThermal inertia

The invention is for an apparatus and method for a fuel injector enabling improved combustion in automotive engines. In one embodiment of the invention, fuel is preheated for greatly improved atomization and evaporation, especially during cold engine start. As a result, harmful pollution is greatly reduced pollution. In addition, alcohol-based automotive fuel may be used in cold ambient conditions. The invention overcomes the limitations of current electrically heated injectors and fuel rails having large thermal inertia and long preheat times. In another embodiment of the invention, optically-driven acoustic waves assist in atomization of injected fuel, thus resulting in reduced engine emissions and improved efficiency. Other applications include production of finely atomized fluid sprays for the manufacture of substrates for industry, applications of coatings, formation of uniform-sized particles for the production of pharmaceutical products, and thin-film deposition techniques for forming resistors, capacitors and other components.

Owner:VETROVEC JAN

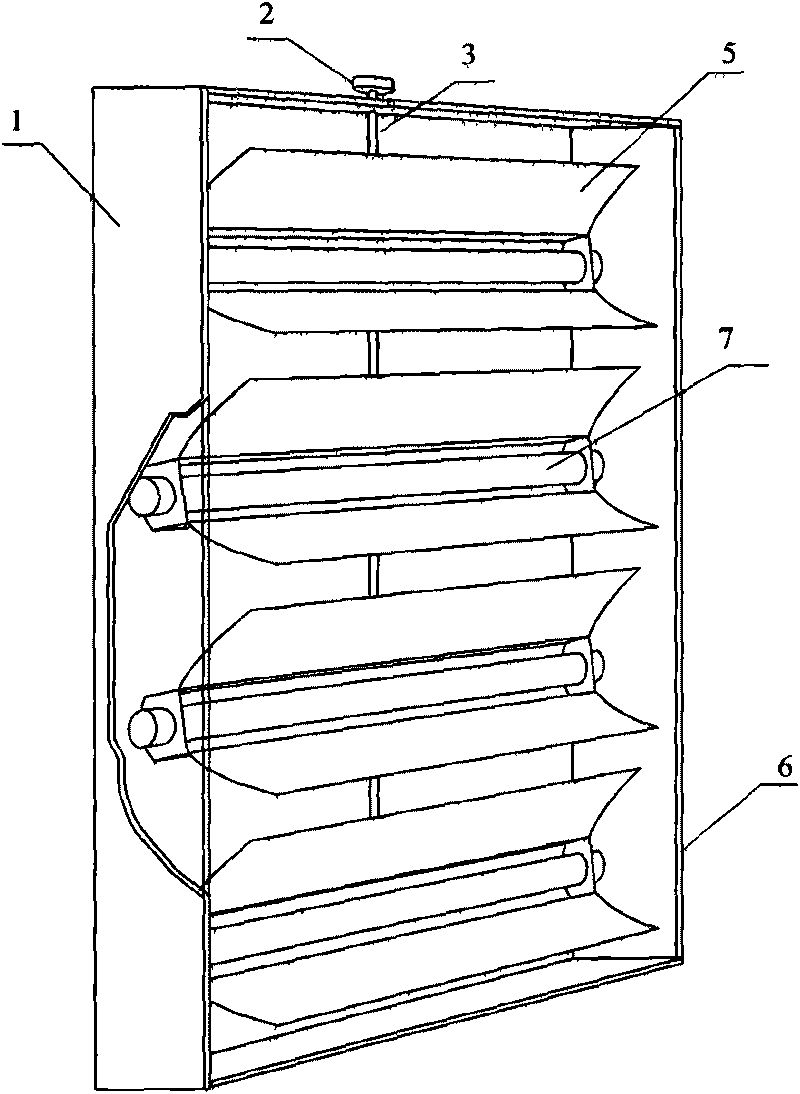

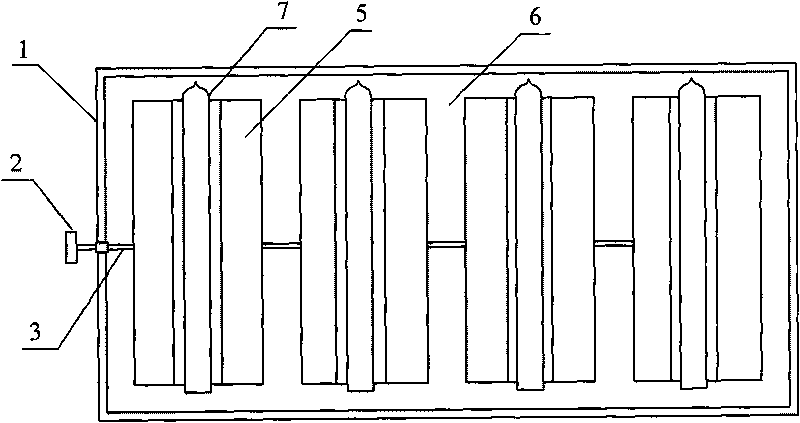

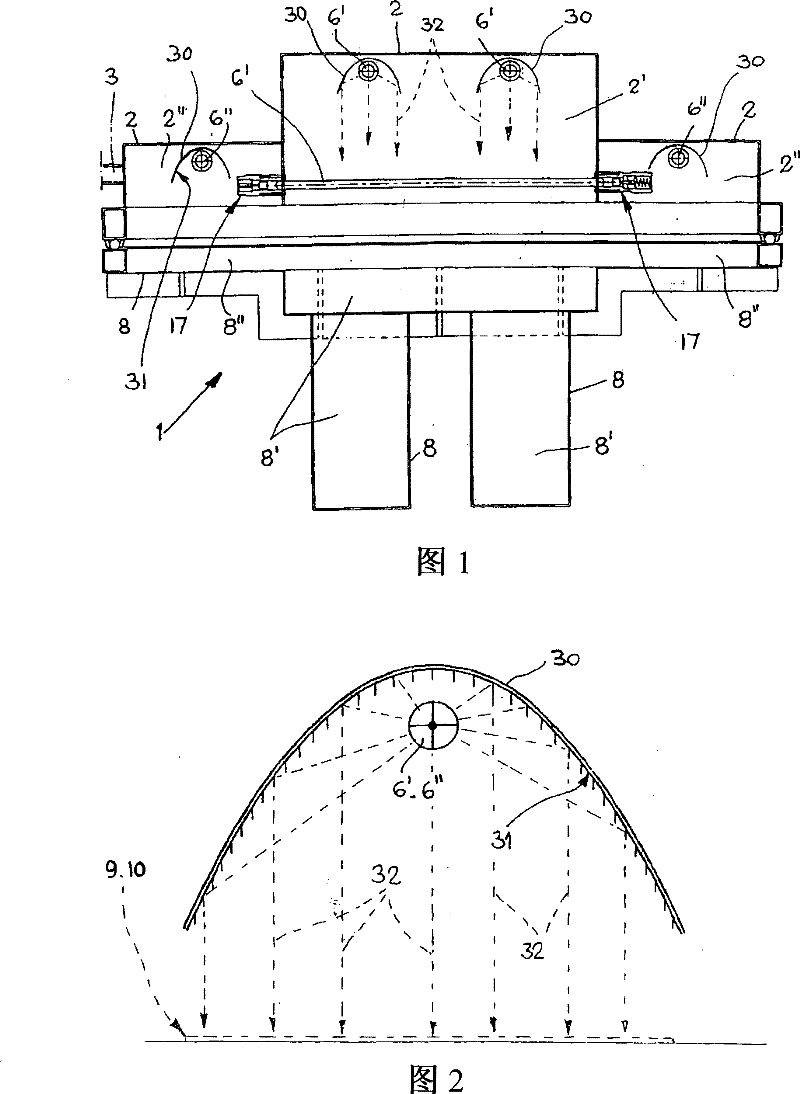

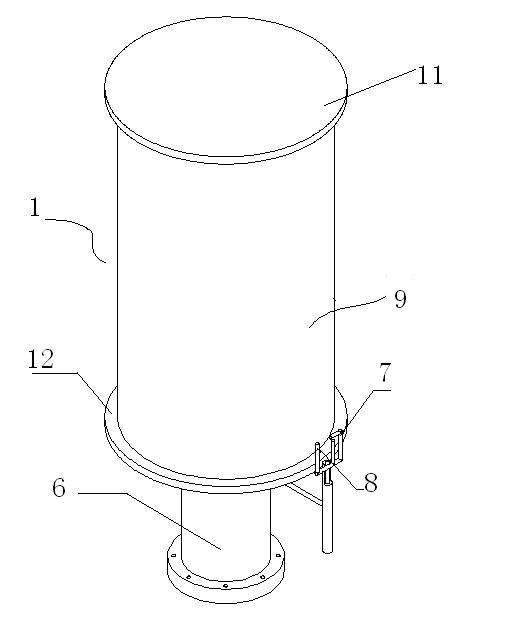

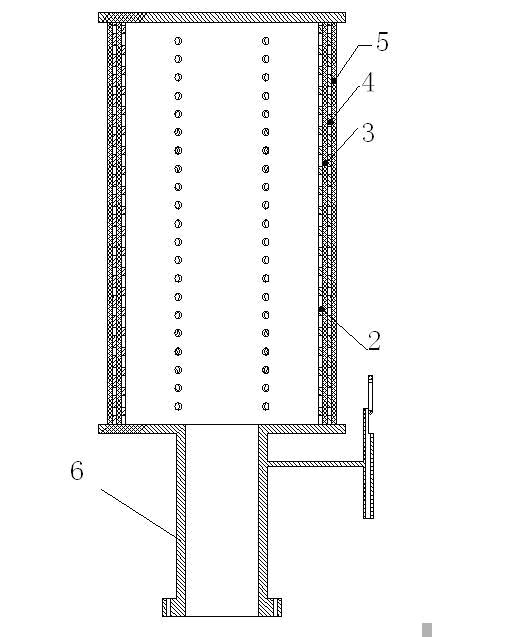

Integrally packaged type solar heat collector with combined curved surface for light collection and vacuum tube for heat collection

InactiveCN101699191ALow technical requirementsGood collection statusSolar heating energySolar heat devicesThermal energySolar light

The invention discloses an integrally packaged type solar heat collector with combined curved surface for light collection and vacuum tube for heat collection, belonging to the technical fields of solar light collection and medium and high temperature solar heat collection. The solar heat collector of the invention comprises a combined curved surface light collector, a vacuum tube heat collector, an adjustable tracker, a packaging shell and the like. After the sun light enters the combined curved surface light collector through a transparent glass cover plate, the sun light is reflected through an inner surface of the combined curved surface light collector and collected onto the vacuum tube heat collector, the vacuum tube heat collector absorbs the sun light to generate high-temperature heat energy, and the heat energy is conducted and transmitted to users by a heat conducting working medium in the vacuum tube heat collector. The invention can collect the sun light with low energy flow density after being reflected by a plurality of curved surfaces on the vacuum tube heat collector, thus the heat conducting working medium in the vacuum tube can be quickly heated to form high-temperature heat energy. The manually adjusted tracker can adjust the orientation of the combined curved surface light collector to track the sun, thereby enabling the heat collector to keep in the optimal sun light collecting state. The invention is especially suitable for use in high-latitude areas and in winter when the solar altitude is smaller.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

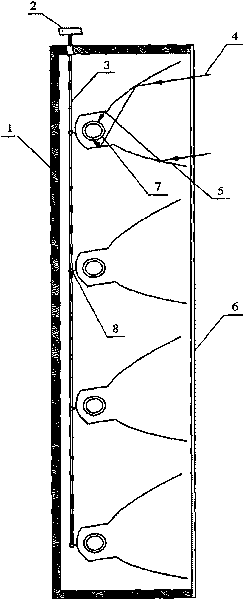

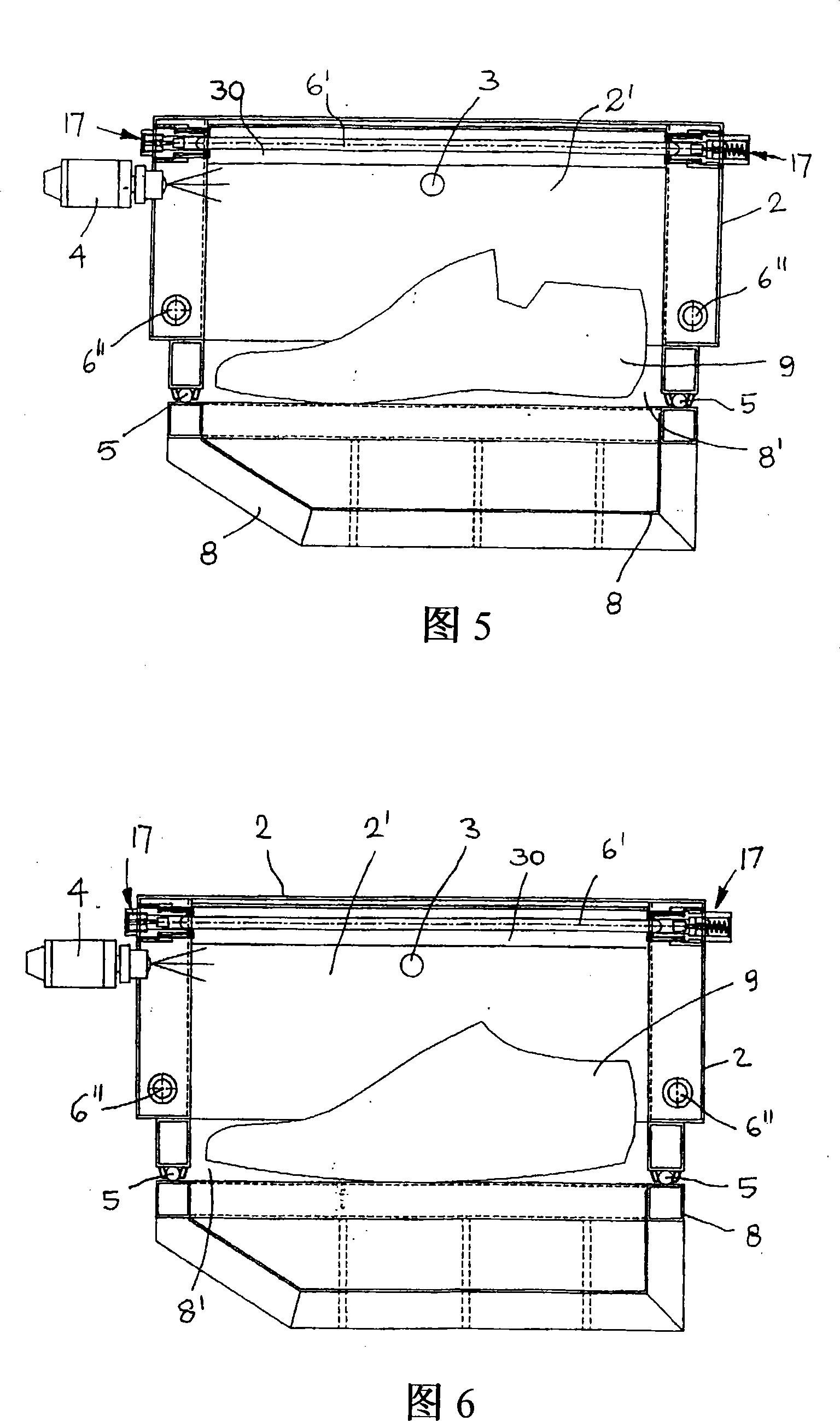

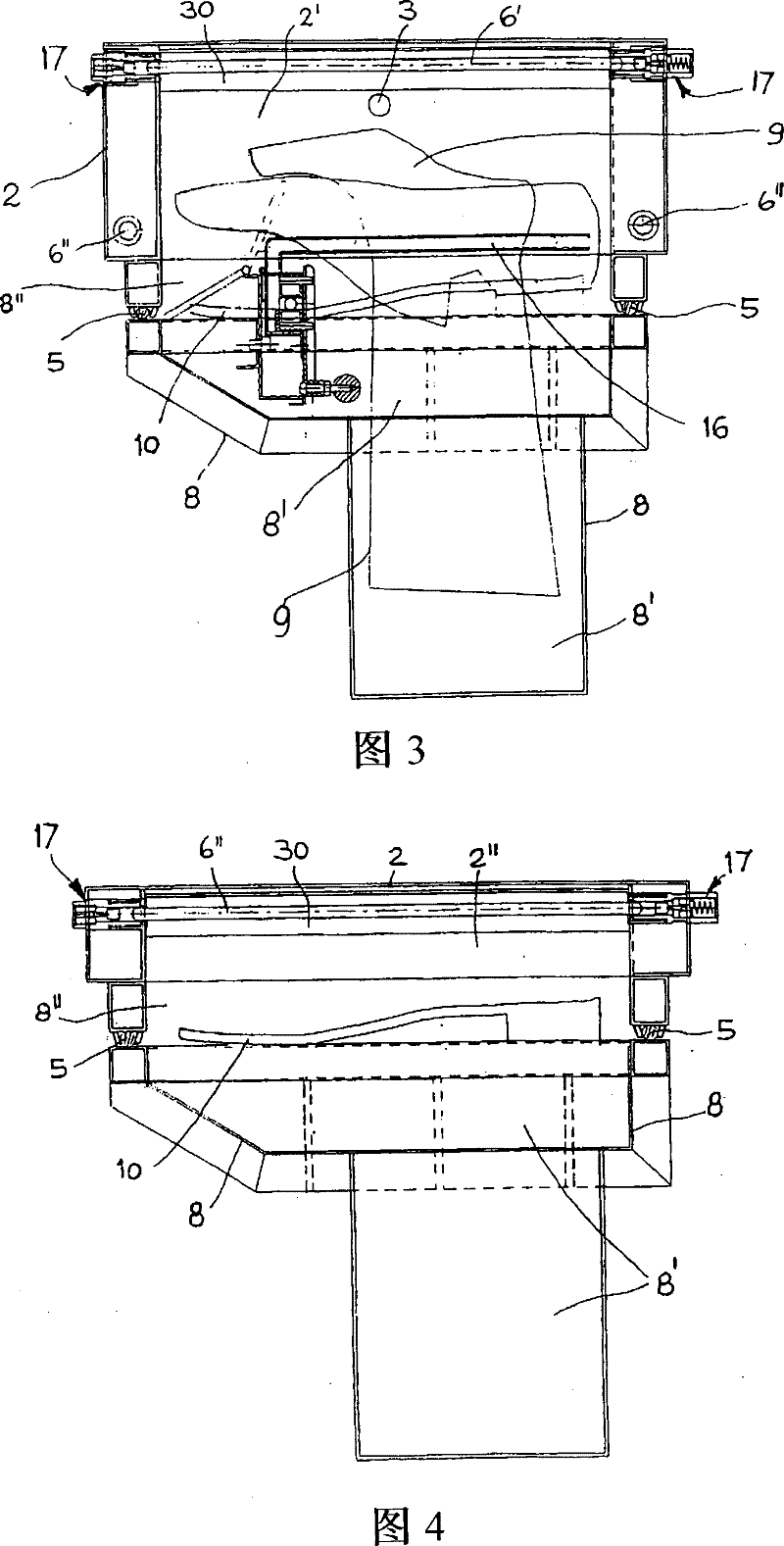

Multifunctional leather goods processing workstation

InactiveCN101176577AImprove quality reliabilityAccurate graspShoemaking devicesLeather softeningInfraredAutomatic control

A multifunctional station for leather product treatment includes at least a cavity with inner part and at least an upper cover casing of a air exhaust port connected with a vacuum pump. The upper cover casing is predetermined to connect with at least a steam interface of peripheral steam generator. Each cavity is provided with at least a near infrared radiation type heating lamp, and a reflection plate with parabolic profile and with inner reflection surface treated through mirror, which is disposed around the middle luminous part of the heating lamp. Each upper cover casing is capable of combining temporarily with corresponding lower carrying tray for putting the treated leather products. No matter the multifunctional station for leather product treatment is set independently, or disposed along continuous production line, the operation of upper cover casing is capable of being programmed through an automatic control element, and performing treatment to the leather products, e.g. drying activation of agglutinant or softening, setting of leather products, etc.

Owner:蓝法兰可·安札尼 +1

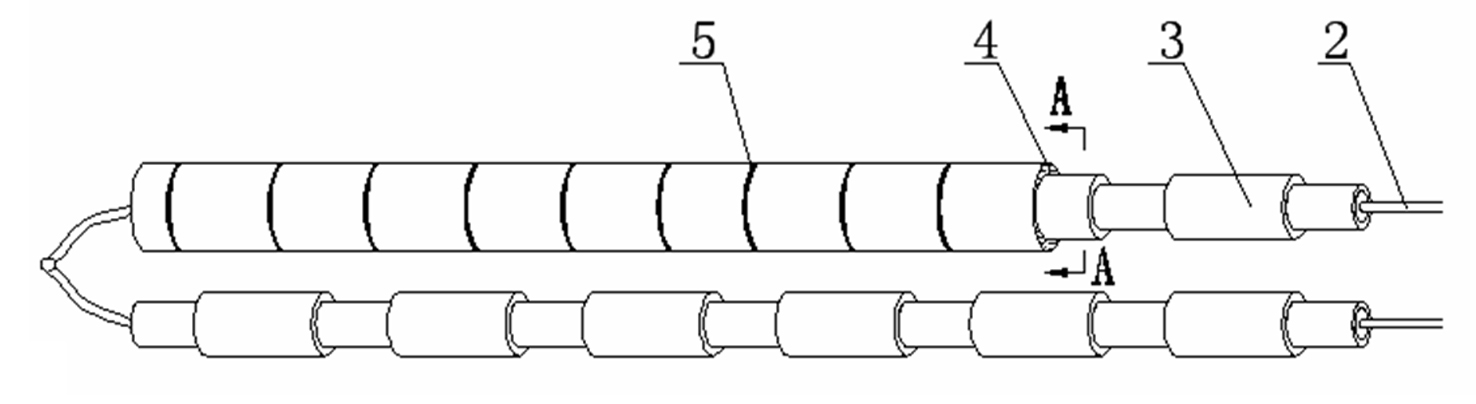

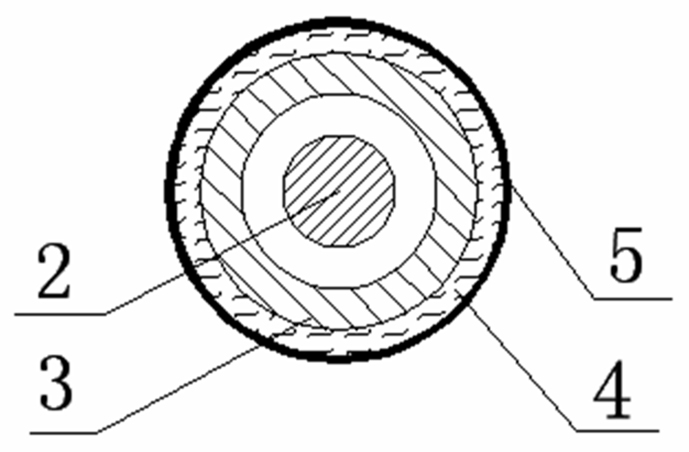

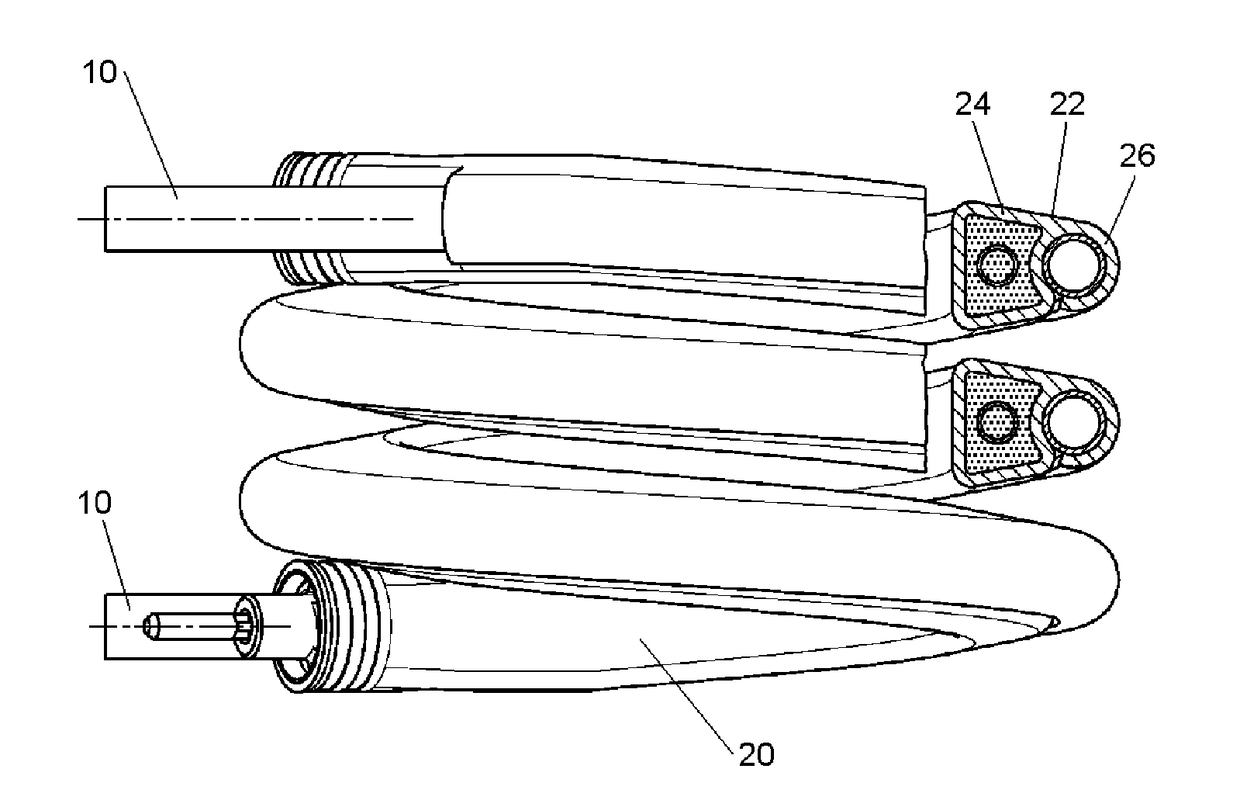

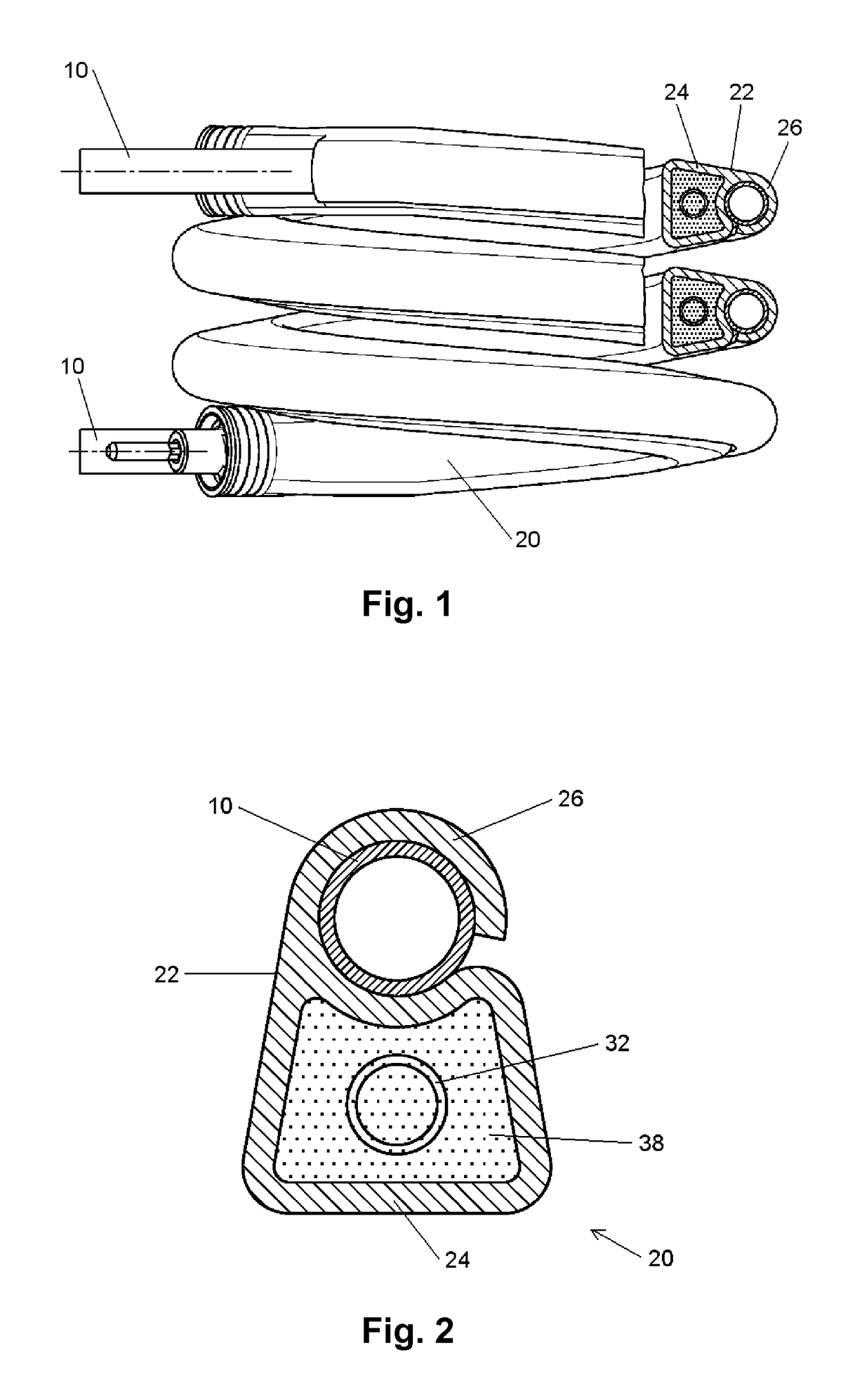

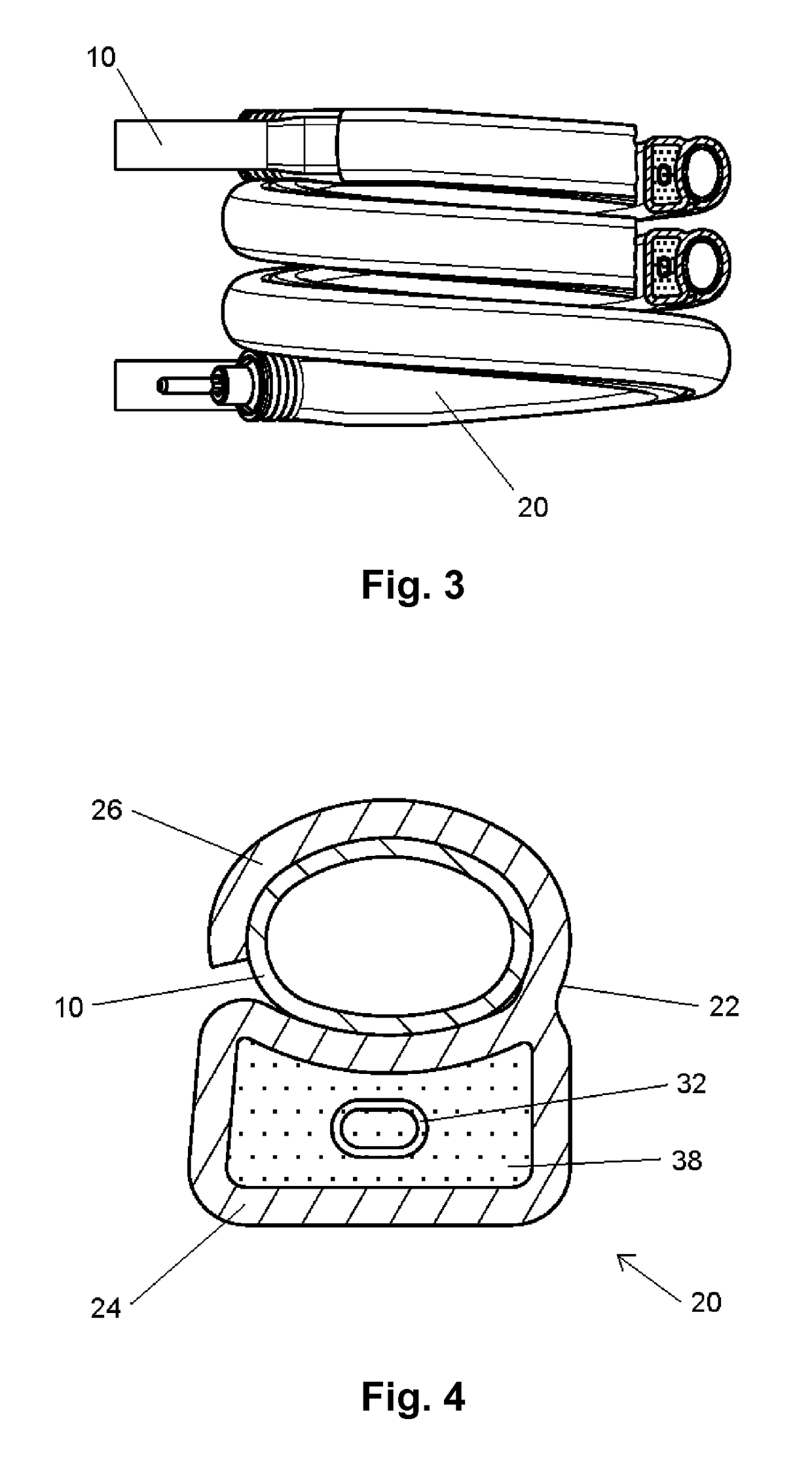

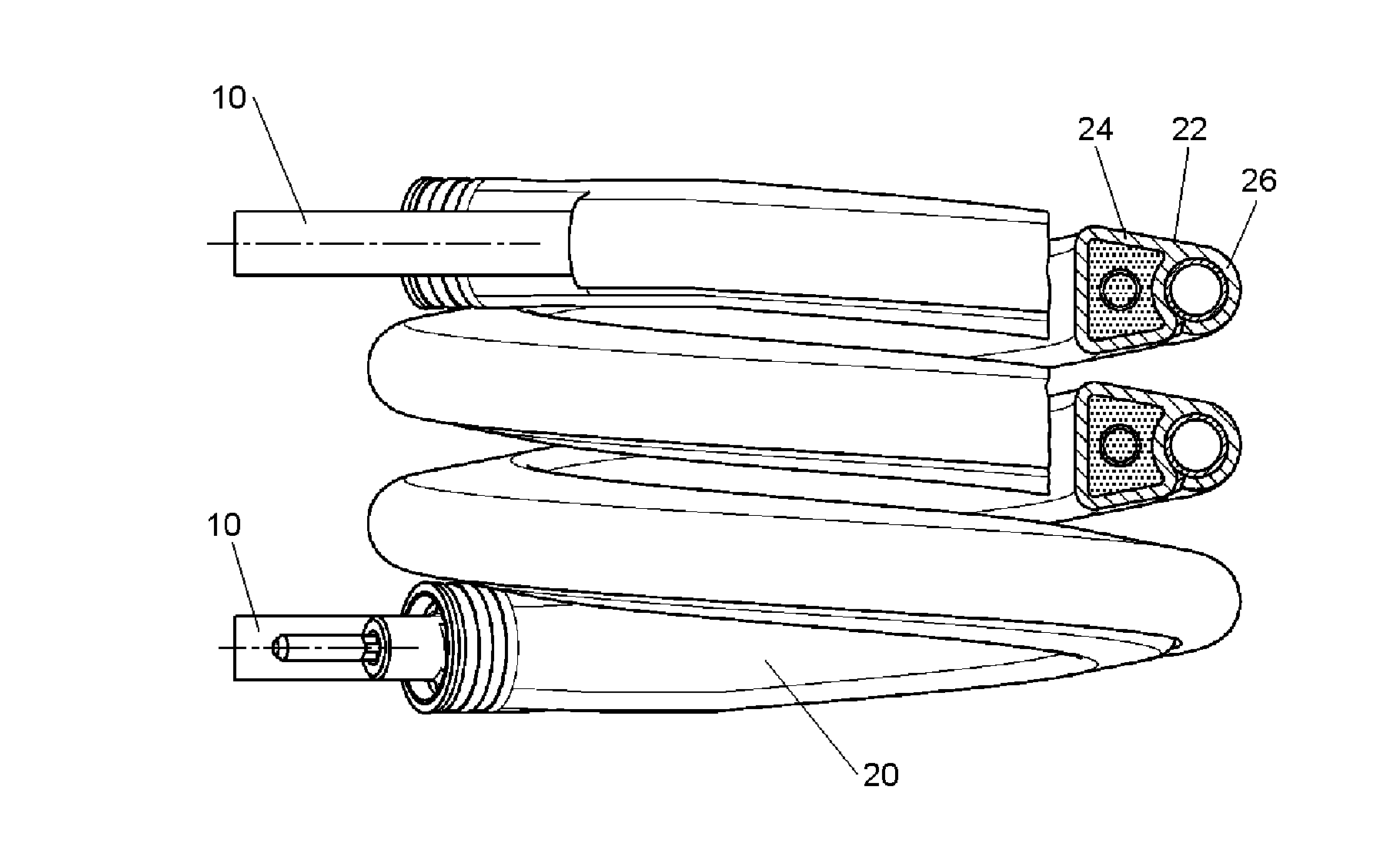

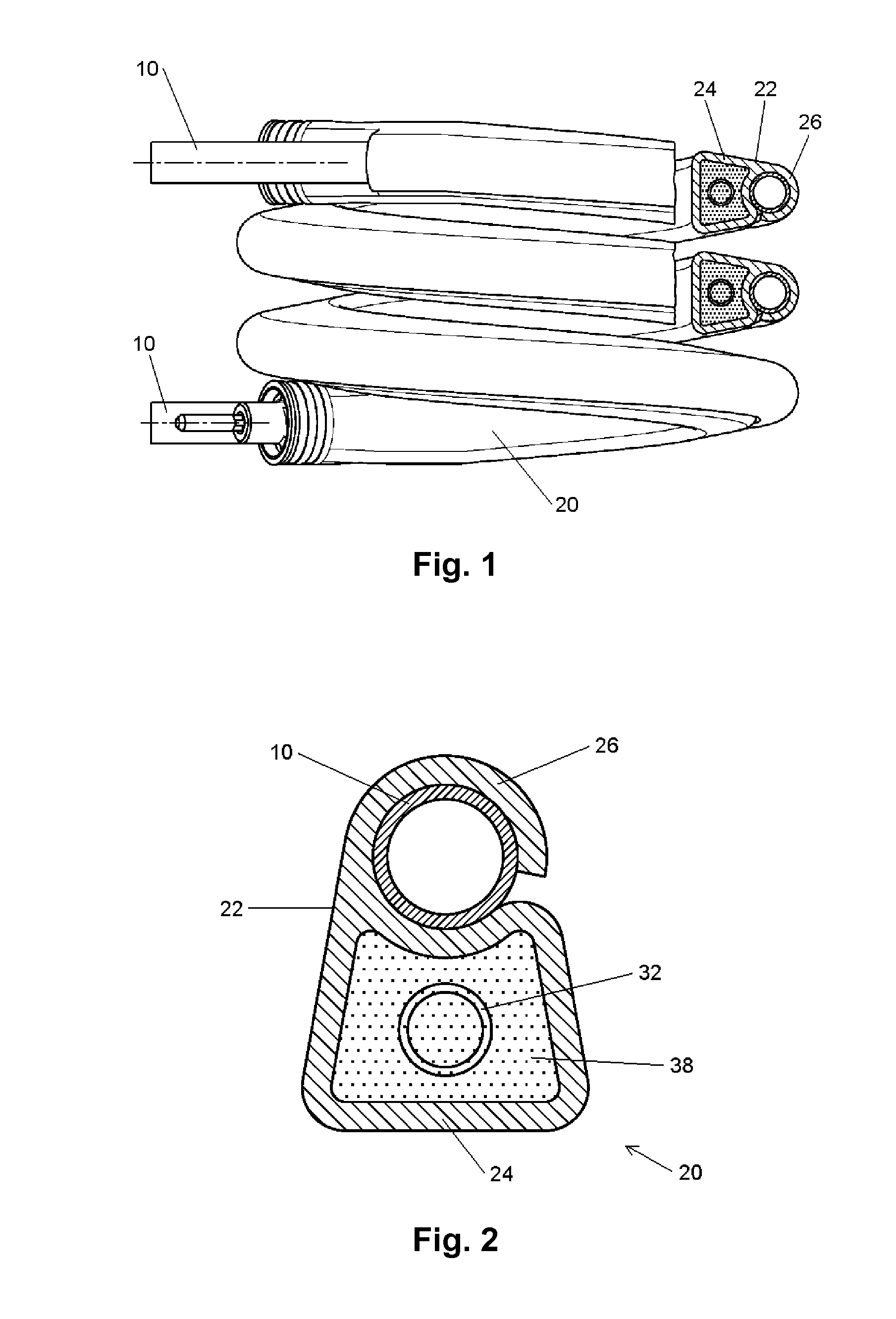

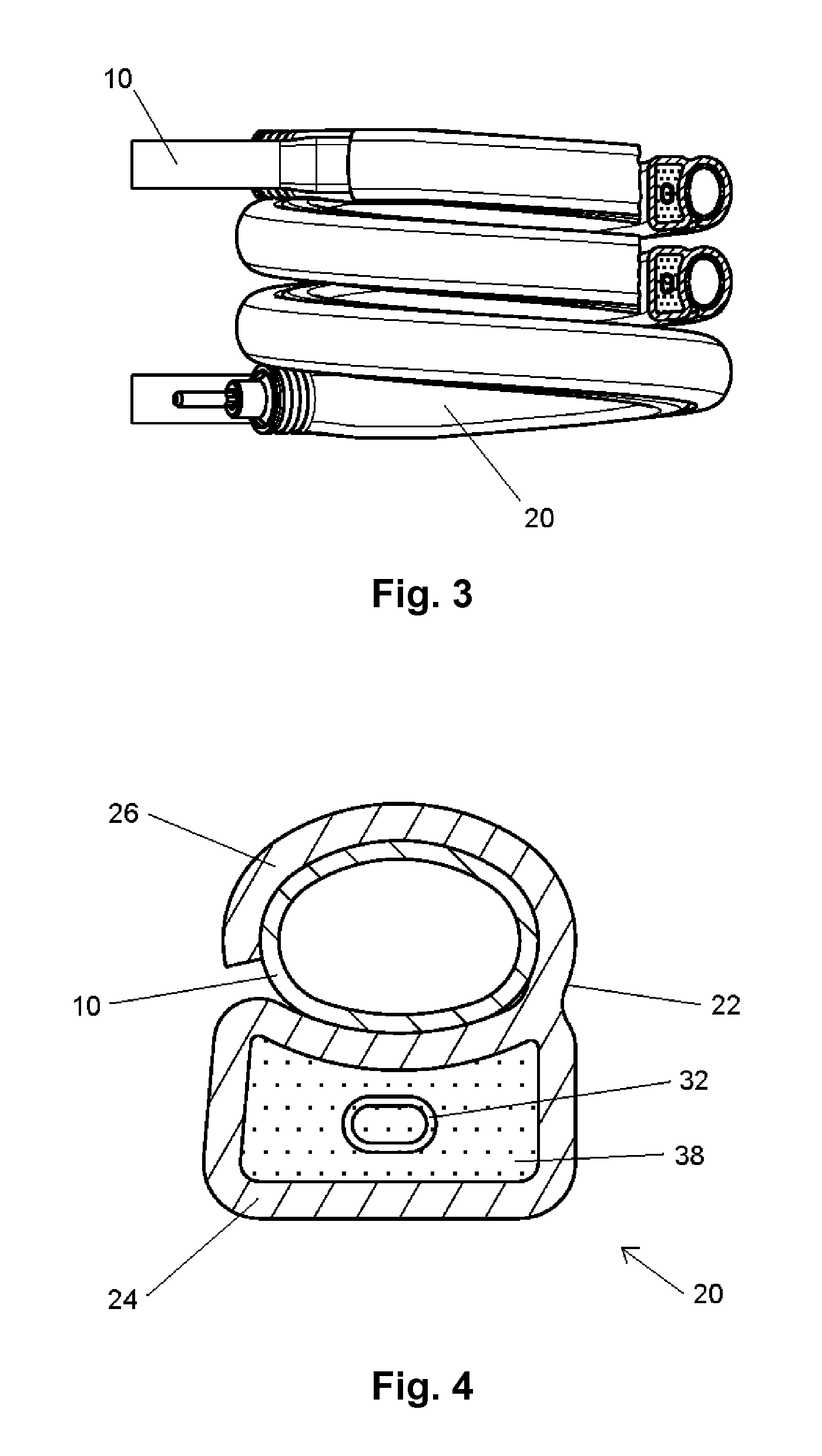

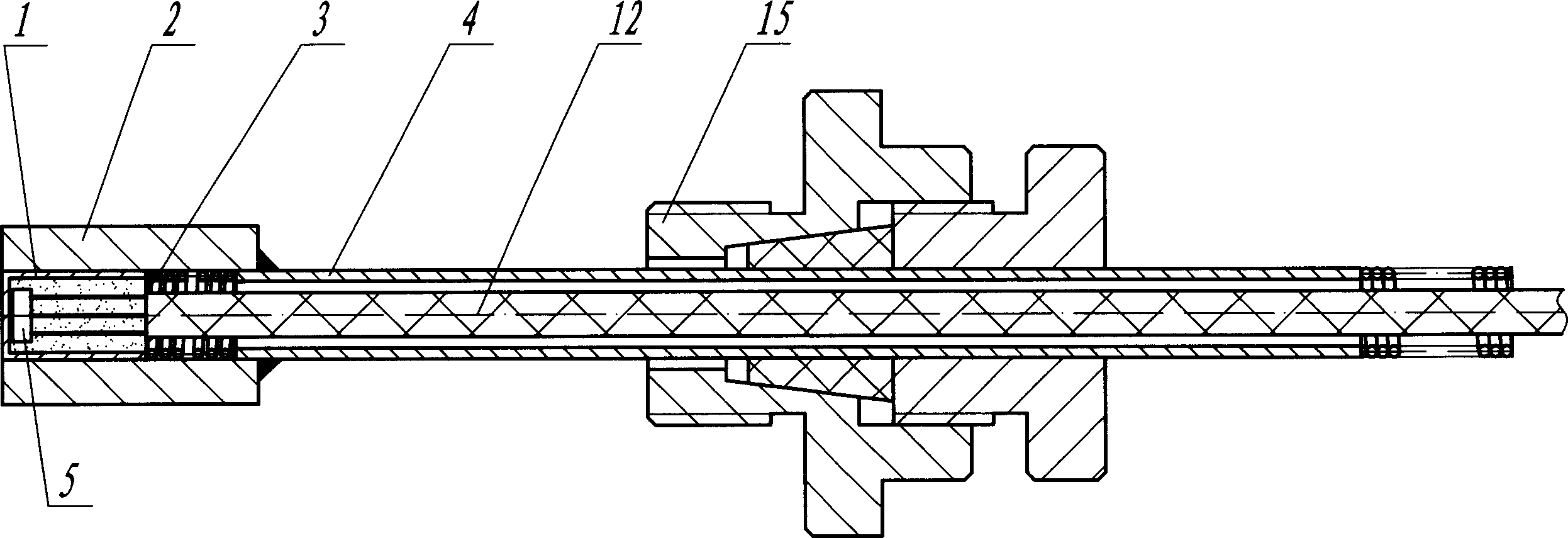

Helical dynamic flow through heater

ActiveUS9648983B2High easeEasy to adaptImmersion heating arrangementsBeverage vesselsEngineeringThermal contact

A flow though heater device comprising a fluid tube carrying a fluid to be heated, a tubular heating element extending at least partially parallel and in thermal contact with the fluid tube, wherein the tubular heating element comprises a profiled casing tube and at least one heating coil mounted in a tubular portion of said profiled casing tube. The profiled casing tube further comprises at least one tab portion laterally protruding from the tubular portion and being wrapped around the fluid tube, wherein the assembly of the fluid tube and the tubular heating element has an approximately helical shape so that the tubular portion of the casing tube is positioned with respect to the helix radially inside of the fluid tube.

Owner:BLECKMANN

Alcohol-base fuel burner with radiant panel fuel nozzle

An alcohol-base fuel burner with radiant panel fuel nozzle comprises an air chamber, a mixed combustion chamber, an atomization injection pipe, wherein one end of the air chamber is opened, and the other end thereof is provided with an air inlet; the mixed combustion chamber is sleeved in the air chamber and is provided with air holes along the wall of the mixed combustion chamber; the center of the atomization injection pipe is a through hole, one end is provided with a radiant panel, the other end is installed on the soleplate of the mixed combustion chamber and is communicated with one end of a fuel supply pipe, and at least two fuel injection holes are uniformly distributed on the same cross section of the wall of the atomization injection pipe. The invention has high combustion efficiency, low energy consumption and less pollutant emission; compared with the existing technology, the discharge amount of CO and NOx is relatively reduced by 50% to 70%, and the heat efficiency reaches up to more than 40%. The burner is safe, environment-friendly, stable in combustion, high in combustion strength, easy and safe for combustion, good in fire adjustment, high-temperature and corrosion resistant, high impact resistant, mechanical impact resistant, low in thermal inertia and long in service life; and the burner is suitable for being applied to various special cookers in catering industry.

Owner:湖南中能力华新能源技术有限公司 +1

Method for producing metal foams and furnace for producing same

InactiveCN1488011ALow thermal inertiaFast heating rateFurnace componentsElectrode carriers/collectorsHot zoneWater vapor

A method for producing a metal structure comprising the following steps: providing a metal-coated polymer substrate; heating the metal-coated polymer substrate in a hot zone, in which a temperature of at least 600 DEG C prevails and in which an atmosphere essentially composed of water vapor or of a mixture of water vapor and neutral gas is maintained, so as to remove the polymer substrate and form a metal structure; and cooling the metal structure in a cooling zone.

Owner:CIRCUIT FOIL LUXEMBOURG R L

Carbon-ceramic heating tube and processing method

InactiveCN1555213ANo cracking will occurImprove thermal stabilityHeating element shapesHeating element materialsWorking lifeOxidation resistant

This invention discloses a ceramic-carbon heating pipe having a heating matrix, an electrode lead-out rod is connected with both ends of matrix sleeved with a protection pipe, insulation and heat conduction powder is filled between matrix and protection pipe. Its electric-heat transformation rate reaches as high as 99.6% and is oxidation resistant, not easy to be broken with a long work life to 50000 hours, 1.5 times higher than that of the national standard.

Owner:马放

De-icing and/or anti-icing system for the leading edge of an aircraft wing

InactiveUS8991763B2Eliminate any withdrawalEasy to changeDe-icing equipmentsHeating element shapesLeading edgeIce protection system

The invention relates to a de-icing and / or anti-icing system for the leading edge of an aircraft wing or for the lip (1) of the air intake of an aircraft engine, characterised in that it includes a plurality of infrared emitting members (13) arranged inside said leading edge or said lip (1), power supply means (17) for said emitters (13), and means (27) for controlling said power supply means (17).

Owner:SAFRAN NACELLES

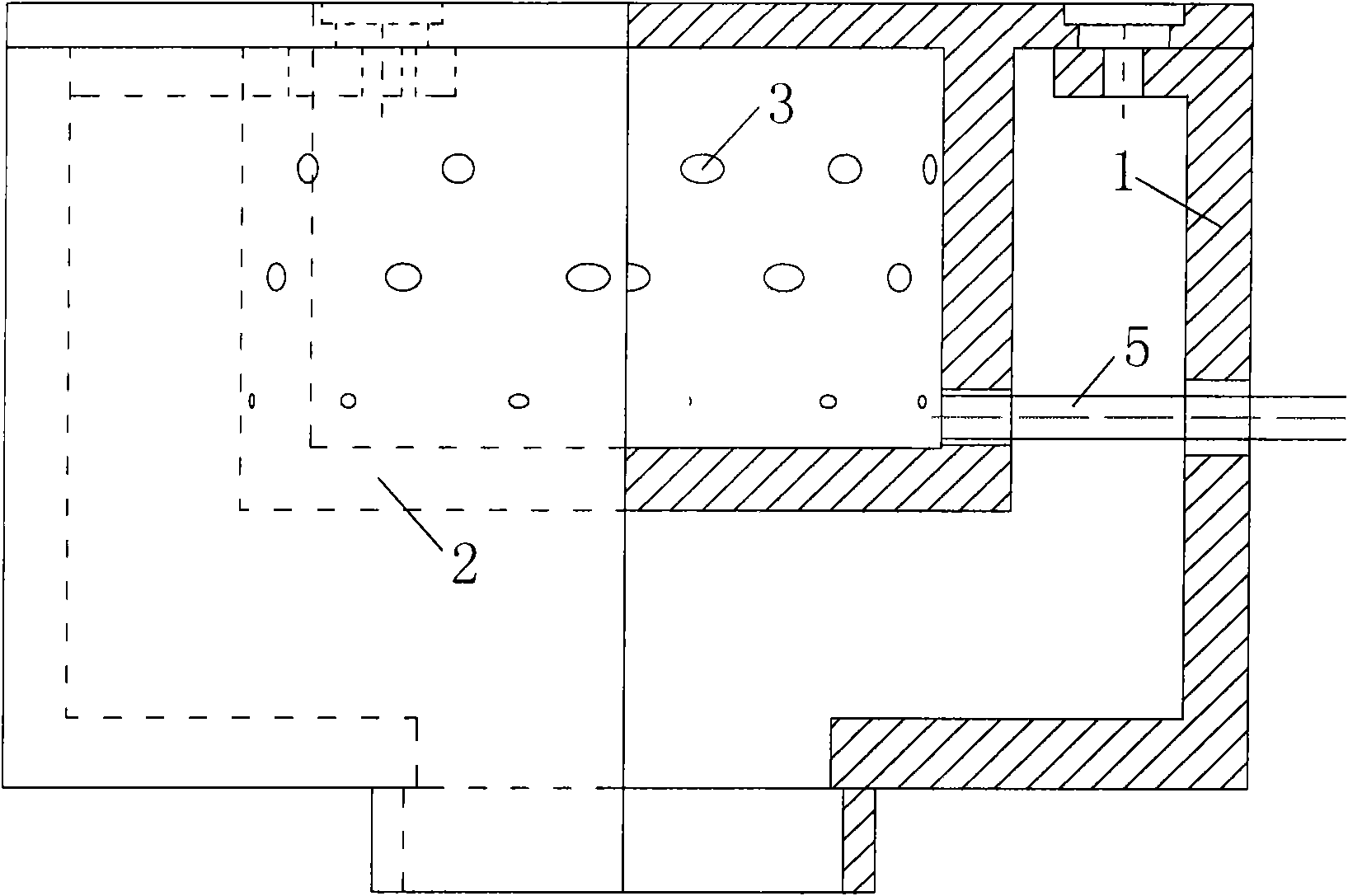

Rapid vulcanization die for building lamination shock insulation rubber bearing

InactiveCN103786282AAvoid heat transfer barriersAchieving direct heat conductionVulcanizationEngineering

The invention discloses a rapid vulcanization die for a building lamination shock insulation rubber bearing. The rapid vulcanization die comprises an inner heating die with a heat conduction strip, an outer heating die with a heat conduction strip, an excessive glue groove, heat conduction strips, an upper heating template, a lower heating template, a positioning shaft, a positioning hole and a positioning shaft mounting groove, wherein the lower heating template is mounted on a support, the outer heating die with the heat conduction strip is arranged on the upper surface of the lower heating template, the inner heating die with the heat conduction strip is arranged in the center of the outer heating die with the heat conduction strip, the height of the outer heating die with the heat conduction strip is equal to that of the inner heating die with the heat conduction strip, and the upper heating template is arranged at the tops of the outer heating die with the heat conduction strip and the inner heating die with the heat conduction strip. The rapid vulcanization die fully utilizes the structural principle of vulcanization equipment and a vulcanization target to realize rapid and uniform vulcanization and efficient mounting, is applicable to vulcanization processing of various rubber bearings, such as a standard rubber bearing, a pencil lead rubber bearing, a high damping rubber bearing and a stacked rubber bearing, and is high in vulcanization efficiency and rapid and convenient to mount and maintain.

Owner:彭勃

Platinum thermal resistance temp. sensor

InactiveCN1405537AReduce volumeEasy to carryThermometers using electric/magnetic elementsUsing electrical meansPlatinumElectrical conductor

This invention relates to a sensor for testing temperature according to the law of conductor resistance varing along with the of temperature which comprises a Teflon jacket tube, a Pt thermal resistor, a pyrocondensate tube, wiring plate in which the Pt thermal resistor ic onnected with the wiring plate via conducting wire passing through the pyrocondensate tube the Pt thermal resistor, the conducting wire and pyrocondensate tube are sleeved with Teflon jacket tubes, the Pt thermal resister is close to tube wall and inside wall of sealing bottom of the Teflon, the outer wall of the pyrocondensate tube is sleeved with the wall of the Teflon jacket mainly used in testing temperature in aid solution above 250 deg.C.

Owner:上海浦东新区台华仪电科技研究所

Compound PTC thermistor heating material

InactiveCN106009685ALow thermal inertiaGood resistance stabilityElectrical resistance and conductanceThermistor

The invention relates to the technical field of heater production, in particular to a composite PTC thermistor heating material. It consists of raw materials with the following weight fractions: conductive silicone rubber 58.5-68.2%; functional materials 18.5-30.8%; additives: 5.6-13.3%. The composite PTC thermistor heating material provided by the invention has high temperature sensitivity, low thermal inertia, good resistance stability, uniform temperature rise, and excellent mechanical, thermal and chemical stability.

Owner:ANHUI NINGGUO TIANCHENG ELECTRICAL APPLIANCES

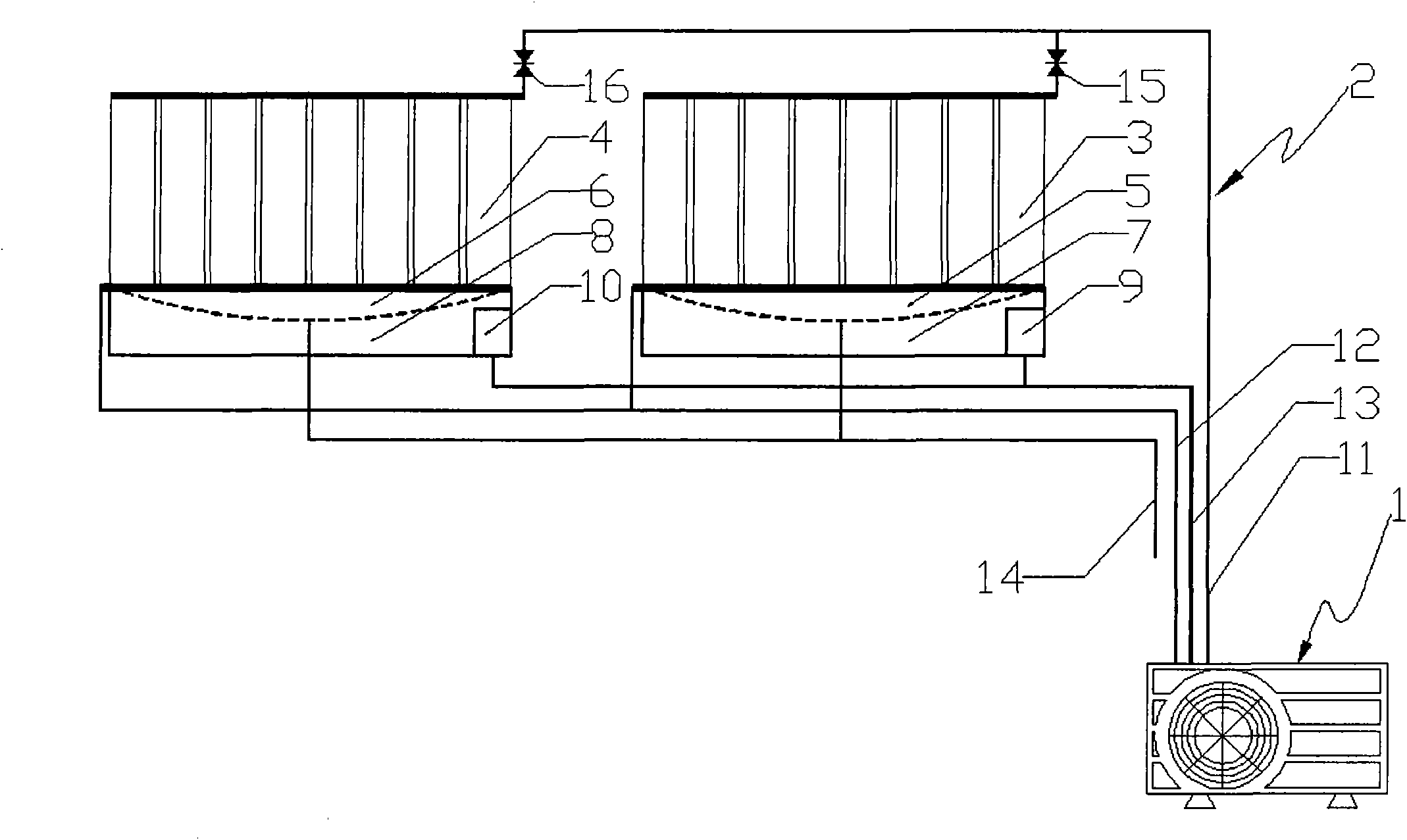

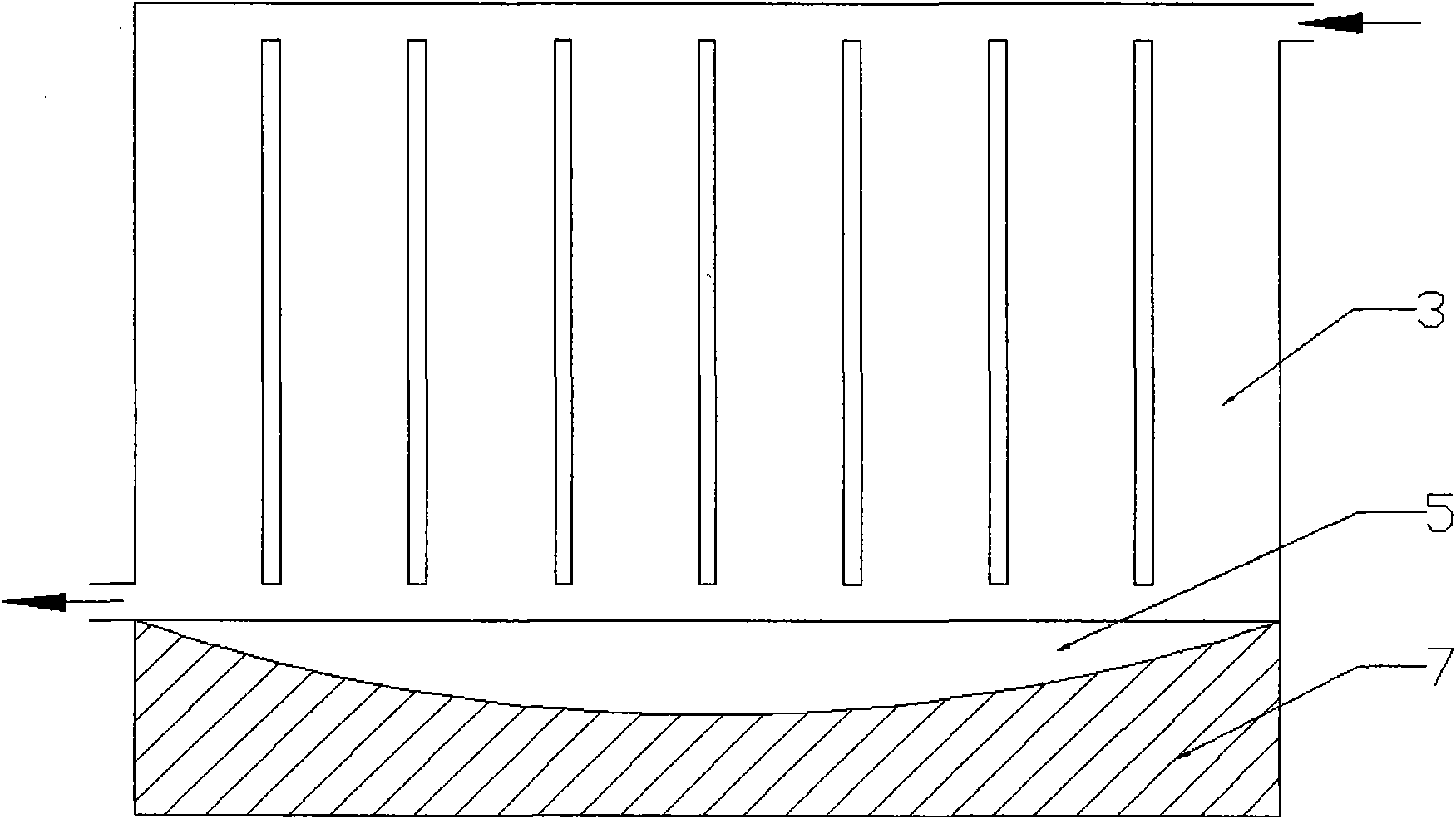

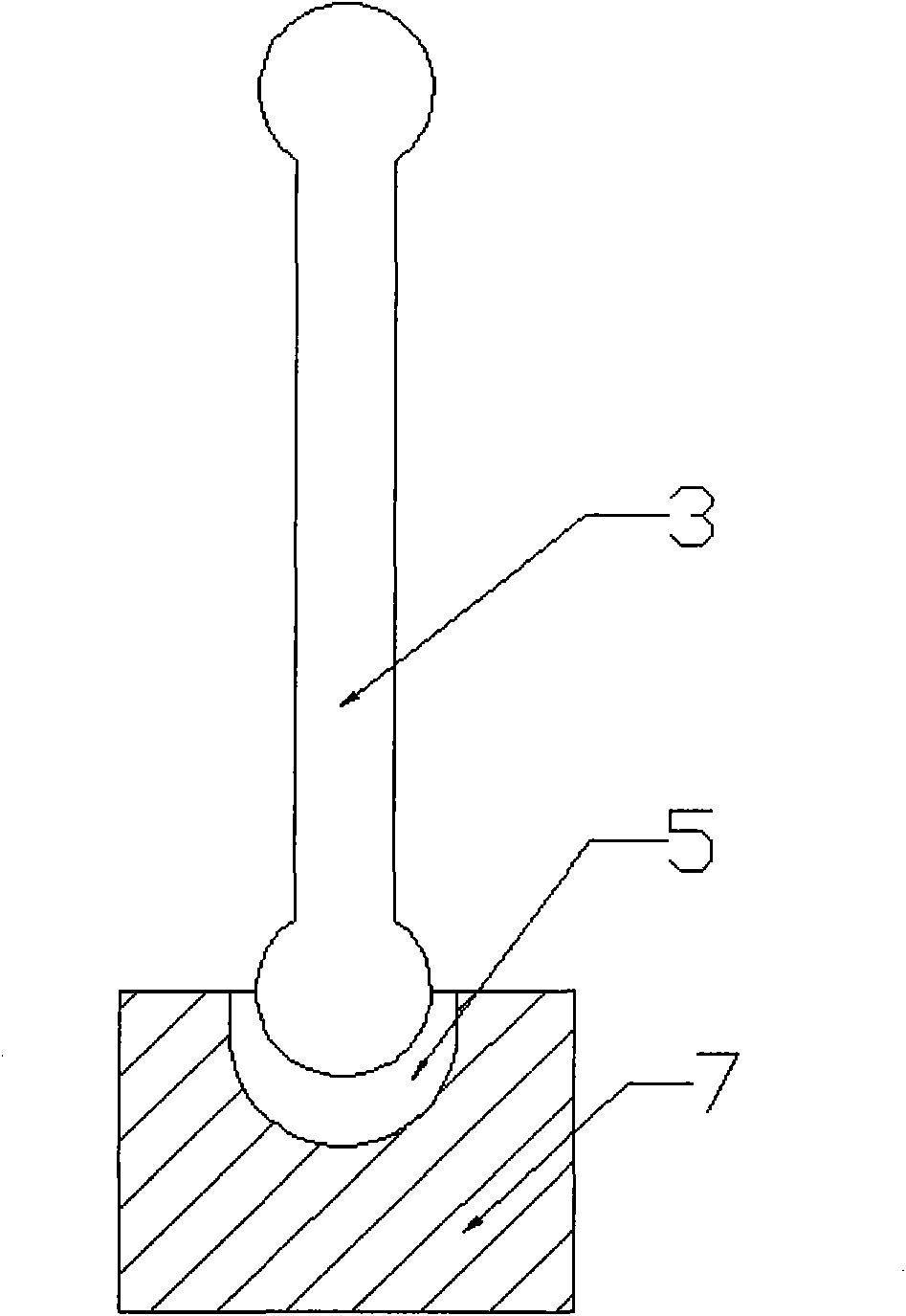

Fanless super-silent split air conditioner

InactiveCN101949560AAvoid Airflow NoiseAvoid vibration noiseCondensate preventionSpace heating and ventilation safety systemsEvaporationEngineering

The invention discloses a fanless super-silent split air conditioner, which comprises an outdoor unit with an outdoor coolant circuit and an indoor unit with an indoor coolant circuit communicated with the outdoor coolant circuit; the radiator of the indoor unit is an evaporation fin having a radiator structure; the evaporation fin is mounted on the indoor unit case; and one end of the evaporation fin is connected with an air pipe of an adaptor, while the other end is connected with the liquid pipe of the adaptor. The indoor unit adopts a heat exchanger, which is an evaporation fin with a large surface area, to perform heat exchange with the air fully and conduct cooling and heating functions; the indoor unit does not have any fan, so air flow noises are prevented and a super-silent effect is realized; and the structure of the air conditioner is simpler than that of the conventional air conditioner, and the air conditioner is particularly suitable to be used in places with very strict requirements on noises.

Owner:GUANGXI UNIV

Helical dynamic flow through heater

ActiveUS20150182064A1The method is simple and reliableImprove heat transfer performanceMetal-working apparatusBeverage vesselsThermal contactBiomedical engineering

A flow though heater device comprising a fluid tube carrying a fluid to be heated, a tubular heating element extending at least partially parallel and in thermal contact with the fluid tube, wherein the tubular heating element comprises a profiled casing tube and at least one heating coil mounted in a tubular portion of said profiled casing tube. The profiled casing tube further comprises at least one tab portion laterally protruding from the tubular portion and being wrapped around the fluid tube, wherein the assembly of the fluid tube and the tubular heating element has an approximately helical shape so that the tubular portion of the casing tube is positioned with respect to the helix radially inside of the fluid tube.

Owner:BLECKMANN

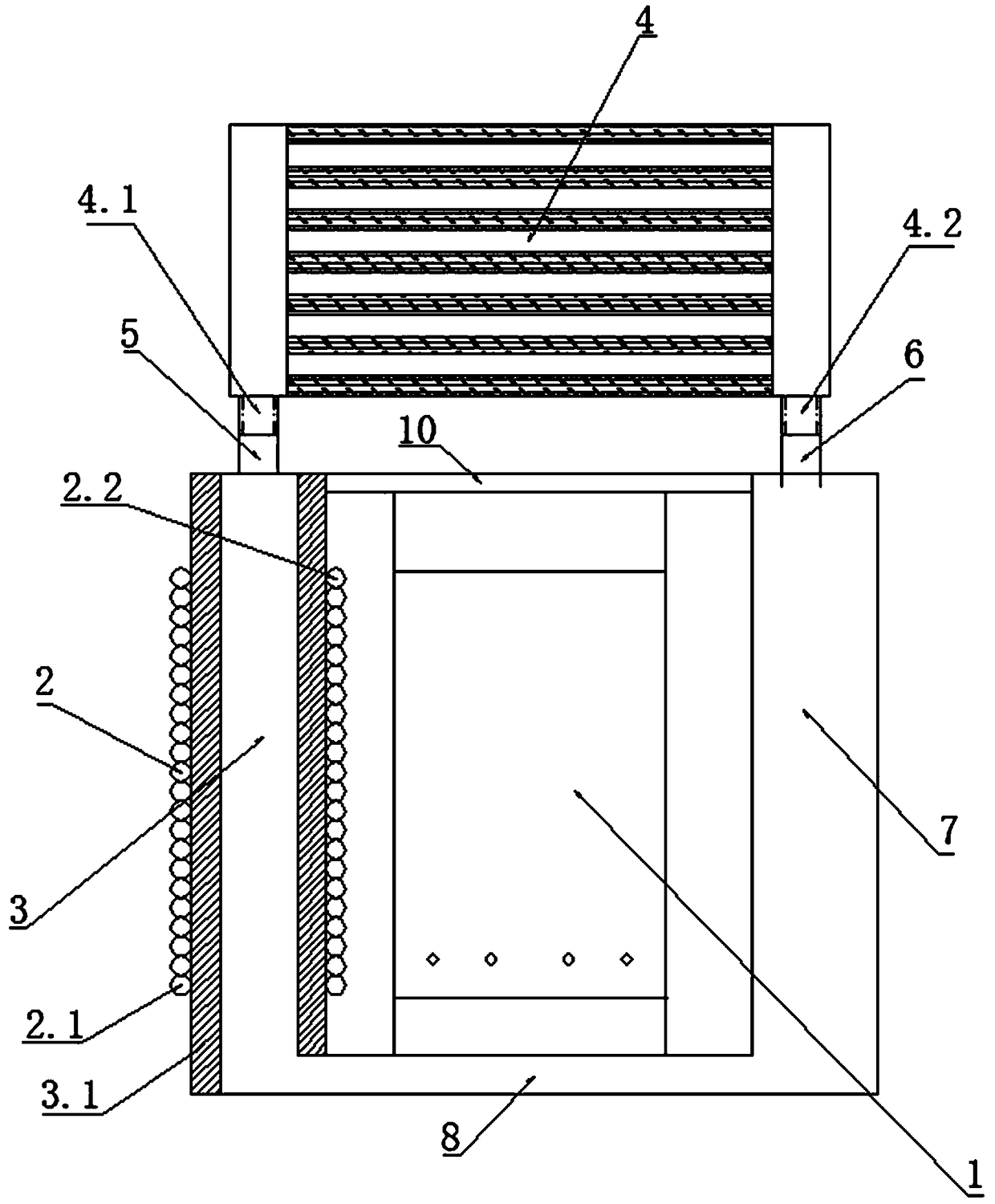

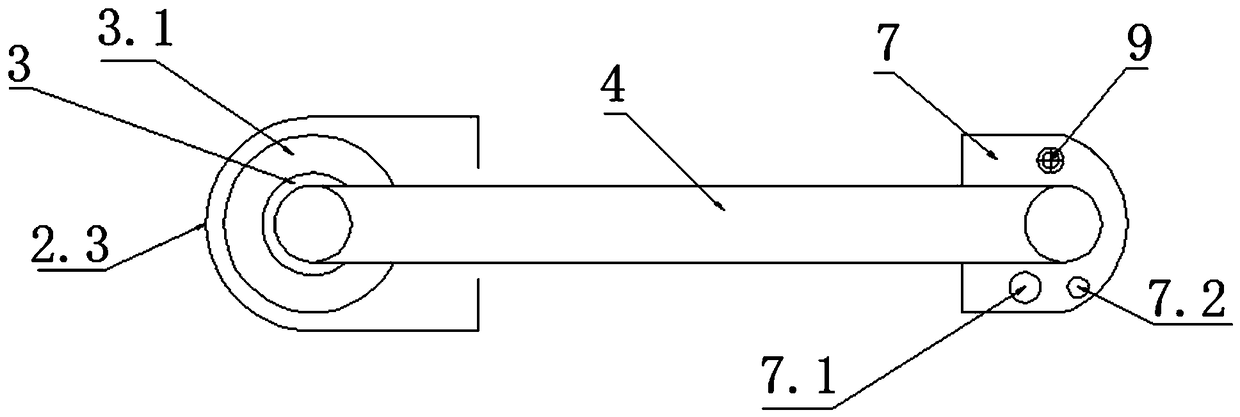

Combined type ceiling radiant plate

InactiveCN103791555ASimple structureEasy to useLighting and heating apparatusAir conditioning systemsTerminal equipmentEngineering

The invention relates to a combined type ceiling radiant plate, belongs to terminal devices of independent temperature and humidity control central air conditioners and can be used in an air conditioning system for refrigeration and heating. A radiant ceiling is composed of a radiant coiler, a heat conduction plate good in heat conduction performance, a decoration ceiling panel and the like. The inflection type radiant coiler is clamped in a pipe groove of the heat conduction plate to increase the downward radiant quantity of the radiant ceiling. The heat conduction plate can be machined into different specifications according to the onsite building structure condition. The decoration panel with or without micro holes clings to the lower surface of the heat conduction plate to serve as a ceiling face, convection heat exchange of the radiant plate and indoor air is improved while radiant heat exchange is conducted, and the refrigeration / heating capability is improved.

Owner:CHINA ACAD OF BUILDING RES

Heating device for the vehicle interior of a vehicle

InactiveUS10137759B2High thermal comfortSmall power demandAir-treating devicesVehicle arrangementsYarnElectrical and Electronics engineering

A heating device for the vehicle interior of a vehicle is configured in the form of an infrared (IR) radiator with a textile-based heating band arranged, in a reflector housing. The textile-based heating band is made of a mixed yarn of basalt and stainless steel. Such a heating device can be installed in a footwell of a vehicle.

Owner:AUDI AG

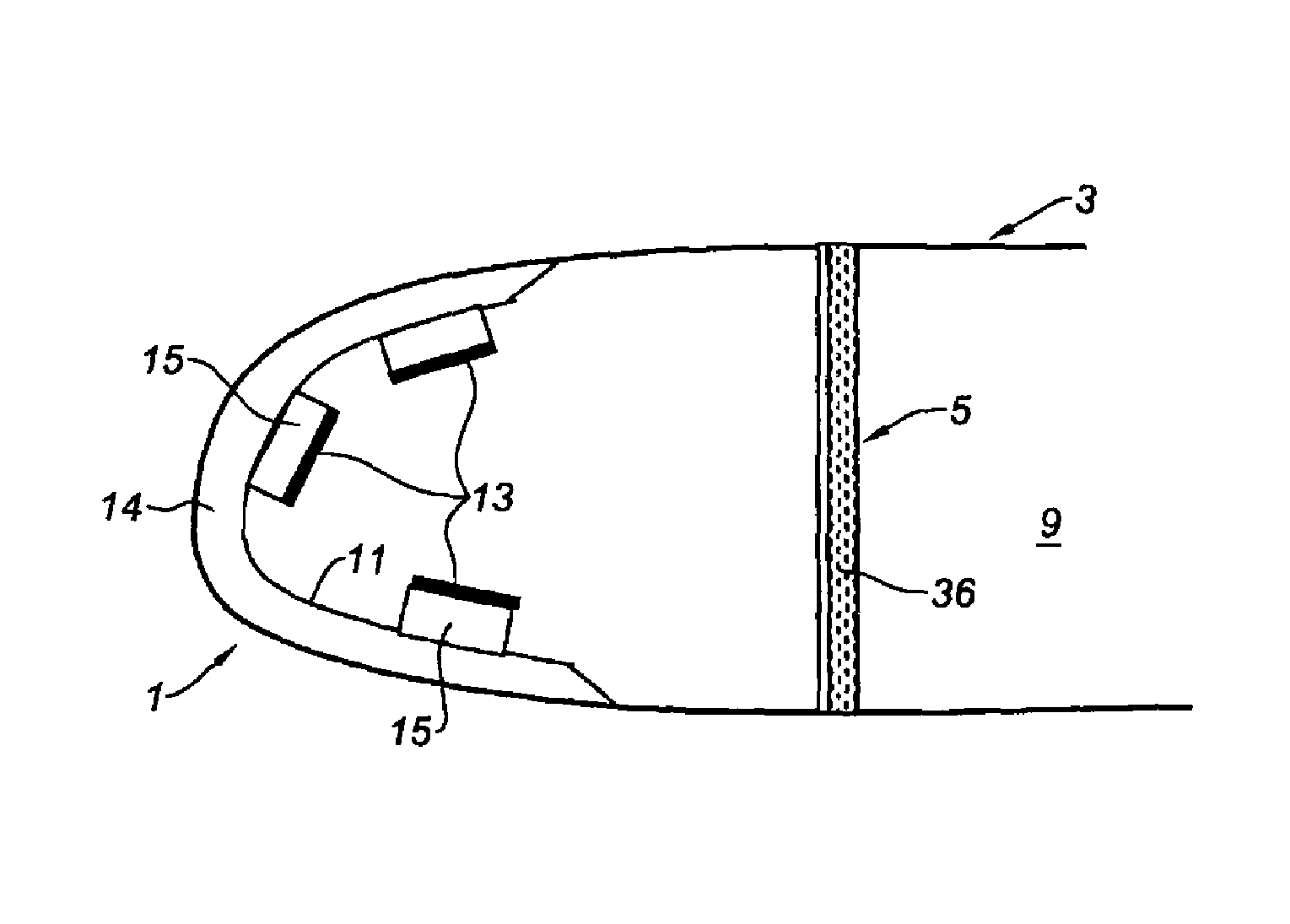

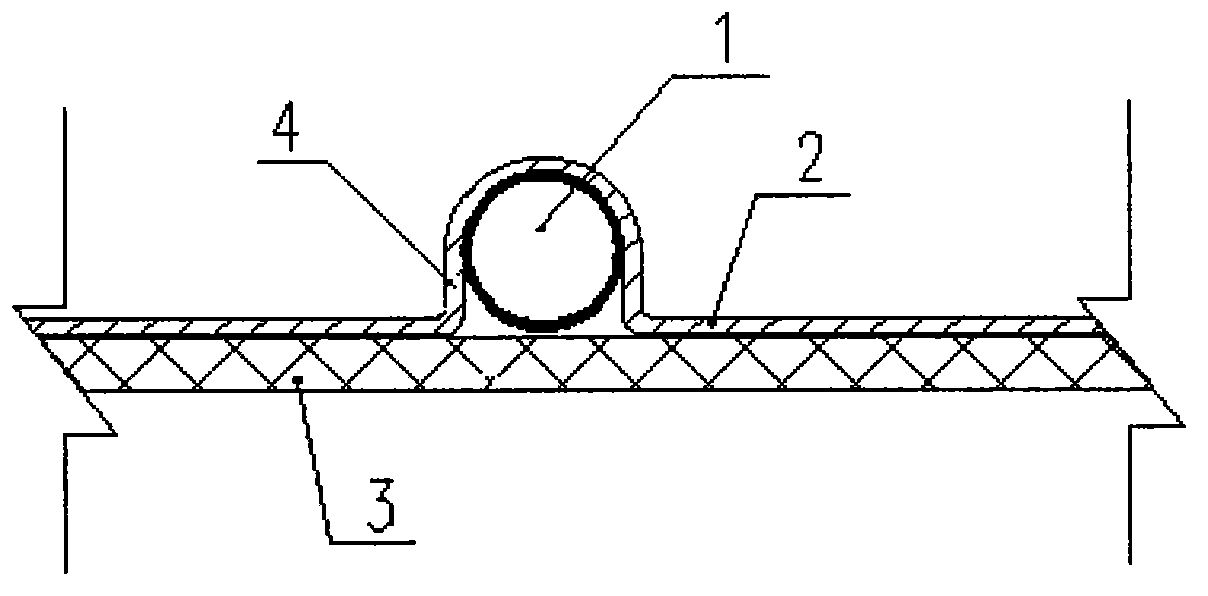

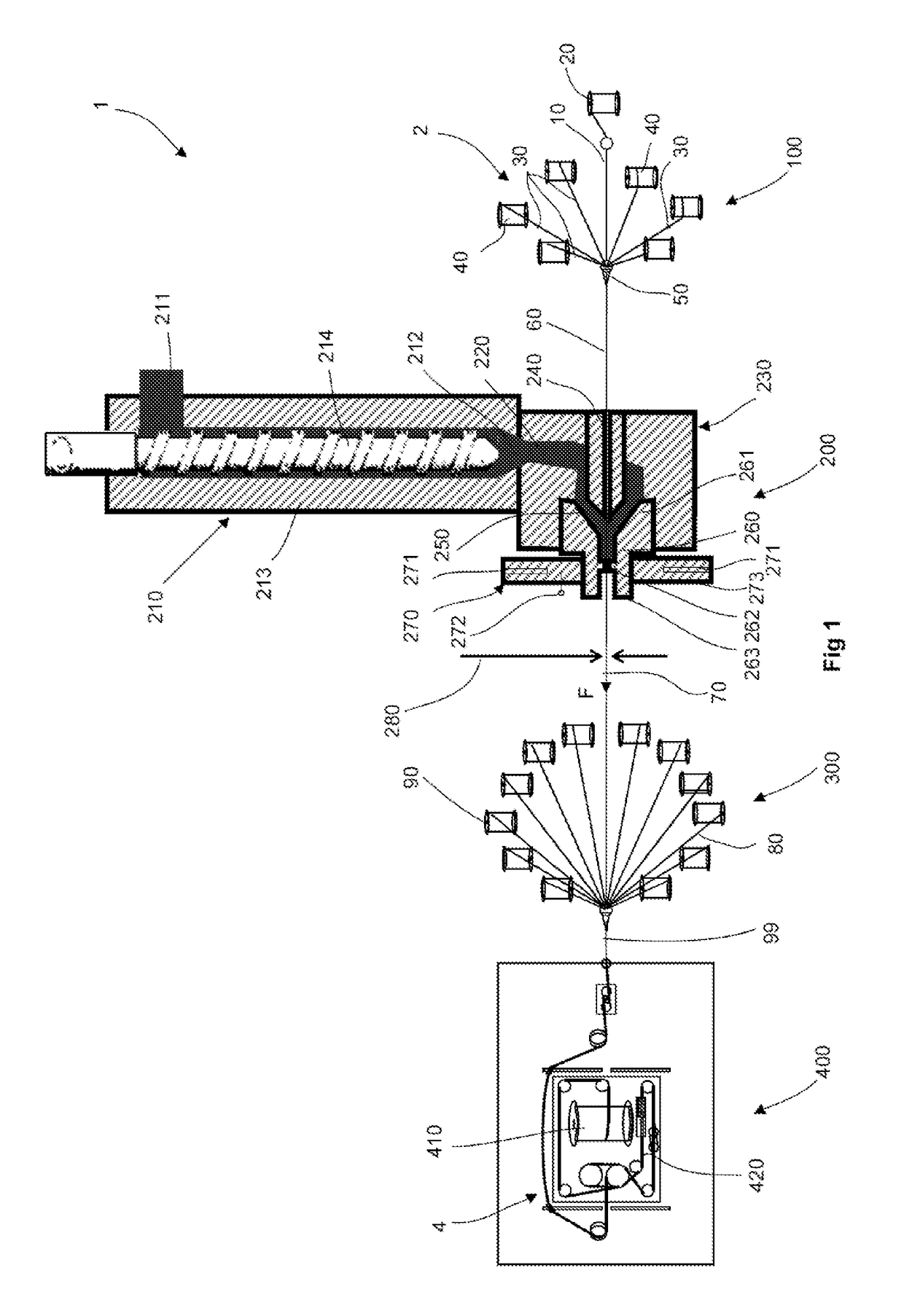

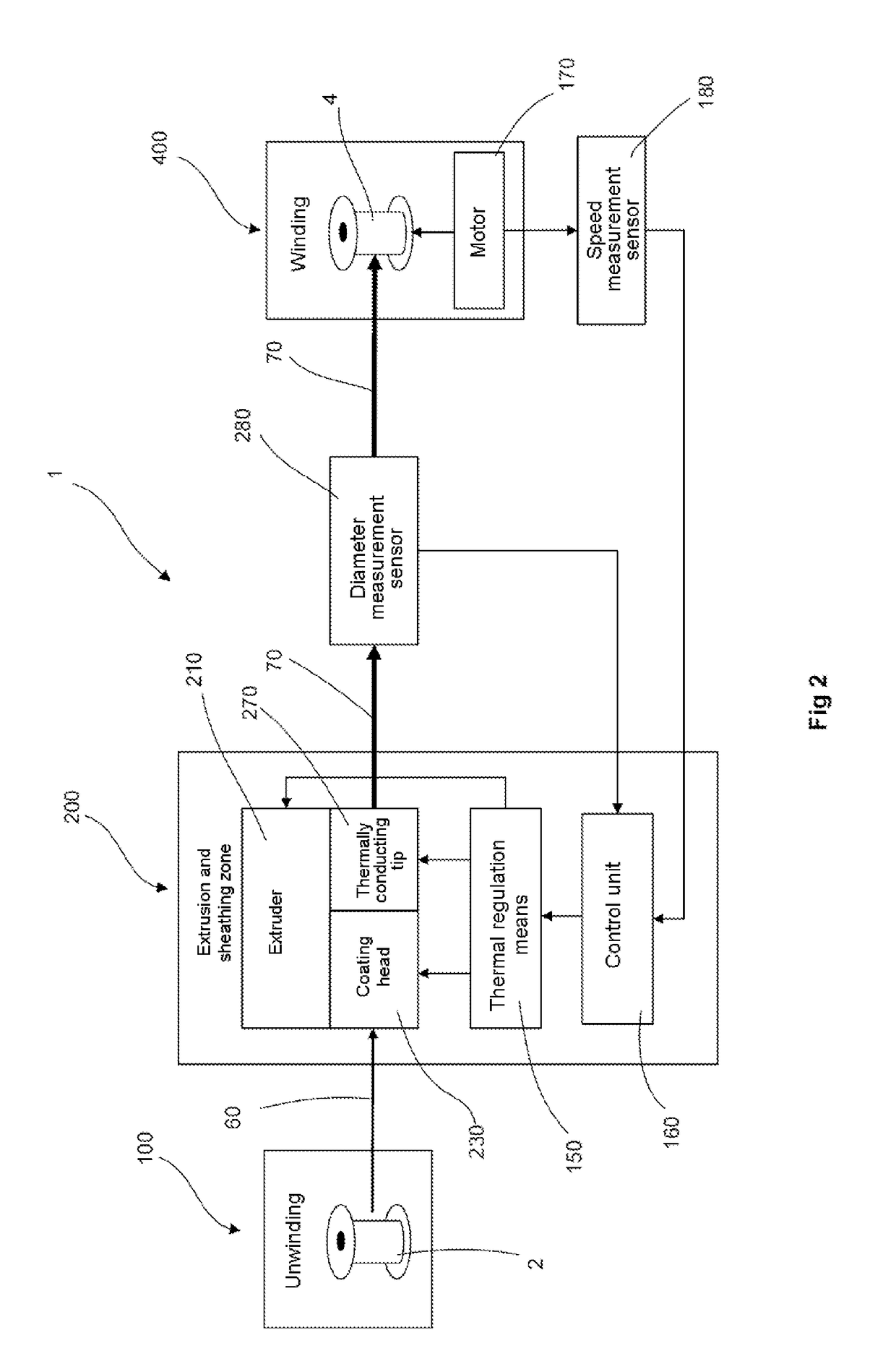

Method and device for producing rubber-coated metal wire

ActiveUS20170136675A1Clear gain in productivityAvoiding unsheathed zoneTyresDomestic articlesWire rodElastomer

A method and device for producing metal wire by sheathing a wire with an elastomer compound coming from an extruder is described herein. The aspects disclosed herein may include a feed canal for feeding a sheathing die, through which the wire is made to pass at a pre-established nominal speed. Various temperatures are controlled during the method based on a variety of parameters such as the measured speed at which the wire is moving is other than the nominal speed.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN +1

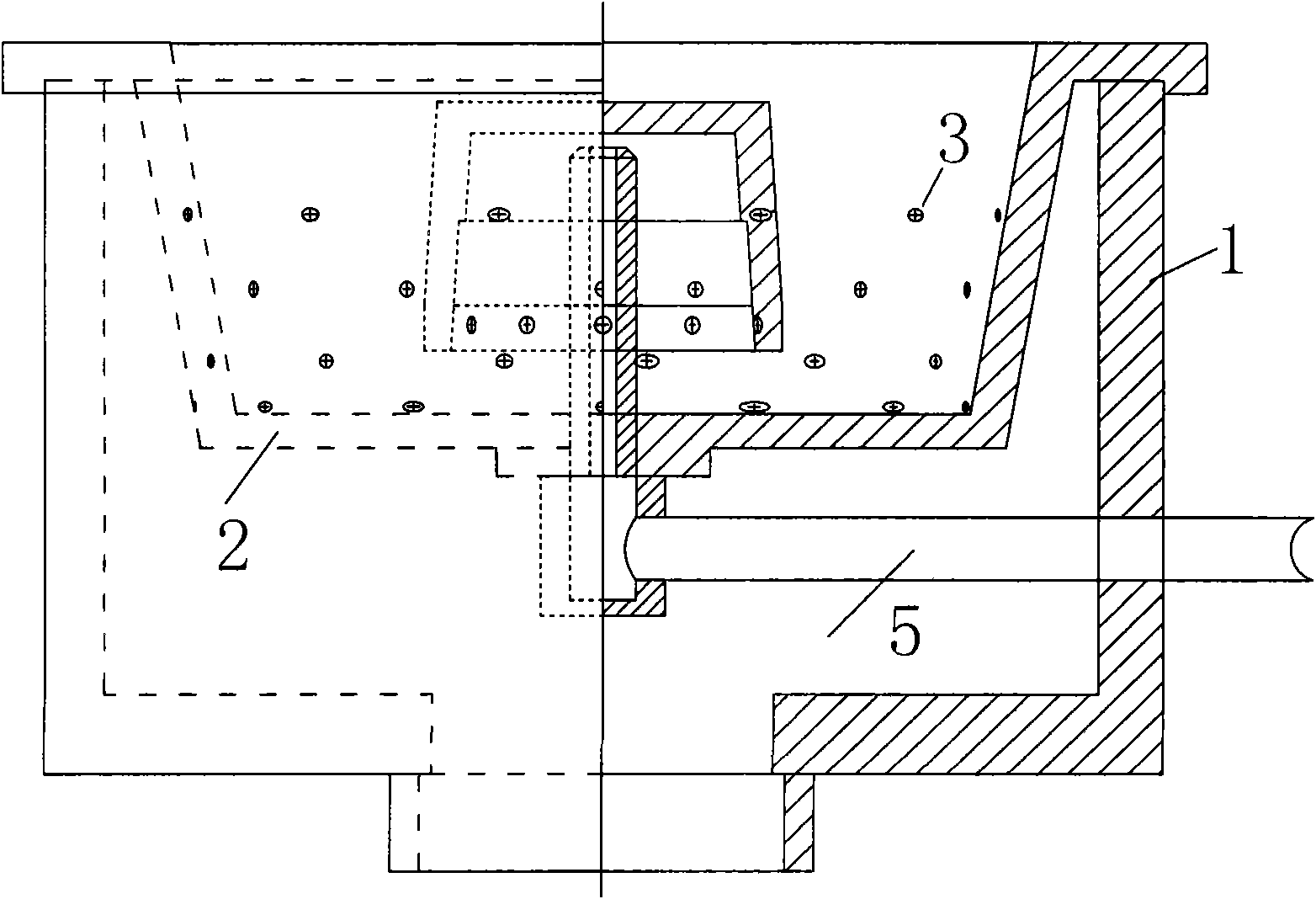

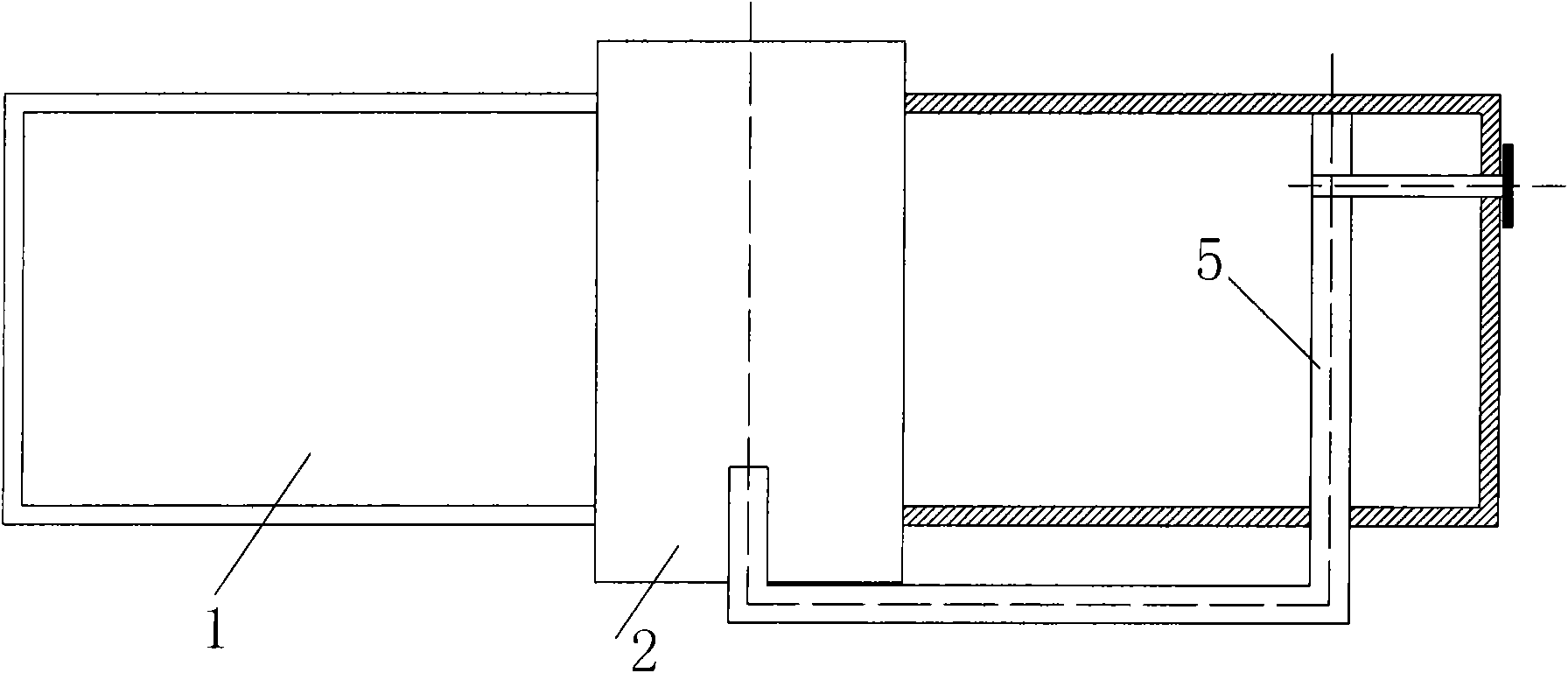

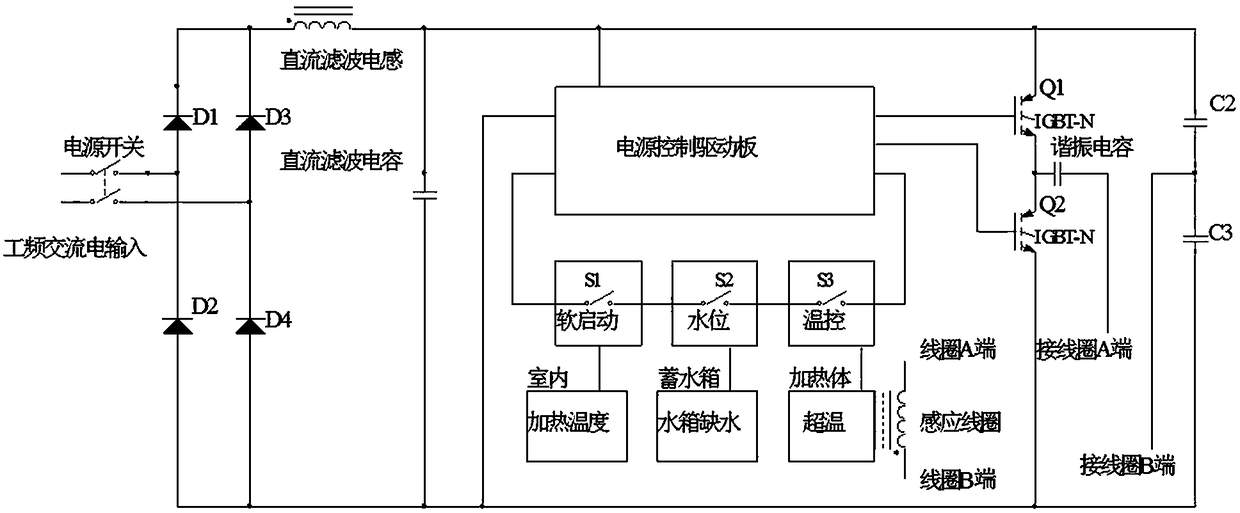

Electromagnetic steam self-circulation air heating device

PendingCN108759090AReduce areaReduce heating auxiliary energy consumptionAir heatersEvaporationEngineering

The invention discloses an electromagnetic steam self-circulation air heating device. The electromagnetic steam self-circulation air heating device is provided with an electromagnetic vortex heating unit, an air heating radiator and a water accumulation box. An inlet of the air heating radiator is connected with the electromagnetic vortex heating unit through a steam throttle pipe. An outlet of the air heating radiator is connected with the water accumulation box through a backflow pipe. The water accumulation box is connected with the electromagnetic vortex heating unit through a water supplypipe. An electromagnetic heating device is utilized for generating normal-pressure steam, after the normal-pressure steam is conveyed to the air heating radiator through the steam throttle pipe for heat releasing, the normal-pressure steam is condensed into water in the backflow pipe and flows back to the water accumulation box, water in the water accumulation box is conveyed to the electromagnetic vortex heating unit through the water supply pipe, and steam is generated. Natural circulation is formed through heating evaporation, heat releasing condensation and backflow water supply, constantheating and heat releasing are conducted, and heat supply is achieved. In the process, a circulation pump is eliminated, heat supply auxiliary energy consumption is reduced, the radiator area is reduced, copper, aluminum and steel used for the radiator are saved, and water pump noise is not generated.

Owner:张欣翼

Method for follow-up testing of temperature of steel billet in furnace

InactiveCN101968385BAvoid damageImprove accuracyThermometers using electric/magnetic elementsUsing electrical meansIron powderThermocouple

The invention relates to a method for follow-up testing of temperature of a steel billet in a furnace, which comprises the steps of primary preparation and the steps of follow-up testing in the furnace. The primary preparation comprises the following concrete steps: (1) drilling a hole on the steel billet to be tested; (2) inserting the hot end part of a thermocouple into the hole drilled in the step (1), and enabling the hot end of the thermocouple to be in contact with the bottom of the hole; filling and compressing the residual space in the hole by the iron powder of which the material is the same as the material of the steel billet to be tested; and (3) connecting the measuring end of the thermocouple to a temperature recorder, enabling the temperature recorder and the steel billet to together enter the furnace, and then, carrying out the steps of follow-up testing in the furnace. The method of the invention can improve the accuracy and the reliability of temperature testing of the steel billet.

Owner:武钢集团有限公司

Multifunctional leather goods processing workstation

InactiveCN101176577BImplement modular designLow costShoemaking devicesLeather softeningInfraredAutomatic control

Owner:蓝法兰可·安札尼 +1

New type sensor for measuring temperature of bearing

InactiveCN1687723AGood orientationReduce contact surfaceThermometer detailsThermometers using electric/magnetic elementsElectrical resistance and conductanceHeat resistance

The invention is a new type of bearing thermometric sensor, which comprises the temperature-sensing head, the guide sleeve, the spring, the connecting pipes and the down-leads. The temperature-sensing head is equipped with the temperature-sensing components (the heat resistance or the heat electric couple). It is characterized in that it adopts the short contacting face temperature-sensing head with hollow guide rob at the bottom and the flexible connecting pipes that can be the sealing winding spring structure or the coiled pipe structure. The effects of the inventions are: 1. avoid the falling and breaking off phenomena of the down-leads of the head when the using and transporting of the sensor; 2. overcome the breaking of the down-leads when curving of the sensor; 3. improve the sensibility.

Owner:陈志成

Fire-retardant low concentration gas burner

ActiveCN102080824AImprove impact performanceEmission reductionGaseous fuel burnerThermodynamicsEngineering

The invention discloses a fire-retardant low concentration gas burner, which comprises a combustor. The combustor comprises a combustor body with a multi-layer structure, and an upper end cover and a lower end cover which are arranged on the upper end and lower end of the combustor body respectively and are closely connected with the combustor body. The combustor body has a supporting layer, a fire-retardant layer, a diversion plate layer and a burning layer from inside to outside in turn. The supporting layer is used for supporting the fire-retardant layer; the fire-retardant layer and the burning layer are made of multi-layer metal fabric or metal fiber sintered felt; the diversion plate layer is provided with a plurality of uniformly distributed diversion channels for communicating the fire-retardant layer and the burning layer, and the diversion plate layer also plays a role in supporting the whole combustor; the burner further comprises a gas inlet pipeline and an ignition device. In the invention, a combustor structure with multi-layer structure is adopted, wherein the fire-retardant layer and the burning layer are made of metal fibers, thereby ensuring a better tempering effect, a higher cooling speed and higher safety of burning of low concentration gas.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

Rare earth electrode slurry of rare earth thick film circuit based on metal plate and its preparation technology

ActiveCN100499940CImprove electrical performanceImprove wettabilityOhmic-resistance electrodesNon-conductive material with dispersed conductive materialSolid componentMass ratio

Owner:GUANGDONGSHENG YUCHEN ELECTRONICS & TECH CO LTD

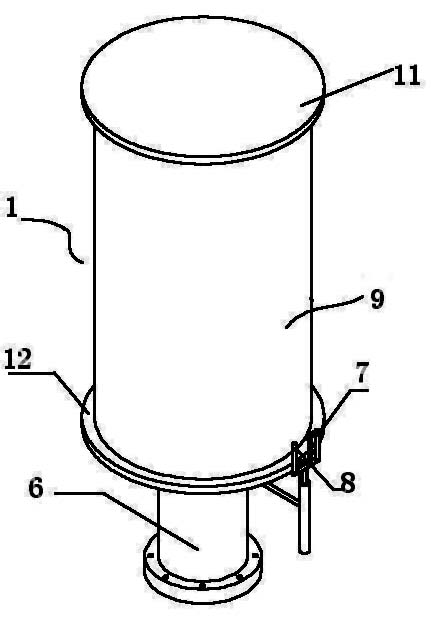

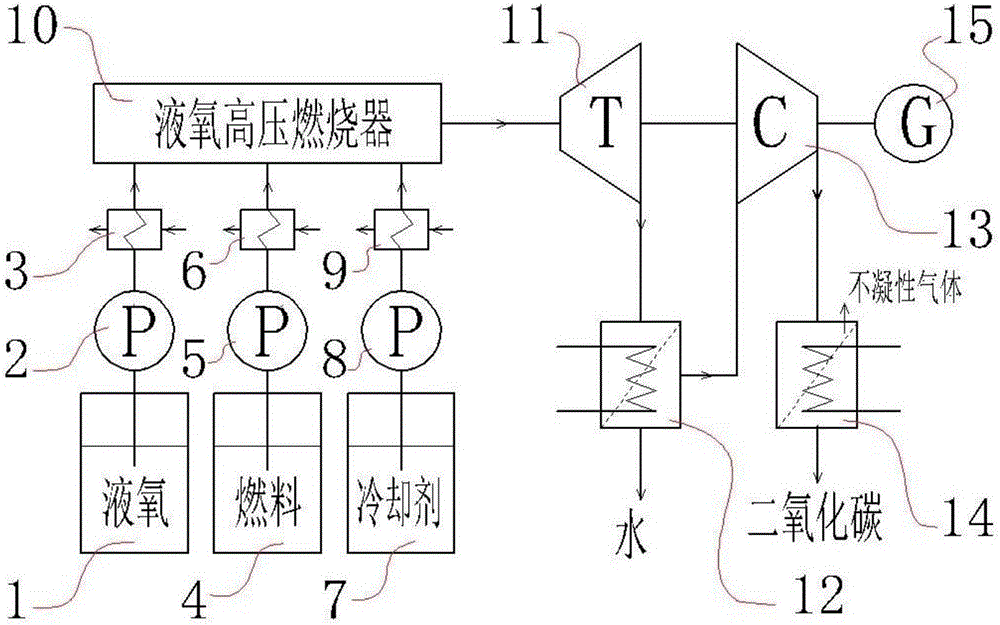

Liquid fuel-liquid oxygen high pressure direct combustion steam power system

ActiveCN105840312AZero emissionWith liquid oxygen scale energy storageGas turbine plantsIndirect carbon-dioxide mitigationNuclear engineeringLiquid fuel

The invention discloses a liquid fuel-liquid oxygen high pressure direct combustion steam power system. According to the system, liquid oxygen and liquid fuel are fed into a high pressure liquid oxygen combustor through a liquid oxygen pump and a fuel pump correspondingly to combust and generate high pressure and high temperature power steam, and the steam temperature is adjusted in the mode that a cooling agent is injected into the high pressure liquid oxygen combustor under high pressure. The ultrahigh pressure and high temperature power steam drives an expansion machine to generate electricity at higher electricity generation efficiency, exhaust steam at an outlet of the expansion machine is separated through condensers, and water and carbon dioxide are liquefied through condensation. The liquid oxygen needed by the system is produced by an air separation device through surplus electricity in the trough load period of a power grid and stored, part of the high cost for liquid oxygen production is counteracted, and the system has the remarkable advantages of large-scale energy storage with liquid oxygen, zero emission of nitrogen oxides, low-cost carbon capture, high-efficiency electricity generation and the like.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com